Abstract

A solid polymer electrolyte (SPE) film consisting of poly(ethylene oxide) (PEO) with magnesium chloride as electrolytic salt and B2O3 as the filler has been prepared by solution casting technique. The polymeric film was flexible and self-standing with proper mechanical strength and studied for application in a solid-state rechargeable magnesium battery. The interactions between the filler and PEO chains are studied by differential scanning calorimeter and Fourier transform infrared techniques. Composition of SPE is optimized, and maximum conductivity is obtained at 2 wt% B2O3. Filler seems to increase the number of free magnesium cations by decoordinating the bond between magnesium cations and ether oxygen of PEO. Cyclic voltammetry results show the reversible capability of magnesium electrode. Solid-state magnesium cell employing magnesium anode, SPE, and manganese oxide was assembled, and its open circuit voltage is found to be 1.9 V.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A variety of dielectric materials, such as polymers, glasses, ceramics, and their combinations, may be useful as solid electrolytes for rechargeable batteries. Among these materials, polymers have received considerable attention in the last two decades because of their low density, manufacturability, and capacity to accommodate volume changes as compared to true rigid, inorganic solid electrolyte. Among the polymers, poly(ethylene oxides) (PEOs) have been widely investigated because of their potential viability in high-performance batteries [1–6]. Despite the advantages of PEO, its room temperature conductivity is currently too low to be practical due to a sharp decrease in ionic conductivity below 60 °C. For the improvement of the ionic conductivity of solid polymer electrolytes (SPEs), addition of non-aqueous organic solvents with a low molecular weight, as a plasticizer, into the matrix polymer has been proposed, which is expected to enhance the ionic mobility of the polymer electrolytes. However, the addition of these organic solvents partially spoils the advantages of the SPEs such as safety. Second is the lower transference number because segmental motions induce the movement of magnesium ions, and the magnesium ions are coordinated strongly with the oxygen atoms of the polyethers [7–9].

Lewis acidic compounds have been proposed as additives to enhance the dissociation of the supporting salt, which are expected to interact with Lewis basic anions. Lewis acid compounds trap the counter anions. In this report, boron compounds act as anion receptor because of the Lewis acidity of boron atoms [10]. In the present communication, PEO-based SPEs, which contain B2O3 as filler, are studied. Studies on ionic conductivity, cyclic voltammetry, infrared spectroscopy, and differential scanning calorimetry are reported. This paper aims to elucidate the mechanism of the filler–polymer system: the interaction effect between the fillers and the polymer electrolyte through infrared spectroscopy results.

Experimental procedure

The PEO/MgCl2/B2O3 composite electrolyte films of different weight percent ratios were made by the solvent casting technique using reagent grade PEO, magnesium chloride (MgCl2), and boron trioxide (B2O3) as filler. A solution of PEO (Aldrich, mol. wt. 7,000,000) and MgCl2 in AR grade methanol was prepared in which B2O3 was dispersed and stirred continuously. After homogenization, colloidal solution was obtained, which was cast and dried into a film with a thickness of about 60–100 μm. Infrared (IR) vibrational spectra were obtained on the films using a PerkinElmer instrument with a wave number resolution of 2 cm−1 in the frequency of 400–4,000 cm−1. Differential scanning calorimeter (DSC) measurements were carried out on Netzsch thermal analyzer, and all the measurements were carried out at a heating rate of 5 °C/min from −100 to 100 °C. The sample weights were maintained at 5–10 mg, and all experiments were carried out under nitrogen flow to avoid any contact with atmospheric moisture; an empty aluminum pan was used as a reference. The cyclic voltammetry behavior of the cells was recorded using a potentiostat/galvanostat (CH Instruments model 7001C), and experiments were conducted at 25 °C. The alternating current impedance measurement was carried out using a CHEN-HWA (model 1061) LCZ bridge in the frequency range of 40 Hz to 200 kHz on stainless steel (SS)/composite electrolyte/SS cells.

Results and discussion

IR spectroscopic studies

A polymer complex with ionic salts and fillers are characterized by IR spectroscopy [10–14, 17, 18]. This technique provides a powerful means to characterize the complex formation. The absorption peak at 1,625 cm−1 corresponds to Mg2+ without complexation, and the decrease in intensity from 1,625 to 1,622 cm−1 at 20 wt% indicates the possible formation of coordinate bond between Mg–O [3, 6, 11] (Sreepathi Rao et al. 1995; Sreekanth et al. 1999; Hashmi et al. 1990). Hence, further experiments are conducted by keeping 20 wt% as the fixed salt concentration. Mg–O bond is basic in nature. To increase its conductivity, we suggested the addition of Lewis acid (B2O3).

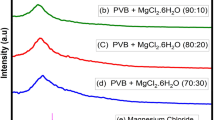

Formation of PEO–B2O3–MgCl2 complex

The IR spectra of pure PEO–MgCl2 without filler and its blending with B2O3 filler are given in Table 1. In Fig. 1, marked changes were found when PEO–MgCl2 polymer electrolytes are blended with B2O3 filler. The CH2 twisting band at 1,273 cm−1 in PEO shifts to 1,277 cm−1 on the addition of B2O3. This increase in wave number results in the decrease in bond length and in the closeness of the species (B2O3 and PEO). The B2O3 exhibits two strong bands at 1,196 and 798 cm−1. The band at 1,196 cm−1 corresponds to triangular B–O stretching. Upon adding PEO, the bond completely disappears resulting in complex formation; the band at 2,853 cm−1 in B2O3 shifts to 2,852 cm−1. This decrease in the wave number results in the increase in bond length, and hence complexation takes place. The band at 528 cm−1 in the PEO is attributed to the bending movement of C–O–C group. With the addition of B2O3, the band shifts to 527 cm−1 thus resulting in PEO–B2O3 complex [B–O (from PEO)]. The resulting bond breaks when MgCl2 is being added to the complex, thus indicating the formation of ternary PEO–MgCl2–B2O3 complex.

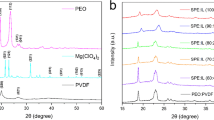

DSC studies

Thermal analysis using DSC was performed in order to observe the change in transition temperature that is caused by the addition of the B2O3 filler. In general, a low glass transition temperature indicates the existence of a greater amount of amorphous phase such that the segmental motion of migrating magnesium ions is more activated. The effect of B2O3 filler on the glass transition temperature (T g) is shown in Table 2. In this table, the enthalpy of melting (ΔH m) is represented as that per unit weight of PEO, and crystallinity is estimated from the ratio of the experimentally determined ΔH m to the value of 203 J/g reported in the literature for the enthalpy of melting of 100% crystalline PEO [20].

All samples exhibit a clear glass transition at T g, at which a glassy phase becomes a rubbery amorphous phase upon heating. The melting heat for the complexed films are observed in the range much lower than as compared with the value of 203 J/g reported in the literature for the melting heat for 100% crystalline PEO, indicating that the samples are partially crystalline. The DSC curves in Fig. 2 suggest that the T g, the heat of fusion, and the melting temperature decreases until 2 wt% of B2O3 addition. It is interesting to note that crystallinity is suppressed more effectively due to disruption of PEO crystallinity up to 2%. Above 2 wt%, the T g, T m, and ΔH m increase with a decrease in the concentration of the boron groups, which play a role of cross-linking points in the polymer electrolytes. These results indicate that the mobility of the polymer chains increases with a decrease in the concentration of the cross-linking points, i.e., boron groups, in the polymer electrolytes because T g is correlated with the segmental motion of polymer chains [10].

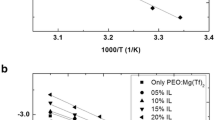

Conductivity studies

The variation in conductivity of the polymer electrolyte as a function of B2O3 filler concentration is given in Table 3. Compositional conductivity of PEO/MgCl2/B2O3 system is shown in Fig. 3. The results indicate that the room temperature conductivity of PEO/MgCl2 increases with increasing filler content up to 2 wt%. In general, the ionic conductivity of SPEs increases with temperature due to the higher segmental motion of polymer chains in the amorphous phase. Under these conditions, the filler’s role in assisting magnesium ion conduction is insignificant, as shown in Table 4 and in Fig. 4 for temperatures above 50 °C. For this reason, the present study focuses on the role and the enhancement mechanism of fillers at room temperature.

The IR studies clearly indicate the complexation occurring between polymer, salt, and filler. Mg–O bond complexation is formed at all concentration of B2O3 (2.5 and 10%), but at 2%, the wave number decreases to 1,137 cm−1. Therefore, the bond length increases, and it is the most favorable composition for complexation (Mg–O) in comparison with 5 and 10 wt%. This bond formed is basic in nature. Hence, upon adding the Lewis acid, which effectively decoordinates the Mg–O bond, the Lewis acid sites on the surface of the filler interact with oxygen atoms of PEO and weaken the interaction between the oxygen atoms and Mg cations, and thus release more number of Mg cations, which are necessary for the conduction [14, 15–17].

The conductivity of a solid-state electrolyte has many determinants, such as carrier concentration (Ci), mobility (mi), and so on [18], as depicted in Eq. (1). The enhancement in ionic conductivity when adding B2O3 filler to a PEO–Mg salt complex might be due to the fact that the active dissociation of the Mg salt results in an increased concentration of mobile carriers (Ci).

Cyclic voltammetry studies

The symmetrical cells (stainless steel) SS/SPE (PEO–Mg–B2O3)/SS and Mg/SPE (PEO–Mg–B2O3)/Mg were subjected to cyclic voltammetry, and the voltagrams are shown in Fig. 5. The experiment was carried out without reference electrode; here, both the reference and the counter electrode terminal were shorted. The magnitude of current through the SS cells was very low, and there were no current peaks on the voltammograms of Mg cells [20]. Furthermore, well-defined anodic and cathodic peaks were present in the voltagram for Mg/SPE (PEO–Mg–B2O3)/Mg cells. The results indicate that cathodic deposition is favored at the interface between magnesium and SPE, and the ratio of cathodic to anodic charge current is only about 70%, thus indicating that the magnesium reaction is quasireversible.

The rate constants are generally lowered, and the curves shift to more reductive potentials.

In this situation, the voltage applied will not result in the generation of the concentrations at the electrode surface predicted by the Nernst equation. This happens because the kinetics of the reaction is ‘slow’, and thus the equilibria are not established rapidly (in comparison to the voltage scan rate), unlike the reversible reaction where the position of the current maximum shifts depending upon the reduction rate constant (and also the voltage scan rate). This occurs because the current takes more time to respond to the applied voltage than the reversible case, which perhaps could be attributed to the presence of the surface films on the magnesium metal [20].

The MnO2 cathode on an aluminum foil consisted of MnO2 with PVdF and carbon of the proportions of 85:5:10 by weight percent. The Mg/SPE (PEO–Mg–B2O3)/MnO2 cell was assembled by sandwiching the SPE between the magnesium anode and MnO2 cathode. The cell was enclosed in a plastic bag and was vacuum-sealed. The open circuit voltage (OCV) of the cell was about 1.9 V. Further work is under progress.

Conclusion

Polymer electrolyte system involving polymer and salt, i.e., PEO–salt complex, is in equilibrium state unless something, may be a filler, is added onto the system. On adding the filler (B2O3), we are disturbing the system, and the system becomes a non-equilibrium state, i.e., the system is under internal stress, and this non-equilibrium nature of the structure below T m is expected to have a major influence on magnesium ion conductivity. A system in non-equilibrium state proceeds towards equilibrium state; such a state is under internal stress, and transformation occurs to relieve the stress. The result of this transformation is a change in the physical properties (in the present situation, the conductivity) of the polymer film, which occurs through molecular rearrangement. In this case, transformation occurs by nucleation and crystallization of PEO spherulites as apparent by DSC data.

SPE consisting of PEO–Mg–B2O3 was cast, and their ionic conductance behavior, the interaction effect between the fillers and the polymer electrolyte, as well as the reversible capability of magnesium electrode using the SPE were investigated as solid electrolyte for all-solid Mg-ion batteries. The results are summarized as follows.

-

The polymeric electrolyte is self-standing with proper mechanical strength.

-

The ionic conductivity depended on the content of B2O3. The highest conductivity of the SPEs examined was 7.16 × 10−6 S/cm (at 30 °C) for the composition of 2% B2O3.

-

The enhancement in ionic conductivity when adding B2O3x filler to a PEO–Mg salt complex might be due to the fact that the active dissociation of the Mg salt results in an increased concentration of mobile carriers (Ci).

-

Cyclic voltammetry studies using the SPE show the reversibility of magnesium electrode. Furthermore, OCV of 1.9 V was obtained for the cell assembled with (SS)Mg/SPE/MnO2(SS).

References

Murata K (1995) Electrochim Acta 40:2177

Hashmi SA, Chandra A, Chandra S (1992) In: B.V.R. Chowdari, et al (eds) Solid state ionics: materials and applications. World Scientific, Singapore, p 567

Sreepathi Rao S, Jaipal Reddy M, Laxmi Narsaiah E, Subba Rao UV (1995) Mater Sci Eng B 33:173

Gorecki W, Jeannin M, Belorizky E, Roux C, Armand M (1995) J Phys Condens Matter 7:6823

Selladurai S, Trends in solid state Ionics, Raj Publishing House, Chennai

Sreekanth T, Jaipal Reddy M, Subramanyam S, Subba Rao UV (1999) Mater Sci Eng B 64:107

Narin K, Forsyhn M (1996) Solid State Ion 86–88:589

Michael MS, Jacob MME, Prabaharan SSR (1997) Solid State Ion 98:167

Alexandre M, Dubois P (2000) Material Science and Engineering 28:1–63

Yamamoto M et al (2003) J Mater Chem 13:280–285

Hashmi SA, Kumar A, Maurya KK, Chandra S (1990) J Phys D 23:784

Croce F, Appetecchi GB, Persi L, Scrosati B (1998) Nature 394:456

Croce F, Curini R, Martinelli A, Persi L, Ronci F, Scrosati B (1999) J Phys Chem B 103:10632

Ji et al (2003) J Power Sources 117:124–130

Doeff M, Georen P, Qiao J, Kerr J, De Jonghe LC (1999) J Electrochim Soc 146:2024

Dupon R, Papke BL, Ratner MA, Whitmore DH, Shriver DF (1982) J Am Chem Soc 104:6247

Kumar B, Stanley J, Rodrigues RJ (2002) Spry. Electrochim Acta 47:1275–1281

Hench LL, West JK (1990) Principles of electronic of ceramics. Wiley, New York, USA, pp 139–198

Wunderlich (ed) (1980) Macromolecular physics, vol 3. Academic, New York, p 67

Girish Kumar G, Munichandraiah N (2000) J Electroanal Chem 495:42–50

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sundar, M., Selladurai, S. Effect of fillers on magnesium–poly(ethylene oxide) solid polymer electrolyte. Ionics 12, 281–286 (2006). https://doi.org/10.1007/s11581-006-0048-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-006-0048-9