Abstract

Biodegradable and natural rice starch (RS) polymer with lithium iodide salt (LiI) was used to prepare polymer electrolytes using solution cast technique. Polymer electrolyte films were characterized by thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), X-ray diffraction (XRD), and scanning electron microscopy (SEM). TGA and DSC thermograms demonstrate that decomposition temperature (Tdc) and glass transition temperature (Tg) for rice starch shift upon complexation with lithium iodide salt. Thermolysis studies using TGA show decomposition temperature decreases with the addition of lithium iodide salt. XRD patterns show increase in amorphous behavior with doping of lithium iodide salt. The morphology studies were observed using SEM in terms of smoothness and miscibility.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, due to non-environmental friendly effects of many synthetic polymers, biodegradable-based polymers have much attraction and portion in investigations. Environmental friendly biodegradable polymer electrolytes have been studied significantly [6, 13, 15] and have many applications in electrochemical devices such as supercapacitors, fuel cells, and solar cells [1, 5, 8, 14, 16]. Among biodegradable polymers, starch has been impressively investigated by researches for some advantages like natural based, eco-friendly, climate protection through CO2 reduction, cheap, abundances in nature, water solubility, good thermal, mechanical, and adhesive properties, and good ability of film forming [3, 4, 7, 9]. Starch is composed of 1,4-α-D-glucopyranosyl units: amylose and amylopectin. The amylose is almost linear, in which the repeating units are linked by 1,4-α linkages; the amylopectin has a 1,4-α linked backbone and ca. 5 % of 1,6-α-linked branches. The relative amounts of amylose and amylopectin depend upon the plant source [10, 11].

In this work, rice starch was used as biodegradable polymer. Rice starches have low viscosity and high amylose [18]. As 1,4-α linkages in amylose are more stable and less steric than 1,6-α linkages, the mobile ions after addition of salt attach more on the amylose units. Thus, rice starches are expected to have more mobile ions and higher conductivity and more amorphism and shift in thermograms as will be discussed in this work. These reasons provide more interest to study on rice starch in this work.

This work reports the influence of lithium iodide salt on thermal properties of rice starch according to thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) thermograms, structure of films for different salt ratios using X-ray diffraction (XRD), morphology of samples, and relation of these properties with ionic conductivity of films.

Experimental

Materials

Biodegradable rice starch (RS) purchased from Sigma-Aldrich was used without further purification. Lithium iodide salt (LiI) was purchased from Aldrich (crystalline powder, 99 % trace metals basis) and kept dry before use.

Preparation of polymer electrolyte films

Polymer electrolyte films were prepared using solvent cast method. Polymer electrolyte films of RS/LiI system were prepared according to equation RS + x wt.% LiI (x = 0, 5, 10, 15, 20, 25, 30, 35). Distilled water as solvent was used with the amount of 25 ml for each sample. Appropriate amounts of rice starch were added into distilled water and heated until 80 °C for about 15 min to dissolve and gelatinize the rice starch. After gelatinization of the rice starch, appropriate amounts of LiI were added according to Table 1. The mixtures were stirred to get homogenous solution and cast onto Teflon petri dish. Furthermore, any amount of water was evaporated in drying oven at 60 °C for 24 h. After drying, solid films were cast and analyzed directly at room temperature. Above 35 wt.% LiI, casting films was not applicable and not easy to handle. Table 1 exhibits designation of samples with related ionic conductivity according to our previous work [2].

Characterization methods

Thermogravimetric analysis

The samples were analyzed for thermogravimetric analysis with TA Instrument Universal Analyzer TGA Q500. The nitrogen flow rate for balance gas and sample gas were 40 and 60 ml/min, respectively. The samples were heated with a ramping rate of 50 °C/min from 4 to 700 °C to obtain decomposition temperature (Tdc).

Differential scanning calorimetry

Polymer electrolyte samples were analyzed for DSC using TA Instrument Universal Analyzer DSC Q2000 with refrigerated cooling system (RCS90). The experiment was performed under nitrogen flow rate of 50 ml/min. Samples followed the range of 3–5 mg weight and sealed in the Tzero aluminum hermetic pan. The samples were analyzed in heat-cool-heat process within 4 cycles with heating and cooling rate of 20 °C/min. At first, the system was equilibrated at 105 °C for 2 min for isothermal purposes and equilibrated at −90 °C for cycle 1. In cycle 2, the rate of 20 °C/min was applied to 230 °C. In cycle 3, this procedure was applied to −50 °C from previous cycle. Finally, in cycle 4, this process was applied to 230 °C. The cycle 4 was used to calculate glass transition temperature (Tg).

X-ray diffraction

XRD patterns of samples were recorded with XRD Siemens D 5000 diffractometer (40 kV, 40 mA) with Cu-Kα radiation and wavelength of λ = 1.540600 Ǻ for 2θ range of 5–80° at ambient temperature.

Scanning electron microscopy

Micrographs of samples were observed using scanning electron microscopy (SEM) (Leica S440). The samples were gold coated to prevent electrostatic charging. The samples were studied with magnification of ×1,000 (at 10 kV and 100 pA).

Results and discussion

TGA analysis

The thermal stability of samples was examined by TGA analysis. Figure 1 shows the results for selected samples for (a) pure rice starch, (b) RS-5 (25 wt.% LiI), (c) RS-6 (30 wt.% LiI), and (d) RS-7 (35 wt.% LiI) with highest ionic conductivity. All selected samples show one-step decomposition with different Tdc. The first derivative weight changes of TGA curves (as reference) confirm that only one-step decomposition process exist for all samples. The decomposition temperature is the temperature where the weight change starts to decrease dramatically. Tdc is ∼292 °C for pure rice starch. Tdc for RS-5, RS-6, and RS-7 is ∼245, 230, and 224 °C, respectively. Figure 2 shows the comparison between samples with different LiI salt content. The results in Fig. 2 confirm that Tdc decreases with addition of lithium iodide salt content. In previous work, FTIR results confirmed that the complexation between RS and LiI at different band assignments has occurred [2]. This complexation can reduce the thermal stability of RS/LiI system compare to RS without LiI (uncomplexed). This is the reason of decreasing Tdc with the addition of lithium iodide salt content. Summary of data obtained from TGA is tabulated in Table 2.

DSC analysis

The thermal properties of samples were further studied through DSC analysis. Figure 3 shows thermograms of samples for RS with and without addition of salt. The figure shows small changes in heat flow from exothermic to endothermic which is known as glass transition temperature (Tg). The Tg for pure rice starch is ∼76 °C. After the addition of salt, glass transition temperature suddenly decrease. Tg values as depicted in Table 2 for samples of RS-5, RS-6, and RS-7 are −23, −22, and −12 °C, respectively. The results show Tg shifts to higher temperatures with increasing salt content. This is due to existing complexation with addition of salt with flexibility of polymer chains [17]. Moreover, increase in the salt content and complexation with polymer results in the increasing number of ionic charge carriers, higher ionic conductivity, and more segmental flexibility of polymeric network due to complexation.

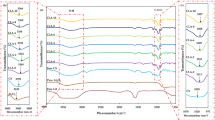

XRD studies

XRD recorded patterns of samples are illustrated in Fig. 4. The figure shows patterns of (a) RS-5 (25 wt.% LiI), (b) RS-6 (30 wt.% LiI), (c) RS-7 (35 wt.% LiI), (d) RS-0 (pure rice starch), and (e) LiI salt. Figure 4e shows very sharp crystalline peak at 2θ = 21° and other crystalline peaks at 2θ = 12 and 30° for lithium iodide salt denoting crystalline characteristic of LiI salt. Pure rice starch pattern in Fig. 4d exhibits amorphous characteristics with small peak at 2θ = 19° and broad hunch at 2θ = 17–22°. After addition of LiI salt, the peaks in pure rice starch shifted and 2θ increased slightly to the range of 20–25° for RS-5, 19–21° for RS-6, and 19–22° for RS-7 as highest LiI salt concentration and conductivity in this system. The results confirm that the intensity of the broad range of sample decreasing with doping of LiI salt which is evidence of dissolution of salt because of elimination of the peaks in salt patterns. The graphs further confirm complexation of polymer with salt which disorders the crystallinity and oriented arrangement of system. The XRD patterns further emphasize that addition of salt increases the amorphous behavior of the RS/LiI system which enhances the ionic conductivity [12] and increase the ion mobility and flexibility of polymer structure.

SEM studies

The micrographs of samples were observed by SEM and illustrated in Fig. 5. Figure 5 shows the surface morphology of (a) pure rice starch, (b) RS-5, (c) RS-6, and (d) RS-7. Figure 5a shows porous surface with small size and unequal pores. Upon addition of salt, the pores became larger in RS-5 micrograph which shows more amorphous matrix. In RS-6 micrographs, there is no porosity and surface became smooth and compact with some small conglomerations which are due to more salt concentration and complexation. Brightness in Fig. 5c, d micrographs can be related to SEM probe for more conductive surface of RS-6 and RS-7 which enhance electron transformation to probe. Because the increased numbers of electrons reaching the detector in SEM can result in brighter display of the sample image that the microscope produces. At highest salt concentration with highest conductivity, RS-7, the surface had more smoothness and compactness compare to RS-6. Because the concentration of LiI salt is higher in this RS/LiI system.

Conclusion

The biodegradable-based rice starch polymer electrolytes were prepared by incorporating the lithium iodide salt. Thermal and structural properties were studied for RS/LiI polymer electrolytes and further confirmed the complexation between polymer and salt. Thermal studies demonstrate that the RS-7 sample with 35 %.wt. of LiI salt with highest achieved ionic conductivity has the lowest decomposition and glass transition temperatures. XRD patterns confirmed more broadening and amorphous matrix which is important for conductivity enhancement. XRD patterns became more broaden and less intense in RS-7. Role of doping of LiI clarified and influence of LiI on surface observed on SEM micrographs. The results revealed that the addition of LiI salt results in increasing ionic mobility of charge carriers, ionic conductivity, amorphous behavior, and decrease in decomposition temperature and glass transition temperature due to increasing the number of charge carriers and flexibility of polymeric chains.

References

Choudhury NA, Ma J, Sahai Y (2012) High-performance and eco-friendly chitosan hydrogel membrane electrolytes for direct borohydride fuel cells. J Power Sources 210:358–365

Khanmrzaei MH, Ramesh S (2013) Ionic transport and FTIR properties of lithium iodide doped biodegradable rice starch based polymer electrolytes. Int J Electrochem Sci 8(7):9977–9991

Lenz, R. (1993). Biodegradable polymers. In R. Langer & N. Peppas (Eds.). Biopolymers I (Vol. 107, pp. 1–40): Springer Berlin Heidelberg.

Liew CW, Ramesh S, Ramesh K, Arof AK (2012) Preparation and characterization of lithium ion conducting ionic liquid-based biodegradable corn starch polymer electrolytes. J Solid State Electrochem 16(5):1869–1875

Lin CW, Liang SS, Chen SW, Lai JT (2013) Sorption and transport properties of 2-acrylamido-2-methyl-1-propanesulfonic acid-grafted bacterial cellulose membranes for fuel cell application. J Power Sources 232:297–305

Liu Y, Du BX, Du DM (2013) Pattern analysis on dielectric breakdown characteristics of biodegradable polyethylene film under nonuniform electric field. Int Trans Electr Energy Syst 23(1):72–82

Lörcks J (1998) Properties and applications of compostable starch-based plastic material. Polym Degrad Stab 59(1–3):245–249

Ma J, Sahai Y (2013) Chitosan biopolymer for fuel cell applications. Carbohydr Polym 92(2):955–975

Manindra Kumar TT, Srivastava N (2012) Electrical transport behavior of bio-polymer electrolyte system: potato starch + ammonium iodide. Carbohydr Polym 88(1):54–60

Maurizio Avella JJDV, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93(3):467–474

Narpinder Singh JS, Kaur L, Sodhi NS, Gill BS (2003) Morphological, thermal, and rheological properties of starches from different botanical sources. Food Chem 81(2):219–231

Rahul Singh NAJ, Majumder S, Bhattacharya B, Singh PK (2013) Novel biopolymer gel electrolyte for dye-sensitized solar cell application. Carbohydr Polym 91(2):682–685

Ramesh S, Shanti R, Morris E (2013) Employment of Amim Cl in the effort to upgrade the properties of cellulose acetate based polymer electrolytes. Cellulose 20(3):1377–1389

Singh R, Jadhav NA, Majumder S, Bhattacharya B, Singh PK (2013) Novel biopolymer gel electrolyte for dye-sensitized solar cell application. Carbohydr Polym 91(2):682–685

Sownthari K, Suthanthiraraj SA (2013) Synthesis and characterization of an electrolyte system based on a biodegradable polymer. Express Polym Lett 7(6):495–504

Sudhakar YN, Selvakumar M, Bhat DK (2013) LiClO4-doped plasticized chitosan and poly(ethylene glycol) blend as biodegradable polymer electrolyte for supercapacitors. Ionics 19(2):277–285

Yoichi Tominaga, S. A., Masao Sumita, Stefania Panero, Bruno Scrosati. (2005). A novel composite polymer electrolyte: effect of mesoporous SiO2 on ionic conduction in poly(ethylene oxide)–LiCF3SO3 complex. Journal of Power Sources, 146(1–2), 402-404-406.

Zhang C, Zhu L, Shao K, Gu M, Liu Q (2013) Toward underlying reasons for rice starches having low viscosity and high amylose: physiochemical and structural characteristics. J Sci Food Agric 93(7):1543–1551

Acknowledgements

M. H. Khanmirzaei acknowledges the University of Malaya Bright Sparks Scheme (SBSUM) for the financial support (BSP 221(3)-12). This work was supported by the University of Malaya Research Grant (UMRG Program: RP001-2013A) and PPP Grant (PG105-2012B).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanmirzaei, M.H., Ramesh, S. Studies on biodegradable polymer electrolyte rice starch (RS) complexed with lithium iodide. Ionics 20, 691–695 (2014). https://doi.org/10.1007/s11581-013-1031-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-013-1031-x