Abstract

The addition of polymethyl methacrylate (PMMA) having different molecular weights to electrolytes containing ammonium trifluoromethanesulfonate (NH4CF3SO3) in diethyl carbonate (DEC) has been found to result in conductivity enhancement and to yield gel electrolytes with conductivity higher than the corresponding liquid electrolytes. The increase in conductivity has been found to be due to the dissociation of undissociated NH4CF3SO3 and ion aggregates present in the electrolytes, and this has been supported by Fourier transform infrared spectroscopy results, which suggests active interaction of PMMA and NH4CF3SO3 in these gel electrolytes. The increase in conductivity also depends upon the molecular weight of the polymer used and is relatively more for PMMA having lower molecular weight. The increase in viscosity with PMMA addition also depends upon the molecular weight of the polymer and is closely related to the conductivity behavior of these electrolytes. Polymer gel electrolytes have been found to be thermally stable up to a temperature of 125 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Non aqueous polymer gel electrolytes obtained by immobilizing salt solution in a suitable polymer matrix have attracted much attention recently as they possess high ionic conductivity, comparable to that of liquid electrolytes, and their suitability for applications in solid state batteries, display devices, supercapacitors, etc. [1–4]. Proton-conducting polymer gel electrolytes are also gaining importance due to their potential use in fuel cells and other devices [5]. Being a salt–solvent–polymer hybrid system, their conductivity and other properties depend upon the nature of its constituents and, hence, can be easily controlled. Although polymer electrolytes containing NH4CF3SO3 were reported in the mid-eighties, yet due to their lower conductivity, they were not pursued thereafter [6–9]. However, polymer gel electrolytes containing NH4CF3SO3 show high conductivity of the order of 10−2 to 10−3 S/cm [10]. The physical properties (viscosity, dielectric constant, melting point, boiling point) of the solvent also play an important role in controlling the dissociation of salt and mobility of the mobile species in these electrolytes, in addition to providing a medium for conduction. The polymer generally provides mechanical stability to these gel electrolytes and polymethyl methacrylate (PMMA), polyacrylonitrile (PAN), polyvinylidene fluoride (PVdF), polyvinylidene fluoride–hexafluoropropylene (PVdF–HFP), polyethylene oxide (PEO), etc. are some of the commonly used polymers in the synthesis of polymer gel electrolytes [11–13]. Recently, some work on the comparative role of different polymers on the solvability and other properties of polymer gel electrolytes has been reported [14, 15]. As the properties of polymer also depend upon its average molecular weight, so the comparison of results reported by different workers could not be made sometimes due to the different molecular weights of the polymer used. Viscosity (η) of gel electrolytes is one such important parameter related inversely to mobility (μ) (μ = q/6πηr where q is the carrier charge and r is the radius of the carrier ions), which depends upon the molecular weight of the polymer, and hence, polymer with different molecular weights may affect the conductivity behavior in different ways. The aim of the present work is to study the role of the molecular weight of polymer on the conductivity and viscosity behavior of polymer gel electrolytes.

Experimental

Polymer gel electrolytes were prepared by adding PMMA (Aldrich) with average molecular weight 15,000, 120,000 and 996,000 in different amounts (expressed as the weight percent of liquid electrolyte) to the liquid electrolytes of NH4CF3SO3 (Aldrich) in diethyl carbonate (DEC) (Merck) along with continuous stirring. Electrical conductivity was measured by complex impedance spectroscopy using the HP4284A precision LCR meter working in the 20 Hz–1 MHz frequency range with a cell having platinum electrodes [16, 17]. The viscosity of electrolytes was measured by the Fungilab rotating viscometer (Visco Basic L) by using a small sample adapter assembly. The thermal properties of the gel electrolytes were studied by differential scanning calorimetry (DSC) and thermo gravimetric analysis (TGA) (Mettler Toledo Star System) in the 25–300 °C temperature range at the heating rate of 10 °C/min under nitrogen atmosphere.

Results and discussion

The variation of conductivity of electrolytes containing NH4CF3SO3 in DEC as a function of salt concentration is given in Fig. 1. The conductivity of the solvent (DEC) (approximately 10−9 S/cm) increases by five orders of magnitude to 6.8 × 10−4 S/cm with the addition of 1 M NH4CF3SO3. The increase in conductivity with salt concentration does not take place at the same rate and slows down at higher concentrations of NH4CF3SO3 due to the formation of ion aggregates which do not take part in the conduction process [18]. Due to the lower dielectric constant of DEC (ɛ = 3.1 at 20 °C), some undissociated NH4CF3SO3 may also be present in these electrolytes.

The formation of ion aggregates at higher salt concentrations was checked qualitatively by mass action considerations [19]. According to this method, if all the ions are present as free ions, then the plot between log σ and log C (where σ and C are the conductivity and concentration of salt in the electrolyte, respectively) will be a straight line and if ion aggregates are formed, then the plot between log σ and log C shall show a deviation from straight line behavior. A plot between log σ and log C for electrolytes containing NH4CF3SO3 in DEC is given in Fig. 1b. At low salt concentrations, the plot shows a straight line behavior, whereas at high salt concentrations, it shows deviation from the straight line behavior and the deviation increases with an increase in salt concentration. This suggests the presence of ion aggregates at higher salt concentrations, which is in agreement with the conductivity results given in Fig. 1a. The addition of salt also increases the viscosity of electrolytes from 0.8 to 1.9 cP.

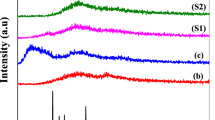

The conductivity and viscosity of polymer gel electrolytes containing PMMA (average molecular weight = 15,000) in the 0.5 M solution of NH4CF3SO3in DEC with PMMA concentration is given in Fig. 2. The conductivity increases by nearly one order of magnitude with the addition of PMMA, and then shows a small decrease at higher PMMA concentrations, but the conductivity of gel electrolytes is higher than the corresponding liquid electrolytes at all PMMA concentrations. The conductivity of liquid electrolytes has been found to increase with the addition of PMMA. The role of PMMA in polymer gel electrolytes along with possible interactions between salt, solvent and polymer were studied by Fourier transform infrared (FTIR) spectroscopy. The FTIR spectra of liquid electrolytes containing 0.5 M NH4CF3SO3 in DEC (a), of gel electrolytes containing 5 and 10 wt% PMMA (b and c) are given in Fig. 3 in the 560 to 775 cm−1 region. The spectra of liquid electrolyte in this region (Fig. 3a) shows peaks at 577, 642 and 762 cm−1, which are due to the asymmetric bending of \({\text{CF}}_{\text{3}} ^ - \), asymmetric bending of \({\text{SO}}_{\text{3}} ^ - \), and symmetric bending of \({\text{CF}}_{\text{3}} ^ - \) in free triflate ions, respectively [20–24]. The peak at 591 cm−1 is due to the presence of ion aggregates whereas the peak at 743 cm−1 is related to the undissociated salt (NH4CF3SO3) present in electrolytes. These peaks are absent in the spectra of polymer gel electrolytes (Fig. 3b and c), which suggests that the addition of PMMA may result in the dissociation of ion aggregates and undissociated salt, which were present in liquid electrolytes [25], resulting in an increase in free ion concentration. Polymer gel electrolytes (Fig. 3b and c) also show a peak at 750 cm−1 due to the rocking of the CH2 group in PMMA [26].

The above FTIR results show that the addition of PMMA results in the dissociation of ion aggregates and undissociated salt present in liquid electrolytes at higher salt concentrations. This leads to an increase in free ion concentration and, hence, conductivity as given in Fig. 2a. The viscosity of gel electrolytes, as given in Fig. 2b, is very small at low concentrations of PMMA and increases sharply at higher concentrations of PMMA. The large viscosity at higher concentration of PMMA results in lower mobility (as mobility is inversely related to viscosity), which decreases conductivity. The increase in conductivity with PMMA addition is quite significant and is despite an increase in viscosity, which shall lower mobility, and a net decrease in salt concentration, as no additional salt has been added along with the polymer and both these factors will lead to lower conductivity.

The viscosity of the polymer depends upon its molecular weight and increases with an increase in molecular weight. So, the viscosity of electrolytes plays a dominant role in the conductivity behavior of polymer gel electrolytes. Keeping this in mind, polymer gel electrolytes containing PMMA with different molecular weights (15,000, 120,000 and 996,000) were prepared and the variation of conductivity and viscosity with PMMA concentration was studied, and the results are given in Fig. 4. The values of conductivity and viscosity at 25 °C for gel electrolytes containing 6 and 15 wt% PMMA having different molecular weights and the ratio of their values for gel and liquid electrolytes (σ g/σ l, η g/η l) are also listed in Table 1. The following general observations can be made on the basis of the results given in Fig. 4 and Table 1:

-

– The conductivity of gel electrolytes containing PMMA (with different molecular weights) is higher than the corresponding liquid electrolytes at all PMMA concentrations.

-

– The increase in conductivity with PMMA addition depends upon the molecular weight of PMMA, and is more for gels containing lower molecular weight (15,000) PMMA.

-

– A small decrease in conductivity observed at higher PMMA concentrations is due to the dominant role of viscosity.

-

– The viscosity of gel electrolytes depends upon the molecular weight of PMMA and is more for gels containing higher molecular weight (996,000) PMMA.

The variation of log conductivity with reciprocal temperature for gel electrolytes containing 20 wt% PMMA (average molecular weight = 15,000) in the 0.5 M solution of NH4CF3SO3 in DEC, measured over the 25–100 °C temperature range, is given in Fig. 5. The conductivity of gel electrolytes is higher than for the corresponding liquid electrolytes at all temperatures. The conductivity of gel electrolytes over the 25–100 °C temperature range increases from 2.87 × 10−4 to 5.85 × 10−4 S/cm, which is quite small and suitable for their use in different devices.

The thermal stability of polymer gel electrolytes was studied by DSC/TGA measurements over the 25–300 °C temperature range. The DSC and TGA plots for gel electrolytes having composition DEC-0.5 M NH4CF3SO3 −10 wt% PMMA are given in the Fig. 6a and b. The TGA plot for the polymer gel electrolyte (Fig. 6a) does not show any appreciable weight loss up to a temperature of 125 °C. The peak at 125 °C is also observed in the DSC thermogram, which corresponds to the glass transition temperature of PMMA and boiling temperature of solvent (DEC). The weight loss increases by more than 50% between the temperature range of 125 and 150 °C. Above the temperature of 250 °C, a weight loss of about 70% is observed, which is due to degradation of PMMA. This loss of weight is also accompanied by an endothermic peak at about 275 °C in DSC thermogram. DSC/TGA studies show that these electrolytes are thermally stable up to 125 °C only.

Conclusions

The addition of PMMA having different molecular weights results in an increase in conductivity and yields gels with conductivity higher than the corresponding liquid electrolytes. This is due to the dissociation of ion aggregates/undissociated salt present in these electrolytes which is also supported by FTIR results. The increase in conductivity and viscosity of polymer gel electrolytes with the addition of PMMA is found to depend upon the molecular weight of PMMA. The increase in conductivity is more for gels containing relatively low molecular weight PMMA, whereas the increase in viscosity is more for gels containing higher molecular weight PMMA. Thus, a proper choice of the molecular weight of PMMA can result in polymer gel electrolytes having the optimum value of conductivity and viscosity.

References

Yasuda Y, Kamiyama T, Shirota Y (2000) Electrochim Acta 45:1537–1541

Conway BE (1999) Electrochemical supercapacitors: scientific fundamentals and technical applicatios. Kluwer, New York

Owens BB (2000) J Power Sources 90:2–8

Scrosati B, Croce F, Panero S (2001) J Power Sources 100:93–100

Colomban P, Novak A (1992) Proton conductors: solids, membranes and gels—materials and devices. Cambridge University Press, Cambridge

Stainer M, Hardy LC, Whitmore DH, Shriver DF (1984) J Electrochem Soc 131:784–790

Ansari SM, Browdwin M, Stainer M, Druger SD, Ratner MA, Shriver DF (1985) Solid State Ionics 17:101–106

Oradd G, Furlani M, Ferry A (2000) Solid State Ionics 136–137:457–461

Mellander BE, Albinsson I (1996) Solid state ionics: new developments. World Scientific, Singapore

Singh HP, Kumar R, Sekhon SS (2005) Bull Mater Sci 28:467–472

Webber A (1991) J Electrochem Soc 138:2586–2590

Song JY, Yang YY, Wan CC (1999) J Power Sources 77:183–197

Chandra S, Sekhon SS, Srivastava R, Arora N (2002) Solid State Ionics 154–155:609–619

Kim CS, Oh M (2001) Electrochim Acta 46:1323–1331

Sharma JP, Sekhon SS (2006) Mater Sci Eng B 129:104–108

Chandra S, Sekhon SS, Arora N (2000) Ionics 6:112–118

Sekhon SS, Singh HP (2002) Solid State Ionics 152–153:169–174

Bruce PG (1991) Synth Met 45:267–278

Ratner MA (1987) Polymer electrolyte reviews, vol. 1. Elsevier, London

Dissananake MAKL, Frech R (1995) Macromolecules 28:5312–5319

Frech R, Chintapalli S (1996) Solid State Ionics 85:61–66

Laik B, Legrand L, Chausse A, Messina R (1998) Electrochim Acta 44:773–780

Wang Z, Ikeda M, Hirata N, Kubo M, Itoh T, Yamamoto O (1999) J Electrochem Soc 146:2209–2215

Deepa M, Sharma N, Agnihotry SA, Chandra R (2002) J Mater Sci 37:1759–1765

Kumar R, Sharma JP, Sekhon SS (2005) Eur Polym J 41:2718–2725

Hummel DO (1966) Infrared spectra of polymers in the medium and long wavelength regions. Wiley, New York

Acknowledgements

One of the authors (SSS) is thankful to DST New Delhi for financial support in the form of a research scheme No. SR/S2/CMP/2003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, R., Sekhon, S.S. Effect of molecular weight of PMMA on the conductivity and viscosity behavior of polymer gel electrolytes containing NH4CF3SO3 . Ionics 14, 509–514 (2008). https://doi.org/10.1007/s11581-008-0209-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-008-0209-0