Abstract

Electroplated cadmium stannous selenide (Cd x Sn1−x Se) thin films were coated on indium-doped tin oxide (ITO) conducting glass substrates from aqueous bath solutions containing CdCl2, SnCl2, and Na2SeO3. The x value was tuned by change in metal ion source concentration of the electrolytic bath solution. The various x values such as 1, 0.7, 0.45, and 0, of Cd x Sn1−x Se thin films were characterized by structural, morphological, compositional, and optical properties using X-ray diffraction, scanning electron microscopy, energy dispersive analysis by X-rays, and UV-vis-NIR spectrophotometer, respectively. X-ray diffraction (XRD) patterns revealed that the deposited films exhibit polycrystalline nature Cd x Sn1−x Se thin films. The microstructural parameters such as crystallite size, dislocation density, microstrain, and number of crystallites per unit area were calculated and presented. Morphological studies revealed that spherical-shaped grains were observed in cadmium-dominated films and nano-rod-shaped grains were observed in tin-dominated films. Optical properties of CdSnSe films were determined from optical transmittance data in the spectral range 400 to 1,100 nm. The optical direct transition energy band gap was estimated using conventional method, and band gap energy was lying between 1.02 and 1.83 eV. The refractive index, extinction coefficient, and real and imaginary parts of dielectric constants were calculated using optical transmission spectra of Cd x Sn1−x Se thin films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The uses of thin film polycrystalline semiconductors have attracted much interest in an expanding variety of applications in various electronic and optoelectronic devices. The technological interests in polycrystalline-based devices are mainly caused by their low production cost. Cadmium selenide is an interesting material because of its efficient room temperature electro-luminescence and nano-electric device [1, 2] applications. CdSe has been investigated for its potential applications in solar cells [3], photoconductors [4], thin film transistors [5], light-emitting diodes [6], and gamma-ray detectors [7]. Tin selenide thin films have numerous applications as an efficient solar cell material [8], memory switching devices [9, 10], and holographic recording system [11]. CdSe and SnSe have been studied in the form of both thin films [12, 13] and single crystals [14, 15]. CdSe is a narrow band semiconductor, and its optical band gap is 1.74 eV [16], whereas the band gap of SnSe is 0.9 eV [17]. SnSe belongs to the group of layer-type orthorhombic IV–VI compounds characterized by a strong anisotropy of the chemical bonds and physical properties. In earlier, Datta et al. [18] have reported electrocrystallized Cd-Sn-Se thin films by varying Sn2+ concentration in the solution bath. They have discussed about the X-ray diffraction, atomic force microscopy, and scanning electron microscopy studies of Cd-Sn-Se thin films. Also, they have observed that optoelectronic properties were determined by spectroscopic analysis and electrochemical measurements. Among the various methods used to prepare thin films are vacuum evaporation, chemical vapor deposition [19, 20], and electrodeposition [21, 22]. Electrochemical deposition is the cheapest known technique for preparation of thin films. It is a slow process, which facilitates a better orientation of the crystallites with an improved grain structure. Our group previously published in electrochemical, structural studies of CdSnSe thin films with different electrochemical bath solutions [23, 24]. In this paper, we have reported the comparison studies of structural, optical, morphological, and compositional properties of the electrodeposited CdSe, Cd x Sn1−x Se, and SnSe thin films.

Experimental details

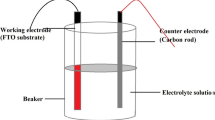

The electrodeposited Cd x Sn1−x Se thin films were grown using potentiostatic mode. A standard three-electrode cell was used for the electrodeposition of CdSnSe. Indium-doped tin oxide (ITO) was used as a working electrode, graphite rod as a counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. ITO-coated glass substrates were first cleaned in acetone and thoroughly rinsed with distilled water. The deposition of CdSnSe thin films was carried out from an aqueous electrolyte bath containing 0.01–0.02 M, 0.01–0.02 M, and 0.005 M concentrations of CdCl2, SnCl2, and SeO2, respectively. Also, we have used 0.02 M EDTA as a supporting electrolyte. The solution pH was adjusted to 2.5 ± 0.1 by the addition of NaOH solution. Electrodeposition was carried out using an electrochemical system consisting of PAR (EG&G Princeton Applied Research, USA Model 362A) potentiostat/galvanostat unit. An X-ray diffractometer system (X’PERT PRO PANalytical, Netherlands) with Cukα radiation (λ = 0.1540 nm) was used to identify the crystal structure of the films. Surface morphology was carried out using a scanning electron microscopy (Philips Model XL 30, USA). Optical properties of the samples were analyzed using a UV-Vis-NIR double beam spectrophotometer (HR-2000, M/S ocean optics, USA).

Results and discussion

X-ray diffraction analysis is a powerful tool for crystal structure and crystal imperfections properties of thin films. X-ray diffraction patterns are obtained for Cd x Sn1−x Se films deposited at various x values such as 1, 0.7, 0.45, and 0, as shown in Fig. 1. The observed d-spacing values are in good agreement with standard JCPDS values (88-2346 & 89-0249). Figure 1a represents the diffraction pattern of Cd x Sn1−x Se thin film prepared at x = 1. In this, pattern revealed that the predominant peak orientation is observed at 25.12° for (111) crystallographic plane. Other dualistic peaks are observed at angles 42.85° and 48.80° for corresponding crystallographic plane (220) and (311), respectively. No other impurity peaks are observed in this diffraction pattern. Figure 1b shows the X-ray diffraction pattern of Cd0.7Sn0.3Se thin film. When the x value is decreased from 1 to 0.7, the diffraction pattern is entirely changed. Because of the inclusion of tin atoms in Cd and Se, diffraction angles are shifted and novel SnSe diffraction lines are emerged. SnSe-related diffraction lines are observed at 30.12° and 31.23° corresponding to (111) and (130), respectively. In addition to that, (220) and (311) peaks are disappeared by introduction of x = 0.3 atomic ratio Sn element in Cd x Sn1−x Se thin film. Figure 1c shows the X-ray diffraction pattern of Cd0.45Sn0.55Se thin film, and it is discovered mix of cubic (CdSe) and orthorhombic (SnSe) structures. The diffraction peaks of cubic CdSe structure 2θ value is observed at 25.50° for (111) lattice orientation. While the diffraction peaks of orthorhombic SnSe structure diffraction angles are observed at 30.40°, 31.21°, and 44.18°, corresponding lattice planes are (111), (130), and (022), respectively. There are more “Sn” ions combined with surplus “Se” ions than “Cd” ions; it may be due to the bond length and atomic radius. Even though “Sn” element is a noble metal, it can easily access to form compound with chalcogenides. When the x value decreases from 0.45 to 0, the predominant peak is observed at (111) plane. Also, some other new peaks are observed at 25.61°, 30.91°, 37.38°, 41.51°, and 44.25°, corresponding to crystallographic plane (021), (040), (131), (002), and (022), respectively. All the peaks are identified from Cd x Sn1−x Se alloy formation; hence, no additional lines observed correspond to individual elements of Cd, Sn, and Se.

The crystallize size of the electrodeposited Cd x Sn1−x Se thin film can be calculated using full width at half maximum (FWHM) data and Debye-Scherrer formula [25]:

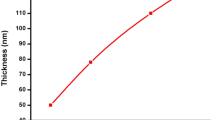

where β is the full width at half maximum of the peak position in radiant, λ is the wavelength 1.540 Ǻ, and θ B is Bragg’s diffraction angles. The calculated crystallite size is varied from 26.5 to 39.5 nm. It is observed from Fig. 2 that the x values decreased and crystallite sizes increased; it may be due to the improvement of crystallinity. In this, crystallinity improvement can be due to the more amount of “Sn” atoms incorporated in alloy films. Also, during the ternary compound formation in CdSe to CdSnSe thin film, the noble metal of Sn domination increases, which depends on the composition ratio. The “Sn” element decreases the crystallite size which may be due to the interaction between the atoms increased in ternary compounds. The crystallite size variation was studied in CdSe thin films by Sarangi and Sahu [26]. The dislocation density δ is defined as the length of dislocation lines per unit volume of the crystal and can be evaluated from the particle size D by the following relation:

where n is a factor, which equals unity giving minimum dislocation density. Figure 2 represents dislocation density variations of Cd x Sn1−x Se thin film for different values of x. The dislocation density increases with decrease of x values; it may be attributed to decrease of crystallite size.

The microstrain ε value is calculated using the following relation [27]:

The crystallite size is indirectly proportional to microstrain and dislocation density of the electrodeposited CdSnSe thin films. The x value decreases from 1 to 0.45; the microstrain, dislocation density, and number of crystallites per unit area of the Cd x Sn1−x Se thin film values increase which are attributed to crystallite size decrease as shown in Fig. 3. The number of crystallites per unit area (N) of the films was determined using the following formula:

where t is thickness of the film, N is the number of crystallites per unit area, and D is the crystallite size. The number of crystallites per unit area is found to rapidly increase with decreases in x values. The number of crystallites per unit area increases which may be attributed to the reduction in crystallite size with increase in x values of Cd x Sn1−x Se thin films shown in Fig. 3.

Optical transmission and reflection spectra are recorded at room temperature in air to obtain information on the optical properties of Cd x Sn1−x Se thin films. The optical transmittance (T) and reflectance (R) spectrum of deposited Cd x Sn1−x Se thin films in the wavelength range 300–1,200 nm. Optical transmission spectra of Cd x Sn1−x Se thin film prepared at various values of x is shown in Fig. 4. The spectrum represented well-oriented grains build up the surface of the film. The high value of x has lowered the value of transmission, and decreased value of x increases the percentage of transmission. The observed transmission spectra is exhibited with semiinterferencefringes. In the absorption edges, the maxima and minima of the fringe of the reflectance spectrum, respectively, occur at the same wavelength positions of the minima and maxima of the transmittance spectrum, respectively. This is an indication of the optical homogeneity of the deposited films. The figure also shows a sharp fall of transmittance at the band edge, which is an indication of good crystallinity of the deposited films. The transmittance increases and it tends to increase in the UV to visible region. Besides, the optical transmittance decreases towards the IR region in electrodeposited Cd x Sn1−x Se thin films. The increase in the transmittance is due to an increase in the band gap with carrier concentration. The optical parameters such as absorption coefficient and band gap are determined from optical absorption measurements. The value of absorption coefficient for strong absorption region of thin film is calculated using Eq. (5) [28]:

where α is the absorption coefficient (cm−1), t is the thickness of the films, A is absorbance, and T is transmittance. The nature of transition is determined using the following equation [29]:

where α is the absorption coefficient (cm−1), hν is a photon energy, E g is an energy gap, A is an energy-dependent constant, and n is an integer depending on the nature of electronic transitions. For the direct allowed transitions, n has a value of 1/2 while for the indirect allowed transitions, n = 2. The Tauc’s plot of Cd x Sn1−x Se thin film is shown in Fig. 5. The band gap energy is estimated to be 1.02 to 1.83 eV using conventional method. The CdSe band gap value is 1.83 eV, and band gap energy decreases with introduced “Sn” element in CdSe. This alloy formation of Cd x Sn1−x Se thin film is a very good novel application in optoelectronic features.

The refractive index (n) and extinction coefficient (k) of Cd x Sn1−x Se films are estimated using the following expressions [30]:

where α is the absorption coefficient, λ is the wavelength, and R is the reflectance of the Cd x Sn1−x Se thin films. The refractive index and the extinction coefficient spectra of Cd x Sn1−x Se thin films as a function of Cd/Sn composition ratio are shown in Fig. 6. It is observed from Fig. 6 that the refractive index decreases with x value decreases, while the extinction coefficient increases for electrodeposited Cd x Sn1−x Se thin films. The value for the refractive index lies between 1.9 and 2.3, and the value of extinction coefficient lies between 0.064 and 0.08. It is attributed to the film thickness variation of Cd x Sn1−x Se thin films.

The real and imaginary parts of the dielectric constant were determined using the following relation [30]:

where ε r and ε i are the real and imaginary parts of the dielectric constant, respectively, and are given by the following relations:

and

The imaginary part of the dielectric constant also showed the same behaviour as that of the real part; the only thing is that its values seem to be very less compared to real dielectric constant values. The real part of dielectric constant decreases, and imaginary part increases with decreases in x values as shown in Fig. 7.

The surface morphology of CdSe thin films has been analyzed using scanning electron microscopy. The films have a smooth surface with spherical grains (Fig. 8). The grains are distributed uniformly over the entire surface of the film with a compact and fine grained morphology. At x = 1, there is no complex surface formation occurred. The nucleation over growth and the film surface is covered with uniform spherical-shaped grain as shown in figure. The sizes of the grains are found to be in the range between 100 and 150 nm. Scanning electron micrograph of Cd0.7Sn0.3Se thin film is shown in Fig. 9. The grains are small with non-uniform morphology, and no well-defined grain boundaries are observed; hence, it is difficult to calculate the average value of grain size. The reason for this state may be attributed to the tense state of the surface of the films. The grain sizes of CdSnSe thin film covered the entire surface of the film and are estimated to be in the range between the range of 150 and 200 nm. When the x value is decreased from 0.7 to 0.45, more grain growths occur; thereby, the average grain size is increased due to agglomeration of smaller grains together as shown in Fig. 10. It is also observed that nano-rod-shaped grains occupied the entire surface of the film. The grains tend to agglomerate, and the tension may be comparatively less in the films with the number of needle-like grains becoming less. It is evident that by altering the Cd and Sn element concentrations in the solution bath enhance the surface features. This nano-rod-like structure is a more featured observation in this alloy formation. This in turn allows the films to lower its total energy by grain growth and decrease in the grain boundary areas. The nano-rod-shaped grains are covered with small nano-needles protruding from the end of the nano-rods as shown in Fig. 11. Optical properties strongly depend on surface morphology of Cd x Sn1−x Se thin films. The transmittance increase after introducing “Sn” element might be due to an increase of optical scattering caused by the densification of grains followed by grain growth and reduction of grain boundary density as depicted in Fig. 4.

Conclusions

Thin films of Cd x Sn1−x Se with the combinations of x = 1, 0.7, 0.45, and 0 were grown by electrodeposition technique. The crystalline sizes were controlled by varying the x values in the solution bath. X-ray diffraction patterns were taken out in order to determine crystal structure of the deposited film. The microstructural properties of Cd x Sn1−x Se thin films were plausibly explained with the suitable compound formations. The optical transmission and reflection spectrum of the electrodeposited Cd x Sn1−x Se thin films were recorded, and, using these results, direct transition energy band gap value was estimated in the range of 1.02–1.83 eV. SEM images revealed that the smooth and uniform surface was observed in Cd x Sn1−x Se thin film, and nano-wires protruding from nano-rods of the surface morphology are observed at x = 0. The Cd x Sn1−x Se nano-structured grains with high surface-to-volume ratio as optoelectronic materials are predicted, and this may be one of the materials for the construction of high efficiency optoelectronic devices.

References

Kelin DL, Roth R, Lim AKL, Alivisatos AP, McEuen PL (1997) Nature 389:699

Mattoussi H, Radzilowski LH, Dabbousi BO, Thomas EL, Bawendi MG, Rubner MF (1998) J Appl Phys 83:7965

Boudrau RA, Rauh RD (1982) Sol Energy Mater 7:385

Kainthla RC, Pandya DK, Chopra KL (1980) J Electrochem Soc 127:277

Van Calster A, Vervaet A, De Rycke I, De Baets J, Vanfleteren J (1988) J Cryst Growth 86:924

Ren J, Bowers KA, Sneed B, Dreifus DL, Cook JW Jr, Schetzina JF, Kolbus RM (1990) Appl Phys Lett 57:1901

Roth M (1989) Nucl Instr Methods A 283:291

Bletskan DI, Kopinets IF, Pogorsh PP, Salkora EN, Chepor DV (1978) Kristallografiya 20:1008

Rao TS, Ray BKS, Chaudhurai AK (1988) Thin Solid Films 165:257

Baxter CR, McLennan WD (1975) J Vac Sci Technol 12:110

Rodot M (1975) Acta Electron 18:345

Eriksson S, Gruszecki T, Carlsson P, Holmström B (1995) Thin Solid Films 269:14

Terada T (1971) J Phys D 4:1991

Burger A, Roth M (1984) J Cryst Growth 67:507

Agnihotri OP, Jain AK, Gupta BK (1979) J Cryst Growth 46:491

Lide DR, Frederikse HPR (eds) (1994) CRC handbook of chemistry and physics. CRC Press, Boca Raton, pp 12–95

Bhatt VP, Gireesan K, Desai CF (1989) Cryst Res Technol 24:187

Dattaa J, Bhattacharya C, Bandyopadhyay S (2006) Appl Surf Sci 252:7493

John J, Pradeep B, Mathai E (1994) J Mater Sci 29:1581

Bennouna A, Tessier P, Priol M, Dang Tran Q, Robin S (1983) Phys Status Solidi 117:51

Subramanian B, Mahalingam T, Sanjeeviraja C, Jayachandran M, Chockalingam MJ (1999) Thin Solid Films 357:119

Engelken RD, Berry AK, Van Doren TP, Boone JL, Shahnazary A (1986) J Electrochem Soc 133:581

Dhanasekaran V, Mahalingam T, Chandramohan R, Chu JP, Rhee J-K (2012) J Mater Sci Mater Electron 23:645–651

Mahalingam T, Dhanasekaran V, Chu JP, Kim T, Kim YD (2011) ECS Trans 35:61–68

Wang Y, Suna A, McHugh J, Hilinski EF, Lucas P, Johnson RD (1990) J Chem Phys 92:6927

Sarangi SN, Sahu SN (2004) Phys E 23:159

Clark AH (1980) In: Kazmerski LL (ed) Polycrystalline and amorphous thin films and devices. Academic, New York

Dhanasekaran V, Mahalingam T (2013) Mater Res Bull 48:3585–3593

Benramdane N, Murad WA, Misho RH, Ziane M, Kebbab Z (1997) Mater Chem Phys 48:119

Osuwa JC, Oriaku CI, Kalu IA (2009) Chalcogenide Lett 9:433–436

Acknowledgments

This research work was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF), funded by the Ministry of Education (2010-0020207, 2012R1A1A2007211).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhanasekaran, V., Jung, J., Lee, K.K. et al. Comparison studies on electrodeposited CdSe, SnSe and Cd x Sn1−x Se thin films. Ionics 21, 1187–1192 (2015). https://doi.org/10.1007/s11581-014-1251-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-014-1251-8