Abstract

The temperature and composition of food, during the printing process, maybe a key factor impacting on rheological properties. Currently, there is no evidence of authors analysing the effect of printing temperature on the characteristics of final products. The aim of this paper was to study the printability of potato puree when affected by printing variables, such as printing temperature and the composition of the potato puree. The printing temperature was studied at 10 °C, 20 °C and 30 °C, and the effect of the product composition on the printability was studied by analysing the rheological and textural properties. Viscosity-temperature profiles, flow curves and dynamic oscillation frequency analysis of potato puree were some of the techniques used in rheology analysis. Forward extrusion assays of formulated potato puree were used to study the compression force in the 3D printer. Results showed the formulation with higher content of dehydrated potato puree (38 g of dehydrated potato puree in 250 mL of whole milk) at a temperature of 30 °C were the most stable. The printability increase with the amount of the consistency index and the reduction of behaviour index. The mean force from extrusion test was correlated with printability but the effect of temperature did not help define this parameter.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

More and more companies and research institutes are working on improving the extrusion-based food printing technology, so as to commercialise new digital cooking devices in kitchens and promote innovative design and healthy lifestyle [24]. For food manufacturing, 3D printing offers the possibility to completely renewing food processing and food personalisation. Consumer’s choice to purchase food is guided by the following criteria: appearance, taste, cost, experience, convenience and nutrition. 3D food printing (3DFP) is capable to satisfy all these criteria, with manufacturing personalised/customised food for specific consumer groups (children, older people, pregnant women, teenagers, athletes, etc.) both in term of sensorial and nutritional properties [20]. However, the available applications are still primitive and need further investigation. The printing of a complex food formula with a desired 3D structure is a challenging task. Even if we only pay attention to the reproducibility of the 3D structure, known as printability, the knowledge of rheological properties of food formulas and the optimisation of printing variables are key factors [5]. The term printability is defined as the properties that allow the material to be handled with dimensional stability capable of supporting its own weight [6]. Consequently, high-printability enables the fabrication of constructs with geometric complexity thereby increasing the applicability of 3D printed food for artistic design with customised shape and controlled texture [13]. Various kinds of foods have been used to print complex structures, such as pasta, hydrogel, cake frosting, cheese, hummus, and chocolate [23].

However, the correlation between the rheological properties of food material and 3D printing behaviour have not been widely investigated [14, 15]. During the extrusion process, the rheological properties of materials are critical for providing efficient extrudability, the ability for binding different layers of foodstuff together and support for the weight of deposited layers. In food printing, soft materials, such as dough and meat paste, have been utilized to print 3D objects [6, 28]. Apparent viscosity (ηap) is an important factor, which should be low enough to allow for easy extrusion and high enough for extruded food to adhere to previously deposited layers [16, 17]. Until recently, limited information on the effects of printer variables, such as the temperature of food, travel speed, print speed, infill levels and layer height, on the printing performances of the food were available [20]. Nevertheless, currently an increasing amount of research studying rheological aspects and the effect of printing conditions on the characteristics of several printed food, such as snacks, potato puree, lemon juice gel, surimi, vegetables, sauces and processed cheese have been carried out ([5, 7, 8, 10, 16, 17, 21, 26]). These authors reveal the increasing interest in this area, to obtain information about printing parameters and physicochemical properties of food that allows improvement of food printers. There are several conditions that need to be optimized in 3D food printing, including proper use of mechanical force, careful design of the digital recipe, and suitable feeding ingredients. For different food formulations different pressures are necessary to be applied, also sometimes room temperature may affect the food mixture flow rate through the food nozzle [12]. While determining the food recipes, the properties of food materials should be considered as having a high strength to fit the needs of printability [25]. There are other studies that use potato in 3D printing [3, 4, 16, 17], but they did not analyze the effect of printing temperature on characteristics of final products. The temperature of food during the printing process may be a key factor in rheological properties. Currently, there is no evidence of analysis studying the effect of printing temperature on the characteristics of the final product associated with rheological properties of the food.

The main aim of this paper was to study the printability of potato puree when affected by printing variables, specifically, the printing temperature as well as the composition of the product studied by analysing the rheological and textural properties.

Material and Methods

Raw Materials

Commercial dehydrated potato puree (Alcampo) and whole milk (Alcampo) were purchased from the local supermarket (Alcampo, Aldaia, Spain). Three potato puree formulations were prepared (Table 1) according to the following ratio: 250 mL of whole milk heated to 40 °C, to which potato powder was added and stirred until a puree was formed. The proximal compositions of formulations are shown in Table 1. Subsequently, all samples were placed in a thermostatic bath, and the temperature was maintained at 10, 20 or 30 °C prior to the printing process and rheological/textural measurements.

Rheological Characterization

The rheological measurements were performed with a rheometer (Kinexus pro+, Malvern Instruments, Worcestershire, UK) controlled with commercial computer software (rSpace, Rheometry software for Kinexus). Samples were analysed for their flow properties using 25 mm plate-plate geometry (DSR II, Upper Plate) with a 1 mm gap between the plates and a heat-controlled sample stage (Peltier Cylinder Cartridge, Malvern Instruments, Worcestershire, UK). For each test, the measured volume of sample (approximately 2 mL) was placed at the bottom plate of the rheometer. The upper plate was lowered, and the excess sample was trimmed off. After loading, samples were rested for 2 min prior to testing (samples were previously tempered in a thermostatic bath). Steady rotational tests were conducted at different temperatures (10, 20 and 30 °C). Viscosity profiles of potato puree were obtained by ramping the shear rate (\( \dot{\gamma} \)) from 0.1 to 100 s−1. Also, temperature sweeps of potato puree were done at a constant shear rate of 50 s−1 while increasing the temperature from 10 °C to 50 °C at a rate of 2 °C/min. The apparent viscosity (ηap) and shear stress (σ) was measured and plotted as a function of the shear rate. The resultant curve was fitted to a Herschel-Bulkley model (Eq. 1) and used to calculate the consistency (k) flow behaviour index (n) of the materials at different temperatures. Equation 2 was used to calculate apparent viscosity (ηap) at a shear rate of 50 s−1.

Where:

k = consistency coefficient (Pa sn); n = flow behaviour index (dimensionless); σ0 = yield shear stress (Pa); σ = shear stress (Pa); \( \dot{\gamma} \) = shear rate (s−1); ηap = apparent viscosity (Pa s).

Dynamic oscillation frequency analysis was conducted at a constant deformation (0.03% strain) within the linear viscoelastic range with the frequency of 0.01 to 100 Hz. The mechanical spectra were obtained recording the G’ and viscous modulus (G”) as a function of frequency (Liu, Zhang, Bhandari, et al., 2018).

The results were reported as the average of three replicates (a new sample was loaded for each repetition).

Instrumental Texture Assessment

The evaluation of extrudability of the potato puree was performed with the use of a texture analyser (model TA-XT2, Stable Micro System Ltd., Leicestershire, UK), with the “Forward Extrusion Cell” attachment (HDP/FE). A cylindrical measurement chamber of 50 mm diameter × 110 mm height and a piston with 50 mm diameter were used. The chamber was filled with potato puree to 40 mm height, the piston was placed at 40 mm height (in contact with the sample) and moved 20 mm down, compressing the sample. The sample was extruded through a hole of 4 mm diameter. The maximum force (N) needed to move the piston 20 mm, the mean force applied in the process (N) and the area under the curve force-time (N s) were measured. The parameters were presented as follows: pre-test speed of 2 mm/s, the test speed 2 mm/s, the post-test speed 2 mm/s, trigger force 5 g. Separate measurements were made at controlled temperatures (10, 20 and 30 °C) using a cooling coil to cover the cylindrical measurement chamber connected to a circulating water bath (Heidolph rotacool chiller, Heildolph, Ilinois, USA). Temperatures of the samples were measured during the test. The measurements of the texture were performed three times for each sample.

Printing Process

A commercial 3D printer (BCN 3D+, BCN3D Technologies, Barcelona, Spain) equipped with a paste extruder nozzle to work with food materials (Paste extruder, BCN3D Technologies, Barcelona, Spain), was used for this investigation. The 3D printing system composed of the following two major parts: an extrusion system (syringe) and an X-Y-Z positioning system using stepper motors. A hollow squared column (40 × 40 mm base by 80 mm height) with two external perimeters and infill in the first layer was extruded at varying temperatures. The figure was created with an online commercial program (Thinkercad, Autodesk, Inc., San Rafael, California, USA). The motion and positioning control was provided by a computer program (Slic3r, free software, developed by Alessandro Ranellucci with the help of contributors and community) to provide g-code files to the printer. The printing process was conducted at different temperatures (10, 20 and 30 °C) using a cooling coil to cover the cylindrical measurement chamber connected to a circulating water bath (Heidolph rotacool chiller, Heildolph, Ilinois, USA) (Fig. 1a). The nozzle height was adjusted so the whole feeding device was 2 mm away from the printing bed, for successive layers was 1 mm could be extruded. The pressure exerted on the sample was applied via the extruder piston. The samples were extruded onto a plastic polymer plate using nozzles of circular shape with a diameter of 2.0 mm. To assess the effects on the extruded geometry, line tests were used where lines of the sample were extruded at varying extrusion rates, with the same movement rates, as to determine the appropriate extrusion speed, these conditions were fixed to 15 mm/s for the bed and 30 mm/s for the successive layers. The percentage of execution (percentage of g-code file executed) was taken as a reference to evaluate the effectivity of the printing conditions (temperature and composition of the potato puree). A value of 100% indicates that the figure was totally built. This percentage is shown on the printer display (Fig. 1b). The printing process was supervised to ensure a correct execution of the figure (Fig. 1c). The end of the printing process was determined when the deposition of the product does not correspond exactly with the bottom layer (Fig. 1d). Three figures were printed for each condition (temperature and composition of the potato puree).

Statistical Analysis

Two-way analysis of variance (ANOVA) was performed and mean comparisons were run by Fisher’s Least Significant Difference (LSD) test using the Statgraphics Centurion XVI system for Windows 10.0 (Statpoint Technologies, Inc., Warrenton, Virginia, USA). Significant differences (p < 0.05) between the mean values of samples were determined.

Results and Discussion

Rheological and Viscoelastic Behaviour

Rheological properties of foods are important indexes to judge their printability [16,17,18]. Rheological studies were used to investigate suitable viscosities for the 3D printing of potato puree into shapes that can retain their structure post-printing. Viscosity profiles of potato puree with different quantity of potato formulation with varying temperatures (Fig. 2) show the expected behaviour of decreasing viscosity (η at a constant shear rate of 50 s−1) with increasing temperature [7]. The effect of temperature on rheological proprieties can be a parameter to consider in 3D printing and its control must be considered in the design of printers. For the potato puree used in this study, the apparent viscosity should be both low enough to allow easy extrusion from a small diameter nozzle and high enough to be stackable with the previously deposited layers. Flow curves demonstrating the dependence of apparent viscosity and shear stress on applied shear rate are shown in Figs. 3 and 4. It can be observed in Fig. 3, flow curves for F28 and F33 presented a pseudoplastic behaviour but F38 presented a critical shear stress at a lower temperature. Structured fluids or semi-solids, show shear-thinning characteristics at a critical shear stress and include products such as sauces, pastes, spreads, mayonnaise, and ice cream. Such fluids also tend to be highly thixotropic therefore rheological measurements are often irreproducible due to the disruption of the microstructure during sample loading and measurement [22]. In general, an increase of shear rate led to an increase in shear stress and a decrease in apparent viscosity. In addition, a small rise in dehydrated potato puree quantity in the formula led to a general increase in shear stress and apparent viscosity as can be shown in Figs. 3 and 4. The solid content for F38 was 20.68% and 18.41% for F28. Therefore, an increase of 2% in puree solid content (carbohydrates) implies relevant rheological changes in formulations, however, lower temperatures also contribute to a consistent structure of food. To understand the flow behaviour of potato puree shear stress profiles (Fig. 3) were measured at varying temperatures and fit to a Herschel-Bulkley model (Table 2). The Herschel-Bulkley equation is a widely used model for pseudoplastic materials [2]. The flow behaviour exponent and consistency behaviour index is especially important in determining if a material is compatible with syringe-extrusion and determining the desired extrusion rates. The flow consistency indices of potato puree represent the viscosity of the material at a shear rate of 1 s−1 and decrease with rising temperature, as would be expected (Table 2). Flow behaviour exponents less than one indicate that purees are shear-thinning materials. Both effects, temperature and formulation composition and their interaction, were significant (p < 0.05) in Herschel-Bulkley parameters obtained. The consistency coefficient (k) increases with the amount of dehydrated potato in the formulation and decreases when rising the temperature, however, there are no significant differences between parameters at 20 and 30 °C. The flow behaviour index (n) decreases with the increased amount of potato quantity and temperature, but like the consistency coefficient, there are no differences between parameters obtained at 20 and 30 °C. Yield shear stress (σ0) decreases with the increased amount of potato quantity and temperature, but in this case, there are no differences between parameters obtained at 10 and 20 °C. These changes and interactions reflect the importance to control the temperature in the 3D printing process.

The rheological properties were influenced by starch content. Potato puree with different starch content showed considerable variation in rheological parameters (Table 2). With the increase of starch content, the consistency coefficient of potato pure also increased. This is mainly due to the increased concentration of starch leading to an increased number of starch molecules per unit volume, and the increased probability of inter-molecular hydrogen bonding, resulting in a more compact network structure, and so the strength of the system increases [26].

Figures 5 and 6 show G’ (elastic modulus) and G” (viscous modulus) versus frequency range of potato puree formulations at different temperatures. G’ defines the elastic solid-like behaviour i.e., substance’s resistance to deform elastically, and it can reflect the mechanical strength of materials [16, 17]. G’ was higher than G”, and both moduli were frequency-dependent. An increase of dehydrated potato puree in the formulation led to an increase in G’ and G”, indicating the formation of a stronger mechanical structure. This might be because that starch granules absorb water and swelled during cooking, finally forming a denser network structure. Also, a decrease of temperature shows an increase of G’ and G”. It has been shown that materials with higher G’ and σ0 facilitate stronger shape retention for the extruded parts [27]. An increase of dehydrated potato puree in the formulation shows a considerable increase in G’ and G” values. This means that both parameters (G’ and G”) are strongly dependent on starch concentration. The effect of temperature was less evident. Only at lower temperatures (10 °C), differences appear for G’ and G” in F38 and F33 samples. It seems that the effect of temperature is more important when the sample is more solid-like and has less fluidity.

Extrusion Behaviour

Forward extrusion assays of formulated potato puree measure the compression force required for a piston disc to extrude a dough through a specifically sized outlet. From the compression force-time curves, the curve plateau representing the force necessary to continue with the extrusion process and the area defined under the curve was used to indirectly assess the sample consistency [19]. The mean value of the plateau force of the force-versus-time curve was considered as an extrusion force and it was used to characterise the samples [1]. Also, the maximum force was evaluated to consider the force that can be achieved by the 3D printer during the printing process. As shown in Table 3, the extrusion mean force ranged from 6.1 to 68 N, extrusion maximum force ranged from 6.7 to 76 N and extrusion area ranged from 62 to 712 N s. The forces required to extrude the samples increased when decreasing the extrusion temperature and increasing the dehydrated potato percentage in potato puree. As for the rheological parameters, both effects, temperature and formulation composition and their interaction, were significant (p < 0.05). ANOVA showed highly significant differences in the extrusion mean force, maximum force and extrusion area of the samples with the quantity of dehydrated potato in potato puree. The effect of temperature was significant but in the parameter of the extrusion area, no differences were found in samples extruded at 20 or 30 °C. Samples F38 extruded at 10 °C showed the highest values of all parameters evaluated, reflecting their greater hardness.

3D Printing

Figure 7 shows the percentage of printing achieved from different formulations at different temperatures. As mentioned before, printing (%) was defined as the percentage of execution of the figure (g-code file execution). Values of 100% indicate that the figure was fully built making a total height of 80 mm. The printing process was stopped when the deposition of the product did not correspond exactly with the bottom layer (Fig. 1d). Other authors [7, 9, 11, 16, 17] used photographs to evaluate the figure building but we considered that the parameter used in this study also allows us to evaluate properly the printing process. The maximum printing percentage achieved was a 50%, corresponding to formulation F38 printed at 30 °C and the minimum achieved was 19%, corresponding to formulation F28 printed at 30 °C. This means that with the formulations and temperature used the maximum height achieved was around 40 mm without deformation of the figure. The two-way ANOVA results showed that the parameters formulation, temperature and their interaction were significant (p < 0.05). At low concentration of dehydrated potato in the puree (F28), the best results of printing were obtained at 10 °C but at greater levels of dehydrated potato in the puree (F38), the best results of printing were obtained at 30 °C. These results reveal the importance of controlling the temperature of the product during the printing process. As mentioned by Liu et al. [14, 15] the printing temperature should be fine-tuned, as the viscosity of the food material is directly correlated with the temperature. The viscosity decreases when the temperature is increased, but an adequate solid-like behaviour of the product is required to build the figure, therefore it is necessary to find the adequate temperature to achieve an appropriate equilibrium between solid-like behaviour and fluency for each component of the formula guaranteeing the stability of figure construction.

Correlation between Rheological/Textural Properties and Printing

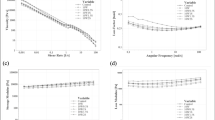

To be able to construct 3D structures it is necessary to fully understand the material properties and relevant technologies [14, 15]. In syringe-extrusion based printing, the properties of food material, such as the moisture content, rheological properties, specific cross-linking mechanisms and thermal properties, are critical to a successful printing. The printing precision and accuracy are critical in the production of an appealing object, and there are several factors, which may be responsible for this: 1) extrusion mechanism; 2) material properties (rheological properties, gelling, melting and glass transition temperature (Tg)); 3) processing factors (nozzle height, nozzle diameter and extrusion speed); 4) post-processing treatments. The effect of material properties and extrusion temperature was analysed. A second order quadratic equation was used to express the response variables as a function of the independent ones. Only the significant model terms (p < 0.05) were considered in the final reduced model. Table 4 shows the regression coefficients of the models with a significant correlation of the response variables with the independent ones. Figure 8 shows the surfaces obtained for different parameters evaluated in this work. Figure 8a shows the percentage of execution of the figure (%) as a function of printing temperature and quantity of potato in potato puree. As mentioned before the best results were obtained with F38 and temperature of 30 °C. In this case, the effect of composition was more relevant than temperature, but it can be observed that a temperature between 20 °C and 30 °C and the higher quantity of potato used in this study (F38) would be the best conditions to print. The actual works on 3D food printing [5, 7, 10, 14, 16, 17, 20, 21, 26] are looking for which kind of parameters are more determinant to establish a relationship between printability and food properties. Rheological properties of food materials are important to improve the printing performance and self-supporting ability in extrusion-based printing. In Fig. 8c and d, the correlation between rheological parameters as consistency coefficient (k) and flow behaviour index (n) with printing temperature and quantity of potato in the potato puree is shown. Comparing Fig. 8a with Fig. 8c and d, we can see that the printability is in direct proportion to k and has an inverse proportion to n. The food material for extrusion printing should be a pseudoplastic fluid with suitable shear-thinning behaviour and rapid structural recovery ability allowing it to be easily extruded from the nozzle with the application of shear force and then solidify rapidly again after leaving the nozzle, indicated by k, and n playing an important role in extrudability and printability [7, 16, 17]. Figure 8b shows the Mean Force (N) from the extrusion test as a function of printing temperature and quantity of potato in potato puree. In this case, the effect of potato pure quantity is well correlated with printability, but the effect of temperature is not well defined. It will be necessary to obtain complex models to take into account all variables that correlate proper printability with properties of food and printing conditions.

Graphical representation of fitted equations obtained for different parameters. a Percentage of execution of the figure (%) as a function of printing temperature and quantity of potato in potato puree; b Mean Force (N) from extrusion test as a function of printing temperature and quantity of potato in potato puree; c Consistency coefficient (k) as a function of printing temperature and quantity of potato in potato puree; d Flow behavior index (n) as a function of printing temperature and quantity of potato in potato puree

Conclusions

The effect of food composition and printing temperature were explored. In this paper, we demonstrated the importance of controlling temperature and composition during the process and characterising of the rheological behaviour of the food products in retaining the structural integrity of the printed materials. The effect of composition was more relevant than temperature. An adequate solid-like behaviour of the product was required to build the figure. The adequate equilibrium between solid-like behaviour and fluency that guarantees the figure construction was achieved with a formulation of higher dehydrated potato content and a temperature of 30 °C. The future of 3D food printing will be associated with the possibility to correlate the printability of a material with properties that allow automatic configuration of 3D printers. It will be necessary to obtain complex models to take into account all variables that correlate proper printability with properties of food and printing conditions. The future of 3D food printing will be associated with the possibility to correlate the printability of a material with properties that allow automatic configuration in 3D printers. From this information included in the food container (ink cartridge, bag, etc.) as a barcode, QR, microchip, etc., the printer will select the optimal printing conditions, modifying parameters such as temperature of extrusion, nozzle height, nozzle diameter and extrusion speed without intervention of the final user.

References

G. Ares, A. Giménez, A. Gámbaro, Instrumental methods to characterize nonoral texture of dulce de leche. J. Texture Stud. 37(5), 553–567 (2006). https://doi.org/10.1111/j.1745-4603.2006.00068.x

S. Bhattacharya, N. Vasudha, K.S. Krishna Murthy, Rheology of mustard paste: A controlled stress measurement. J. Food Eng. 41(3), 187–191 (1999). https://doi.org/10.1016/S0260-8774(99)00102-8

F. Chuanxing, W. Qi, L. Hui, Z. Quancheng, M. Wang, Effects of pea protein on the properties of potato starch-based 3D printing materials. Int. J. Food Eng. 14(3), 1–10 (2018). https://doi.org/10.1515/ijfe-2017-0297

I. Dankar, M. Pujolà, F. El Omar, F. Sepulcre, A. Haddarah, Impact of mechanical and microstructural properties of potato puree-food additive complexes on extrusion-based 3D printing. Food Bioprocess Technol. 11(11), 2021–2031 (2018). https://doi.org/10.1007/s11947-018-2159-5

A. Derossi, R. Caporizzi, D. Azzollini, C. Severini, Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 220, 65–75 (2018). https://doi.org/10.1016/j.jfoodeng.2017.05.015

F.C. Godoi, S. Prakash, B.R. Bhandari, 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 179, 44–54 (2016). https://doi.org/10.1016/j.jfoodeng.2016.01.025

C.A. Hamilton, G. Alici, M. in het Panhuis, 3D printing vegemite and marmite: Redefining “breadboards”. J. Food Eng. 220, 83–88 (2018). https://doi.org/10.1016/j.jfoodeng.2017.01.008

S. Holland, T. Foster, W. MacNaughtan, C. Tuck, Design and characterisation of food grade powders and inks for microstructure control using 3D printing. J. Food Eng. 220, 12–19 (2018). https://doi.org/10.1016/j.jfoodeng.2017.06.008

H.W. Kim, H. Bae, H.J. Park, Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 215, 23–32 (2017). https://doi.org/10.1016/j.jfoodeng.2017.07.017

C. Le Tohic, J.J. O’Sullivan, K.P. Drapala, V. Chartrin, T. Chan, A.P. Morrison, et al., Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 220, 56–64 (2018). https://doi.org/10.1016/j.jfoodeng.2017.02.003

M. Lille, A. Nurmela, E. Nordlund, S. Metsä-Kortelainen, N. Sozer, Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 220, 20–27 (2018). https://doi.org/10.1016/j.jfoodeng.2017.04.034

H. Lipson, M. Kurman, Fabricated: The New World of 3D Printing (John Wiley and Sons, Inc, New York, 2013)

J.I. Lipton, Printable food: The technology and its application in human health. Curr. Opin. Biotechnol. 44, 198–201 (2017). https://doi.org/10.1016/j.copbio.2016.11.015

Z. Liu, M. Zhang, B. Bhandari, Y. Wang, 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 69, 83–94 (2017a, September). https://doi.org/10.1016/j.tifs.2017.08.018

Liu, Z., Zhang, M., Bhandari, B., & Yang, C. (2017b). Impact of Rheological Properties of Mashed Potatoes on 3D Printing. https://doi.org/10.1016/j.jfoodeng.2017.04.017

Z. Liu, M. Zhang, B. Bhandari, C. Yang, Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 220, 76–82 (2018a). https://doi.org/10.1016/j.jfoodeng.2017.04.017

Z. Liu, M. Zhang, C.h. Yang, Dual extrusion 3D printing of mashed potatoes/strawberry juice gel. Lwt 96(February), 589–596 (2018b). https://doi.org/10.1016/j.lwt.2018.06.014

S. Mantihal, S. Prakash, F.C. Godoi, B. Bhandari, Optimization of chocolate 3D printing by correlating thermal and flow properties with 3D structure modeling. Innovative Food Sci. Emerg. Technol. 44(September), 21–29 (2017). https://doi.org/10.1016/j.ifset.2017.09.012

F. Ronda, S. Pérez-Quirce, A. Angioloni, C. Collar, Impact of viscous dietary fibres on the viscoelastic behaviour of gluten-free formulated rice doughs: A fundamental and empirical rheological approach. Food Hydrocoll. 32(2), 252–262 (2013). https://doi.org/10.1016/j.foodhyd.2013.01.014

C. Severini, A. Derossi, D. Azzollini, Variables affecting the printability of foods: Preliminary tests on cereal-based products. Innov. Food Sci. Emerg. Technol. 38, 281–291 (2016). https://doi.org/10.1016/j.ifset.2016.10.001

C. Severini, A. Derossi, I. Ricci, R. Caporizzi, A. Fiore, Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 220, 89–100 (2018). https://doi.org/10.1016/j.jfoodeng.2017.08.025

J.R. Stokes, J.H. Telford, Measuring the yield behaviour of structured fluids. J. Non-Newtonian Fluid Mech. 124(1–3 SPEC. ISS), 137–146 (2004). https://doi.org/10.1016/j.jnnfm.2004.09.001

J. Sun, Z. Peng, W. Zhou, J.Y.H. Fuh, G.S. Hong, A. Chiu, A review on 3D printing for customized food fabrication. Procedia Manufacturing 1, 308–319 (2015). https://doi.org/10.1016/j.promfg.2015.09.057

J. Sun, W. Zhou, L. Yan, D. Huang, L.y. Lin, Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 220, 1–11 (2018). https://doi.org/10.1016/j.jfoodeng.2017.02.028

F. Yang, M. Zhang, B. Bhandari, Recent development in 3D food printing. Crit. Rev. Food Sci. Nutr. 57(14), 3145–3153 (2017). https://doi.org/10.1080/10408398.2015.1094732

F. Yang, M. Zhang, B. Bhandari, Y. Liu, Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT Food Sci. Technol. 87, 67–76 (2018). https://doi.org/10.1016/j.lwt.2017.08.054

M. Zhang, A. Vora, W. Han, R.J. Wojtecki, H. Maune, A.B.A. Le, et al., Dual-responsive hydrogels for direct-write 3D printing. Macromolecules 48(18), 6482–6488 (2015). https://doi.org/10.1021/acs.macromol.5b01550

L. Zhang, Y. Lou, M.A.I. Schutyser, 3D printing of cereal-based food structures containing probiotics. Food Struct. 18(August), 14–22 (2018). https://doi.org/10.1016/j.foostr.2018.10.002

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martínez-Monzó, J., Cárdenas, J. & García-Segovia, P. Effect of Temperature on 3D Printing of Commercial Potato Puree. Food Biophysics 14, 225–234 (2019). https://doi.org/10.1007/s11483-019-09576-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-019-09576-0