Abstract

In this paper, we report an enhancement in ionic conductivity in a new nano-composite solid polymer electrolyte namely, (PEG) x LiBr: y(SiO2). The samples were prepared, characterized, and investigated by XRD, IR, NMR, and impedance spectroscopy. Conductivity as a function of salt concentration shows a double peak. Five weight percent addition of silica nanoparticles increases the ionic conductivity by two orders of magnitude. Conductivity exhibits an Arrhenius type dependence on temperature. IR study has shown that the existence of nanoparticles in the vicinity of terminal O―H group results in a shift in IR absorption frequency and increase in amplitude of vibration of the terminal O―H group. This might lead to an enhancement in conductivity due to increased segmental motion of the polymer. 7Li NMR spectroscopic studies also seem to support this. Thus addition of nanoparticle inert fillers still seems to be a promising technique to enhance the ionic conductivity in solid polymer electrolytes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid polymer electrolytes (SPEs) are mainly studied for applications in the field of battery industry due to various reasons including its capability to eliminate the problem of leakage which occur in liquid electrolytes, easy to process, high energy density, wide electrochemical window, wide operating temperature range, light weight, etc. Hence, various groups around the globe have been working in this field from the past few decades [1–9].

The compositions of polymer electrolytes play an important role in its application as an end product. The required enhancement of the ionic conductivity of polymer electrolytes at ambient conditions can be obtained by various techniques like irradiation with swift ions [10], γ-rays [8], swift electrons, and quenching at low temperature [9], etc. One of the better approaches to enhance ionic conductivity is to incorporate a plasticizer/inert fillers which results in reduction of ion pairing thereby paving way for an enhanced ionic conductivity. The addition of plasticizers to polymer electrolytes to enhance the electrochemical and mechanical properties has been studied well earlier [11–15].

Plasticized polymer electrolytes have been proved to be promising for use as electrolytes of the lithium batteries owing to their high ionic conductivity. In the study by M. M. E. Jacob, three types of ester class plasticizers, namely dioctyl phthalate, dibutyl phthalate, and dimethyl phthalate, were employed to examine their effect on the ionic conductivity of polyethylene oxide (PEO)–LiClO4 polymer complex. It was found that the conductivity of 10−5 Scm−1 can be achieved for all electrolyte systems added with either of the plasticizers at room temperature, which are a few orders of magnitude higher than the conventional PEO-based polymer electrolyte without plasticizers [16]. Silica based nano-composite solid polymer electrolytes (NCSPEs) have also been studied in the past [17, 18]. These studies have revealed an enhancement of ionic conductivity with addition of silica nanoparticles. Conductivity of the order of 10−5 Scm−1 has been achieved with the addition of silica nanoparticles [19].

In this paper, we report the preparation and characterization of SPEs and NCSPEs, namely, (PEG) x LiBr and (PEG) x LiBr: y(SiO2). Here x represents the ratio of number of ether oxygen in a monomer unit of polymer to the number of cation and y represents the weight percent of silica nanoparticles in the SPEs. High molecular weight PEG-based SPEs (mol. wt. ~8,000 and 10,000 gmol−1) has been studied earlier by Shiuli Gupta [19] with various inorganic salts including LiBr, LiClO4, LiCl, LiI, NaI, KI, and CsI. The effect of the addition of Al2O3 nanoparticle is also studied by the same group. A maximum ionic conductivity of 3.9 × 10−5 Scm−1 was observed for O/Li ratio of 10 at room temperature for SPE with PEG-10,000 and LiBr. Also, the conductivity variation with salt shows a characteristic double peak behavior. However, low-molecular weight (Rouse region with molecular weight <3,200 gmol−1) PEG could exhibit additional transport properties due to different viscosity and diffusion behaviors [20]. NCSPEs based on PEG, LiClO4, and γ-alumina nanoparticles of particle size 0.3 μm studied earlier have shown an increase in ionic conductivity up to three times to that of pure SPEs [19].

In the present work, low-molecular weight PEG was chosen as a host polymer. Lithium bromide is dissociated into the polymer matrix using methanol as common solvent. Samples were characterized with X-ray diffraction studies. Alternating current (AC) impedance measurements were carried out as a function of salt concentration, as a function of weight percent of nanoparticles and as a function of temperature. Infrared spectroscopy studies were also carried out on the SPEs and NCSPEs. Room temperature 7Li NMR linewidth measurements were carried out for a few NCSPEs.

Experimental

PEG (average molecular weight of 2,000 gmol−1 which is well below the Rouse region as studied by Shi and Vincent [20]) from Merck, fumed silica nanoparticles (average particle size of ~7 nm) from Aldrich were used for preparation without further purification, while LiBr (with a large anionic radius of 196 pm compared with cation radius of 68 pm which is one of the basic necessities for a suitable salt for polymer electrolytes) from Aldrich was kept at 130 °C for more than 8 hours before preparation since it is hygroscopic. (PEG) x LiBr and (PEG) x LiBr: y(SiO2) were prepared by solution cast technique in which weighed proportions of polymer, salt, and nanoparticles were dissolved in 20 ml of methanol and stirred for 6–8 hours to obtain a homogeneous mixture. Various compositions of the SPEs with different values of x and y were prepared and it was observed that the samples with low salt concentrations were harder solids. As the concentration of salt increases, the samples become softer and moderately hygroscopic. With the addition of nanoparticles, the samples seemed to gain mechanical strength as they were much easier to handle. Here, x represents the ratio of number of ether oxygen in a monomer unit of polymer to the number of cations (x = 10, 20, 30, 46, 70, 100, 200, 400, and 500) and y represents the weight percent of silica nanoparticles in the SPEs (y = 5%, 10%, and 20%). X-ray diffractograms were recorded using Bruker AXS model D8 ADVANCE to confirm the complexation of salt with the host polymer. IR spectroscopy studies using Alpha Bruker instrument were carried out on a few SPEs and NCSPEs. A dual phase lock-in amplifier (PAR-5210) was used to measure the conductivity of all the samples. Samples were poured into teflon rings of average diameter 7 mm and average thickness 2.5 mm. Samples dried in inert atmosphere for more than 8 hours were placed between electrodes of a home-built conductivity rig for AC impedance measurements. Conductivity was measured as a function of (1) salt concentration for all compositions, (2) weight percent of SiO2 nanoparticles and (3) temperature in the range 260 to 300 K for selected compositions. Bruker VT-1000 temperature controller unit was used for this purpose. Room temperature 7Li NMR linewidth measurements were carried out for three sets (x = 20 and y = 0%, 5%, 10%, and 20%; x = 30 and y = 0%, 5%, and 10%; x = 46 and y = 0%, 5%, 10%, and 20%) using Bruker DSX-300 NMR spectrometer operating at 116.49 MHz.

Results and discussions

X-ray diffraction studies

Figure 1 shows the XRD plots for various compositions of SPEs. The XRD peaks of pure PEG appear at 2θ = 19.3° and 23.6°. In the SPEs, these peaks are broadened and are less intense. Full Width at Half Maximum (FWHM) of pure PEG peak at 2θ = 23.6° is 0.920°, FWHM of (PEG)200 LiBr peak at 2θ = 23.6° is 1.22° and FWHM of (PEG)100 LiBr peak at 2θ = 23.6° is 2.78°. This may be due to the incorporation of LiBr salt into the polymer matrix which may increase the amorphous content of the host polymer. The peaks corresponding to the polymer still appears in the XRD pattern of SPEs while the peaks corresponding to LiBr salt (peaks at 2θ = 27.5°, 33.8°, 43.9°, and 57.6°) in the XRD plots of SPEs disappear. This confirms the complexation between the host polymer and salt. The observations also apparently reveal that with the addition of salt, the polymer itself undergoes a few physical changes (increase in amorphous content) while the structure of the polymer still remains the same.

Infrared spectroscopy studies

Figure 2a shows the IR spectra of pure PEG, (PEG)46 LiBr, and (PEG)46 LiBr: y(SiO2) in the range 400 cm−1 to 4,000 cm−1 and figure 2b shows the shift in absorption peak with addition of nanoparticles. Figure 2c shows the IR spectra of pure PEG, (PEG)20 LiBr, and (PEG)20 LiBr: y(SiO2) in the range 400 cm−1 to 4,000 cm−1 and figure 2d shows shift in absorption peak with addition of nanoparticles. The absorption peak of terminal O―H group of the polymer occurs around 3,500 cm−1 (as can be seen in plot of pure PEG). Various absorption peaks can be seen in figure 2a and c between 1,100 cm−1 to 1,480 cm−1 which are due to C―H bending in various planes. The C―H out of plane bending of the polymer can be seen at 1,112 cm−1. An absorption peak at 1,476 cm−1 is seen which is assigned to the in-plane bending of CH2 group of the polymer. The absorption peak at 3,429 cm−1 (seen in IR spectra of pure polymer) corresponding to the O―H stretching of the polymer is shifted to 3,395 cm−1 (seen in IR spectra of all NCSPEs and is shown by the arrow in the figure 2b and d) with the addition of silica nanoparticles. The presence of SiO2 near the terminal O―H group of the polymer might be the reason for the shift in the frequency of absorption of the O―H stretching.

a IR spectra of pure PEG, (PEG)46 LiBr, and few NCSPEs in the range 400 to 4,000 cm−1. b IR spectra showing the shifted peak of terminal O―H group in (PEG)46 LiBr system. c IR spectra of pure PEG, (PEG)20 LiBr, and few NCSPEs in the range 400 to 4,000 cm−1. d IR spectra showing the shifted peak of terminal O―H group in (PEG)20 LiBr system

To compare the IR energy absorption by all the samples, the y-axis of IR plots representing the absorption of IR energy was normalized using normalization function in the Origin software. The amount of energy absorbed by the O―H stretching after the addition of silica nanoparticles to the SPEs shows an increase (clearly seen in the normalized IR plots of SPEs and NCSPEs). The amount of increase in IR absorption energy can be attributed to an increase in amplitude of vibration of the O―H bond. It is well known that the increase in temperature of the sample will increase the amplitude of vibration of a molecule and thus an IR plot of the same sample taken at a higher temperature would show an increase in amplitude of the same signal. But in this case, it is interesting to see that addition of nanoparticles has resulted in an increase of amplitude of vibration of O―H stretching. This can be understood as follows: The presence of SiO2 close to the terminal O―H group of the polymer may attract bromide ion which is coordinated to the O―H group of the polymer. It is also well known in the literature that the addition of nanoparticles to SPEs results in adsorption of anions onto the surface of nanoparticles [21]. The anions which are coordinated with terminal O―H group of the polymer now gets attracted by the SiO2 nanoparticles and may tend to increase the amplitude of vibration of O―H stretching of the polymer. The increase in stretching vibration of the terminal O―H group of the polymer may lead to an enhanced segmental motion of the polymer chain thus facilitating the transport of conducting ions.

Conductivity studies

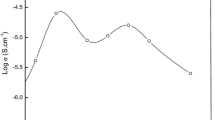

Ionic conductivity of SPEs has been studied as a function of salt concentration. Figure 3 shows the room temperature ionic conductivity behavior on a log scale as a function of salt concentration. It can be seen that the ionic conductivity depends on the salt content in the solid polymer electrolytes. The ionic conductivity isotherm shows a characteristic double peak one in the lower salt concentration region with value of x = 200 and the other at fairly higher salt concentration with value of x = 70. The occurrence of double peak in the conductivity isotherm and its origin is well explained in the literature [19]. The initial growth curve in conductivity versus salt content depicts the increase in number of conducting species (region with x value 500 to 400). There exists a particular salt concentration (in the present case, x of about 400) after which the ion–ion interaction increases leading to impeding ionic motion and also stiffening of polymer chains as a result of cross links formed by cations [22] which reduces the ionic conductivity. But further addition of salt may results in triple ion formation which increases the conductivity. In our case, the second peak occurs at about x = 70. At very high salt concentration with value of x < 46, the conductivity isotherm exhibits a fluctuation. One possible reason could be the nature of sample at high salt concentration. The samples with higher salt concentration are softer and moderately hygroscopic. The highest ionic conductivity was observed to be 6.47 × 10−6 Scm−1 for the composition x = 15.

Ionic conductivity was studied as a function of nanoparticles content in NCSPEs. Figure 4 shows the enhancement in ionic conductivity on a log scale due to the addition of nanoparticles for a few compositions. An enhancement in ionic conductivity by one to two orders of magnitude is seen in all the NCSPEs with addition of 5 wt.% of nanoparticles. Enhancement in ionic conductivity with further addition of nanoparticles is only marginal. The increase in ionic conductivity may be due to the adsorption of anions onto the surface of the nanoparticles [21] thereby reducing the formation of ion pairs and/or ion–ion interaction which hinders the ionic conductivity in SPEs. Highest ionic conductivity of 1.71 × 10−5 Scm−1 was shown by (PEG)70 LiBr: 20(SiO2).

An interesting observation here is the enhancement in ionic conductivity for (PEG)46 LiBr: y(SiO2) system. With 5% addition of silica nanoparticle the enhancement is more than two orders in this system. The conductivity decreases for further addition of nanoparticles and then levels off. This concentration might be the one in which the formation of ion pairs and/or the ion–ion interaction is maximum. So the role of nanoparticles to reduce the formation of ion pairs and/or to reduce the ion–ion interaction is more significant at this concentration which may be the reason for a higher enhancement in ionic conductivity with addition of nanoparticles when compared with other systems.

Ionic conductivity was studied as a function of temperature in the range 260 to 300 K to determine the activation energy for transport of conducting species in the host polymer. Figure 5 shows the plot of ionic conductivity on log scale plotted versus 1000/T. In SPEs, the temperature dependence of conductivity exhibits one of the five behaviors [19, 22–26]:

-

(a)

Vogel–Tammman–Fulcher (VTF) behavior;

-

(b)

Arrhenius behavior at low temperature and VTF behavior at high temperature;

-

(c)

Arrhenius behavior throughout, but with two different activation energies;

-

(d)

VTF behavior for temperature slightly greater than glass transition temperature T g, but Arrhenius behavior at higher temperature;

-

(e)

and a behavior which is neither like Arrhenius nor like VTF at all temperatures.

The case (a) is very common; there are a few reports of case (b), (c), and (d) but case (e) is very rare [19, 22–26].

In the present case, the variation of ionic conductivity of SPEs and NCSPEs with temperature is of Arrhenius type. Hence all the plots were fit using Arrhenius equation

The samples were first cooled to a temperature of 260 K and ionic conductivity was measured in the heating cycle. The activation energies were calculated for all the compositions. It was observed that the activation energy for transport of conducting species decreases drastically from 0.514 eV to 0.188 eV for (PEG)20 LiBr with addition of 5 wt.% of silica nanoparticles. But further addition of silica nanoparticles (10 and 20 wt.% SiO2) decreases the activation energy only marginally from 0.188 eV to 0.167 eV to 0.159 eV. The decrease in activation energy and hence increase in ionic conductivity with addition of silica nanoparticles may be attributed to the adsorption of anions onto the surface of nanoparticles [21] thereby reducing the hindrances produced by ion pairing and/or ion–ion interaction.

NMR studies

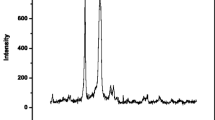

Room temperature 7Li NMR studies were carried out on a few SPEs and NCSPEs using Bruker DSX-300 NMR spectrometer. The linewidth was measured from the recorded spectra. It is known that the NMR linewidth of the conducting sample is sensitive to the interaction of ions with the host. Lesser the interaction of ions with the host polymer, smaller is the NMR linewidth. Anna Johansson's “Compressive Summaries of Uppsala Dissertations from Faculty of Science and Technology” describes the variation of NMR linewidth and relates the reduced NMR linewidth to the decoupling/decrease in interaction of conducting species with the host polymer resulting in enhanced ionic mobility and hence enhancement in ionic conductivity. Several other studies [12, 27, 28] have also suggested a similar behavior with the addition of nano-fillers to the SPEs.

In our samples, it was observed that addition of nanoparticles to the SPEs lead to a sharp decrease in linewidth which can be attributed to the decrease of lithium ion interaction with the polymer [27] and hence increase in lithium ion mobility resulting in enhancement of ionic conductivity of the samples. The linewidth of various SPEs and NCSPEs is given in Table 1 and figure 6 shows the NMR spectra of (PEG)20 LiBr: y(SiO2).

Conclusions

New PEG-2000 based SPEs and NCSPEs were prepared, characterized and studied by ionic conductivity measurements as a function of salt content, nanoparticles content, and temperature. Addition of nanoparticles increases the ionic conductivity by one to two orders of magnitude. An attempt is made to explain the enhancement of ionic conductivity due to the addition of nanoparticles to SPEs through IR spectroscopy studies of pure polymer, SPEs, and NCSPEs. 7Li NMR results also seem to support the enhancement of ionic conductivity with addition of nanoparticles. Thus, the technique of adding inert nanoparticle fillers to the SPEs provides itself one of the better techniques for enhancing the ionic conductivity of the SPEs.

References

Bruce PG, Vincent CA (1993) J Chem Soc Faraday Trans 89:3187–3203

Bischoff H, Rahner D, Wiesener K, Steurich T, Sandner R (1993) J Power Sources 44(1–3):473–479

MacFarlane DR, Newman PJ, Nairn KM, Forsyth M (1998) Electrochim Acta 43(10–11):1333–1337

Appetecchi GB, Croce F, Marassi R, Panero S, Ronci F, Savo G, Scrosati B (2001) Solid State Ionics 143(1):73–81

Manuel Stephan A, Nahm KS (2006) Polymer 47(16):5952–5964

Callens S, Nest J-F, Gandini A, Armand M (1991) Polym Bull 25(4):443–450

Chandrasekaran R, Ruth Mangani I, Vasanthi R, Selladurai S (2000) Ionics 7(1–2):94–100

Mohd Asri MT, Saion E (2005) Ionics 11(5–6):468–471

Damle R, Kulkarni PN, Bhat SV (2009) Pramana 72(3):555–568

Saikai D, Kumar A, Singh F, Avasthi DK (2006) J Phys D Phys 39:4208–4214

Shanmukaraj D, Wang GX, Murugan R, Liu HK (2008) J Phys Chem Solids 69(1):243–248

Joykumar Singh Th, Bhat SV (2004) J Power Sources 129:280–287

Liang Y-H, Wang C-C, Chen C-Y (2005) J Power Sources 146:55–65

Pradhan DK, Samantaray BK, Choudhary RNP, Thakur AK (2005) J Power Sources 139:384–393

Sundar M, Selladurai S (2006) Ionics 12(4–5):281–286

Jacob MME, Michael MS, Prabaharan SRS, Radhakrisna S (1997) Solid State Ionics 98:167–174

Sekhon SS, Sharma JP, Park JS (2007) Macromol Symp 249–250(1):209–215

Jitender PS, Sekhon SS (2008) Port Electrochim Acta 26:493–501

Shiuli Gupta (1994) Ph.D thesis submitted to IIT, Kanpur

Shi J, Vincent CA (1993) Solid State Ionics 60(1–3):11–17

Bhattacharya AJ, Mayer J (2004) Adv Mater 16(9–10):811–814

Gray FM (1991) Solid polymer electrolyte-fundamentals and technological applications. VCH, New York

Gupta RK, Jung HY, Whang CM (2002) J Mater Chem 12:3779–3782

Judeinstein P, Titman J, Stamm M, Schmidt SH (1994) Chem Mater 6:127–134

Th. Joykumar Singh (2004), Ph.D thesis submitted to IISc, Bangalore

Kulkarni PN (2008), Ph.D thesis submitted to Bangalore University, Bangalore

Anna J (1995) Dynamic properties of polymer electrolytes studied by NMR spectroscopy. ACTA Universitatis Upsaliensis, Uppsala

Chung SH, Wang Y, Greenbaum SG, Marcinek M, Persi L, Croce F, Wieczorek W, Scrosati B (2001) J Phys Condens Mat 13(50):11763

Acknowledgements

The authors acknowledge financial support for the work from Board of Research in Nuclear Sciences (DAE-BRNS). The authors acknowledge the assistance from Prof. Vishnu Kamath and his students for carrying out XRD and IR measurements in the Department of Chemistry, Bangalore University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Praveen, D., Bhat, S.V. & Damle, R. Enhanced ionic conductivity in nano-composite solid polymer electrolyte: (PEG) x LiBr: y(SiO2). Ionics 17, 21–27 (2011). https://doi.org/10.1007/s11581-010-0476-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-010-0476-4