Abstract

New measurements have been made on the equilibrium distribution of selenium and tellurium between molten slag and metal phases under a controlled CO-CO2 atmosphere. Distribution coefficients of Se and Te between magnesia-saturated calcium ferrite slag and copper or silver alloy were measured at 1473 to 1673 K and oxygen patrial pressures of 10−11 to 10−0.68 atm. For the calcium ferrite slag, the highest distribution coefficients were recorded at the highest lime content, under strongly reducing conditions and at higher temperature. The selenide and telluride capacities were also calculated for each slag and were found to increase with increasing temperature and increasing lime activity. Activity coefficients of Se in the slag phase were found to be much lower than those of Te, and values for both minor elements decreased considerably with increasing activities of lime and ferrous oxide in the slag. Selenium showed strong negative deviation from the ideal behavior, while Te showed positive deviation up to 1573 K.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The presence of trace amounts of minor impurity elements in metal products can have a significant adverse effect on their electrical and mechanical properties. Selenium (Se) and tellurium (Te) are common minor components of sulfide ore, and as such must be managed during the extraction of metals such as copper and nickel. Selenium, for example, has a high affinity for copper, and even at concentrations < 1 ppm can affect the softening properties of Cu metal. Although Se and Te have value in that they have uses in electronic components and as a colorant in glass, they are not in great demand. While it is preferable to remove certain impurities at the final refining step, these and other minor elements will become increasingly problematic as high grade ore reserves are depleted and low grade deposits containing larger amounts of impurities are relied upon. Knowledge of the thermodynamic behavior of these elements is therefore necessary to successfully eliminate them from the final metal product, and to assess whether waste materials could potentially pose an environmental hazard if not handled appropriately.

The pyrometallurgical extraction of copper from sulfide ore has traditionally been carried out with an iron silicate (fayalite, Fe2SiO4) based slag. However, this slag type has inherent deficiencies in that it has high viscosity, high solubility of copper, and low solubility of ferric iron oxides. A recent alternative has been the use of calcium ferrite (CaO-FeO x ) slag in the copper converting step. Studies of the thermodynamics and physico-chemical properties of the CaO-FeO-Fe2O3 system[1,2,3] have been used to establish the applicability of this type of slag to certain processes. The thermodynamics of calcium ferrite slag in regard to its direct application in the Mitsubishi process for copper converting is discussed by Tanaka et al.[4] This type of slag allows for easier operation over fayalite in terms of improvement in the factors mentioned previously. It is also expected to have different holding capacity for impurity elements such as Se and Te due to its basic, rather than acidic, nature. If this is the case, there arises the possibility that these elements will exit the process stream early and become dispersed with the waste slag.

The behavior of Se and Te has been determined in iron silicate[5] and sodium carbonate[6] slag-copper systems, and while some minor elements have been studied in calcium ferrite slag, gaps in the knowledge remain. The aim of this work is to characterize the behavior of Se and Te in terms of key operating variables and slag composition for representative copper production systems making use of calcium ferrite–based slag. Both the solubility and oxidation state of the minor elements in the slag are to be determined, with additional focus on the generation of thermodynamic activity data. It is hoped that the successful prediction of the occurrence of Se and Te in the calcium ferrite slag and metal phases can lead to the application of procedures for their removal from copper metal at the desired step, enabling sustainable, economical copper production from previously unusable ore.

Experimental

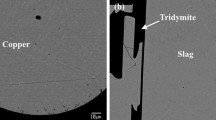

Calcium ferrite master slag was synthesized by melting together high-purity ferric iron oxide and calcium carbonate powders in a magnesia crucible inside an induction furnace. Nitrogen was bubbled through the molten slag to assist mixing. Portions of the slag produced were prereduced to the desired oxygen partial pressure ( \( p_{{{\text{O}}_{{\text{2}}} }} \)) in a vertical tube furnace at 1573 K. This was to reduce the time needed to reach equilibrium with the metal alloy and also prevent the formation of metal droplets in the bulk slag. Copper alloy with approximately 1 wt pct of Se and Te was prepared by adding powdered Se and Te to molten copper inside an induction furnace. The molten alloy was extracted by suction through silica glass tubing. Silver alloy with approximately 2.4 wt pct of Se and Te was prepared in a similar manner inside a vertical tube furnace.

Distribution experiments involved equilibrating portions of the slag and alloy in a sealed vertical tube furnace under a controlled flow of CO2 and CO at temperatures from 1473 to 1673 K. A schematic diagram of the furnace setup is shown in Figure 1. Roughly equal amounts of 4 to 5 g of alloy and slag were placed in a tapered “egg-cup” shaped recrystallized magnesia crucible. A series of preliminary experiments with slag and Cu alloy showed that equilibrium was reached after 8 to 16 hours, so a reaction time of 24 hours was used in all subsequent experiments. The required CO2:CO flow ratio for the desired \( p_{{{\text{O}}_{{\text{2}}} }} \) for an experiment was determined by using Eq. [1] of Yazawa and Takeda.[7] The most reducing experiment was at 10−11 atm,Footnote 1 while the most oxidizing was in air (10−0.68 atm).

The crucible was lowered under Ar flow into the hot zone of the furnace, a region 4-cm long over which the temperature variation was ±2 K. Over the course of an experiment, the temperature, as measured by an R-type (Pt/Pt-13 pct Rh) thermocouple, remained constant to ±1 K. The CO2 and CO gases, regulated by a set of precalibrated mass flow controllers, were introduced once the furnace had reached the set temperature. A total flow rate of 500 mL/min was maintained over the duration of each experiment. The gases were dried by passing through a column of silica gel and deoxidized by passing them through Cu metal turnings at 500 °C.

Reactions were terminated by lifting the crucible assembly out of the top of the furnace, then quickly plunging it into water to the level of molten material until the contents had solidified. This process typically took several seconds. The slag and metal phases were then removed from the crucible and separated by physical means. Samples were analyzed by inductively coupled plasma (ICP) techniques following acid digestion. The bulk composition of master slags was determined by x-ray fluorescence analysis. The ferrous iron content of slags was determined by dichromate titration following acid digestion under nitrogen.

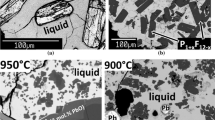

The temperature for the majority of experiments was 1573 K. For variations in \( p_{{{\text{O}}_{{\text{2}}} }} \) and temperature, a calcium ferrite slag containing about 20 wt pct CaO was used. For the composition variation study, the \( p_{{{\text{O}}_{{\text{2}}} }} \) was held constant at 10−9 atm for slags containing about 15 to 30 wt pct CaO. According to Yazawa et al.,[2] the liquid slag at 1573 K in the CaO-FeO-Fe2O3 system should extend from 10−11 to > 1 atm \( p_{{{\text{O}}_{{\text{2}}} }} \) and from approximately 10 to 35 wt pct CaO.

Results

The equilibrium concentration of components of the slag and metal phases is shown in Table I. The final concentration of Te was similar to that of Se in the metal, but around an order of magnitude lower in the slag. The equilibrium distribution coefficient of minor element M between the slag and metal phases (D M) is defined as the ratio of its concentration in the slag to that in the metal.

Variations in D M with the key variables studied are the main indicator of how changing conditions can control the minor element content of the slag and metal phases. The measured ferric to ferrous ratios of the slag at equilibrium were found to be in good agreement with those determined by Takeda et al.[1]

Oxygen Partial Pressure

The effect of oxygen partial pressure on the distribution coefficients of Se and Te between calcium ferrite slag and copper is shown in Figure 2. The amount of Cu entering the slag is also dependent on \( p_{{{\text{O}}_{{\text{2}}} }} \), as shown in Figure 3. The magnesia content of the slags varied between 3 and 6 wt pct MgO. These are elevated relative to the results of Yan et al.,[8] but this may be attributable to contamination of the slag samples by fragments of the MgO crucible or the magnesiowustite layer that forms between the slag and the refractory crucible in the present work.

It is evident that the \( p_{{{\text{O}}_{{\text{2}}} }} \) has a strong influence on the distribution coefficient and that there is a significant difference between the extent to which Se and Te are partitioned between the molten phases. The measured copper concentrations agree reasonably well with the existing data.[7,9] At 10−6 atm \( p_{{{\text{O}}_{{\text{2}}} }} \), there is some discrepancy, but this may be due to the degree to which the slag in each experiment was contaminated by entrained Cu metal. Yazawa and Takeda[7] derived an equation for the solubility of copper in calcium ferrite slag as a function of temperature and \( p_{{{\text{O}}_{{\text{2}}} }} \) from their experimental results, and this study agrees with their results.

Similar experiments were performed with a silver alloy to extend the work into the oxidizing region. Silver is not readily oxidized and so is not taken up by the slag; as such, experiments with the Ag alloy are not expected to alter the bulk composition of the slag as copper does. The Ag alloy used was doped with higher amounts of minor elements to overcome detection limit restrictions already encountered with the Te assays and anticipated at higher \( p_{{{\text{O}}_{{\text{2}}} }} \). The distribution coefficients from the Ag experiments are shown in Figure 4.

Under reducing conditions, the resulting concentration of Te in the slag was always less than that of Se. As the \( p_{{{\text{O}}_{{\text{2}}} }} \)was increased beyond a certain point, a change in the behavior of each element was observed. The distribution coefficient of Se appears to be independent of \( p_{{{\text{O}}_{{\text{2}}} }} \) at 10−5 atm and above, while D Te increases with further increases in \( p_{{{\text{O}}_{{\text{2}}} }} \) from 10−6 atm.

Temperature

For the temperature variation study, experiments were initially carried out at 50 K intervals over the range 1473 to 1673 K at a \( p_{{{\text{O}}_{{\text{2}}} }} \)of 10−10 atm with calcium ferrite slag and Cu alloy. The loss of the minor elements through volatilization was not found to be a problem as levels in the slag remained well within the detection limits of the ICP analysis. The experiments were then repeated keeping the CO2:CO ratio constant instead of the \( p_{{{\text{O}}_{{\text{2}}} }} \). In the latter experiments, the Fe3+:Fe2+ ratio of the slag should be close to constant across the entire series as in the equation of Takeda et al.;[1] the increase in temperature is offset by the corresponding increase in \( p_{{{\text{O}}_{{\text{2}}} }} \), which means that calculated capacities and activity coefficients should not be distorted by any difference in the strength of the interactions between each minor element and the different oxidation states of iron. A CO2:CO ratio of 2.265 was chosen, which resulted in the \( p_{{{\text{O}}_{{\text{2}}} }} \) increasing from 10−10.3 atm at 1473 K to 10−7.87 atm at 1673 K. The distribution coefficients of Se and Te at each temperature are shown in Figures 5 and 6, respectively. The results show that, at a given \( p_{{{\text{O}}_{{\text{2}}} }} \), partitioning to the slag is increasingly favored with increasing temperature and that a certain degree of distribution can be maintained at a lower temperature by also lowering the \( p_{{{\text{O}}_{{\text{2}}} }} \).

The final copper content of the slag always followed the opposite trend to that of the minor elements. At constant \( p_{{{\text{O}}_{{\text{2}}} }} \), losses to the slag decrease with increasing temperature from 1.31 to 0.69 wt pct. In this case, the values from the present work are all higher than expected from previous existing measurements by 0.1 to 0.5 wt pct.[7] However, when CO2:CO was kept constant, the amount taken up by the slag increases slightly with increasing temperature from 1.1 to 1.8 wt pct.

Slag Composition

The effect of lime content on the distribution coefficients of Se and Te between calcium ferrite slag and copper is shown in Figure 7. Selenium and tellurium are affected similarly in that both D M increases with increasing additions of lime to the calcium ferrite slag. The increase in D Se from the lowest to highest lime slags was only about 1.8 times, with the corresponding increase in D Te only 1.2 times. The copper contents of the calcium ferrite slags do not show a clear trend, varying from 1 to 1.5 wt pct, confirming the conclusion of Yazawa and Takeda[7] that copper in calcium ferrite slag is determined by the temperature and \( p_{{{\text{O}}_{{\text{2}}} }} \) only.

Discussion

Oxidation State

The results from the Cu/slag experiments at varying oxygen partial pressures at 1573 K show that the partitioning of Se and Te has a strong negative dependence on \( p_{{{\text{O}}_{{\text{2}}} }} \), in that their solubility in the slag decreases as conditions become more oxidizing. This suggests that it is a negatively charged (reduced) species of each that forms in the slag in this more reducing region. Where this is the case, D Se is higher in the present work than in fayalitic slag,[5] suggesting that the activity coefficients of the minor elements (γ M) in the slag are significantly lower in the basic calcium ferrite slag. The distribution coefficients between slag and silver match reasonably well those calculated from the Cu/slag experiments, indicating that the activity coefficients of Se and Te in the silver alloy are similar to the corresponding values measured in the copper alloy. The negative dependence on \( p_{{{\text{O}}_{{\text{2}}} }} \) is continued up to 10−5 atm for Se and to 10−6 atm in the case of Te. The increasing D Te beyond this point is indicative of a positively charged (oxidized) species of Te becoming the dominant form in the slag.

Where there is negative dependence of D M on \( p_{{{\text{O}}_{{\text{2}}} }} \), the distribution data for both minor elements fit a slope close to –0.5, indicating the formation of the selenide (Se2−) and telluride (Te2−) according to Eq. [3]

Where the dependence of D Te on \( p_{{{\text{O}}_{{\text{2}}} }} \) becomes positive, dissolution into the slag occurs as an oxidized species. The data fit a slope close to 0.5, indicating it is the +2 oxidation state that has become dominant, forming according to Eq. [4]

The transition to an oxidized species of sulfur has also been observed in gas/calcium ferrite slag equilibria,[10,11] although there it was to the +6 oxidation state. Similarly, with Se and Te in sodium carbonate slags and Cu,[6,12] the +4 oxidation state of both minor elements became dominant in the oxidizing region. The change from negative dependence to independence on \( p_{{{\text{O}}_{{\text{2}}} }} \) has been observed for Se and Te in fayalitic slags,[5,13] where D M began to level off above about 10−8 atm. The behavior of Se observed in the present experiments is therefore not considered unusual.

The reactions for the formation of the oxides of Te are

for which the equilibrium constants at 1573 K are K 5 = 5.13 and K 6 = 37.6,[5] indicating that the tetravalent oxide is more stable at \( p_{{{\text{O}}_{{\text{2}}} }} \) greater than 2 × 10−2 atm. As such, the \( p_{{{\text{O}}_{{\text{2}}} }} \) of the current experiments was such that Reaction [5] remains dominant. Similarly, for Se, equilibrium constants for the formation of the monoxide and dioxide are 6.79 and 297, respectively,[5] yet no transition was observed.

The observed increase in partitioning of Se and Te to the calcium ferrite slag as the lime content was increased (Figure 7) indicates that they enter the slag by forming a complex with Ca. Because Se and Te are considered to be acidic elements, it is to be expected that the dominant interactions are with the most basic component of the slag. Published data[14] on the Gibbs energy of formation of the selenides and tellurides from the elements confirm this, as the values for the calcium compounds are much more negative at a given temperature than the corresponding iron compounds.

In the reducing region, a general mechanism would be given by Eq. [7]

and for Te in the oxidizing region (>10−6 atm \( p_{{{\text{O}}_{{\text{2}}} }} \))

However, the D M values remained less than unity as CaO up to 31 wt pct was added to the slag, indicating that partitioning to the metal phase was always preferred. This suggests that increasing the lime content of the calcium ferrite slag by itself is not a practical way to enhance removal of Se and Te from copper.

Capacities

The selenide and telluride capacities (C M) of the calcium ferrite slag can be calculated in a similar manner to the sulfide capacity, using the general equation for the capacity as

where [M]slag is the concentration in the slag phase in wt pct and \( p_{{{\text{M}}_{{\text{2}}} }} \) is the partial pressure of minor element M. The partial pressure of each minor element was calculated using the known values of the activity coefficients in liquid copper,[15] applying the regular solution approximation to estimate the appropriate value at each temperature in this study and the known temperature dependence of the vapor pressures.[5] The activity of lime (a CaO) in this case was estimated for each slag from the iso-activity diagram of Takeda et al.[1] This is a better indicator of the basicity of the system than the concentration of CaO, because Fe2O3 will also interact with CaO in the slag, reducing a CaO. Figure 8 shows the selenide and telluride capacities of the calcium ferrite slag from the Cu/slag experiments with varying \( p_{{{\text{O}}_{{\text{2}}} }} \).

As expected from the final minor element content of the slags, C Se is always much higher than C Te. Figures 8 and 9 show that the capacities appear constant across the a CaO range studied, although there is some scatter in the Te data. This is somewhat unexpected, as at a given temperature, the capacity is a function of the free oxygen in the slag (which in calcium ferrite would mainly be provided by CaO), and so should increase with increasing a CaO. It is possible that there is some component of [M]slag attributable to direct interactions between iron and the minor elements, which leads to higher C M values being recorded. Douglas and Zaman[16] observed the formation of the Fe3+S2− amber chromophore in glasses, so it is possible that there also exist interactions between Fe3+ and Se and Te. “Free” ferric iron in the slag increases with decreasing a CaO, so these interactions will elevate capacities at the low a CaO (high \( p_{{{\text{O}}_{{\text{2}}} }} \)) end in this work, resulting in the apparent constant values for C M.

As with the \( p_{{{\text{O}}_{{\text{2}}} }} \), the effect of lime content of the calcium ferrite slag on capacity is only slight, with values of C M again appearing constant against a CaO. These are shown in Figure 9, in which the data from the experiments with varying \( p_{{{\text{O}}_{{\text{2}}} }} \) are combined. The points for each element match rather well, but there is some scatter. This also suggests that ferric iron contributes to C M; however, if this were the case, it would mean that the interactions between Fe3+ and the minor elements are as strong as those between calcium and the minor elements for the capacity values to come out equal at high and low a CaO.

Selenide and telluride capacities were calculated in the same manner as previously discussed at each temperature. The capacities increase with increasing temperature, with the values at constant \( p_{{{\text{O}}_{{\text{2}}} }} \) and constant CO2:CO ratio matching closely, even though [M]slag decreased with increasing temperature at constant CO2:CO ratio. The temperature variation data are combined and compared to existing sulfide capacity of calcium ferrite slag data[17] in Figure 10. It can be seen that each element follows the same trend against temperature and that capacity decreases down the group of the periodic table. This is an expected result because these elements are chemically similar, and the affinity for this basic slag type should decrease down the group as the minor elements become less acidic in nature.

The increasing copper losses to the slag with increasing temperature where the CO2:CO ratio was kept constant is also partly attributed to the corresponding increase in \( p_{{{\text{O}}_{{\text{2}}} }} \) across this series. So while high temperature and low \( p_{{{\text{O}}_{{\text{2}}} }} \) result in improved copper recovery, they also result in the highest amount of Se and Te being taken up by the slag.

Activities

At equilibrium, the activity of each minor element (a M) will be the same in the slag phase as it is in the metal phase. Activity coefficients of Se and Te (γ M) in the slag were calculated using Eq. [10]:

where X M is the mole fraction of the element in the slag. The activities of the minor elements were determined using the same activity coefficient in liquid copper as in the determination of the partial pressure[15] and the mole fraction of the element in the alloy as calculated from the analytical results.

Further experiments were conducted using calcium ferrite slag and Cu alloys of varying minor element concentration for the purpose of determining minor element behavior in terms of changing concentration in the slag without changing the experimental conditions. Activity coefficients calculated from these experiments are shown in Figure 11. The values are constant, confirming that γ M(slag) are independent of [M]slag, which means that any variation will be due only to changes in the experimental conditions or slag chemistry. It also demonstrates that both elements follow Henrian behavior over the concentration range studied. Because the activities of Se were lower than that of Te, and because Se was much more concentrated in the slag than Te, the resulting γ Se values are much less than γ Te. The result is that Te shows slight positive deviation from the ideal (Raoultian) behavior, whereas Se shows strong negative deviation. This reflects the difference in strength of the overall interactions between the slag components and each minor element; that is, the interactions are stronger with Se than with Te.

According to Figure 12, the activity coefficients of Se calculated from the equilibrium data on copper and calcium ferrite slag with varying \( p_{{{\text{O}}_{{\text{2}}} }} \), decreased by a few orders of magnitude with decreasing \( p_{{{\text{O}}_{{\text{2}}} }} \), and subsequently with increasing a CaO. The deduced values of activity coefficients of Se from the experiments with constant \( p_{{{\text{O}}_{{\text{2}}} }} \), but varying lime content, also decrease with increasing a CaO, but the effect is not as pronounced. As shown in Figure 13, similar behaviour is apparent for the dependence of γ Te in these slags. As γ M(slag) are shown to decrease over several orders of magnitude with varying a CaO, the assumption of a constant value is not valid when determining capacities as a function of slag basicity.

According to the iso-activity data of Takeda et al.,[1] for a calcium ferrite slag of the given CaO content, as the \( p_{{{\text{O}}_{{\text{2}}} }} \) is decreased, the activities of CaO and FeO (a FeO) increase. As a result, it is apparent that increasing interactions between CaO and FeO in the slag and the minor elements bring about the observed decrease in γ M (slag). It is possible that where lime in the slag was varied, interactions between iron and the minor elements are strongest at low a CaO, counterbalancing the lack of interactions with CaO at low lime content, resulting in the shallower dependence on a CaO. In both of these series of experiments with calcium ferrite slag, γ Se << γ Te, indicating that the strengths of interactions between lime in the slag and Se are much stronger than those between lime and Te.

The activity coefficients of Se and Te in the slag from the temperature variation experiments are shown in Figure 14. As observed previously, γ Te > γ Se, and those of Se are always < 1. The activity coefficients of Te are mostly greater than 1, indicating positive deviation from the ideal behavior, at temperatures up to 1573 K at a \( p_{{{\text{O}}_{{\text{2}}} }} \) of 10−10 atm. However, it is expected that as the temperature is increased, deviations from the ideal should decrease, that is, γ M should approach unity. When the \( p_{{{\text{O}}_{{\text{2}}} }} \) was held constant, the decrease in γ M (slag) across this series of experiments corresponds to the interval over which the Fe3+:Fe2+ ratio of the slag is decreasing. The reduced interactions between Fe2O3 and CaO, as temperature increased, results in a corresponding increase in a CaO, which would subsequently leave more CaO available to interact with the minor elements. This could account for the observed decrease in γ M if there are no direct interactions between FeO x and the minor elements in this system. When the CO2:CO ratio was held constant instead, the influence of temperature does not seem to be as strong as at constant \( p_{{{\text{O}}_{{\text{2}}} }} \). Because the values of γ Te are all > 1 in this case, the deviations from the ideal are again not decreasing. In this series of experiments, increasing the temperature leads to a corresponding increase in the \( p_{{{\text{O}}_{{\text{2}}} }} \), which in turn brings about a decrease in a CaO. Simulations using CSIRO’s Multi-Phase Equilibria (MPE) program[18] predict that a FeO in the magnesia-saturated calcium ferrite slag also decreases with increasing temperature in this series of experiments, as shown in Figure 15. The reduced interactions between Ca and Fe in the slag and the minor elements would then account for the observed increase in γ M. Further to this, simulations on slags of varying lime content show that while a CaO increases, a FeO decreases significantly with additions of lime to the slag, as shown in Figure 16. This confirms that it is ferrous iron that has an influence on the behavior of Se and Te, and that this influence is of similar significance to that of lime. It is apparent from the results of this work that the chemistry of the slag has a more significant influence on the behavior of Se and Te in the slag phase than does the temperature, although the exact extent of the role of iron remains unconfirmed.

Summary and conclusions

The ability of calcium ferrite–based slag to take up the minor impurities Se and Te from Cu and Ag alloys was investigated in terms of oxygen partial pressure, temperature, and slag composition by an equilibrium distribution technique over the range 1473 to 1673 K and 10−11 to 10−0.68 atm \( p_{{{\text{O}}_{{\text{2}}} }} \). Distribution coefficients between the slag and metal phases were less than unity in all experiments, except those for Se under strongly reducing conditions and at temperatures of 1573 K and above. The observed negative dependence of D M on \( p_{{{\text{O}}_{{\text{2}}} }} \) between 10−11 and 10−6 atm indicates that under typical copper converting conditions, the minor element-containing species are expected to be CaSe and CaTe. The low capacity of the slag for Se and Te under these conditions indicates that using calcium ferrite slag should not lead to significantly more dispersion of these elements in waste slag before the final refining step. The capacities however are increased by increasing the temperature and CaO content of the slag.

Through the determination of the activity coefficients of the minor elements, the slag was shown to interact more strongly overall with Se than with Te. Selenium showed strong negative deviation from the ideal behavior, whereas Te showed slight positive deviation from the ideal behavior except above 1573 K at 10−10 atm \( p_{{{\text{O}}_{{\text{2}}} }} \). The activity coefficients of the minor elements in the calcium ferrite slag varied by some orders of magnitude and appeared to be strongly dependent on the activity of lime. The observed dependence on temperature was not as strong as the slag chemistry. Activity coefficients of Se and Te in the slag did also appear to decrease in conjunction with the increasing activity of ferrous oxide, although the relative effect of ferric oxide has not yet been quantified. The strong dependence of the activity coefficients on the slag chemistry implies that the capacity cannot be determined from a simple dependence on the basicity of the slag.

Notes

1 atm = 1.013 × 105 Pa

References

Y. Takeda, S. Nakazawa, and A. Yazawa: Can. Metall. Q., 1980, vol. 19(3), pp. 297–305

A. Yazawa, Y. Takeda, and Y. Waseda: Can. Metall. Q., 1981, vol. 20(2), pp. 129–34

S. Jahanshahi, and S. Sun: Proc. Yazawa Int. Symp., TMS, Warrendale, PA, 2003, pp. 227–44

F. Tanaka, O. Iida, and Y. Takeda: Proc. Yazawa Int. Symp., TMS, Warrendale, PA, 2003, pp. 495–508

M. Nagamori, and P.J. Mackey: Metall. Trans. B, 1977, vol. 8B, pp. 39–46

G.R. Alvear, T. Kanai, H. Fukuyama, T. Fujisawa, and C. Yamauchi: Mater. Trans. JIM, 1994, vol. 35(8), pp. 508–15.

A. Yazawa, and Y. Takeda: Trans. Jpn. Inst. Met., 1982, vol. 23 (6), pp. 328–33.

S. Yan, S. Sun, and S. Jahanshahi: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 651–56

M.A. Somerville: MSc. Thesis, The University of Melbourne, Melbourne, 2000

G.R. St. Pierre, and J. Chipman: AIME Trans., 1956, vol. 206, pp. 1474–83

E.T. Turkdogan, and L.S. Darken: Trans. TMS-AIME, 1961, vol. 221, pp. 464–74.

K.P.A. Taskinen, and K.R. Lilius: Metall. Trans. B, 1985, vol. 16B, pp. 171–72

L. Fang, and D.C. Lynch: Metall. Trans. B, 1987, vol. 18B, pp. 181–87

I. Barin, O. Knacke, and O. Kubaschewski: Thermochemical Properties of Inorganic Substances Supplement, Springer-Verlag, Berlin, 1977

G.K. Sigworth, and J.F. Elliott: Can. Metall. Q., 1974, vol. 13(3), pp. 455–61

R.W. Douglas, and M.S. Zaman: Phys. Chem. Glasses, 1969, vol. 10(4) pp. 125–32

M.M. Nzotta, D. Sichen, and S. Seetharaman: ISIJ Int., 1999, vol. 39(7), pp. 657–63

L. Zhang, S. Jahanshahi, S. Sun, C. Chen, B. Bourke, S. Wright, and M. Somerville: JOM, 2002, vol. 54(11), pp. 51–56

Acknowledgments

This paper was partly presented at the 2006 TMS Fall Extraction and Processing Meeting. MDJ gratefully acknowledges the award of the CSIRO Metallurgical Processing Scholarship through the School of Biomedical, Biomolecular and Chemical Sciences, The University of Western Australia, where this work forms part of a Ph.D. program. Financial support from the Cooperative Research Centre for Sustainable Resource Processing, established under the Australian Government Cooperative Research Centres Program, is also acknowledged. The assistance of the High Temperature Processing Group, especially Mr. Rowan Davidson for his help with the experimental setup and the Analytical Services staff at CSIRO Minerals, is also gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted: January 4, 2007.

Rights and permissions

About this article

Cite this article

Johnston, M., Jahanshahi, S. & Lincoln, F. Thermodynamics of Selenium and Tellurium in Calcium Ferrite Slags. Metall Mater Trans B 38, 433–442 (2007). https://doi.org/10.1007/s11663-007-9048-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-007-9048-z