Abstract

The phase equilibria in the Cu-Fe-Zr ternary system was experimentally investigated by optical microscopy, electron probe micro-analyzer and x-ray diffraction on the equilibriated alloys. Three isothermal sections of the Cu-Fe-Zr ternary system at 1000, 1100 and 1200 °C were experimentally determined, and no ternary compound was found in this system. The further result in the present work shows that the Fe23Zr6 phase in the Cu-Fe-Zr ternary system is an equilibrium phase rather than oxygen-stabilized phase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metallic glasses have stimulated widespread research enthusiasm due to its excellent properties of strength, hardness, magnetism, wear and corrosion resistance.[1-3] However, the applications of metallic glasses have been limited due to the poor plasticity caused by shear localization and work softening.[4] To solve this problem, great attention has been paid to crystalline/amorphous composite through liquid immiscibility.[5-7] The Cu-Fe-Zr-B is a good candidate for the composites, owing to its sufficiently high glass-forming ability (GFA) in the Fe-Zr-B system,[8] and a positive enthalpy of mixing in the Fe-Cu atomic pair.[9] The phase equilibria information in the Cu-Fe-Zr ternary subsystem is needed to pinpoint the alloy compositions with liquid immiscibility in the Cu-Fe-Zr-B quaternary system. However, until now, such information in the Cu-Fe-Zr ternary system has not been available in the relevant literature. Therefore, it is necessary to comprehensively determine the phase equilibria in the Cu-Fe-Zr ternary system.

Three binary phase diagrams of the Cu-Fe,[10] Cu-Zr[11] and Fe-Zr,[12] constituting the Cu-Fe-Zr ternary system, are shown in Fig. 1. The Cu-Fe binary system[10] is a simple system without any intermediate phase. The Cu-Zr binary system[11] has ten intermediate phases, Cu5Zr, Cu51Zr14, Cu8Zr3, Cu2Zr, Cu24Zr13, Cu10Zr7, CuZr, Cu5Zr8, αCuZr2 and βCuZr2. The Cu5Zr phase forms through peritectic reaction at 1012 °C. The Fe-Zr binary system[12] has five intermediate phases, FeZr3, FeZr2, αFe2Zr, βFe2Zr and Fe23Zr6. All the stable solid phases in the three binary systems are summarized in Table 1.

The purpose of the present work is to experimentally investigate the phase equilibrium the Cu-Fe-Zr ternary system at 1000, 1100 and 1200 °C by using optical microscopy (OM), electron probe micro-analyzer (EPMA) and x-ray diffraction (XRD), which will provide a better understanding of microstructures and information for the thermodynamic database of Cu-Fe-Zr-B quaternary phase diagram.

Experimental Procedure

Highly-pure copper (99.9 wt.%), iron (99.9 wt.%) and zirconium (99.9 wt.%) were used as starting materials. Bulk alloy buttons were prepared from pure elements by arc melting under a highly-pure argon atmosphere using a non-consumable tungsten electrode. The ingots were melted at least five times in order to achieve their homogeneity. The sample weight was around 10 g and the weight loss during melting was generally less than 0.20%. Afterwards, the ingots were cut into small pieces for heat treatment and further observations.

All samples were put into quartz capsules evacuated and backfilled with argon gas. The specimens were annealed at 1000, 1100 and 1200 °C, respectively. The time of heat treatment varied from several hours to several days depending on the annealing temperature and the composition of the specimen. After the heat treatment, the specimens were quenched into ice water.

After annealing standard metallographic preparation, the microstructural observations were carried out by OM. The equilibrium compositions of the phases were measured by EPMA (JXA-8800R, JEOL, Japan). Pure elements were used as standards and measurements were carried out at 20.0 kV. The XRD was used to identify the crystal structure of the constituent phases. The XRD measurement was carried out on a Bruker D8 Advance X-pert diffractometer using CuKα radiation at 35.0 kV and 20 mA. The data were collected in the range of 2θ from 20° to 120° at a step of 0.02°.

Results and Discussion

Microstructure and Phase Equilibria

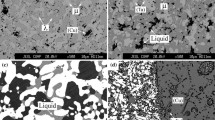

Back-scattered electron (BSE) images of typical ternary Cu-Fe-Zr alloys are shown in Fig. 2(a)-(j). Phase identification was based on the equilibrium composition measured by EPMA and XRD results. Figure 2(a) shows the two-phase microstructure ((αFe) + Liquid) of the Cu49.5Fe49.5Zr1 (at.%) alloy annealed at 1200 °C for 1 day. In the Cu5Fe85Zr10 (at.%) alloy annealed at 1100 °C for 60 days, the two-phase microstructure (Fe23Zr6 + (αFe)) was observed (Fig. 2b) and substantiated by the XRD result, as shown in Fig. 3(a), where the characteristic peaks of the Fe23Zr6 and (αFe) phases were found and well marked by different symbols. The (αFe) phase at room temperature came from the phase transition in (γFe) phase during quenching. Moreover, the composition of the (αFe) phase at room temperature and the (γFe) phase at high temperature are the same. The oxygen-content detected by EPMA in the Fe23Zr6 phase in all samples is very low in the Cu-Fe-Zr ternary system, which is different from the Fe23Zr6 phase stabilized by oxygen in the Fe-Zr system.[26] Combined with the EPMA element mapping (Fig. 4) of the selected area of the Cu5Fe85Zr10 (at.%) alloy annealed at 1100 °C for 60 days, the Fe23Zr6 phase is an equilibrium phase in the Cu-Fe-Zr ternary system.

Typical ternary BSE images obtained from: (a) Cu49.5Fe49.5Zr1 (at.%) alloy annealed at 1200 °C for 1 day; (b) Cu5Fe85Zr10 (at.%) alloy annealed at 1100 °C for 60 days; (c) Cu5Fe45Zr50 (at.%) alloy annealed at 1100 °C for 4 days; (d) Cu5Fe10Zr85 (at.%) alloy annealed at 1100 °C for 4 days; (e) Cu49.5Fe49.5Zr1 (at.%) alloy annealed at 1000 °C for 60 days; (f) Cu45Fe45Zr10 (at.%) alloy annealed at 1200 °C for 2 days; (g) Cu38Fe38Zr24 (at.%) alloy annealed at 1200 °C for 2 days; (h) Cu41Fe41Zr18 (at.%) alloy annealed at 1000 °C for 4 days; (i) Cu37Fe37Zr26 (at.%) alloy annealed at 1000 °C for 4 days; and (j) Cu60Fe10Zr30 (at.%) alloy annealed at 1000 °C for 12 h

X-ray diffraction patterns obtained from: (a) the Cu5Fe85Zr10 (at.%) alloy annealed at 1100 °C for 60 days; (b) the Cu49.5Fe49.5Zr1 (at.%) alloy annealed at 1000 °C for 60 days; (c) the Cu41Fe41Zr18 (at.%) alloy annealed at 1000 °C for 4 days; (d) Cu47.5Fe47.5Zr5 (at.%) alloy annealed at 1000 °C for 60 days; and (e) the Cu5Fe85Zr10 (at.%) alloy annealed at 1000 °C for 60 days

The Cu5Fe45Zr50 (at.%) and Cu5Fe10Zr85 (at.%) alloys annealed at 1100 °C are located in two two-phase equilibrium regions of the (Fe2Zr + Liquid) and ((βZr) + Liquid), respectively, as characterized in Fig. 2(c) and (d). A three-phase equilibrium of the (Fe23Zr6 + (αFe) + (Cu)) was observed (Fig. 2e) in the Cu49.5Fe49.5Zr1 (at.%) alloy annealed at 1000 °C for 60 days and the XRD results is shown in Fig. 3(b), where the characteristic peaks of Fe23Zr6, (αFe) and (Cu) phases were confirmed. Figure 2(f) presents the three-phase equilibrium microstructures of the (Fe23Zr6 + (αFe) + Liquid) in the Cu45Fe45Zr10 (at.%) alloy annealed at 1200 °C for 2 days, and Fig. 2(g) shows a three-phase equilibrium of the (Fe23Zr6 + Fe2Zr + Liquid) in the Cu38Fe38Zr24 (at.%) alloy annealed at 1200 °C for 2 days. There is a three-phase equilibrium of the (Fe23Zr6 + Fe2Zr + (Cu))in the Cu41Fe41Zr18 (at.%) annealed at 1000 °C (Fig. 2h) and the XRD results is shown in Fig. 3(c). Two three-phase equilibria of the (Fe2Zr + (Cu) + Liquid) and (Fe2Zr + Cu51Zr14 + Liquid) were observed in the Cu37Fe37Zr26 (at.%) and Cu60Fe10Zr30 (at.%) alloys annealed at 1000 °C, and were indicated in Fig. 2(i) and (j), respectively. XRD results of the Cu47.5Fe47.5Zr5 (at.%) and Cu5Fe85Zr10 (at.%) alloys annealed at 1000 °C are presented in Fig. 3(d) and (e), respectively. According to the XRD results, the lattice parameters of phases in the Cu49.5Fe49.5Zr1 (at.%), Cu47.5Fe47.5Zr5 (at.%), Cu5Fe85Zr10 (at.%), Cu41Fe41Zr18 (at.%) alloys annealed at 1000 °C and Cu5Fe85Zr10 (at.%) alloy annealed at 1100 °C have been calculated, respectively (Table 2).

Isothermal Section

The equilibrium compositions of the Cu-Fe-Zr ternary system at 1000, 1100 and 1200 °C obtained from EPMA are listed in Tables 3-5, respectively. Base on the experimental data determined by this work, three isothermal sections of 1000, 1100 and 1200 °C were constructed in Fig. 5(a)-(c), respectively.

Figure 5(a) shows the isothermal section at 1000 °C. In the section, four three-phase regions of (Fe23Zr6 + (γFe) + (Cu)), (Fe23Zr6 + Fe2Zr + (Cu)), (Fe2Zr + (Cu) + Liquid) and (Fe2Zr + Cu51Zr14 + Liquid)) appear. The results show that the maximum solubility of Cu in the Fe2Zr and Fe23Zr6 phases are about 15 and 5 at.%, respectively. In the isothermal section of 1100 °C shown in Fig. 5(b), two three-phase regions of (Fe23Zr6 + (γFe) + Liquid) and (Fe23Zr6 + Fe2Zr + Liquid) were experimentally determined in this work. The maximum solubility of Cu in the Fe2Zr phase was found to be about 12.5 at.%, and the maximum solubility of Cu in the Fe23Zr6 phase was approximately 4.5 at.%. The phase relationships in the isothermal section of 1200 °C containing two three-phase regions of (Fe23Zr6 + (γFe) + Liquid) and (Fe23Zr6 + Fe2Zr + Liquid) (Fig. 5c), is quite similar to that at 1100 °C. Undetermined three-phase equilibria in Fig. 5(a) and (b) are shown in dashed lines. Compared with the above mentioned three isothermal sections, it should be noted that the area of liquid phase increases at the temperature range from 1000 to 1200 °C.

Conclusions

The isothermal sections of the Cu-Fe-Zr ternary system at 1000, 1100 and 1200 °C were experimentally determined by the means of EPMA and XRD. The area of liquid phase increases at the temperature ranging from 1000 to 1200 °C.

References

M.E. McHenry, M.A. Willard, and D.E. Laughlin, Amorphous and Nanocrystalline Materials for Applications as Soft Magnets, Prog. Mater. Sci., 1999, 44, p 291-433

W.H. Wang, C. Dong, and C.H. Shek, Bulk Metallic Glasses, Mater. Sci. Eng. R, 2004, 44, p 45-89

J. Tan, Y. Zhang, B.A. Sun, M. Stoica, C.J. Li, K.K. Song, U. Kühn, F.S. Pan, and J. Eckert, Correlation Between Internal States and Plasticity in Bulk Metallic Glass, Appl. Phys. Lett., 2011, 98, p 151906-1-3

M.G. Chen, A Brief Overview of Bulk Metallic Glasses, NPG Asia Mater., 2011, 3, p 82-90

J. He, H.Q. Li, B.J. Yang, J.Z. Zhao, H.F. Zhang, and Z.Q. Hu, Liquid Phase Separation and Microstructure Characterization in a Designed Al-Based Amorphous Matrix Composite with Spherical Crystalline Particles, J. Alloy. Compd., 2010, 489, p 535-540

H.J. Chang, W. Yook, E.S. Park, J.S. Kyeong, and D.H. Kim, Synthesis of Metallic Glass Composites Using Phase Separation Phenomena, Acta Mater., 2010, 58, p 2483-2491

Y. Yu, Y. Takaku, M. Nagasako, C.P. Wang, X.J. Liu, R. Kainuma, and K. Ishida, Liquid-Immiscibility-Induced Formation of Micron-Scale Crystalline/Amorphous Composite Powder, Intermetallics, 2012, 25, p 95-100

B.R. Rao, A.K. Shan, M. Srinivas, J. Bhatt, A.S. Gandhi, and B.S. Murty, On Prediction of Amorphous Phase Forming Compositions in the Iron-Rich Fe-Zr-B Ternary System and Their Synthesis, Metall. Mater. Trans. A, 2011, 42A, p 3913-3920

A.R. Miedema, P.F. de Châtel, and F.R. de Boer, Cohesion in Alloys-Fundamentals of a Semi-Empirical Model, Physica B, 1980, 100, p 1-28

L.J. Swartzendruber, Cu-Fe (Copper-Iron), Phase Diagrams for Binary Alloys, 2nd ed., H. Okamoto, Ed., ASM International, Materials Park, 2010, p 308

H. Okamoto, Cu-Zr (Copper-Zirconium), J. Phase Equilib. Diffus., 2008, 29(2), p 204

H. Okamoto, Fe-Zr (Iron-Zirconium), J. Phase Equilib. Diffus., 2006, 27(5), p 543-544

I.K. Suh, H. Ohta, and Y. Waseda, High-Temperature Expansion of Six Metallic Elements Measured by Dilatation Method and X-Ray Diffraction, J. Mater. Sci., 1988, 23, p 757-760

D.R. Wilburn and W.A. Bassett, Hydrostatic Compression of Iron and Related Compounds: An Overview, Am. Mineral., 1978, 63, p 591-596

J. Haglund, F. Fernandez-Guillermet, F.G. Grimvall, and M. Korling, Theory of Bonding in Transition-Metal Carbides and Nitrides, Phys. Rev. B, 1993, 48, p 11685-11691

P. Forey, J.L. Glimois, J.L. Feron, G. Develey, and C. Becle, Preparation, identification et structure cristalline de Cu5Zr, Comptes Rendus Hebdomadaires des Séances de l’Académie des Sciences C, 1980, 291, p 177-178

L. Bsenko, Crystallographic Data for Intermediate Phases in the Copper-Zirconium and Copper-Hafnium Systems, J. Less-Common Met., 1975, 40, p 365-366

E.M. Carvalho and I.R. Harris, Constitutional and Structural Studies of the Intermetallic Phase ZrCu, J. Mater. Sci., 1980, 15, p 1224-1230

M.V. Nevitt and J.W. Downey, A Family of Intermediate Phases Having the Si2Mo-Type Structure, Trans. Metall. Soc. AIME, 1962, 224, p 195-196

N.V. German, A.A. Bakanova, L.A. Tarasova, and Yu.N. Sumulov, Phase Transition of Titanium and Zirconium in Shock Waves, Solid State Phys., 1970, 12, p 637-639

B. Olinger and J.C. Jamieson, Zirconium: Phases and Compressibility to 120 Kilobars, High Temp. High Press., 1973, 5, p 123-131

P.I. Kripyakevich, V.S. Protasov, and E.E. Cherkashin, Crystal Structure of the Compound ZrFe3, Zh. Neorg. Khim., 1965, 10(1), p 151-152

A. Israel, I. Jacob, J.L. Soubeyroux, D. Fruchart, H. Pinto, and M. Melamud, Neutron Diffraction Study of Atomic Bonding in the Hydrogen-Absorbing Zr(Al x Fe1−x )2 System, J. Alloy. Compd., 1997, 253, p 265-267

E.E. Havinga, H. Damsma, and P. Hokkeling, Compounds and Pseudo-Binary Alloys with the CuAl2(C16)-Type Structure. I. Preparation and X-Ray Results, J. Less-Common Met., 1972, 27, p 169-186

K.H.J. Buschow, I. Vincze, and F. van der Wonde, Crystallization of Amorphous Zr-Rich Alloys, J. Non-Cryst. Solids, 1983, 54, p 101

F. Stein, G. Sauthoff, and M. Palm, Experimental Determination of Intermetallic Phases, Phase Equilibria, and Invariant Reaction Temperatures in the Fe-Zr System, J. Phase Equilib. Diffus., 2002, 23(6), p 480-494

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51031003 and 51201145) and the Ministry of Science and Technology of China (Grant No. 2009DFA52170). The support from the National Key Basic Research Program of China (973 Program, 2012CB825700) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, W.L., Yu, Y., Yang, S.Y. et al. Experimental Investigation of Phase Equilibria in the Cu-Fe-Zr Ternary System. J. Phase Equilib. Diffus. 34, 438–446 (2013). https://doi.org/10.1007/s11669-013-0257-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-013-0257-7