Abstract

Clothing with conductive textiles for health care applications has in the last decade been of an upcoming research interest. An advantage with the technique is its suitability in distributed and home health care. The present study investigates the electrical properties of conductive yarns and textile electrodes in contact with human skin, thus representing a real ECG-registration situation. The yarn measurements showed a pure resistive characteristic proportional to the length. The electrodes made of pure stainless steel (electrode A) and 20% stainless steel/80% polyester (electrode B) showed acceptable stability of electrode potentials, the stability of A was better than that of B. The electrode made of silver plated copper (electrode C) was less stable. The electrode impedance was lower for electrodes A and B than that for electrode C. From an electrical properties point of view we recommend to use electrodes of type A to be used in intelligent textile medical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Biomedical clothing and conductive textiles (also referred to as smart textiles and e-textiles) have in the last decade been of an upcoming research interest. Conductive textiles enable development of smart garments, which are desirable both in health care and military applications, e.g. monitoring of physiological parameters [5, 11–14]. The possibility of knitting or weaving conductive yarns into electrodes, with the advantage of being comfortable and integrated in clothes, make them particularly usable in situations such as long-term monitoring and in home health care [4, 7, 16, 17, 19]. The advantages of such sensors have been thoroughly discussed. However, the performance of such electrodes compared to traditional electrodes is not yet fully investigated.

This study aims to investigate the electrical characteristics of three different conductive yarns (resistance) and three different textile electrodes applied to the skin (impedance and polarization potential) in order to determine their suitability as ECG-electrodes.

2 Theory

When using skin electrodes, an electrode gel is placed as a contact medium between the skin and the electrode. The electrolyte and the electrode create a galvanic cell with a half cell polarization potential which adds to the original potential difference. The addition due to polarization potential can be described by the Nernst equation [8].

where E 0 i is the potential of the materials compared to the standard hydrogen electrode, R the molar gas constant, T the temperature, n the number of valence electrons in the metal, F the Faraday constant and a i the electrolyte concentrations.

By choosing stable electrode materials and suitable gel electrolytes, the difference E and especially the time fluctuation of this difference can be minimized.

There is also liquid junction potentials between the electrode gel and the subcutaneous body electrolytes, given by a version of the Nernst equation [8]:

where u + and v − are the mobilities of the cation and anion and C i electrolyte concentrations. The junction potential is low if the mobility difference between cations and anions is small [8].

When the electrode conveys a current from the body, the ionic current induces a varying potential in the skin electrode with a negative phase angle. The phase shift is due to the charged layer in the transit between the electrode and the electrode gel. The impedance of the electrodes can be described as a resistance in series with a capacitance, where the capacitance varies as C ∼ f −α, where α is a constant [8].

Electrically, the skin acts as a barrier between the surface and the interior of the body and it can be modeled as in Fig. 1. R 0 is the resistive part of the skin, C is the skin capacitance and R is the surrounding tissues resistance. R 0 and C are highly dependent on the skin preparation. If the outer layer of stratum corneum is removed for example by rubbing the skin, R 0 decreases and C increases. When the skin is moistened it is mainly R 0 that will be decreased [8].

3 Methods

The electrical properties of three yarns and three corresponding textile electrodes were investigated.

3.1 Yarns and electrodes

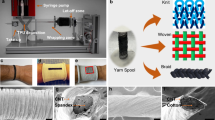

Three commercially available yarns (A–C) with varying metal rates and construction techniques were chosen for the investigation. Three electrodes (Electrodes A–C) were produced by weaving or knitting one out of each yarn. Yarn A (Beakart Bekinox VN tex, 500/f275/2) consists of multifilaments of 100% stainless steel and the corresponding electrode, electrode A, is plain knitted. Yarn B (Beakart Bekitex BK 50/2, dtex 400) consists of 20% stainless steel and 80% polyester and is spun of a mixture of short staple fibers. Electrode B is wave knitted resulting in a corrugated structure. Yarn C (Swiss Shield CUPES-L 54 nm, dtex 185) has a core of polyester fibers with a monofilament of silver plated copper twined around it and electrode C is a woven fabric. The yarns and electrodes are presented in Fig. 2.

Yarn A consists of twined filaments of 100% stainless steel. Electrode A is plain knitted (top). Yarn B consists of 20% stainless steel and 80% polyester staple fibers. The gray staples are the stainless steel fibers. Electrode B is wave knitted and has a corrugated structure (middle). Yarn C is made out of a core of polyester and a single twined silver plated copper wire. Electrode C is a woven fabric (bottom)

3.2 Measurement setup

The first measurement aimed to investigate how the resistance of a single thread varies with thread length, tension and frequency. The resistance of yarns A–C was measured over three lengths (50, 100, and 150 cm) and three tensions (weights 0, 50, and 200 g) and five frequencies (1, 10, 100 Hz, 1 and 10 kHz). Measurements were repeated for two or three samples from each yarn. The investigated yarn was suspended to a rigid support allowing the thread to hang vertically in the air. At the bottom, a weight was applied to obtain a well defined tension in the thread. Sinusoidal signals were fed to the system from a signal generator (model 123, Exact Electronics, Inc, USA). The measurements were made by an Universal Impedance Bridge (Model 250DE, Electro Scientific Industries).

In the second measurement, the polarization potential and electrode impedance for electrodes A–C were measured. The textile electrodes (5 cm2) were moistened with a physiological saline solution (0.9% NaCl). The electrodes were then positioned on the thigh of the test person and held in place with an elastic rib top fabric made out of a non-conducting material. The distance between the electrodes was 5 cm. After each measurement of polarization potential and impedance, the electrodes were moved 5 cm to include effects of local variations in skin properties. Measurements were performed in ten positions for each textile electrode (five on each leg). Standard electrodes (Unilect longterm Ag/AgCl electrodes, Unomedical Ltd, GB) were placed above the knee for reference measurements.

Polarization potentials were measured with a Metrahit 15 s multimeter (ABB Metrawatt, Germany) with input impedance of 10 MΩ by measuring the potential between the two electrodes. The potential difference was registered every minute for 30 min for each position resulting in ten measurement series for each material.

A schematic view of the impedance measurement setup is shown in Fig. 3. A signal generator (model 123, Exact Electronics, Inc., USA) fed the circuit with a sinusoidal voltage. Investigated frequencies were 10, 100, 500 and 1,000 Hz. The current density through the electrode was limited to 0.3 mA/cm2. For each frequency a gain phase meter (3575A, Hewlett Packard, USA) gave the phase shift φ and magnitude quotient Q (in dB), over the electrodes relative to the resistive reference load R ref. The electrode impedance \( \overline{Z} , \) was calculated using the following relation:

3.3 Data processing

All obtained data were processed and visualized using Matlab (version 7.0, Mathworks Inc, USA). The stability of the polarization potentials were studied as the mean polarization drift in a measurement series calculated as:

resulting in ten mean values for each electrode type.

4 Results

4.1 Thread resistance

Thread resistance is constant while changing the frequency, implicating the threads to be purely resistive in the investigated range, see Fig. 4 (top). Yarns A and C have a linear relation to the length with a resistance of 15 and 30 Ω/m, respectively and the applied tension does not affect the resistance. For yarn B the resistance changes both with the length and the tension and a relatively large variation between different samples and measurements is observed, see Fig. 4 (middle and bottom). For no tension the result varies between 5 and 10 kΩ for the 150 cm long yarn sample. When stretched with a weight, the impedance scatter is reduced to 250 Ω. Yarns A and C show a distinct value for different lengths regardless of the weight applied Fig. 4 (bottom).

Resistance plotted versus the frequency (top). The samples were 1 m long and stretched with a 50 g weight. Resistance plotted versus the length of the samples (middle). The full line represents the yarns under no strain and the dash dotted and the dotted lines represent the tension of 50 and 200 g, respectively. For yarn C the 200 g series is missing since the samples broke. Resistance plotted versus the applied force (bottom). The dotted line represent the 150 cm samples and the dash dotted and the full line represents 1 and 0.5 m, respectively

4.2 Polarization potential

The mean polarization drift for the electrodes as described in the data processing section is shown in Fig. 5 (left). Electrode A is the most stable of the textile electrodes but shows a somewhat larger drift than the reference electrode. Electrode B shows a varying mean polarization potential between 2 and 4 mV/min, while electrode C has a variation between 4 and 16 mV/min.

Figure 5 (right) shows the polarization potential for the textiles and the reference electrodes. The plot shows the median value (when outliers are excluded). The box represents the upper and lower quartiles and the whiskers show the rest of the data content. Outliers (+) were defined as measurements that deviate more than one and a half time the interquartile range from the box. As can be seen in the plot, the results from electrode C show a wide range, while electrode A and B show similar results. The outliers for electrode B, all originate from one measurement series. The reference electrode shows the best results with the lowest median value.

4.3 Electrode impedance

The impedances in this frequency range are 0.5–2 × 105 Ω for electrodes A and B and generally the values are less scattered for higher frequencies (Fig. 6).

Overall, electrode C has the largest spread of results. Reference electrodes have the lowest impedance but the difference between this electrode and electrodes A and B is limited to a factor of 2.

The phase shift shows capacitive properties which stabilize with increasing frequency. Electrode C has the lowest phase shift, whereas, electrode A and the reference electrodes have the highest.

5 Discussion

The usability of a measurement garment is strongly related to the signal quality of the obtained bioelectric signal. As in conventional ECG-recording, the electrodes can be expected to be the weakest link. To obtain adequate electrode properties of smart textiles, the electrochemical factors that determine the electrode potential and liquid junction potential have to be considered in a similar way as for regular electrodes. Furthermore, the theory behind the electrode impedance has to be known. We have shortly presented this theory as a background for the measurements and as a help to interpret the results. The study investigates the electrical characteristics of the yarns and textile electrodes. Electrodes A and B showed performance characteristics close to regular ECG electrodes, but electrode C was considerably worse. Overall, electrode A showed the best electrical characteristics of the textile electrodes.

In ECG-measurements, the electrode impedance is in series with the input resistance of a differential amplifier. A possible adverse effect of a high electrode impedance, is that the suppression of line interferences, decreasing due to a reduction of the effective common mode rejection ratio of the amplifier [6]. Even for monitoring ECG, the line interference can not be totally avoided by filtering since the range of R-wave frequency content coincide with line frequency. An electrode impedance up to 50 kΩ at 50 Hz is probably acceptable [1]. The impedance for electrodes A and B are substantially lower than 50 kΩ at this frequency, while the impedance for electrode C is higher, typically 150 kΩ.

The polarization potential and junction potential must be stabile enough so that the fluctuations do not interfere with the ECG signal. For regular electrodes, this is usually taken care of by appropriate choice of material (e.g. Ag/AgCl) and by suppressing these disturbances using a high pass filter. For example the American Heart Association recommends filtering a diagnostic ECG with a bandpass filter with cut-off frequencies at 0.05 and 100 Hz [10].

We studied the mean polarization potential drift per minute. If this disturbance comes from low frequencies (with durations longer than 20 s), they will be suppressed by the filter. However, even small variations can pose problems if the frequency coincides with the heart rate. A diagnostic ECG should be able to cover a low rate of 40 bpm. Distributing the polarization potential drift evenly over the heart beats gives an amplitude change of 5, 13 and 40% of 1 mV R-wave amplitude, for electrodes A, B and C, respectively. The corresponding value for the reference electrode is <3%. From this it can be concluded that electrode A is the most stable, B seems to have an acceptable polarization drift even under these worst case circumstances, while electrode C has a possible drift that may disturb the ECG interpretation. The results for electrode C were expected since the polarization potential of silver and copper has poor stability [8]. However, the potential drift might be reduced if the conductive filament is coated with a layer of silver chloride, which can be interesting to consider in further studies.

Our impedance measurement of yarn A–C shows similar results as presented in other studies [3] and by the manufacturer. Our main contribution in this study is the data on how the yarns react to different tensions and frequencies. Interesting to note is that the yarn B has shown quite high impedance whilst the impedance of the corresponding electrode, electrode B, is comparable to electrode A. A probable explanation is that, when the material is knitted, the number of contact points between the conducting metal staples within the yarn is increased as well as the contact area between the knitted loops, causing a parallel shunting of the current and hence reduces the resistance.

Skin impedance can alter greatly between locations due to varying thickness and composition of the stratum corneum [18]. To include such influences and get consistent measurements, electrodes were placed in different measurement sites. Measurements were performed on the thigh since it allows a relative large area of skin with similar characteristics [1]. The large variation in skin impedance might be an explanation to the presence of outliers presented in Figs. 5 and 6.

Preferably, electrodes should be used without any preparations to increase the usability despite the fact that the perspiration might substantially reduces the impedance. Wijesiriwardana et al. [19] showed, however that, dry electrodes performed better under long-term conditions than moistened. If the electrode is covered with an impermeable membrane, the body vapor is captured and will function as an electrolyte. Grimnes [9] showed that it is mainly the perspiration duct that conducts the ions through the skin, resulting in a favorable measurement situation under the presence of perspiration. This is in accordance with a study in the University of Ghent [15], where a model of the skin- electrode impedance has been investigated under dry and perspiratory circumstances. With our measurement setting and protocol, we observed highly varying impedances for dry electrodes. The final approach, however, included slightly moistened electrodes with a physiological saline solution as a model of a coated electrode.

An approach which has been used to reduce the skin-electrode impedance is to use a membrane of hydrogel as an interlayer between the skin and electrode [2, 13, 16]. The hydrogel has the advantage of being an ionic medium and can at the same time behave as a solid material. The disadvantage is that these membranes eventually will dry out and need to be replaced. On the other hand it is more durable than by merely moistening the electrode. An advantage of the hydrogel is that the electrochemical contact is established instantly and one does not have to wait for the accumulation of sweat.

6 Conclusion

Impedance measurements have been performed on both yarns and textile electrodes and the polarization potential has been investigated for the electrodes. The yarns showed a purely resistive characteristic and their comparably low resistance enables their use in textile electrodes. The electrode measurements show that both electrode A (multifilaments of 100% stainless steel) and B (staple yarn of 20% stainless steel and 80% polyester) seem to fulfill the required electrode potential stability, where electrode A is the most stable. Electrode C (polyester core with a monofilament of silver plated copper) on the other hand seems not to have the desired stability. In terms of electrode impedance, electrodes A and B have lower values than electrode C. We therefore consider electrode A as the best choice from an electrical properties point of view under the given circumstances.

References

Ask P, Öberg PÅ, Ödman S, Tenland T, Skogh M (1979) ECG electrodes, a study of electrical and mechanical long-term properties. Acta Anaesth Scand 23:189–206

Axisa F, Schmitt PM, Gehin C, Delhomme G, McAdams E, Dittmar A (2005) Flexible technologies and smart clothing for citizen medicine, home healthcare, and disease prevention. IEEE Trans Inf Technol Biomed 9:325–336

Berglin L (2006) Interactive textile structures in Department of Computer Science and Engineering, vol. Licenciate. Gothemburg: Chalmers University of Technology

Bonfiglio A, De Rossi D, Kirstein T, Locher IR, Mameli F, Paradiso R, Vozzi G (2005) Organic field effect transistors for textile applications. IEEE Trans Inf Technol Biomed 9:319–324

Catrysse M, Puers R, Hertleer C, Van Langenhove L, van Egmond H, Matthys D (2004) Towards the integration of textile sensors in a wireless monitoring suit. Sens Actuators A Phys 114:302–311

Cobbold RSC (1974) Transducers for biomedical measurements: principles and applications. Wiley, New York

Cottet D, Grzyb J, Kirstein T, Troster G (2003) Electrical characterization of textile transmission lines. IEEE Trans Adv Packag 26:182–190

Geddes LA (1972) Electrodes and the measurement of bioelectric events. Wiley, New York

Grimnes S (1984) Pathways of ionic flow through human skin in vivo. Acta Derm Venereol 64:93–98

Kligfield P, Gettes LS, Bailey JJ, Childers R, Deal BJ, Hancock EW, van Herpen G, Kors JA, Macfarlane P, Mirvis DM, Pahlm O, Rautaharju P, Wagner GS (2007) Recommendations for the standardization and interpretation of the electrocardiogram: part I: the electrocardiogram and its technology: a scientific statement from the american heart association electrocardiography and arrhythmias committee, council on clinical cardiology; the american college of cardiology foundation; and the heart rhythm society endorsed by the international society for computerized electrocardiology. Circulation 115:1306–1324

Noury N, Dittmar A, Corroy C, Baghai R, Weber JL, Blanc D, Klefstat F, Blinovska A, Vaysse S, Comet B (2004) A smart cloth for ambulatory telemonitoring of physiological parameters and activity: the VTAMN project

Ottenbacher J, Römer S, Kunze C, Grossman U, Stork W (2004) Integration of a bluetooth based ECG system into clothing. Presented at international symposiom on wearable computers

Paradiso R, Loriga G, Taccini N (2005) A wearable health care system based on knitted integrated sensors. IEEE Trans Inf Technol Biomed 9:337–344

Park S, Jayaraman S (2003) Enhancing the quality of life through wearable technology. IEEE Eng Med Biol Mag 22:41–8

Priniotakis G, Westbroek P, Van Langenhove L, Kiekens P (2005) An experimental simulation of human body behavior during sweat production measured at textile electrodes. Int J Cloth Sci Technol 17:232–241

Scilingo EP, Gemignani A, Paradiso R, Taccini N, Ghelarducci B, De Rossi D (2005) Performance evaluation of sensing fabrics for monitoring physiological and biomechanical variables. IEEE Trans Inf Technol Biomed 9:345–352

Sergio M, Manaresi N, Tartagni M, Guerrieri R, Canegallo R (2002) A textile based capacitive pressure sensor. Sens Lett 2(2):153–160

Treager RT (1966) Physical functions of the skin. Academic, London

Wijesiriwardana R, Mitcham K, Dias T (2004) Fiber-meshed transducers based real time wearable physiological information monitoring system. Presented at eighth international symposium on wearable computers

Acknowledgments

This work is supported by a fund of the Swedish Governmental Agency for Innovation Systems (VINNOVA).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rattfält, L., Lindén, M., Hult, P. et al. Electrical characteristics of conductive yarns and textile electrodes for medical applications. Med Bio Eng Comput 45, 1251–1257 (2007). https://doi.org/10.1007/s11517-007-0266-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11517-007-0266-y