Abstract

The relation between viscosity and electrical conductivity of binary silicate melts is studied. The logarithm of viscosity varied linearly with the logarithm of conductivity. Furthermore, the lines are different for a MO-SiO2 system than for a M2O-SiO2 system. Compared with the MO-SiO2 system, the viscosity of the M2O-SiO2 system decreases more with the increase in conductivity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Viscosity (η) is an important physicochemical property for high-temperature melts, which is closely related to metallurgical processes, such as extracting, refining, and continuous casting in steel making. Electrical conductivity (κ) is another property that plays a prominent role in the modeling and operation of electric smelting furnaces. Both are sensitive to the structure change of silicate slag and exhibit an abrupt and complicated change with composition. So it is difficult to comprehend their composition dependence over wide composition ranges with only the available experimental data. Thus, pressing demands are being made for a model to estimate them over a broad composition range. Many models have been developed to predict viscosity[1–8] and electrical conductivity.[9,10] However, little research has been focused on the relationship between viscosity and electrical conductivity of silicate melts. Mills pointed out that both properties can be well correlated by the nonbridging oxygen per tetrahedrally coordinated cation (NBO/T) or revised optical basicity[11]; therefore, some relation may exist between them. Walden’s rule[12] is the first quantitative expression for viscosity and electrical conductivity, which shows that their product for an ionic liquid is constant related to the physical property of ion. However, Walden’s rule is not strictly satisfied in the oxide melt because of the obvious differences between the activation energy of viscosity and the conductivity.[13] Later, Kato and Minowa[14] studied the relation in CaO-Al2O3-SiO2-based melts and gave the relationship in the product of ηκ n. Based on plenty of experimental viscosity data and the electrical conductivity model,[10] the present author gave a more accurate relation for CaO-Al2O3-SiO2 and CaO-MgO-Al2O3-SiO2 aluminosilicate systems.[15] However, the previous studies only cover a narrow composition range in a few systems. Therefore, it is necessary to investigate whether this relations is suitable for other slag systems. Furthermore, the influence of different metal oxide on the relation between viscosity and conductivity is still unclear. In this study, MgO-SiO2, CaO-SiO2, SrO-SiO2, BaO-SiO2, Li2O-SiO2, Na2O-SiO2, and K2O-SiO2 binary systems are studied.

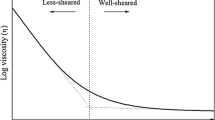

The viscosity and electrical conductivity of melts are structure dependent, and both change sharply as the melt structure changes. In general, the influence of different component on the melt structure is different. The acidic oxide SiO2 can form the so-called silicon–oxygen tetrahedron in which the Si cation is located at the center of the tetrahedron and oxygen anions are located at the corners. By sharing the oxygen ions, these tetrahedrons are joined together in chains or rings to form a network structure. When basic oxides are introduced, they will release oxygen ions that can combine with the Si cation in the silicon–oxygen tetrahedron. Consequently, the network structure is broken. Generally, the viscosity, which reflects the viscous resistance of the melt in the flow process, prominently relies on the big complex anions (e.g., SiO 4−4 , Si2O 6−7 , and Si3O 8−10 ). The longer the mean length of chains, the higher the viscosity. Thereby, the melts will have a high value of viscosity when there is a high content of SiO2. With the increase of basic oxide, the network structure is gradually destroyed, which results in the decrease of viscosity.

Concerning the electrical conductivity of melts, the following factors influence the charge transport process: the transport resistance and the concentration of the metal cation. The resistance is mainly determined by the degree of polymerization of the melt and cation itself. Generally, the enhancement of the degree of polymerization means an increase in the resistance and, thus, a decrease in conductivity and vice versa. For the slag without amphoteric oxide, the increase in the basic oxide content will result in a decrease of the degree of polymerization as well as an increase in the metal cation concentration, both of which benefit the enhancement of conductivity. Therefore, a decreasing function might be related to the viscosity and electrical conductivity.

In general, it is difficult to collect both viscosity and conductivity data for slags of the same composition in the literature, which results in some difficulties in correlating these two properties. If the temperature and composition dependence of viscosity could be established first, then one may have both viscosity and conductivity values in the same composition, and the obstacle may be overcome.

A great deal of data of viscosity has been retrieved for the MgO-SiO2,[16–18] CaO-SiO2,[17–20] SrO-SiO2,[16,18] BaO-SiO2,[16,18] Li2O-SiO2,[16] Na2O-SiO2,[16,21] and K2O-SiO2[16,21] systems. To minimize error, different expressions are assigned to different systems for the viscosity calculation based on the following equations:

where η is the viscosity; T is the absolute temperature; and P 1, P 2, P 3, and P 4 are empirical parameters, respectively. By applying Eqs. [1] through [3] to the seven slag systems mentioned, the empirical parameters can be obtained through regression analyses of the available experimental data. The optimized parameters have been obtained and listed in Table I. In regard to the accuracy of this method, one can use the mean deviation Δ to judge, which is defined as follows:

where η i,mea and η i,cal are the measured and estimated value, respectively, and N represents the number of the samples. The mean deviation of every system is also shown in Table I.

Compared with the viscosity of slags, the electrical conductivity data of slags measured by the experiment are scarce. Bockris[13] did systematic research on the conductivity of the binary systems discussed. Data from Keller et al.[22] on CaO-SiO2 also are taken into consideration in the present study. The viscosity values of slags whose electrical conductivity has been measured experimentally can be calculated by Eqs. [1] through [3] using the parameters shown in Table I. When plotting the logarithm of viscosity as a function of the logarithm of conductivity (shown in Figure 1), the relation between them can be described by a linear equation regardless of temperature. The linear relation for MgO-SiO2, CaO-SiO2, SrO-SiO2, and BaO-SiO2 systems (MO-SiO2 system) is different from that for Li2O-SiO2, Na2O-SiO2, and K2O-SiO2 systems (M2O-SiO2 system). The relations between viscosity and conductivity are shown as follows:

MO-SiO2 system:

or

M2O-SiO2 system:

or

As mentioned earlier, the electrical conductivity is determined by the transport resistance and the concentration of the metal cations, which have a greater mobility than the anion ions. At least the following three factors can influence the transport resistance: degree of polymerization of melt, the size, and the polarizing power of the cation. Generally, the higher the degree of polymerization of the melt, the larger the resistance. The degree of polymerization mainly results from the size of anion ion. The size of cation has a paradox influence on the resistance. Generally, for cations with the same valence, the smaller the radius, the greater the mobility. However, when considering the polarization of the cation, especially when there is a high valance, the small cation has a stronger polarizing ability, which means a stronger interaction with the anion ions and, thus, a great resistance. When the polarizing effect dominates, it is easier for the big cation to transport, whereas in the case of weaker polarization, the smaller cation may have greater mobility. Suginohara et al.[23] measured the electrical conductivity of PbO-SiO2 melts by systematically adding various oxides (M2O and MO oxides). Good correlations were found between the electrical conductivity and the ionic radius. In the case of M2O, the electrical conductivity decreases with an increasing ionic radius, whereas the opposite tendency is found in MO. Therefore, it may be the case, that the size factor is dominant for M2O; thus, the small ion has greater mobility. Although the polarizing effect is much stronger for MO with a high valence, the small ion has a weaker mobility. Furthermore, the electrical conductivities of CaO and MgO at a temperature just above the melting point are 40 Ω−1·cm−1 (2853 K [2580 °C]) and 35 Ω−1·cm−1 (3073 K [2800 °C]),[24] which also give proof. According to these analyses, the size of the cation plays a significant role in the electrical conductivity. However, in modeling the relation between viscosity and conductivity, the cations with the same valance follow the same line, which shows that the effect of cation size is small.

The experience told us that the temperature dependence of both the viscosity and the electrical conductivity can be described approximately by the Arrhenius form in Eq. [1]. Equations [6] and [8] show that the expression correlating viscosity and electrical conductivity is independent of temperature and composition. Therefore, the activation energy of viscosity and electrical conductivity should fulfill constant relations, and the relations are different for MO-SiO2 system and M2O-SiO2 system. The activation energy of viscosity is 1.1 times as large as that of the electrical conductivity for the MO-SiO2 system, whereas the value is 2.87 for the M2O-SiO2 system.

The basic oxide M x O could release oxygen that bonds with silicon ion. The amount of oxygen released by basic oxide is determined by the content of basic oxide M x O regardless of the covalence of the M ion. Therefore, the decrease of the degree of polymerization resulting from the combination of the released oxygen with the silicon ion is almost the same for MO and M2O oxides. However, the M cation with a different covalence may cause some differences. The univalent metal ion can lead to a much looser melt structure because of its weaker attraction with the oxygen ion compared with the bivalent metal cation. At equimolar compositions, the bivalent ion participates in the continuous linking of the network by “bridging” two oxygen atoms, whereas the two univalent ions do not. So the M2O can decrease the viscosity more than MO with the same content.

However, the different covalence of the M ion also influences the conductivity. Normally, different ions have a different mobile ability under external electrical files, thereby contributing differently to the conductivity. Because the complex anion ions have little mobile ability under an external electrical field, their contribution to the electrical conductivity can be neglected. Furthermore, it is conceivable that the mobile ability of the bridging oxygen and the nonbridging oxygen are low for the strong attraction of the Si4+ ion. Therefore, the conductance is mainly the result of the transport of metal cation ion. The concentration of an univalent metal cation is two times as large as the bivalent metal cation, and the interaction of an univalent metal cation with other ions is smaller than that of the bivalent ion. Furthermore, the polymerization of a melt is much looser in the M2O-SiO2 system. Thereby, it is possible that the activation energy of the electrical conductivity of M2O-SiO2 system is much smaller compared with the MO-SiO2 melt with the same content of MO.

According to these analyses, substitution of M2O with the same content of MO will lead to a decrease in both the activation of the viscosity and the conductivity. However, the activation of conductivity may decrease much more than viscosity. Therefore, in the M2O-SiO2 system, the activation of conductivity is smaller than for viscosity relative to the MO-SiO2.

In our previous article,[14] the relation between viscosity and electrical conductivity for CaO-Al2O3-SiO2 and CaO-MgO-Al2O3-SiO2 aluminosilicate systems are discussed. It is assumed that, in the composition range of \( x_{\text{MO}} > x_{{{\text{Al}}_{2} {\text{O}}_{3} }}, \) all Al ions are incorporated into the network structure in the form of AlO 5−4 , and the charge carriers primarily consist of Ca2+ and Mg2+. The incorporation of Al ions need metal cations for the charge to balance; thus, the cations in charge of balancing duties will have a weaker mobility when compared with the cations acting as network modifiers. The revised optical basicity[11] is used to distinguish the different effects of MO acting as charge balancer and network modifier in the electrical conductivity model[10] when calculating the conductivity. A linear relation is proposed to correlate the logarithm of viscosity and the logarithm of conductivity. When putting the data together with the data of the MO-SiO2 system (shown in Figure 2 ), it is shown that they obey the same law. Regress the data again, and the following expression can be obtained:

or

If extrapolating the two lines in Figure 1 to the condition corresponding to the pure SiO2, then it theoretically should have an intersection. But they can never intersect if the liner relation between viscosity and electrical conductivity is always fulfilled. Therefore, the present liner laws are valid only near the conductivity or viscosity range shown in Figure 1. However, the viscosity and electrical conductivity of the slags in which we are interested always fall in this region.

References

G. Urbain: Steel Res. Int., 1987, vol. 58, pp. 111-16.

P.V. Riboud, Y. Roux, L.-D. Lucas, and H. Gaye: Fachber. Hüttenprax. Metallweiterverarb., 1981, vol. 19, pp. 859-69.

T. Lida, H. Sakal, Y. Kita, and K. Shigeno: ISIJ Int., 2000, vol. 40, pp. 110-14.

D. Sichen, J. Bygden, and S. Seetharaman: Metall. Trans. B, 1994, vol. 25B, pp. 519-25.

L. Zhang and S. Jahanshahi: Metall. Mater. Trans. B, 1998, vol. 29B, pp. 177-86.

M. Nakamoto, J. Lee, and T. Tanaka: ISIJ Int., 2005, vol. 45, pp. 651-56.

Q.F. Shu and J.Y Zhang: ISIJ Int., 2006, vol. 46, pp. 1548-53.

K.C. Mills and S. Sridhar: Ironmaking Steelmaking, 1999, vol. 26, pp. 262-68.

Q. Jiao and N.J. Themelis: Metall. Trans. B, 1988, vol. 19B, pp. 133-40.

G.H. Zhang and K.C. Chou: Metall. Mater. Trans. B, 2010, vol. 41B, pp. 131-36.

K.C. Mills: ISIJ Int., 1993, vol. 33, pp. 148-55.

Y. Waseda and J.M. Toguri: The Structure and Properties of Oxide Melts, World Scientific, Singapore, 1998, p. 143.

J.O’M. Bockris, J.A. Kitchener, S. Ignatowicz, and J.W. Tomlinson: Trans. Faraday Soc., 1952, vol. 48, pp. 75-91.

M. Kato and S. Minowa: Trans. ISIJ, 1969, vol. 9, pp. 47-52.

G.H. Zhang, Q.G. Xue, and K.C. Chou, Ironmaking Steelmaking, in press.

J.O’M. Bockris, J.D. Mackenzie, and J.A. Kitchener: Trans. Faraday Soc., 1955, vol. 57, pp. 1734-48.

G. Urbain: Rev. Int. Hautes Temp. Refract., 1974, vol. 11, pp. 133-45.

G. Urbain, Y. Bottinga and P. Richet: Cosmochim. Acta, 1982, vol. 46, pp. 1061-72.

J.O’M. Bockris and D.C. Lowe: Proc. R. Soc. London, 1954, vol. 226A, pp. 423-35.

P. Kozakevitch: Rev. Metall., 1960, vol. 57, pp. 149-60.

E. Eipeltauer and G. Jangg: Kolloid Z., 1955, vol. 142, pp. 77-84.

H. Keller, K. Schwerdtfeger, and K. Hennesen: Metall. Trans. B, 1979, vol. 10B, pp. 67-70.

Y. Suginohara, T. Yanagase, and H Ito: Trans. Japan Inst. Metals, 1962, vol. 3, pp. 227-33.

C. Diaz: INCRA Monograph on Metallurgy of Copper, vol. III, International Copper Research Association, New York, NY, 1974, pp. 68-73.

The authors wish to thank the Chinese Natural Science Foundation for their kind support under the contracts 50774004 and 50974011 as well as the “Changjiang Scholars and Innovative Research Team in University,” “PCSIRT” support under No: IRT0708. Thanks are also given to the Key Lab of Ecologic & Recycle Metallurgy, Ministry of Education.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 8, 2010.

Rights and permissions

About this article

Cite this article

Zhang, GH., Yan, BJ., Chou, KC. et al. Relation Between Viscosity and Electrical Conductivity of Silicate Melts. Metall Mater Trans B 42, 261–264 (2011). https://doi.org/10.1007/s11663-011-9484-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9484-7