Abstract

A steady-state free dendritic growth model applicable to concentrated alloys was proposed as an extension of Wang et al.’s model.[14] The present model adopted a realistic thermodynamic model to replace the Baker–Cahn equation and included a generalized marginal stability criterion and a nondilute solute trapping model to completely eliminate the dilute alloy limitation. Comparative analysis shows that Wang et al.’s model is a very close approximation to the present model at low undercoolings for dilute alloys. However, the difference appears at high undercoolings even for dilute alloys. Furthermore, the difference of the model predictions for both models increases with nominal composition of alloys due to the inherent limitation of dilute alloys in Wang et al.’s model. A comparison with the experimental data for Cu70Ni30 alloy demonstrates the applicability of the present model to nondilute alloys.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The free dendritic growth in an undercooled alloy melt as a main subject in the research of solidification theory has fueled increasing attention in past decades.[1–3] In the original free dendritic growth model (LGK model),[4] Lipton et al. assumed local equilibrium condition with no interfacial kinetic effect and adopted a morphological stability criterion along with an equation for the total undercooling to predict the radius of curvature and the velocity at the tip. In order to describe high Péclet number conditions, i.e., deviations from the local-equilibrium state, some models[5–8] were proposed later. Among them, the Boettinger–Coriell–Trivedi (BCT) model[7] received wide acceptance due to its relative simplicity as well as the ability to describe rapid solidification by introducing the thermodynamic driving force, the kinetic undercooling, and Aziz’s solute trapping model.

Several simplifying assumptions, however, restrict the application of the BCT model. One of them is the assumption of straight solidus and liquidus. It leads to a significant discrepancy in model predictions for alloys with the retrograde-type solidus and curved liquidus. Divenuti and Ando eliminated this limitation and developed a model (DA model)[8] with curved (real) phase boundaries, based on the BCT model. Another assumption in the BCT model is the equilibrium solute diffusion in bulk liquid. That is the BCT model does not take into account the relaxation effect of nonequilibrium liquid diffusion, which is supported by experiments[9–11] and theories.[12] Galenko and Danilov (GD model)[13] and Wang et al.[14] incorporated the relaxation effect into the BCT model with and without linear phase boundary assumptions, respectively. These two models have a finite value for the solutal diffusion velocity in bulk liquid in contrast with the previous models, in which the relaxation time is neglected and thus the diffusion velocity is infinite.

All of the preceding models are restricted to dilute alloys. Consequently, the range of application is limited. Most importantly, the dilute assumption can bring on remarkable deviations under certain conditions. This was demonstrated for planar interface migration[15] and marginal stability criterion.[16] Recently, Önel and Ando[17] modified the DA model by using a thermodynamic solution model to replace the Baker–Cahn equation limited by Henry’s law. Also, Hartmann et al.[18] introduced a nondilute solute trapping equation into the GD model to describe the solidification behavior for Ti45Al55 alloy. However, these modifications are partial and incomplete. In this study, a steady-state free dendritic growth model, which is applicable to nondilute alloys, was proposed as an extension of Wang et al.’s model. The present model is self-consistent since it revised all three parts of the free dendritic growth model, namely, the interfacial driving force, the marginal stability criterion, and the solute trapping equation. A comparison with Wang et al.’s model and the available experimental data was also made.

2 Model

2.1 Interfacial Driving Force

Founded on Galenko’s extended irreversible thermodynamic analysis[19] for migration of a solid/liquid interface, the interfacial driving force (\( \Updelta G_{\text{eff}} \)) applicable to nondilute alloys can be derived as[15]

where subscripts 1 and 2 denote solvent and solute, respectively, for a binary alloy solution; scripts l and s represent liquid and solid phases, respectively; μ is the chemical potential; \( \Updelta \mu \) is the change in μ upon solidification (\( \mu^{s} - \mu^{l} \)); \( V \) is the interface migration velocity; \( V_{D} \) is the solutal diffusion velocity in bulk liquid; and \( C_{s}^{*} \) and \( C_{l}^{*} \) are the solute concentrations at the interface and \( C^{*} = (1 - \gamma )C_{s}^{*} + \gamma C_{l}^{*} \), respectively. The parameter \( \gamma \) is introduced to unify both forms of \( \Updelta G_{\text{eff}} \) without (\( \gamma = 0 \)) and with (\( \gamma = 1 \)) solute drag. And the values 0 ~ 1 of \( \gamma \) indicate the forms with partial solute drag. The so-called solute drag[20–22] refers to a phenomenon that a part of total Gibbs free energy change in solidification is dissipated by the solute-solvent redistribution and is not available to drive interfacial motion. It leads to slowing of the interfacial migration.

The last term in Eq. [1a] is the change of free energy corresponding to local nonequilibrium diffusion caused by the relaxation effect. This term disappears when \( V \ge V_{D} \) due to the occurrence of partitionless solidification. For dilute alloys, Eqs. [1a] and [1b] with \( \gamma = 1 \) reduce to Galenko’s result[19] on the assumption of linear phase boundaries and reduce to the following expressions used in Wang et al.’s model with real solidus and liquidus:[14]

where \( C_{l}^{eq'} \) and \( C_{s}^{eq'} \) are the curvature modified equilibrium solute concentrations in the liquid and solid, respectively, at the interface; \( k_{e}^{'} \) is the curvature modified equilibrium partition coefficient (\( k_{e}^{'} = C_{s}^{eq'} /C_{l}^{eq'} \)); \( k \) is the nonequilibrium partition coefficient; Rg is the gas constant; and \( T_{i} \) is the interfacial temperature. In the two expressions, the chemical potential differences, \( \Updelta \mu_{1} \) and \( \Updelta \mu_{2} \), were replaced by the results from Baker and Cahn:[23]

where an approximation (\( \ln (1 + x) \approx x \), in Eq. [3a]) is adopted to further simplify Baker and Chan’s results. Note that for the phase diagrams of most alloy systems, the equilibrium solute concentration \( C_{l}^{eq'} \) is not suitable for the approximation \( \ln (1 - C_{l}^{eq'} ) \approx - C_{l}^{eq'} \) at high undercoolings, i.e., low interfacial temperatures. Therefore, the application of Wang et al.’s model is considerably limited. For the interfacial driving force, a detailed comparative analysis of the present model and other typical models including Wang et al.’s model can be found in Reference 15.

According to Turnbull’s chemical rate theory,[24] \( \Updelta G_{\text{eff}} \) can be related to \( V \) as

where f is the site fraction for growth to occur at the interface, \( V_{0} \) is the maximum crystallization velocity, and \( \Updelta T_{r} \) is the curvature undercooling caused by the Gibbs–Thompson effect. Different from the planar interface migration, the curvature correction is necessary for dendritic growth.[7,8]

2.2 Marginal Stability Criterion

In previous work, a generalized marginal stability theory for a planar interface during solidification was proposed.[16] In this section, the aim is to describe the curvature radius \( r \) at the tip (curved interface) during dendritic solidification. This is also based on the generalized marginal stability theory.[16]

For an unperturbed (planar) interface, the curvature effect disappears and the interface response function, Eq. [4], reduces to

where \( C_{f} \) is the liquid composition at the planar interface. Assuming this interface is subjected to an infinitesimal sinusoidal perturbation \( \phi = \delta (t)\sin \omega x \), where \( \delta \) is the perturbed amplitude, \( \omega \) is the perturbed wave number, \( t \) is time, and \( x \) is the interfacial position, Eq. [5] is then rewritten as

where \( \Upgamma \omega^{2} \delta \sin \omega x \) represents the curvature undercooling \( \Updelta T_{r} \); \( \Upgamma \) is the Gibbs–Thompson coefficient; and \( V^{\phi } \),\( T_{i}^{\phi } \), and \( C_{f}^{\phi } \) are the migration velocity, the temperature, and the liquid composition, respectively, corresponding to the perturbed interface. They are linearly approximated by

Combining Eqs. [5] and [7] with the first-order approximation to Eq. [6], one obtains the following stability equation:

where \( M(V,T_{i} + \Updelta T_{r} ,C_{f} ) \) is regarded as the kinetic liquidus slope defined by

and the related parameters are given as

The kinetic liquidus slope \( M(V,T_{i} + \Updelta T_{r} ,C_{f} ) \) would reduce to \( M(V,T_{i} + \Updelta T_{r} ) \), which is used in Wang et al.’s model,[14] if \( C_{f} \) is separated.

Solving the steady-state thermal and non-Fickian solutal diffusion equations (Eqs. [18] through [20] in Reference 14) around a perturbed interface, and combining the boundary conditions on the perturbed interface (transport balances (Eq. [34] in Reference 14)), one yields the constant values of a and b. Consequently, from Eq. [8], the marginal stability criterion for dendritic growth can be obtained as (\( C_{f} \) is replaced by \( C_{l}^{*} \))

where

in which \( \psi = 1 - V^{2} /V_{D}^{2} \); \( \sigma^{*} \) is the stability constant (\( \sigma^{*} \approx 1/4\pi^{2} \));[25] \( P_{t} = rV/2\alpha \) is the thermal Péclet number; \( P_{c} = rV/2D \) is the solute Péclet number; \( \alpha \) and \( D \) are the thermal diffusivity and solute diffusion coefficient, respectively, in the liquid; and \( G_{c} \) is the solutal concentration gradient at interface in the liquid.[14] In addition, \( G_{l} \) and \( G_{s} \) are the thermal gradients at interface in the liquid and solid, respectively. Generally, \( G_{s} \) is negligible; i.e., \( G_{s} = 0 \). From the boundary condition \( K_{s} G_{s} - K_{l} G_{l} = \Updelta H_{f} V \), \( G_{l} \) is then given as

where \( K_{s} \) and \( K_{l} \) are the thermal conductivities of solid and liquid, \( \Updelta H_{f} \) is the latent heat of fusion, and \( C_{p} \) is the heat capacity of liquid alloy.

According to Langer and Muller-Krumbhaar, the radius of curvature \( r \) at the dendritic tip can be approximated by the perturbed wavelength \( \lambda \left( {\lambda = 2\pi /\omega } \right) \) with the marginal stability.[25] Consequently, from the marginal stability criterion Eq. [12], the expression of \( r \) is obtained as follows:[8,14,25–27]

The expression of \( \xi_{t} \) (\( \xi_{l} \)) is the same as that used in the previous models[5–8,13,14] except for the LGK model, in which an approximation to a small thermal Péclet number \( P_{t} \) is made. This is due to the fact that all the models are based on the same thermal diffusion equation (Eqs. [18] and [19] in Reference 14). However, there are differences in \( \xi_{c} \) between these models. In contrast with Wang et al.’s model, the present model includes an additional term \( 2C_{l}^{*} \partial k/\partial C| {_{{C = C_{l}^{*} }} } \) in \( \xi_{c} \). This is because the present model considers the dependency of the nonequilibrium partition coefficient \( k \) on the interface solute concentration \( C_{l}^{*} \) (Eq. [20]). Furthermore, \( \xi_{c} \) used in Wang et al.’s model reduces to that of the GD model on the assumption of the linear phase boundaries (neglect the dependency of \( k \) on \( T_{i} \)) and reduces to that of the BCT model if the relaxation effect is neglected further.

2.3 Solute Trapping Equation

For dilute alloys, including the relaxation effect of nonequilibrium liquid diffusion, the modified Aziz solute trapping equation is given as:[28]

where \( V_{DI} \) is the interfacial solute diffusive speed defined by \( D_{i} /a_{0} \), \( D_{i} \) is the solute diffusion coefficient at the interface, and \( a_{0} \) is the interface width.

For nondilute alloys, Eq. [19] used in Wang et al.’s model needs to be extended. Galenko developed an extended description of the solute partition coefficient, which is well suitable for concentrated alloys:[29]

where \( \kappa^{\prime}_{e} \) is the curvature corrected partitioning parameter defined by[20]

2.4 Ivantsov Treatments

Ivantsov assumed that the interface exhibits a dendritic morphology with a paraboloid of revolution (near the tip), and the chemical composition and the temperature are constant along the interface. Solving the steady-state thermal and solutal diffusion equations in the liquid phase from the interface to infinite, Ivantsov obtained the dimensionless thermal undercooling \( \Upomega_{t} \) and the dimensionless supersaturation \( \Upomega_{c} \), respectively:[30,31]

where Iv is the Ivantsov function, \( T_{\infty } \) is the melt temperature far from the tip, and \( C_{0} \) is the initial composition of alloys. Rewriting Eqs. [22] and [23], the interfacial temperature \( T_{i} \) and the liquid composition at the interface \( C_{l}^{*} \) can be given as

As defined explicitly in the DA model,[8] the present work also considers the four parts of bath undercooling (\( \Updelta T \)): the curvature undercooling (\( \Updelta T_{r} = 2\Upgamma /r \)), the thermal undercooling \( \Updelta T_{t} \) defined by \( T_{i} - T_{\infty } \), the constitutional undercooling \( \Updelta T_{c} \) determined by \( T_{l} (C_{0} ) - T{}_{l}(C_{l}^{*} ) \) (\( T{}_{l} \) is the liquidus temperature), and the kinetic undercooling \( \Updelta T_{k} \).

Up to now, the entire model has been established. In the present model, the interface migration velocity \( V \), the radius of curvature at the dendritic tip \( r \), the interfacial temperature \( T_{i} \), and the solute concentrations at the interface \( C_{s}^{*} \) and \( C_{l}^{*} \) are chosen as five independent variables. These variables can be uniquely determined by solving the set of equations including Eqs. [4], [18], [20], [24], and [25] with the iteration method, for a given alloy system at a given bath undercooling \( \Updelta T \) (or \( T_{\infty } \)).

3 Comparative Analysis

In order to make a comparison between the present model and Wang et al.’s model, the Pb-Sn alloy, a typical eutectic system, was adopted in the computations. The detailed comparative analysis of Wang et al.’s model and the previous models can been found in Reference 14. The free energy functions of solid and liquid phases are required as a main input, which are described by the temperature-dependent subregular solution model:[32]

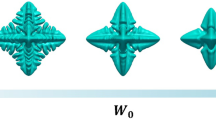

where \( X \) is the mole fraction of Pb, \( T \) is the temperature (Kelvin), the superscript \( i \) denotes the solid phase (\( \alpha \), with BCT structure) or liquid phase (L), and the \( \Upomega \) terms are the interaction parameters. The related thermodynamic parameters are given in Table I. The thermodynamic model and the parameters are well based on Fecht et al.’s experimental results[32] and optimized using the CALPHAD (calculation of phase diagram) method.[33] Other parameters used in the model computations are given in Table II. In addition, the hypercooling \( \Updelta H_{f} /C_{p} \) is calculated with classical thermodynamic formulas based on the free energy data from Table I. As shown in Figure 1, it is variable with temperature.

The calculated model predictions with different nominal compositions of alloys, \( C_{0} \), are shown in Figures 2 through 5. The driving force is calculated without solute drag (\( \gamma = 0 \)). Introducing \( \gamma \) makes it possible to readily discuss the influence of solute drag on the solidification behavior and to search the solute drag effect. Based on the present model, these works were carried out applying to Pb-Sn and Si-As systems. The corresponding study for the diffusive interface model applicable to concentrated alloys should also be undertaken. However, these studies are out of the scope of the present article and will be published elsewhere.

Interfacial driving force \( \Updelta G_{\text{eff}} \) and growth velocity vs bath undercooling, calculated by the present model and Wang et al.’s model[14] for \( C_{0} \)= 0.01

Figure 2 shows the effective driving force \( \Updelta G_{\text{eff}} \) as a function of the bath undercooling for \( C_{0} \) = 0.01, i.e., dilute alloys. The difference increases with the undercooling, and it is significant at high undercoolings. The difference of \( \Updelta G_{\text{eff}} \) includes two parts. Part one comes from the approximation to the realistic thermodynamic driving force by using the Baker–Cahn equation[23] in Wang et al.’s model. It is well known that the Baker–Cahn equation is only suitable for an ideal solution. Part two comes from the simplification for the Baker–Cahn equation on the dilute assumption (Eqs. [3]). For a dilute solution, the ideal solution approximation is reasonable and part one of the difference is neglectable. However, part two of the difference cannot be neglected at high undercoolings. This is because Wang et al.’s model adopts an approximation, \( \ln (1 - C_{l}^{eq'} ) \approx - C_{l}^{eq'} \), to simplify the Baker–Cahn equation (Eq. [3]). In the equilibrium phase diagram of Pb-Sn alloy, it can be clearly explicated that below the eutectic temperature, this approximation is not suitable at all. Therefore, even for dilute alloys, Wang et al.’s model is not suitable to high undercoolings. As for concentrated alloys, computation indicates that part one of the difference also appears owing to the ideal solution approximation in Wang et al.’s model.

From Turnbull’s growth law (Eq. [4]), the tip velocity is strongly dependent on the driving force. This phenomenon is also illustrated in Figure 2. For these two models, velocities are calculated by using both linear (\( \Updelta G_{\text{eff}} /{\text{R}}_{\text{g}} (T_{i} + \Updelta T_{r} ) + V/fV_{0} = 0 \)) and exponential growth laws to show the divergence resulting from the linear approximation in Wang et al.’s model. In this figure, it can be found that at high undercoolings, the values of \( V/fV_{0} \) (\( V_{0} = 500 \) m/s and \( f = 1 \)) reach about 0.5. Thus, the linear approximation \( \ln (1 - V/fV_{0} )\sim - V/fV_{0} \) is also not suitable at high undercoolings.

The tip radius as a function of the bath undercooling is shown in Figure 3. Compared with the present model, Wang et al.’s model has a transition region that moves rightward for \( C_{0} \)= 0.05 and moves leftward for \( C_{0} \)= 0.12, while for \( C_{0} \)= 0.01, the results for both models are similar. Furthermore, computation indicates that the positions of the transition region are also similar for both models at about 0.09 for \( C_{0} \). This is just a coincidence. Through numerical analysis, it was concluded that the interesting phenomenon is attributed to two main factors. The first is that Wang et al.’s model universally overestimates the kinetic liquidus slope \( M \) (Figure 4). From Eq. [18], the increase of \( M \) advances the diffusion-controlled regime. The second one is that Wang et al.’s model overestimates the tip velocity (Figure 2), particularly at high undercoolings. It is well known that the high solidification velocity suppresses the solute diffusion and accelerates the solute trapping to occur. Thus, the two opposite factors compete with each other and result in the interesting phenomenon.

Tip radius vs bath undercooling, calculated by the present model and Wang et al.’s model[14] for different \( C_{0} \). The different solidification regimes are separated into four regions shown at the curves for \( C_{0} \) = 0.05. These regions indicate the mainly diffusion-controlled, the transition, and the mainly and purely thermal-controlled regimes, respectively, from low to high undercoolings

Relationship between the kinetic liquidus slope \( M \) and bath undercooling, calculated by the present model and Wang et al.’s model[14] for different \( C_{0} \). The vertical dot lines are the same as that in Fig. 2

The relationship between the nonequilibrium partition coefficient \( k \) and the bath undercooling \( \Updelta T \) is shown in Figure 5. The interfacial liquid solute concentration \( C_{l}^{*} \) vs \( \Updelta T \) is shown in the insert. It implies that the significant disagreement for \( k \) occurs mainly at undercoolings where \( C_{l}^{*} \) values are larger than 0.1. This can be understood through comparing the solute trapping equations used in both models. For Wang et al.’s model (Eqs. [19]), the simplification lies in omitting the term \( (1 - \kappa^{\prime}_{e} )C_{l}^{*} \) in Eq. [20a], except replacing \( \kappa^{\prime}_{e} \) by \( k^{\prime}_{e} \). Therefore, it is the simplification with the dilute alloy assumption that brings the significant divergence for \( k \) when \( C_{l}^{*} \) is larger than 0.1.

Nonequilibrium partition coefficient \( k \) vs bath undercooling \( \Updelta T \), calculated by the present model and Wang et al.’s model[14] for different \( C_{0} \). The insert is the liquid composition \( C_{l}^{*} \) at the interface as a function of \( \Updelta T \). The vertical dot lines are the same as that in Fig. 2

From the results of model computations, it should also be highlighted that the difference of the model predictions for both models increases with the nominal composition \( C_{0} \), by reason of the inherent limitation of dilute alloys in Wang et al.’s model. So, it is necessary to examine the applicability of the present model to nondilute alloys. A comparison with the available experimental data for Cu70Ni30 alloy was made. The thermodynamic model and data are from References 34 and 35 for computation and optimization of the Cu-Ni phase diagram. The related values of the parameters used in the model computation are also given in Table II. Figure 6 shows the data points from the electromagnetic levitation experiment,[9] and the calculated dendritic growth velocity as a function of the bath undercooling for the present model, with (γ = 0) and without (γ = 0) solute drag, and Wang et al.’s model. As can be seen clearly, the present model with solute drag can give a satisfactory agreement with the experimental data.

Calculated (curves) and experimental[9] (open circle) dendritic growth velocities vs the bath undercooling for Cu70Ni30 alloy. The parameter \( f \) is assumed to be 0.65 to obtain the best description of the experimental results

4 Summary

A steady-state free dendritic growth model applicable to concentrated alloys was developed as an extension of Wang et al.’s model.[14] The present model adopted a reasonable thermodynamic model to replace the Baker–Cahn equation and included a generalized marginal stability criterion and a nondilute solute trapping model to completely eliminate the dilute alloy limitation. It was concluded by a comparative analysis that the difference between the present model and Wang et al.’s model increases with the nominal composition of alloys due to the inherent dilute limitation in Wang et al.’s model. Furthermore, Wang et al.’s model has a reasonable approximation to the present model at low undercoolings for a dilute alloy. However, the discrepancy appears at high undercoolings even for dilute alloys. A comparison with the available experimental data demonstrates the applicability of the present model to nondilute alloys.

References

D.M. Herlach: Mater. Sci. Eng. R, 1994, vol. 12, pp. 177–272.

W.J. Boettinger, S.R. Coriell, A.L. Gereer, A. Karma, W. Kurz, M. Rappaz, and R. Trivedi: Acta Metall., 2000, vol. 48, pp. 43–70.

F. Liu and G.C. Yang: Int. Mater. Rev., 2006, vol. 51, pp. 145–70.

J. Lipton, M.E. Glicksman, and W. Kurz: Mater. Sci. Eng., 1984, vol. 65, pp. 57–63.

J. Lipton, W. Kurz, and R. Trivedi: Acta Metall., 1987, vol. 35, pp. 957–64.

R. Trivedi, J. Lipton, and W. Kurz: Acta Metall., 1987, vol. 35, pp. 965–70.

W.J. Boettinger, S.R. Coriell, and R. Trivedi: in Rapid Solidification Processing: Principles and Technologies IV, R. Mehrabian, and P.A. Parrish, eds., Claitor’s Publishing Division, Baton Rouge, LA, 1988, pp. 13–25.

A.G. Divenuti and T. Ando: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 3047–56.

R. Willnecker, D.M. Herlach, and B. Feuerbacher: Appl. Phys. Lett., 1990, vol. 56, pp. 324–26.

K. Eckler, R.F. Cochrane, D.M. Herlach, B. Feuerbacher, and M. Jurisch: Phys. Rev. B, 1992, vol. 45, pp. 5019–22.

C.B. Amold, M.J. Aziz, M. Schwarz, and D.M. Herlach: Phys. Rev. B, 1999, vol. 59, pp. 334–43.

D. Jou, J. Casas-Vazquez, and G. Lebon: Rep. Prog. Phys., 1999, vol. 62, pp. 1035–1142.

P.K. Galenko and D.A. Danilov: J. Cryst. Growth, 1999, vol. 197, pp. 992–1002.

H.F. Wang, F. Liu, Z. Chen, G.C. Yang, and Y.H. Zhou: Acta Mater., 2007, vol. 55, pp. 497–506.

S. Li, J. Zhang, and P. Wu: J. Cryst. Growth, 2010, vol. 312, pp. 982–88.

S. Li, J. Zhang, and P. Wu: Scripta Mater., 2009, vol. 61, pp. 485–88.

S. Önel and T. Ando: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2449–58.

H. Hartmann, P.K. Galenko, D. Holland-Moritz, M. Kolbe, D.M. Herlach, and O. Shuleshova: J. Appl. Phys., 2008, vol. 103, p. 073509.

P.K. Galenko: Phys. Rev. B, 2002, vol. 65, p. 144103.

M.J. Aziz and T. Kaplan: Acta Metall., 1988, vol. 36, pp. 2335–47.

M. Hillert: Acta Mater., 1999, vol. 47, pp. 4481–4505.

S. Li, J. Zhang, and P. Wu: Scripta Mater., 2010, vol. 62, pp. 716–19.

J.C. Baker and J.W. Cahn: Solidification, ASM, Metals Park, OH, 1971, pp. 23–58.

D. Turnbull: J. Phys. Chem., 1962, vol. 66, pp. 609–13.

J.S. Langer and H. Muller-Krümbhaar: Acta Metall., 1978, vol. 26, pp. 1681–87.

R. Trivedi and W. Kurz: Acta Metall., 1986, vol. 34, pp. 1663–70.

P.K. Galenko and D.V. Danilov: Phys. Rev. E, 2004, vol. 69, p. 051608.

S.L. Sobolev: Phys. Rev. E, 1997, vol. 55, pp. 6845–54.

P.K. Galenko: Phys. Rev. E, 2007, vol. 76, p. 031606.

G.P. Ivantsov: Dokl Akad Nauk SSSR, 1947, vol. 58, pp. 567–69.

G.P. Ivantsov: Dokl Akad Nauk SSSR, 1952, vol. 83, pp. 573–76.

H.J. Fecht, M.X. Zhang, Y.A. Chang, and J.H. Perepezko: Metall. Trans. A, 1989, vol. 20A, pp. 795–803.

U.R. Kattner: JOM, 1997, vol. 49 (12), pp. 14–19.

S. An Mey and R.W.T.H. Aachen: CALPHAD, 1992, vol. 16, pp. 255–60.

X.Y. Yan, Y.A. Chang, Y. Yang, F.Y. Xie, S.L. Chen, F. Zhang, S. Daniel, and M.H. He: Intermetallics, 2001, vol. 9, pp. 535–38.

Acknowledgments

The authors are grateful to Professor Teiichi Ando for the valuable discussion of this work. The constructive suggestions of Peter Galenko as well as the helpful comments of Haifeng Wang and Feng Liu on the manuscript are kindly acknowledged. The work was supported by the National Natural Science Foundation of China (Grant Nos. 51074112 and 51101046), the Key Program of the Tianjin Natural Science Foundation (Grant No. 11JCZDJC22100), and the Scientific Research Fund of the Heilongjiang Provincial Education Department (Grant No. 12511073).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 11, 2009.

Rights and permissions

About this article

Cite this article

Li, S., Zhang, J. & Wu, P. Analysis for Free Dendritic Growth Model Applicable to Nondilute Alloys. Metall Mater Trans A 43, 3748–3754 (2012). https://doi.org/10.1007/s11661-012-1189-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1189-2