Abstract

New NiMoO4/CoMoO4 composite materials on Ni foam were successfully synthesized by a facile hydrothermal method using the mixture powers of Ni(NO3)2·6H2O and Co(NO3)2·6H2O as raw materials. The phase composition, microstructure, and morphology of the as-prepared composites were investigated by XRD, FTIR, SEM, EDS, and XPS. The electrochemical behaviors of the composites were tested by cyclic voltammetry, galvanostatic charge-discharge, and electrochemical impedance spectroscopy. The results indicated that the as-prepared composites are uniformly distributed on the surface of Ni foam with diameters between 2 and 3 μm, and the NiMoO4/CoMoO4 composite displays the best electrochemical properties when the molar ratio of Ni/Co is 1:1. In 3 mol L−1 KOH electrolytes with current densities of 1, 4, 7, and 10 A g−1, the discharge specific capacitance of NiMoO4/CoMoO4 composite is 2221, 1868, 1678, and 1568 F g−1, respectively, indicating its promising applications for high electrochemical performance energy storage device.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Energy is the material basis of human activities, the core driving force for economic development, and the essential condition for a country’s core competitiveness and sustainable economic and social development [1,2,3,4,5,6,7]. Supercapacitors (SCs), also known as electrochemical capacitors, electrochemical double-layer capacitors, pseudocapacitors, ultracapacitors, power capacitors, and gold capacitors, etc. [8, 9], are devices that store energy through a double electrical layer at the electrode/electrolyte interface, or through the electrochemical Faraday redox reactions [10, 11]. As a new type of energy storage device with high efficiency and cleanness, SC has higher energy density and power density than traditional dielectric capacitor. Compared with traditional battery, supercapacitor has the advantages of high power density, fast charging and discharging speed, long cycle life, and wide working temperature range [12]. It can be widely used in backup batteries, energy storage, and auxiliary peak power and so on. The situation has great market value and commercial potential in industrial control, military, electric power, new energy vehicles, etc. [13, 14]. However, the low energy density of SCs is an important reason to limit their development. At present, the main solution is to develop electrode materials with high electrochemical performance. Previous studies on electrode materials for SCs are mainly focused on transition metal oxides or hydroxides with pseudocapacitive properties, for example, NiO [15, 16], RuO2 [17], MnO2 [18], Co(OH)2 [19], V2O5 [20], and Ni(OH)2 [21]. The RuO2 exhibits the best electrochemical performance. However, its high price and toxicity limit its wide commercial application [22].

In recent years, the multi-hybrid nanomaterials of SCs (such as NiMoO4 [23,24,25], CoMoO4 [26], ZnCo2O4 [27], NiCo2O4 [28], MnMoO4 [29], NiO@CeO2 [30], NiO@MnO2 [31], NiCo2O4@NiWO4 [32], NiMoO4/CoMoO4 [33], NiCo2S4@NiMoO4 [34], and CoMoO4-NiMoO4·xH2O [35]) have become a strong exploration trend due to their intrinsic properties, such as low cost, natural abundance, reliable redox transformation, and synergistic effects [36]. It is worth mentioning that the good electrochemical activity of nickel ions and the better conductivity of molybdenum elements can be attributed to the excellent electrochemical capacitance of the obtained bimolybdate [37, 38]. For examples, Huang et al. [39] successfully prepared wall-like hierarchical metal oxide MMoO4 (M = Ni, Co) nanosheet arrays electrode material by a facile hydrothermal method, which exhibited a high specific capacitance of 1483 and 452 F g−1 for NiMoO4 and CoMoO4 at a current density of 2 A g−1. Cai et al. [40] synthesized NiMoO4 nanospheres and nanorods by a facile hydrothermal method, which exhibited a high specific capacitance of 974.4 F g−1 at a current density of 1 A g−1. Furthermore, Tian et al. [41] rationally designed porous worm-like NiMoO4 by electrostatic spinning, which offered good rate capability (860.3 F g−1 at a current density of 20 A g−1), high specific capacitance (1088.5 F g−1 at a current density of 1 A g−1), and long cycle life with a capacity retention of 73.9% after 5000 cycles. Usually, NiMoO4 electrode material can offer high capacitance and low cycle stability, while CoMoO4 exhibits a lower capacitance and good rate capability [33]. Zhao et al. [42] prepared CoMoO4 nanorod electrode, which exhibited a specific capacitance of 89.5 F g−1 at a current density of 1 mA cm−2. Veerasubramani et al. [43] synthesized plate-like CoMoO4 nanostructures via a facile sonochemical approach, which showed a specific capacitance of 133 F g−1 at a current density of 1 mA cm−2, and the capacitance retention is about 84% after 1000 cycles. Zhang et al. [44] prepared NiMoO4@CoMoO4 nanospheres on Ni foam, which delivered a greatly enhanced specific capacitance of 1601.6 F g−1 at a current density of 2 A g−1, as well as better cycling stability and rate capability than pure NiMoO4 or CoMoO4 material. Therefore, a large number of scientists trend to investigate composite electrode materials for SCs, and use the synergistic effect between different components to increase the rapid diffusion and transport of electrons and ions, which illustrate that the electrochemical performance of the composite material is superior to that of the single material.

However, most current NiMoO4 or CoMoO4 literatures [33, 45,46,47] adopt cladding paste electrode, making its actual discharge capacity much smaller than its theoretical value. Based on the above considerations, an integrated NiMoO4/CoMoO4 electrode (with binder-free) based on Ni foamed is prepared by a simple hydrothermal method, which is helpful to reduce the contact resistance between electrode materials and collector, and to improve the capacitive performance. As far as we know, the novel NiMoO4/CoMoO4 micron structure has rarely been reported. And the excellent electrochemical properties of the composites are attributed to the synergistic effect of NiMoO4 and CoMoO4. What’s more, the unique structure can provide channels for rapid diffusion process and enrich active reaction sites; shorten electron/ion transport pathways, improving the redox reaction of active material not only on the surface of electrode but also in the electrolyte; and then improve the utilization of active materials. Using these advantages, the as-prepared NiMoO4/CoMoO4 electrode materials have great potential application value in the development of electrochemical energy storage devices.

Experimental

Material preparation

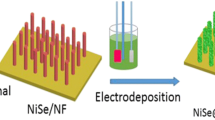

Nickel foam was cleaned with acetone, deionized water, hydrochloric acid, and deionized water for 10 min through ultrasonic cleaning, and then completely dried in air. In the typical hydrothermal synthesis process, all reagents are used as raw materials without further purification. The molar ratios of Ni and Co were controlled to be 1:2, 1:1, 2:1, 3:1, 4:1, and 5:1, respectively. The mass of Ni(NO3)2·6H2O and Co(NO3)2·6H2O at different nickel-cobalt ratios is calculated, and then, 0.4839 g Na2MoO4·2H2O and 0.1089 g Na acetate are weighed. The volume ratio of water to ethanol is 2:1, that is, 40 mL water and 20 mL ethanol are mixed evenly and divided into 3 equal parts to dissolve the above substances. Then, the Ni(NO3)2 solution, Co(NO3)2 solution, and Na acetate solution were added to Na2MoO4 solution drop by drop and stirred fully under a magnetic stirrer. After that, the homogeneous solution and the prepared nickel foam are transferred to the Teflon-lined stainless steel autoclave. The hydrothermal reaction was maintained at 150 °C for 6 h. After a reactor was naturally cooled to room temperature, a precursor was washed several times with distilled water and anhydrous ethanol, and then dried completely in air at 60 °C throughout the night. Finally, the NiMoO4/CoMoO4 composite material was obtained after annealing at 300 °C for 5 h.

Structure characterizations

The phase and crystal structure of the prepared samples were examined by X-ray powder diffraction (XRD, D8, Bruker) equipped with Cu Kα radiation in the 2θ range of 10–80° at a scanning rate of 4° min−1. The chemical composition of the samples were determined by Fourier transform infrared spectroscopy (FTIR). The morphology and microstructures of the as-products were characterized by scanning electron microscopy (SEM; JSM 6490) and energy-dispersive spectrometry (EDS). The surface chemical compositions of the obtained sample were analyzed by X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi) with an Al Kα source.

Electrochemical measurements

The electrochemical performance of the NiMoO4/CoMoO4 composites was examined by CHI 660E electrochemical workstation using three-electrode cell system in 3 mol L−1 KOH aqueous solution. The prepared NiMoO4/CoMoO4, platinum foil, and Hg/HgO were used as a working electrode, counter electrode, and reference electrode, respectively. The electrochemical impedance spectroscopy (EIS) measurement is also operated in the frequency range of 0.01~100 kHz with AC amplitude of 5 mV. The specific capacitance (Cm, F g−1), energy density (E, Wh kg−1), and power density (P, W kg−1) were calculated using the following equations [48]:

where i (A), m (g), Δt (s), and Δu (V) represent the discharge current, the mass of active electrode material, the total discharge time, and the potential window, respectively.

Results and discussion

Determination of the optimum ratio sample

Figure 1a displays the typical cyclic voltammetry (CV) curves of NiMoO4/CoMoO4 composite electrodes with different Ni/Co molar ratios at a scan rate of 5 mV s−1 recorded in a potential window of 0–0.5 V. Apparently, the CV curves of the resulting NiMoO4/CoMoO4 composite electrode supply typical Faradaic capacitive behavior with a pair of well-defined redox peaks are based on Ni and Co diffusion controlled reversibly changing their oxidation states (Ni2+/Ni3+ and Co2+/Co3+) [49], which is distinct from that of EDLCs characterized by nearly a rectangular shape. And the oxidation peak potential and reduction peak potential of NiMoO4/CoMoO4 composites are about 0.47 V and 0.37 V, respectively. Furthermore, although Mo is a transition metal, it does not participate in the redox reaction directly, but rather enhances the electrical conductivity, thus improving the electrochemical performance of the electrode [50].

In order to further compare and analyze the electrochemical properties of NiMoO4/CoMoO4 composite electrodes, a series of experiments on Ni/Co molar ratio were carried out, and the corresponding galvanostatic charge-discharge (GCD) curves recorded in a potential window of 0–0.5 V at 1 A g−1 are shown in Fig. 1b. The GCD curves of NiMoO4/CoMoO4 composite electrodes displayed lines with charge-discharge platform rather than smooth lines, which indicates the pseudocapacitive nature and consistent with the CV results. The near symmetry of the GCD curves indicates that the Faraday redox reaction is highly reversible. More importantly, according to Eq. (1), the specific capacitance of the electrode can be calculated using the charge-discharge curve. A maximum specific capacitance was observed for the composite with a Ni/Co mass ratio of 1:1, which may be promising candidates for the practical application of SCs.

The electrochemical impedance spectroscopy (EIS) is used to investigate the internal resistance of the electrode material, and the resistance between the electrode material and the electrolyte. Figure 2 shows the EIS plots of NiMoO4/CoMoO4 composites with different Ni/Co molar ratios recorded from 0.01~100 kHz with a perturbation amplitude of 5 mV. Figure 2a shows a semicircle section in the high-frequency region and a slant line in the low-frequency region. All the plots are almost the same, including semicircles and oblique lines. High-frequency semicircles represent the induced resistance caused by electron transfer of interfacial active substances. Diameter determines the resistance of electron transfer on the surface of electrodes, and the sloped lines at the low frequency region represent the Warburg impedance caused by diffusion [51]. In addition, the intercepts of the semicircles and the real axis at high frequency can also be obtained. Figure 2b shows the intercepts of NiMoO4/CoMoO4 composites with different Ni/Co molar ratios are approximately the same. In other words, the equivalent series resistance does not change much. The slope value of the composites with a Ni/Co molar ratio of 1:1 is higher than that of other samples, which indicates that the Warburg impedance is smaller and the diffusion impedance of the active substance in the electrolyte is smaller, which thus accelerates the diffusion of ions in active substances and electrolytes, as well as the transfer of electrons and ions, and improves the degree of the Faraday reaction [52]. As mentioned above, when the molar ratio of Ni/Co is 1:1, the obtained NiMoO4/CoMoO4 composite has the best electrochemical performance.

Characterization of the optimum ratio sample

Figure 3a shows the CV curves of NiMoO4/CoMoO4 composite with Ni/Co molar ratio 1:1 at various scan rates of 2, 5, 10, 15, and 20 mV s−1 in the potential range of 0–0.5 V. With the increase of scanning rate from 2 to 20 mV s−1, the redox peak potential almost remains unchanged, but the area of CV curve and peak current gradually increased. Therefore, accelerating electron transport and optimizing electrode structure can realize the rapid redox reaction process for energy storage. The shape of CV curve changed slightly, which indicated that the sample had good rate characteristics and excellent electrochemical properties [53,54,55,56].

a CV curves of NiMoO4/CoMoO4 composite electrode with Ni/Co molar ratio 1:1 at various scan rates of 2, 5, 10, 15, and 20 mV s−1. b GCD curves of NiMoO4/CoMoO4 composite electrode with Ni/Co molar ratio 1:1 at various current densities of 1, 4, 7, and 10 A g−1. c Specific capacitances of the electrode as a function of current densities

Figure 3b shows the GCD curves of NiMoO4/CoMoO4 composite with Ni/Co molar ratio 1:1 at various current densities of 1, 4, 7, and 10 A g−1, respectively. A well-defined platform can be observed in the GCD curves, and the discharge specific capacitance calculated according to Eq. (1) is shown in Fig. 3c. When the discharge current densities are 1, 4, 7, and 10 A g−1, the excellent discharge specific capacitances of the composite are 2221, 1868, 1678, and 1568 F g−1, respectively. When the current density increases from 1 to 10 A g−1, the discharge time and discharge specific capacitance decrease gradually. It is impressive that the highest discharge specific capacitance is 2221 F g−1 at 1 A g−1. When the current density increases to 10 A g−1, the discharge specific capacitance (1568 F g−1) is 70.6% retention for 1 A g−1. However, according to literature report [41], the specific capacitance of NiMoO4 is 1088.5 F g−1 at current density of 1 A g−1, which indicates that the synergistic effect of NiMoO4/CoMoO4 composite makes it a high capacity and excellent rate material [48].

To demonstrate the advantages of the material, in Table 1, we compare the related properties (such as specific capacitance at low and high current densities) of NiMoO4/CoMoO4 electrode with other recently reported transition metal oxide–based electrodes in the literature. Compared with previous studies, the NiMoO4/CoMoO4 electrode reported in this paper has higher specific capacitance and bigger rate capability. This is due to the fact that NiMoO4 and CoMoO4 components exhibit good synergies, making the composite exhibit better capacitive properties, indicating that NiMoO4/CoMoO4 composite is an ideal material for building SCs.

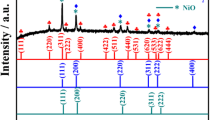

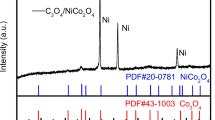

Figure 4 shows the XRD results of the as-synthesized NiMoO4/CoMoO4 composite with Ni/Co molar ratio 1:1. The diffraction patterns of single NiMoO4 and pure CoMoO4 are consistent with the standard spectra of NiMoO4 (JCPDS card no. 33-0948) and CoMoO4 (JCPDS card no. 25-1434), respectively. In addition, the present both the characteristic diffraction peaks of NiMoO4 and CoMoO4 phases are appeared in the spectra of NiMoO4/CoMoO4 composite, indicating the coexistence of NiMoO4 and CoMoO4. For the hybrid composite, the diffraction peaks at 14.3°, 25.3°, 28.8°, 32.7°, 43.8°, and 47.5° are attributed to the reflections of (110), (002), (220), (022), (330), and (204) planes, which is in good agreement with the standard spectrum of NiMoO4 [51]. In addition, the other diffraction peaks occurring at 14.1°, 25.1°, 28.5°, 32.3°, and 43.2° can be readily indexed to CoMoO4 [78,79,80]. Therefore, XRD analysis shows that we have successfully synthesized NiMoO4/CoMoO4 composite on Ni foams. Besides, there are still some weak peaks, showing a lower crystallinity.

Figure 5 shows the FTIR spectra of the prepared samples. Obviously, the typical peaks 958 cm−1, 873 cm−1, and 738 cm−1 were observed on the NiMoO4/CoMoO4 curve, corresponding to the absorption vibrations of Mo–O, Co–O, and Ni–O bonds, respectively. The extra peak at 3423 cm−1 is due to the stretching vibration of -OH. In addition, the bending vibration of the FTIR peak at 1620 cm−1 is due to the physical adsorption of water molecules in the sample, this can indicate the presence of crystal water in the sample [81].

In order to further investigate the valence states of elements in the as-synthesized NiMoO4/CoMoO4 composite, XPS experiments were performed, and the corresponding results are shown in Fig. 6. In detail, the survey spectra (Fig. 6a) of the composite sample exhibits the distinct peaks of Co 2p, Ni 2p, Mo 3d, and O 1s peaks located at 781.2, 854.7, 231.2, and 530.1 eV, revealing the presence of Co, Ni, Mo, and O elements, respectively. Figure 6b shows the Co 2p core level spectrum; the two main fitted peaks at 796.7 and 780.6 eV, accompanied two diminutive satellite peaks at 803.1 and 784.2 eV, are assigned to Co 2p1/2 and Co 2p3/2 energy level, respectively. The primary peaks and shakeup satellite peaks of Co 2p1/2 and Co 2p3/2 indicate the Co2+ valence state [33]. As depicted in Fig. 6c, the Ni 2p spectrum was fitted by four peaks. The major peak at 873.4 eV and its satellite peak at 879.9 eV are owning to Ni 2p1/2 level, whereas those at 855.6 and 861.7 eV are ascribed to Ni 2p3/2 level. Further, the gap in binding energy between the main peaks of Ni 2p1/2 and Ni 2p3/2 is 17.8 eV, proving the existence of the Ni2+ oxidation state [44]. The deconvoluted Mo 3d spectrum (Fig. 6d) exhibits two major peaks at 235.3 and 232.2 eV which can be assigned to Mo 3d3/2 and 3d5/2 energy level, respectively. The two peaks are separated by a binding energy of 3.1 eV, confirming the existence of an oxidation state of Mo6+ [82], which is consistent with the previous reports [83]. In addition, the O 1s spectrum (Fig. 6e) can deconvoluted into three oxygen peaks, located at 529.9, 530.5, and 532.2 eV of O1, O2, and O3 components, respectively. The O1 component is related to metal–oxygen bond, while O2 component is attributed to functional groups and defect sites, and O3 component is ascribe to the surface physical adsorption of H2O [84].

Figure 7a is the EDS spectrum of NiMoO4/CoMoO4 composite, which shows the surface composition of the component. The results show that the material is composed of Co, Ni, Mo, and O elements, and the ratio of Co to Ni is close to 1:1, suggesting that the sample is mainly composed of Co, Ni, Mo, and O, which is consistent with the XRD results [44, 85]. As shown in Fig. 7b–e, the element mapping images indicate the uniform distribution of Co, Ni, Mo, and O in NiMoO4/CoMoO4 composite sample, suggesting the coexistence of NiMoO4 and CoMoO4.

Figure 8a and b show the SEM images of synthesized NiMoO4/CoMoO4 composite with Ni/Co molar ratio 1:1. SEM images of prepared composite show grain-like morphology. The low-magnification SEM images in Fig. 8 depict the as-prepared composites are uniformly distributed on the surface of nickel foam after mild hydrothermal procedures. The aggregation of these small particles forms a porous structure, and their sizes are between 2 and 3 μm. This porous structure composite material formed on nickel foam provides abundant space and electroactive sites for electrochemical reaction, and shortens the length of diffusion path, so that its electrochemical properties can be significantly improved.

Conclusions

In summary, NiMoO4/CoMoO4 composite was successfully synthesized by an affinity hydrothermal method, which have the advantages of simplicity and cost-effectiveness. The results indicated that the as-prepared composite with the Ni/Co molar ratio of 1:1 has the best electrochemical properties, which are uniformly distributed on the surface of nickel foam with diameters between 2 and 3 μm. The specific capacitance of NiMoO4/CoMoO4 composite was 2221, 1868, 1678, and 1568 F g−1 at the current density of 1, 4, 7, and 10 A g−1 in 3 mol L−1 KOH electrolytes. In terms of specific capacitance, rate capability, cost, and simple synthesis process, its excellent electrochemical performance is satisfactory, even better than that reported in the literature, indicating its broad application prospect in high-performance SCs. The enhancement of electrochemical performance can be mainly due to the introduction of CoMoO4 and the synergistic effect of cobalt molybdates and nickel molybdates, which can provide channel for quick diffusion and transport of electrons and ions and a large number of active sites.

References

Wang L, Gao H, Fang H, Wang S, Sun J (2016) Effect of methanol on the electrochemical behaviour and surface conductivity of niobium carbide-modified stainless steel for DMFC bipolar plate. Int J Hydrog Energy 41(33):14864–14871

Gao H, Liao S, Zhang Y, Wang L, Zhang L (2017) Methanol tolerant core-shell RuFeSe@Pt/C catalyst for oxygen reduction reaction. Int J Hydrog Energy 42(32):20658–20668

Li X, Xia T, Dong H, Shang Q, Song Y (2013) Preparation of nickel modified activated carbon/AB5 alloy composite and its electrochemical hydrogen absorbing properties. Int J Hydrog Energy 38(21):8903–8908

Cao Y, Zhang A-Q, Zhang H, Ding G-Q, Zhang L-S (2020) A facile route to achieve Fe2O3 hollow sphere anchored on carbon nanotube for application in lithium-ion battery. Inorg Chem Commun 111:107633

Wang R, Li X, Wang Z, Zhang H (2017) Electrochemical analysis graphite/electrolyte interface in lithium-ion batteries: p-toluenesulfonyl isocyanate as electrolyte additive. Nano Energy 34:131–140

Ma D, Li Y, Mi H, Luo S, Zhang P, Lin Z, Li J, Zhang H (2018) Robust SnO2-x nanoparticle-impregnated carbon nanofibers with outstanding electrochemical performance for advanced sodium-ion batteries. Angew Chem Int Ed 57(29):8901–8905

Yi T-F, Zhu Y-R, Tao W, Luo S, Xie Y, Li X-F (2018) Recent advances in the research of MLi2Ti6O14 (M = 2Na, Sr, Ba, Pb) anode materials for Li-ion batteries. J Power Sources 399:26–41

Zhang Y, Yao Q-q, Gao H-l, Wang L-z, Jia X-l, Zhang A-q, Song Y-h, Xia T-c, Dong H-C (2014) Facile synthesis and electrochemical performance of manganese dioxide doped by activated carbon, carbon nanofiber and carbon nanotube. Powder Technol 262(0):150–155

Luo S, Zhao J, Zou J, He Z, Xu C, Liu F, Huang Y, Dong L, Wang L, Zhang H (2018) Self-standing polypyrrole/black phosphorus laminated film: promising electrode for flexible supercapacitor with enhanced capacitance and cycling stability. ACS Appl Mater 10(4):3538–3548

Fang H, Meng F, Yan J, Chen G-y, Zhang L, Wu S, Zhang S, Wang L, Zhang Y (2019) Fe3O4 hard templating to assemble highly wrinkled graphene sheets into hierarchical porous film for compact capacitive energy storage. RSC Adv 9(35):20107–20112

Chen X, Xu G, Ren X, Li Z, Qi X, Huang K, Zhang H, Huang Z, Zhong J (2017) A black/red phosphorus hybrid as an electrode material for high-performance Li-ion batteries and supercapacitors. J Mater Chem A 5(14):6581–6588

Li Y, Han X, Yi T, He Y, Li X (2019) Review and prospect of NiCo2O4-based composite materials for supercapacitor electrodes. J Energy Chem 31:54–78

Li J, Wang N, Tian J, Qian W, Chu W (2018) Cross-coupled macro-mesoporous carbon network toward record high energy-power density supercapacitor at 4 V. Adv Funct Mater 28(51):1806153–1806161

Chee WK, Lim HN, Zainal Z, Huang NM, Harrison I, Andou Y (2016) Flexible graphene-based supercapacitors: a review. J Phys Chem C 120(8):4153–4172

Sun W, Xiao L, Wu X (2019) Facile synthesis of NiO nanocubes for photocatalysts and supercapacitor electrodes. J Alloys Compd 772:465–471

Li Q, Wei Q, Xie L, Chen C, Lu C, Su F-Y, Zhou P (2016) Layered NiO/reduced graphene oxide composites by heterogeneous assembly with enhanced performance as high-performance asymmetric supercapacitor cathode. RSC Adv 6(52):46548–46557

Mohajernia S, Hejazi S, Mazare A, Nguyen NT, Hwang I, Kment S, Zoppellaro G, Tomanec O, Zboril R, Schmuki P (2017) Semimetallic core-shell TiO2 nanotubes as a high conductivity scaffold and use in efficient 3D-RuO2 supercapacitors. Mater Today Energ 6:46–52

Zhang Y, Yao Q-q, Gao H-l, Wang L-x, Wang L-z, Zhang A-q, Song Y-h, Xia T-c (2014) Synthesis and electrochemical properties of hollow-porous MnO2-graphene micro-nano spheres for supercapacitor applications. Powder Technol 267(0):268–272

Fang H, Chen G, Wang L, Yan J, Zhang L, Gao K, Zhang Y, Wang L (2018) Facile fabrication of hierarchical film composed of Co(OH)2@carbon nanotube core/sheath nanocables and its capacitive performance. RSC Adv 8(67):38550–38555

Saravanakumar B, Purushothaman KK, Muralidharan G (2012) Interconnected V2O5 nanoporous network for high-performance supercapacitors. ACS Appl Mater 4(9):4484–4490

Li Q, Lu C, Xiao D, Zhang H, Chen C, Xie L, Liu Y, Yuan S, Kong Q, Zheng K, Yin J (2018) β-Ni(OH)2 nanosheet arrays grown on biomass-derived hollow carbon microtubes for high-performance asymmetric supercapacitors. ChemElectroChem 5(9):1279–1287

Fang H, Zhang LS, Xing YL, Zhang SC, Wu SD (2018) Nanostructured manganese oxide films for high performance supercapacitors. Int J Electrochem Sci 13(9):8736–8744

Oudghiri-Hassani H, Al Wadaani F (2018) Preparation, characterization and catalytic activity of nickel molybdate (NiMoO4) nanoparticles. Molecules 23(2):273–285

Peng S, Li L, Wu HB, Madhavi S, Lou XWD (2015) Controlled growth of NiMoO4 nanosheet and nanorod arrays on various conductive substrates as advanced electrodes for asymmetric supercapacitors. Adv Energy Mater 5(2):1401172–1401178

Zhang Y, Gao H-l, Jia X-d, Wang S-w, Yan J, Luo H-w, Gao K-z, Fang H, Zhang A-q, Wang L-z (2018) NiMoO4 nanorods supported on nickel foam for high-performance supercapacitor electrode materials. J Renew Sustain Ener 10(5):054101–054110

Fang L, Wang F, Zhai T, Qiu Y, Lan M, Huang K, Jing Q (2018) Hierarchical CoMoO4 nanoneedle electrodes for advanced supercapacitors and electrocatalytic oxygen evolution. Electrochim Acta 259:552–558

Li M, Yang W, Huang Y, Yu Y (2018) Hierarchical mesoporous Co3O4@ZnCo2O4 hybrid nanowire arrays supported on Ni foam for high-performance asymmetric supercapacitors. Sci China Mater 61(9):1167–1176

Li Q, Lu C, Chen C, Xie L, Liu Y, Li Y, Kong Q, Wang H (2017) Layered NiCo2O4/reduced graphene oxide composite as an advanced electrode for supercapacitor. Energy Storage Mater 8:59–67

Lee G-H, Lee S, Kim J-C, Kim DW, Kang Y, Kim D-W (2017) MnMoO4 electrocatalysts for superior long-life and high-rate lithium-oxygen batteries. Adv Energy Mater 7(6):1601741–1601748

Yi T-F, Mei J, Xie Y, Luo S (2019) Hybrid porous flower-like NiO@CeO2 microspheres with improved pseudocapacitiveproperties. Electrochim Acta 297:593–605

Yi T-F, Mei J, Guan B, Cui P, Luo S, Xie Y, Liu Y (2020) Construction of spherical NiO@MnO2 with core-shell structure obtained by depositing MnO2 nanoparticles on NiO nanosheets for high-performance supercapacitor. Ceram Int 46(1):421–429

Chen S, Yang G, Jia Y, Zheng H (2017) Three-dimensional NiCo2O4@NiWO4 core–shell nanowire arrays for high performance supercapacitors. J Mater Chem A 5(3):1028–1034

Nti F, Anang DA, Han JI (2018) Facilely synthesized NiMoO4/CoMoO4 nanorods as electrode material for high performance supercapacitor. J Alloys Compd 742:342–350

Chen S, Zhang Z, Zeng W, Chen J, Deng L (2019) Construction of NiCo2S4@NiMoO4 core-shell nanosheet arrays with superior electrochemical performance for asymmetric supercapacitors. ChemElectroChem 6(2):590–597

Liu M-C, Kong L-B, Lu C, Ma X-J, Li X-M, Luo Y-C, Kang L (2013) Design and synthesis of CoMoO4-NiMoO4·xH2O bundles with improved electrochemical properties for supercapacitors. J Mater Chem A 1(4):1380–1387

Zhu D, Shao Y (2018) NiO/ZnO nanocomposite as electrode material for supercapacitors. Int J Electrochem Sci 13(4):3601–3612

Wang C, Guan Z, Shen Y, Yu S, Fu X-Z, Sun R, Wong C-P (2018) Shape-controlled synthesis of CoMoO4@Co1.5Ni1.5S4 hybrids with rambutan-like structure for high-performance all-solid-state supercapacitors. Chem Eng J 346:193–202

Chen C, Yan D, Luo X, Gao W, Huang G, Han Z, Zeng Y, Zhu Z (2018) Construction of core–shell NiMoO4@Ni-Co-S nanorods as advanced electrodes for high-performance asymmetric supercapacitors. ACS Appl Mater 10(5):4662–4671

Huang Z, Zhang Z, Qi X, Ren X, Xu G, Wan P, Sun X, Zhang H (2016) Wall-like hierarchical metal oxide nanosheet arrays grown on carbon cloth for excellent supercapacitor electrodes. Nanoscale 8(27):13273–13279

Cai D, Wang D, Liu B, Wang Y, Liu Y, Wang L, Li H, Huang H, Li Q, Wang T (2013) Comparison of the electrochemical performance of NiMoO4 nanorods and hierarchical nanospheres for supercapacitor applications. ACS Appl Mater 5(24):12905–12910

Tian X, Li X, Yang T, Wang K, Wang H, Song Y, Liu Z, Guo Q (2018) Porous worm-like NiMoO4 coaxially decorated electrospun carbon nanofiber as binder-free electrodes for high performance supercapacitors and lithium-ion batteries. Appl Surf Sci 434:49–56

Zhao Y, Teng F, Liu Z, Du Q, Xu J, Teng Y (2016) Electrochemical performances of asymmetric super capacitor fabricated by one-dimensional CoMoO4 nanostructure. Chem Phys Lett 664:23–28

Veerasubramani GK, Krishnamoorthy K, Radhakrishnan S, Kim N-J, Kim SJ (2014) Synthesis, characterization, and electrochemical properties of CoMoO4 nanostructures. Int J Hydrog Energy 39(10):5186–5193

Zhang Z, Liu Y, Huang Z, Ren L, Qi X, Wei X, Zhong J (2015) Facile hydrothermal synthesis of NiMoO4@CoMoO4 hierarchical nanospheres for supercapacitor applications. PCCP 17(32):20795–20804

Hao Y, Huang H, Wang Q, Wang Q, Zhou G (2019) Nitrogen-doped carbon/NiMoO4 nanospheres assembled by nanosheets and ultrasmall nanoparticles for supercapacitors. Chem Phys Lett 728:215–223

Sharma GP, Pala RGS, Sivakumar S (2019) Ultrasmall NiMoO4 robust nanoclusters-active carbon composite for high performance extrinsic pseudocapacitor. Electrochim Acta 318:607–616

Li J, Zhao C, Yang Y, Li C, Hollenkamp T, Burke N, Hu Z, Van Tendeloo G, Chen W (2019) Synthesis of monodispersed CoMoO4 nanoclusters on the ordered mesoporous carbons for environment-friendly supercapacitors. J Alloys Compd 810:151841

Wang J, Zhang L, Liu X, Zhang X, Tian Y, Liu X, Zhao J, Li Y (2017) Assembly of flexible CoMoO4@NiMoO4·xH2O and Fe2O3 electrodes for solid-state asymmetric supercapacitors. Sci Rep 7:41088–41098

Hu X, Zhang W, Liu X, Mei Y, Huang Y (2015) Nanostructured Mo-based electrode materials for electrochemical energy storage. Chem Soc Rev 44(8):2376–2404

Ma X-J, Zhang W-B, Kong L-B, Luo Y-C, Kang L (2015) NiMoO4-modified MnO2 hybrid nanostructures on nickel foam: electrochemical performance and supercapacitor applications. New J Chem 39(8):6207–6215

Li Y, Jian J, Fan Y, Wang H, Yu L, Cheng G, Zhou J, Sun M (2016) Facile one-pot synthesis of a NiMoO4/reduced graphene oxide composite as a pseudocapacitor with superior performance. RSC Adv 6(73):69627–69633

Zhang Y, Yao Q-q, Gao H-l, Zhang L-s, Wang L-z, Zhang A-q, Song Y-h, Wang L-x (2015) Synthesis and electrochemical performance of MnO2/BC composite as active materials for supercapacitors. J Anal Appl Pyrolysis 111:233–237

Huang L, Zhang W, Xiang J, Xu H, Li G, Huang Y (2016) Hierarchical core-shell NiCo2O4@NiMoO4 nanowires grown on carbon cloth as integrated electrode for high-performance supercapacitors. Sci Rep 6:31465–31472

Zhang H, Liu J, Tian Z, Ye Y, Cai Y, Liang C, Terabe K (2016) A general strategy toward transition metal carbide/carbon core/shell nanospheres and their application for supercapacitor electrode. Carbon 100:590–599

Zhou C, Du H, Li H, Qian W, Liu T (2019) Electrode based on nanoporous (Co-Ni)@(CoO,NiO) nanocomposites with ultrahigh capacitance after activation. J Alloys Compd 778:239–246

Zhang L, Zheng D, Pei S, Ye L, Geng S, Lian J (2019) Rational fabrication of nanosheet-dewy NiMoO4/Ni3S2 nanohybrid for efficient hybrid supercapacitor. J Alloys Compd 783:399–408

Zhang Y, Li G-y, Lv Y, Wang L-z, Zhang A-q, Song Y-h, Huang B-l (2011) Electrochemical investigation of MnO2 electrode material for supercapacitors. Int J Hydrog Energy 36(18):11760–11766

Feng X, Ning J, Wang D, Zhang J, Xia M, Wang Y, Hao Y (2019) Heterostructure arrays of NiMoO4 nanoflakes on N-doping of graphene for high-performance asymmetric supercapacitors. J Alloys Compd 816:152625

Mei Y, Zhang H, Mei H, Kang W, Xiao Z, Zhang X, Fan W, Xu B, Hu S (2019) Effective preparation of Ni1.4Co0.6P@C micro-spheres with prolonged cycling lives for high performance hybrid supercapacitors. J Alloys Compd 818:152828

Li B, Luo B, Zhao J, Pan Y, Zhou H, Xiao Y, Lei S, Cheng B (2019) High electrical conductivity-induced enhancement effect of electrochemical performance in mesoporous NiCo2S4 nanorod-based supercapacitor. J Energy Storage 26:100955

Chen H, Xue C, Hai Z, Cui D, Liu M, Li Y, Zhang W (2019) Facile synthesis of 3D gem shape Co3O4 with mesoporous structure as electrode for high-performance supercapacitors. J Alloys Compd 819:152939

Bhagwan J, Khaja Hussain S, Yu JS (2020) Aqueous asymmetric supercapacitors based on ZnCo2O4 nanoparticles via facile combustion method. J Alloys Compd 815:152456

Wang X, Yang Y, Zhang F, Tang J, Guo Z (2020) Facile synthesis of Co3O4/CdO nanospheres as high rate performance supercapacitors. Mater Lett 261:127141

Faid AY, Ismail H (2019) Ternary mixed nickel cobalt iron oxide nanorods as a high-performance asymmetric supercapacitor electrode. Mater Today Energ 13:285–292

Liu M, Shang N, Zhang X, Gao S, Wang C, Wang Z (2019) Microwave synthesis of sodium nickel-cobalt phosphates as high-performance electrode materials for supercapacitors. J Alloys Compd 791:929–935

Huang C, Hao C, Zheng W, Zhou S, Yang L, Wang X, Jiang C, Zhu L (2019) Synthesis of polyaniline/nickel oxide/sulfonated graphene ternary composite for all-solid-state asymmetric supercapacitor. Appl Surf Sci Available online 5 November:144589

Zhang Y, Chang C-r, Jia X-d, Huo Q-y, Gao H-l, Yan J, Zhang A-q, Ru Y, Mei H-x, Gao K-z, Wang L-z (2020) Morphology-dependent NiMoO4/carbon composites for high performance supercapacitors. Inorg Chem Commun 111:107631

Zhu X, Hou D, Tao H, Li M (2020) Simply synthesized N-doped carbon supporting Fe3O4 nanocomposite for high performance supercapacitor. J Alloys Compd 821:153580

Liu Y, Wang Y, Chen Y, Wang C, Guo L (2020) NiCo-MOF nanosheets wrapping polypyrrole nanotubes for high-performance supercapacitors. Appl Surf Sci 507:145089

Acharya J, Ko TH, Seo M-K, Khil M-S, Kim H-Y, Kim B-S (2020) Oxalic acid assisted rapid synthesis of mesoporous NiCo2O4 nanorods as electrode materials with higher energy density and cycle stability for high-performance asymmetric hybrid supercapacitor applications. J Colloid Interface Sci 564:65–76

Zhou Y, Liu C, Li X, Sun L, Wu D, Li J, Huo P, Wang H (2019) Chemical precipitation synthesis of porous Ni2P2O7 nanowires for supercapacitor. J Alloys Compd 790:36–41

Wei H, Wang X, Zhang D, Du W, Sun X, Jiang F, Shi T (2019) Facile synthesis of lotus seedpod-based 3D hollow porous activated carbon/manganese dioxide composite for supercapacitor electrode. J Electroanal Chem 853:113561

Zheng Y, Tian Y, Zhang H, Guo Q, Luo J (2019) Microwave rapid synthesis of NiO/Ni3S2@graphite nanocomposites for supercapacitor applications. Inorg Chem Commun 110:107596

Yang Y, Ma F, Wang J, Li J, Cao J, Han W, Gu H, Zhang Y (2020) Comparative analysis of Co9S8/S-doped rGO composites as high-performance electrodes via facile one-step anneal fabrication for supercapacitor application. J Alloys Compd 815:152448

Zheng Y, Tian Y, Liu S, Tan X, Wang S, Guo Q, Luo J, Li Z (2019) One-step microwave synthesis of NiO/NiS@CNT nanocomposites for high-cycling-stability supercapacitors. J Alloys Compd 806:170–179

Chhetri K, Tiwari AP, Dahal B, Ojha GP, Mukhiya T, Lee M, Kim T, Chae S-H, Muthurasu A, Kim HY (2020) A ZIF-8-derived nanoporous carbon nanocomposite wrapped with Co3O4-polyaniline as an efficient electrode material for an asymmetric supercapacitor. J Electroanal Chem 856:113670

Zhang Y, Chang C-r, Jia X-d, Cao Y, Yan J, Luo H-w, Gao H-l, Ru Y, Mei H-x, Zhang A-q, Gao K-Z, Wang L-z (2020) Influence of metallic oxide on the morphology and enhanced supercapacitive performance of NiMoO4 electrode material. Inorg Chem Commun 112:107697

Dury F, Meixner S, Clément D, Gaigneaux EM (2005) Coupling the deoxygenation of benzoic acid with the oxidation of propylene on a Co molybdate catalyst. J Mol Catal A Chem 237(1):9–16

Yu X, Lu B, Xu Z (2014) Super long-life supercapacitors based on the construction of nanohoneycomb-like strongly coupled CoMoO4–3D graphene hybrid electrodes. Adv Mater 26(7):1044–1051

Guo D, Zhang H, Yu X, Zhang M, Zhang P, Li Q, Wang T (2013) Facile synthesis and excellent electrochemical properties of CoMoO4 nanoplate arrays as supercapacitors. J Mater Chem A 1(24):7247–7254

Adhikary MC, Priyadarsini MH, Rath SK, Das CK (2017) 3D porous NiMoO4 nanoflakes arrays for advanced supercapacitor electrodes. J Nanopart Res 19(9):314–321

Chen S, Chandrasekaran S, Cui S, Li Z, Deng G, Deng L (2019) Self-supported NiMoO4@CoMoO4 core/sheath nanowires on conductive substrates for all-solid-state asymmetric supercapacitors. J Electroanal Chem 846:113153

Shen J, Wang Q, Zhang K, Wang S, Li L, Dong S, Zhao S, Chen J, Sun R, Wang Y, Jian Z, Zhang W (2019) Flexible carbon cloth based solid-state supercapacitor from hierarchical holothurian-morphological NiCo2O4@NiMoO4/PANI. Electrochim Acta 320:134578

Zhang H, Lu C, Hou H, Ma Y, Yuan S (2019) Tuning the electrochemical performance of NiCo2O4@NiMoO4 core-shell heterostructure by controlling the thickness of the NiMoO4 shell. Chem Eng J 370:400–408

Umapathy V, Neeraja P, Manikandan A, Ramu P (2017) Synthesis of NiMoO4 nanoparticles by sol–gel method and their structural, morphological, optical, magnetic and photocatlytic properties. Trans Nonferrous Metals Soc China 27(8):1785–1793

Funding

This work is supported by the key R&D and Promotion Projects (Science and Technology Key Projects) of Henan Province of China (Grant Nos. 202102310226, 202102210389), and the Key Scientific Research Project of the Higher Education Institutions of Henan Province of China (Grant No. 20A530001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Mei, Hx., Yang, J. et al. New NiMoO4/CoMoO4 composite electrodes for enhanced performance supercapacitors. Ionics 26, 3579–3590 (2020). https://doi.org/10.1007/s11581-020-03470-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-020-03470-3