Abstract

Objective

Sensor systems in the operating room may encounter intermittent data losses that reduce the performance of surgical workflow management systems (SWFMS). Sensor data loss could impact SWFMS-based decision support, device parameterization, and information presentation. The purpose of this study was to understand the robustness of surgical process models when sensor information is partially missing. SWFMS changes caused by wrong or no data from the sensor system which tracks the progress of a surgical intervention were tested.

Materials and methods

The individual surgical process models (iSPMs) from 100 different cataract procedures of 3 ophthalmologic surgeons were used to select a randomized subset and create a generalized surgical process model (gSPM). A disjoint subset was selected from the iSPMs and used to simulate the surgical process against the gSPM. The loss of sensor data was simulated by removing some information from one task in the iSPM. The effect of missing sensor data was measured using several metrics: (a) successful relocation of the path in the gSPM, (b) the number of steps to find the converging point, and (c) the perspective with the highest occurrence of unsuccessful path findings.

Results

A gSPM built using 30 % of the iSPMs successfully found the correct path in 90 % of the cases. The most critical sensor data were the information regarding the instrument used by the surgeon.

Conclusion

We found that use of a gSPM to provide input data for a SWFMS is robust and can be accurate despite missing sensor data. A surgical workflow management system can provide the surgeon with workflow guidance in the OR for most cases. Sensor systems for surgical process tracking can be evaluated based on the stability and accuracy of functional and spatial operative results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In modern operating theaters, the surgeon is surrounded by a large variety of technical devices, all with the purpose of giving him assistance during the operation. Because of the lack of interoperability between those devices, some functionality cannot be used or could only be used with additional preliminary effort [1]. The lack of interoperability not only affects data integration but also causes context integration issues. Context integration describes the possibility of sharing common knowledge of the surgical process. By using surgical process models described in [2], comprehensive knowledge of the surgical process can be provided during the operation by a workflow management engine (WFMS).

To provide surgical assistance system with the current step of the operation, the WFMS has to know the actual step of the surgery. To detect this process information, the WFMS must rely on the interpretation of various sensor information gathered in the OR. Based on this sensor information, the current step can be derived and aligned with the process model loaded by the WFMS. From the knowledge of the actual step and the preloaded model of the overall intervention, the system is able to derive the next step. Therefore, services can be activated and devices can be parameterized accordingly. The two most important requirements for successful implementation of the aforementioned approach are the availability of a valid process model and accurate sensor information.

However, in practice, the accuracy of the sensor information cannot be guaranteed. The data can be inaccurate due to various disorders or nonexistent due to sensor failure. In addition to this, the interpretation of different sensor data can produce the wrong result. Since the WFMS receives an interpretation of the sensor data as input information, an incorrect interpretation can cause the WFMS to be completely unsynchronized or to arrive at the wrong step completely. Therefore, a high quality of sensor information is needed. This can be achieved by fusing information of many sensor systems [3]. To reduce the overall complexity of the system and the computational operating cost, it is of interest to not make every sensor system redundant, but to evaluate which information and which sensors are error prone. From this, a system can be developed which takes the quality of information into account.

In other words, having high-quality sensor information is just as important as the generation of a sufficiently accurate and valid process model. In business information systems, process models can be created due to their relatively high linearity using a top–down analysis of the process. In surgery, this approach is limited due to the high variability of the process [4]. The high variability is due to the diversity of patients, their diagnosis, and the skill of the surgeons. A top–down modeling approach leads to relatively coarse descriptions of the procedure. In [4], the authors describe an inductive method for the generation of a surgical process model. This method is based on the fusion of process models from many observations.

The aim of this work is to assess an inductively created process model with respect to the problems that can arise from incomplete or erroneous sensor information. Incomplete sensor information can lead to a break in the path observation of the process model and thus lead to an undefined state in the process. In the case of such an event, the system must be set to an exception state until the path in the model has been found again. As a prerequisite, we use the 6-layer approach published in [3]. Here, the sensor information is transformed through 6 abstraction layers from a very basic representation (hardware abstraction layer) to a generic, human readable representation (application layer). The application layer of this approach is, with a few adaptations, readably for every WFMS. In this study, we clarify the question of how many steps are required to reconverge upon the correct track in the process model after the system has lost its way. Furthermore, we investigated how the model responds to the absence of entire categories of sensor information. We also investigated sensitive input parameters in order to derive a prioritization of compensatory strategies.

In the literature, there are different approaches to dealing with surgical workflows. In [5], all processes in and around the operating room were recorded by using a structured time recording sheet in order to investigate potential weaknesses of the process. The analysis revealed a significant inefficiency of unused surgical capacity caused by delays in the perioperative environment. The documentation of the surgical process is also the subject of the question in [6]. The process was recorded from multiple significant points using four video sources in the operating room. By combining the video recordings with text-based recordings of events during the intervention, some evaluation questions could be answered in a subsequent analysis which could not be answered prior to the study. By analyzing the size of the compression of video data, the group in [7] investigates the movement in the OR. Their work aims to detect higher movement of the OR personnel during critical situations in the process. An overview of various sensor systems for monitoring in the operating room is presented in [8]. The authors identify knowledge of the surgical procedure as a prerequisite for the development of error-prevention systems in the OR. None of the above-mentioned works use process models of the intervention to predict the next step and therefore none determine their models with respect to robustness of the process model. In automotive systems, the handling of sensor data is a routinely done task. In [9], the authors present a detail overview of commonly used fault tolerant design techniques in this domain. The authors of [10] introduced a new multistep ahead predictive filter scheme with a predominant performance in compensation of missing data compensation. Nevertheless, in this domain, the underlining process model is very basic compared to the surgical process in itself.

In this work, we show, based on 100 clinical recordings of cataract eye surgery, how a generalized and inductively generated surgical process model reacts to the failure of sensor information. In the methodology section, we will first address the clinical records and the creation of a general surgical process model. In addition, the construction of the test system and the study design for the validation of the model are described.

Methodology

Surgical process modeling

From a modeling perspective, the term surgical process model (SPM) refers to an actual surgical intervention. This definition is based on the definition of the Workflow Management Coalition[11] where a process model is described as: “...a set of one or more linked procedures or activities that collectively realize a surgical objective within the context of an organizational structure defining functional roles and relationships .” A surgical process model is defined as: “...a simplified pattern of a Surgical Process that reflects a predefined subset of interest of the Surgical Process in a formal or semi-formal representation” [12]. In this model, every activity corresponds to one specific action of the surgeon during the intervention. A process model based on the procedure of one single patient is referred to in this paper as an individual surgical process model (iSPM).

Each activity consists of a tuple of five elements that give different perspectives on the particular surgical step (Fig. 1). These perspectives are defined as follows:

-

Organizational: The entity under consideration

-

Functional: The action undertaken by the entity under consideration

-

Operational: The instrument which is used for this activity

-

Spatial: The anatomical structure currently being worked on

-

Behavior: The duration of the activity

Since these are generic definitions from the field of process management, in this paper, we refer to them as following (Table 1).

To produce a generalized surgical process model (gSPM), several iSPMs are combined. The iSPMs are first divided into their surgical phases. Subsequently, for each surgical phase, the corresponding activities of the iSPMs are determined and combined into one activity in the gSPM. Similarly, the predecessor and successor activities are determined and connected by transitions between the activities. The probability of a transition from one activity to the next is determined based on the frequency of occurrence in the iSPMs. By statistical averaging based on the merging of multiple iSPMs, the gSPM represents an averaged model of a type of surgical intervention. A schematic example of a gSPM is given in Fig. 2.

The aforementioned problem of the high variability of the surgical procedure and hence the resulting problems of modeling can be taken into account in this model. By mapping the variability through probabilistic transitions, all possible process variations in the model are considered.

The gSPM was implemented as a XML data structure. For further processing, this data structure must be converted into a format which is able to be processed by the workflow management system. For this research, the Yet Another Workflow Language (YAWL) [13] and the matching YAWL workflow management system were used. YAWL implements, based on the formal logic of Petri nets, all of the workflow patterns proposed by the workflow patterns initiative [14] and extends them to the patterns of concurrency and cancelation.

Test system

To conduct this study, a test system was developed. This system consisted of four interconnected standalone software components (Fig. 3).

In the process simulation unit, the gSPM was created from the iSPMs in the SPM database. The simulation set, consisting of iSPMs, was then provided to the process simulator. The process simulator passed each activity from each iSPM in the test set to the uncertainty generator. Perspectives were randomly deleted from each activity to simulate uncertainties in the sensor data. The process monitor then sent the activity one by one to the workflow management system. To store the iSPMs, a postgres 8.2 [15] database was used. All other components were proprietary developments in Java.

To generate a gSPM from the test set, the set was sent to the gSPM generator. The resulting workflow schema was sent to the workflow management system. The workflow management system executed the process model within the workflow engine. In the workflow log, the success of the execution was logged for later analysis. The analysis was done with the statistical tools R [16] and SPSS [17].

Since the goal of the study was to investigate the model regarding the problems that could arise from incomplete or erroneous sensor information, the uncertainties generator simulated sensor defects. For this purpose, perspectives were hidden from subsequent activities. This could lead to the problem that the path of the gSPM was not clearly identifiable, and thus the unambiguous tracking of the path could not be guaranteed. This situation can occur in reality when a sensor system, like the instrument tracking system, cannot produce any output, for example, the system detects the action “cut” and the anatomical structure but not whether the instrument is a scalpel or the scissors. In this situation, multiple paths must be followed until a unique path is found. An example is given in Fig. 4. On the left side, a fully defined iSPM and the corresponding gSPM are depicted. During the course of the intervention, simulated by the iSPM, the WFMS was able to find a corresponding activity in the gSPM for each activity of the intervention. On the right side of Fig. 4, on task two of the iSPM, the perspective b is corrupted (marked with the underscore). From that, two possible process states in the corresponding gSPM can be found. The WFMS must follow the two possible paths until a unique entry point can be found.

System evaluation study design

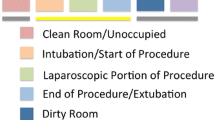

Cataract operations for the surgical treatment for glaucoma [18] were used as the data for the study, as they are one of the most frequently performed eye surgeries in Germany. For the study, 100 cataract operations were recorded as described below. The operations consisted mainly of four different phases. First, the anterior capsule is opened and then the opacified lens is removed, after that the artificial intraocular lens is implanted, and finally, viscoelastic material used to support the operation is removed. All the operations were performed by three different surgeons at the University Hospital Leipzig, Germany.

The recordings of the iSPMs were made by means of a method developed at the ICCAS institute for the generation of surgical process models. This method is based on the recordings of trained medical students. The recordings were used to simulate the interpreted sensor data. In [12], this method is described in detail and explains the assurance of a valid and accurate process model. The students used the ICCAS surgical workflow editor to record the operation step by step. The ICCAS Surgical Workflow Editor is a piece of software developed specifically for this task and operates on a tablet PC with pen input. After recording and analyzing the iSPMs, a total of 120 individual surgical tasks could be defined. Thus, a gSPM consists of a maximum of 120 tasks.

In order to test the reliability of the workflow schema that was generated from iSPMs, two criteria were selected as dependent variables. The first criterion was the identification of a successful entry point. This variable tests the model with respect to the existence of a point at which the system can converge back to the correct path. The second criterion was the number of activities sent by the process monitor that was needed to successfully track the path again. With the combination of these variables, a statement can be made about how long it takes to locate a unique path in the model.

The study was guided by the following procedure: first, iSPMs were randomly chosen from the SPM database to create a gSPM as a test set, first from 10 %, then from 20, 30, up to 100 % of the available iSPMs. The gSPM was then tested against 10 disjoint iSPMs from the database. To guarantee the highest possible randomization of the study, the aforementioned steps were repeated 250 times (Fig. 5). Based on 250 runs, 10 different test-set sizes, six intervention phases, 10 tested iSPMs, and the gradual deletion of three different perspectives, 450,000 records were produced.

Results

In this validation study, we investigated how many iSPMs were needed to build up a generalized model of the process to successfully relocate the path in the model after it was lost. This was to gain knowledge of the variation of the model. In order to do that, the number of iSPMs to build the gSPM was varied. The number of steps required to converge was also recorded. We also investigated the influence of the perspectives on successful path location. Our dependent variables were the rate of locating a path, the steps needed to locate it, and the deleted perspective.

In Table 2, the “Test-set size” column indicates the variation of the test set used to generate the gSPM. Columns “Success rate of path location” and “Number of step to find the converging point” are subdivided according to the observed perspective of the process. The columns inside of the “Success rate of path location” section display the mean success rate as a percentage, the standard deviation, and the maximum and minimum. Correlating to this, the column “Number of step to find the converging point” in Table 2 shows the number of steps required to locate the path dependent on the number of iSPMs used to build the gSPM and the deleted perspectives.

In Fig. 6, the average success rate is shown dependent to the deleted perspective and size of the learning set. For example, with the deleted perspective “instrument,” the success rate drops from \(95\,\%\pm 6.78\,\%\) to \(92.88\,\%\pm 8.15\,\%\) when the learning-set size is reduced from 80 to 50 %.

Figure 7 shows the decline in the number of the steps needed to locate the paths with respect to the learning-set size. For instance, when using 70 % of the iSPMs to create the gSPM and deleting the perspective instrument, \(1.81\pm 0.36\) steps are needed to locate the path in the model again. The decline of these values results from the lower success rate of locating a path in the model.

Discussion

In this work, we tested a process model created from patients’ individual models with respect to the relevance of the completeness of sensor information to monitor the process. It was possible to determine how many steps were needed to resume the process flow after losing track of the path.

The inductive model, i.e., the fusion of many patient-specific process models, already takes into account the fact of the high variability of surgical procedures during its creation. In the resulting model, all possible process variations can be shown.

Exactly 100 models of individual cataract surgery operations were used for the study. These interventions were recorded by trained medical students using the ICCAS workflow editor. The cataract surgery offered a good basis for the study through its frequency and high degree of linearity. Because of the high degree of formalization and automation in conducting this study, any other operations available as individual process models could be tested equally.

In our validation study, we investigated how many individual iSPMs were needed to create a robust gSPM as a basis for a workflow schema that can relocate the path in the model after it was lost due to a variation in the actual process. Furthermore, we investigated how long it would take to locate the path again. We showed that even with a small set of only 30 % of iSPMs, a workflow schema could be generated that finds the path more than 90 % of the time. Since the model built from the iSPM should reflect the cataract surgery at the University Hospital in Leipzig, we did not created a surgeon-specific model. In the future, this model could be approved by being more specific in choosing iSPM for its creation, for example, all selected iSPMs are from one surgeon, from patients with similar preconditions, and similar age.

We showed that correct information of all three perspectives is crucial for successful process tracking. The data also show that the functional and spatial perspectives are more sensitive with respect to missing information. Missing information in these perspectives leads to more interruption of process tracking and poorer detection of convergence points. We did not investigate to which extend a specific action or a specific anatomical structure influences this. The operational perspective in comparison is less sensitive to missing information. This could be because a certain action can be performed with more than one instrument but not vice versa (e.g., cutting can be executed with a scalpel or the scissors but you can only cut with the scalpel or the scissors). This leads to more unique actions in the gSPM even if the operation perspective is missing.

There are a variety of potential uses for a surgical workflow management system in the operating room of the future. For example, the correct information could be displayed at the right place at the right time, the relevant devices can be automatically parameterized, and the remaining duration of the operation can be estimated and thus the next patient can be prepared at the right moment. Prerequisites for all of these potential applications however are the presence of high-quality models of the operation and correctly interpreted sensor information.

Through this study, it was shown that an inductively created process model can serve as a valid basis for a surgical WFMS. Even after losing track of the path, in most cases, a convergence point could be found.

Conclusion

The creation of a process model that represents a surgical procedure accurately but is also robust to variance is a challenging task. Inductive creation of a process model has proven itself to be a method which takes in account the different needs.

The aim of this study was to validate generalized process models that were generated by using many patient-specific process models. This validation took place by finding the number of required steps to return to the valid path after diverging. In addition, which perspectives of the process model are particularly important during the process observation were determined. About 100 models of cataract surgery were used to create a generalized process model. In addition, a system was developed that supports the processing of the above questions. We showed that the functional and the spatial perspectives were almost equally important with respect to successfully reconverging on the path in case the process tracking was interrupted.

We showed that such models can be a valid solution to the problems of high variability in tracking surgical procedures.

References

Lemke H, Vannier M (2006) The operating room and the need for an IT infrastructure and standards. Int J Comput Assist Radiol Surg 1:117–121

Neumuth T, Liebmann P, Wiedemann P, Meixensberger J (2012) Surgical workflow management schemata for cataract procedures. Process model-based design and validation of workflow schemata. Methods Inf Med 51:371–382

Neumuth T, Meißner C (2012) Online recognition of surgical instruments by information fusion. Int J Comput Assist Radiol Surg 7:297–304

Neumuth T, Jannin P, Schlomberg J, Meixensberger J, Wiedemann P, Burgert O (2010) Analysis of surgical intervention populations using generic surgical process models. Int J CARS 6:59–71

Welker A, Wolcke B, Schleppers A, Schmeck SB, Focke U, Gervais HW, Schmeck J (2010) Ablauforganisation im Operationssaal. Anaesthesist 59:904–913

Cone SW, Leung A, Mora F, Rafiq A, Merrell RC (2006) Multimedia data capture and management for surgical events: evaluation of a system. Telemed J E Health 12:351–358

Suzuki T, Sakurai Y, Yoshimitsu K, Nambu K, Muragaki Y, Iseki H (2010) Intraoperative multichannel audio-visual information recording and automatic surgical phase and incident detection. In: Conference, proceedings of IEEE Engineering in Medicine and Bioloy Society 2010, pp 1190–1193

Kranzfelder M, Schneider A, Gillen S, Feussner H (2010) New technologies for information retrieval to achieve situational awareness and higher patient safety in the surgical operating room: the MRI institutional approach and review of the literature. Surg Endosc 25:696–705

Krishnamurthy AH, Ravikumar R (2006) Fault tolerance in automotive systems. Sens Actuator A 132:370–375

Hoseinnezhad R, Bab-Hadiashar A (2005) Missing data compensation for safety-critical components in a drive-by-wire system. IEEE Trans Veh Technol 54:1304–1311

Workflow Management Coalition (1999) Terminology & glossary. Document number WFMC-TC-1011, Document Status—issue 3.0

Neumuth T, Jannin P, Strauss G, Meixensberger J, Burgert O (2009) Validation of knowledge acquisition for surgical process models. J Am Medi Inform Assoc 16:72–80

Van der Aalst WMP, Ter Hofstede AHM (2005) YAWL: yet another workflow language. Inf Syst 30:245–275

Van der Aalst WM, Aldred L, Dumas M, Ter Hofstede AH: Design and implementation of the YAWL system. In: Proceedings of the 16th international conference on advanced information systems engineering. Springer, Verlag, pp 142–159

PostgreSQL: The world’s most advanced open source database. http://www.postgresql.org/

The R project for statistical computing. http://www.r-project.org/

IBM SPSS Software für predictive analytics—Deutschland. http://www-01.ibm.com/software/de/analytics/spss/

Kataraktoperation: Risikominderung einer Blutung bei oraler Antikoagulation (10.01.2005). http://www.aerzteblatt.de/archiv/44945

Acknowledgments

The authors thank the team that supported the performance of the study and the preparation of the article at the Innovation Center for Computer Assisted Surgery, University of Leipzig: Caroline Elzner, Michael Thiele, and Alexander Oeser. ICCAS is funded by the German Federal Ministry of Education and Research (BMBF) and the Saxon Ministry of Science and Fine Arts (SMWK) in the scope of the Unternehmen Region with grant numbers 03 ZIK 031 and 03 ZIK 032 and by funds from the European Regional Development Fund (ERDF) and the state of Saxony within the framework of measures to support the technology sector.

Conflict of Interest

The paper is not, nor was it previously, under consideration by any other journal. The funding sources had no involvement in the study design, data collection, analysis or interpretation of the results, or in the writing of the report. All authors have no conflicts of interest. The decision to submit the paper for publication was ours alone.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liebmann, P., Meixensberger, J., Wiedemann, P. et al. The impact of missing sensor information on surgical workflow management. Int J CARS 8, 867–875 (2013). https://doi.org/10.1007/s11548-013-0824-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11548-013-0824-8