Abstract

In this present work, we synthesized poly (lactic acid) (PLA)/curcumin composite films using a twin-screw extruder and evaluated their mechanical, optical, thermal, and barrier properties. The composite films were characterized using Fourier transform infrared spectroscopy (FTIR), Universal testing machine (UTM), thermogravimetric analysis (TGA), ultraviolet-visible spectrometry (UV-visible), colorimetry, goniometry, and oxygen permeation analysis. The results confirmed that, the composite films exhibited better ultraviolet radiation-blocking properties and hydrophobicities than did the reference PLA film. The oxygen and water vapor permeabilities of the composite films were also lower than those of the reference PLA film.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

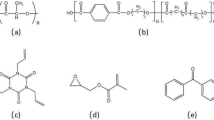

With the growth of civilization, human lifestyle has also changed significantly. In the modern world, food packaging has come to play a major role in ensuring the quality and safety of food products by preventing adverse issues, such those arising from exposure to chemical contaminants, oxygen, light, moisture, and microorganisms [1]. In order to maintain food quality and safety, it is essential to develop novel packaging materials, natural preservatives, and innovative packaging technologies [2]. These days, owing to growing concerns about the environment, renewable resources are increasingly being used to fabricate packaging materials instead of petrochemical-based nonbiodegradable plastic packaging resources [3].The most promising biodegradable candidate is poly(lactic acid) (PLA). It is derived from renewable resources and is the most attractive biopolymer [4]. Owing to its good physical, mechanical, and water vapor barrier properties, it can be used to produce packaging materials for different products [5, 6]. However, PLA exhibits a number of drawbacks, such as high gas permeability, low toughness, and high production costs. With the purpose of expanding the applicability of PLA, several researchers are studying methods of modifying PLA to improve its characteristics. Moreover, efforts are also being made to enhance the physical and chemical properties of biopolymer-based films [7, 8].

These days, the focus of food packaging research has shifted to active packaging, which can contain different additives such as antioxidants, colorants, antimicrobials, and flavors for improving the appearance and shelf life of food products [9]. For this reason, we concluded that curcumin would be a suitable additive for food packaging materials. Curcumin is derived from the root of Curcuma longa. It is a hydrophobic polyphenolic compound and is yellow-orange in its natural state. Further, it shows strong antioxidant, antitumor, anticancer, and antibacterial properties. [10]. Naksuriya et al. reviewed various curcumin nanoformulations and found that, it useful in cancer treatment as well as a pharmaceutical agent [11]. Sampath et al. fabricated nanofiber films of poly(lactic-co-glycolic) acid containing curcumin. These films were then used to treat carcinomas [12]. Further Yakub et al. prepared films of poly(l-lacticide-co-D,l-lacticide) incorporating curcumin using the electrospinning method and found that these films also showed good antioxidant, anticoagulant, and antibacterial properties [13]. Nguyen et al. fabricated curcumin-loaded PLA nanofibers by electrospinning. The obtained nanofibers were investigated for their in-vivo wound-healing capabilities using a mouse model [14]. Dhuraiet al. prepared nanofilms of curcumin-incorporating chitosan reinforced with PLA by electrospinning and investigated their in-vitro cytotoxicity as well as drug release and antioxidant properties to evaluate their wound-healing abilities [15]. Chen et al. also studied the anticoagulation properties of curcumin-loaded PLA composite membranes by using them as drug-eluting stents [16].

Given the above-mentioned uses of the curcumin, we incorporated curcumin in different concentrations into PLA and formed composite films with the help of a twin-screw extruder and a hot-melt press. To our knowledge, this is the first instance of the fabrication of PLA composite films using a twin-screw extruder. Finally, we investigated the mechanical, optical, thermal, and barrier properties of the fabricated composite films.

Materials and Methods

PLA polymer (4060D) granules with an average diameter of 81 μm and a density of 1.24 g/cm3 were supplied by Nature Works LLC, USA. The melt-flow rate, melt temperature, and glass-transition temperatures of the PLA sample used were 4–8 g/10 min (190 °C/2160 g), 140–152 °C wide range of melting temperature, and 56.7–57.9 °C, respectively. Curcumin powder of high purity (> 95%) was purchased from a local market in Seoul, South Korea. In order to remove all the moisture from the powder, it was placed in an oven at 70 °C for 24 h to dry.

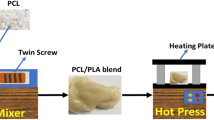

Pelletization of PLA/Curcumin Biocomposite Films by Extrusion and Hot Pressing

In this process, the curcumin power was mixed with 100 g of the PLA granules in the following concentrations: 1, 3, 5, 7, 10, 15, and 20% w/w. The resulting composites are hereafter referred to as PC1, PC3, PC5, PC7, PC10, PC15, and PC20, respectively. The PLA/curcumin mixture was then processed using a twin-screw extruder (BA-19, Bautek Co., Republic of Korea). For the extrusion process, the screw speed was set at 140 rpm and the temperatures of the barrels of the molding block zones in the extruder were set at 190, 180, 180, 180, 180, 170, 150, and 140 °C. The PLA/curcumin extracts were cooled to the ambient temperature in a water bath. Then, using a pelletizer, these extracts were cut into small pellets about 5 mm and dried at 50 °C for 5 h to remove moisture. Next, 3 g of these pellets was weighted and pressed into a film using a hot-pressing machine (QM900S, MESYS); this was done at a processing temperature at 160 °C at a pressure of 25 MPa. The thicknesses of the resulting films on average size 0.27 ± 0.032 mm [17].

Fourier Transform Infrared Spectroscopy (FT-IR)

The functional groups of the PLA/curcumin composite films (1cm2 each) were analyzed using an FT-IR system (FT/IR-6100, JASCO, Japan) equipped with an attenuated total reflectance accessory for wavenumbers of 4000–400 cm−1; approximately 32 scans were performed for each film with 4 cm−1 resolution. To compensate humidity effect and the presence of carbon dioxide in the air, a blank spectrum was obtained before each test for spectra subtraction.

Tensile Tests

The tensile properties of the films, such as their tensile strength, tensile modulus, and elongation at breakage, were measured as per the ASTM D882–2 standard using a universal testing machine (Zwick Co., Germany); the initial grip separation was set at 50 mm, and the crosshead speed was 50 mm/min. Five measurements were performed and averaged for the result.

Thermal Stability

The thermal stability and decomposition properties of the PLA/curcumin films were evaluated using a thermogravimetric analyzer (Pyris1, Perkin Elmer). About 5 mg of each sample was loaded into a ceramic pan and heated from 25 °C to 600 °C at a constant heating rate of 10 °C/min in a high purity nitrogen (99.5% nitrogen, 0.5% oxygen content) atmosphere to prevent unwanted oxidation.

Contact Angle Analysis

To determine the hydrophobicities of the PLA/curcumin composite films, contact-angle measurements were performed with a goniometer using the sessile drop method. Drops of distilled water were placed on the left and right sides of the sample at room temperature, and the contact angles were measured and subsequently averaged [18].

Color and Transparency Measurements

The colors of the films were measured using a colorimeter (Minolta CR300 Series, Minolta Camera Co., Ltd., Osaka, Japan). The colorimeter was calibrated using a standard white plate (L* = 96.36, a* = −0.45, and b* = 1.46), where ‘L’ is the brightness, ‘a’ is the redness, and ‘b’ is the yellowness. The color measurements were performed by placing the film specimens over the colorimeter. All the measurements were performed thrice [19]. The total color difference (∆E) and whiteness index is calculated by using the below formula.

∆E= \( \sqrt{{\left({L}^{\ast }-L\right)}^2+{\left({a}^{\ast }-a\right)}^2+{\left({b}^{\ast }-b\right)}^2} \) (1)

The transmittance of the PLA/curcumin composite films was studied with respect to ultraviolet (UV) radiation and visible light were measured using a UV-visible spectrometer (UV-1650PC, Shimadzu, Japan). Before the measurement, each film was cut into a 2.5 × 1 cm rectangle shape and attached to quvvet [20].

Barrier Properties

The oxygen vapor permeability (OVP) values of the PLA/curcumin composite films were measured in accordance with the ASTM D 3985–5 standard using an oxygen permeation analyzer (8001,Systech Illinois). During the OVP tests, a barrier film with a size of 5 cm2 was sealed between a chamber containing oxygen and a chamber void of oxygen at room temperature and a relative humidity of 50%. A coulometric sensor was used to measure the amount of oxygen transmitted through the material. The water vapor permeability (WVP) values of the composite films were measured by the desiccant method as per the ASTM E-96 M-10 standard.

Field Emission Scanning Electron Microscopy (FE-SEM)

FE-SEM was used to observe the fracture surface morphology of the films samples generated from the tensile test in a FE-SEM (SUPRA 55VP-31-04) operating at EHT and 2 kV accelerating Voltage. Prior to each measurement, all samples were coated with Au layer under sufficient vacuum conditions.

Result and Discussion

FTIR Analysis

Fig. 1 shows the FTIR spectra of the PLA/curcumin composite films. It can be seen from the figure that the spectra exhibit typical peaks related to PLA and curcumin. A transmission band related to curcumin was observed at 3305.4 cm−1; this was attributable to the stretching vibrations of the phenolic O-H group. In the case of the PLA/curcumin composite films, this band was shifted to 3328.53 cm−1. Furthermore, a noisy peak was seen at 1649.2 cm−1; it was related to the stretching of the C-C bond of the benzene ring. Another noisy peak was seen at 1507.1 cm−1; this was ascribable to the bending vibrations of the C-H bond of the olefin bound to the benzene ring of curcumin. These noisy peaks were shifted to 1648.3 cm−1 and 1513.2 cm−1, respectively, in the case of the PLA/curcumin composites. Based on these shifts, it was confirmed that curcumin was perfectly loaded in the PLA matrix in the composite films. Further, the peaks observed in the case of pure curcumin at 828.27 cm−1 and 1016.3 cm−1, which were attributable to the vibrations of the phenyl ring C–O in –C–OCH3, were not detected in the case of the PLA/curcumin composites, given the high intensity of the peaks of PLA. Moreover, notable similar peaks were found in pure PLA and the PLA/curcumin composites. For instance, three distinctive peaks were observed in the case of PLA; these were shifted in the case of the PLA/curcumin composites. A spike-like peak was seen at 1747.2 cm−1 in the spectrum of PLA. It was related to the stretching of the C = O carbonyl bond in the –CO–O– group of PLA and was shifted to 1750 cm−1 in the case of the PLA/curcumin composites. Another spike-like peak was seen at 1181.19 cm−1; this corresponded to the stretching vibrations of the –C–O– bond in the –CH–O– chains of PLA and was shifted to 1183.24 cm−1 in the case of the composites. In addition three peaks were observed at 1128.2, 1080.0, and 1044.3 cm−1, respectively; these were ascribable to the stretching vibrations of the C–O bond of the –CO–O– group of the PLA polymer chains and were shifted to 1128.2, 1081.9, and 1043.3 cm−1, respectively, in the case of the composites [21].

Tensile Tests

Figs. 2 and 3 shows the tensile strength, tensile modulus, and elongation at break values of the curcumin-loaded PLA composites with different curcumin contents. It can be seen from Figs. 2 and 3 that there was no improvement in the tensile performance of PLA after being loaded with curcumin; the exception was PC3, which showed better tensile properties. Moreover, the films were broken in two pieces after a small elongation; this suggests that the PLA/curcumin films were inelastic in nature. In fact, the increasing curcumin content to the pure PLA shows a marginal decrease in tensile performance as compared to that of the reference pure PLA film. The films exhibited tensile strengths higher than 41 MPa up to PC7 without plasticizer. Further, the films up to PC7 tensile moduli were 0.86–0.94 GPa, and elongation at break value was 41%. Herein, the tensile properties of the films up to PC7 were suggested that the tensile properties of PLA marginally deteriorated after addition of curcumin. However, these withstanding results of composites films up to PC7 also suggested that there was good interfacial interaction between the curcumin and the PLA. A similar effect has been observed in cellulose/curcumin composite films [10]. In addition, the tensile strengths of the PLA/curcumin composite films were higher than those of films of a PLA-limonene blend, whose strengths were 22–38 MPa [22]. However, it should be noted that, in keeping with our expectation, the PC20 composite film exhibited dramatically poorer mechanical properties, owing to the agglomeration of curcumin with PLA.

Thermal Analysis

The thermal stabilities of the PLA/curcumin composites films were studied through thermogravimetric analyses. The primary thermograms and thermal parameters of the PLA/curcumin composites films are shown in Fig. 4. It can be seen from the figure that the thermal decomposition (i.e., 5% weight loss) of the pure PLA film started at ~326 °C, whereas for curcumin, it started at ~206 °C. As the curcumin content increased to PLA from PC1 to PC20, composite films the decomposition (i.e., 5% weight loss) is ~ 322 °C to 271 °C. Further, it was seen that, as the curcumin content was increased, there was a marginal decrease in the thermal stability of the composite films; this was probably owing to the volatile components present in curcumin [19]. The maximum degradation temperature, Tmax, of curcumin during the second stage of the analysis was ~ 331 °C for a weight loss of 54%, which is lower than the maximum degradation temperature of PLA ~ 375 °C at weight loss of 10%. On the other side, the Tmax value of the composite films for PC1 to PC20 to the 10% residue content was ~ 334 to ~373 °C [23]. The presence of phenyl rings in curcumin resulted in a greater amount of char residue 34% as compared 10% residue to the cases for PLA and the composite films. It can also be seen from the thermograms that the curves of all the composite films lay between those of curcumin and PLA. These results were in keeping with our expectations and confirmed that curcumin was perfectly dispersed in the PLA matrix and that there was good interaction between them while they were in the extruder.

Contact Angle Analysis

In order to measure the wettability of a surface by a liquid, contact angle analysis is performed. Using this method, it is possible to determine whether a surface is hydrophobic or hydrophilic in nature. It can be seen from Fig. 5 that, as the curcumin content in the PLA/curcumin composites was increased, the contact angle also increased, with the composite films exhibiting higher angles than that of the reference PLA film. For reference PLA film contact angle is around 51.630, with incorporation curcumin for PC1 this angle extended to 59.380 and further increasing curcumin content the contact angle also increased marginally up to 63.120. The abrupt increment in contact angle observed in PC1 compare with reference PLA sample, further the contact angle value saturated. May be the weak mechanical properties saturates the contact angle. This result indicated that since curcumin is hydrophobic, it caused the PLA/curcumin films to also be hydrophobic [24].

Color and Transparency Measurements

With respect to the shelf life of food products, the color and transparency of the packaging material plays a vital role in determining consumer acceptance. Generally, most consumer goods that attract the attraction of buyers are packed in transparent packaging materials. However, this allows the UV rays in sunlight to penetrate the packaging and can adversely affect the quality and safety of food products. It can be seen from Fig. 6 that, with respect to UV radiation and visible light, the pure PLA film exhibited a higher transmittance (54%) than that of the PLA/curcumin composite films. Further, with an increase in the curcumin content of the composite films, there was a significant decrease in the transmittance for wavelengths of 400–500 nm and almost it fall to ~ 0% of transmittance below 500 nm. This indicated that the films would be ideal for use as a packaging material to block UV rays partially and improve the quality and safety of the packaged food products.

Table 1 shows that the ‘L’ value of the pure PLA film, which indicates that it had a high brightness. However, after the addition of curcumin to pure PLA, the film brightness decreased, with the resultant composite films being yellowish. In addition, as the curcumin content was increased, the difference in the colors of the films (∆E) also increased till a curcumin content of 10 phr. With further increases in the curcumin content, the color difference decreased, with the films turning reddish-yellow. However, the decrease in color characteristics of the composites films with comparing reference standard plate. The obtained color measurements coincide with transparency measurement and suggested that they would be suitable for blocking UV rays [20].

Barrier Properties

The OVP and WVP values of the PLA/curcumin composite films are shown in Fig. 7. The WVP values of the reference PLA film were higher than those of the composite film produced by adding 5phr curcumin to PLA and OVP values near to the reference PLA film up to 5phr. This suggested that WVP values decreased with the addition of curcumin, owing to the hydrophobic nature of curcumin, which prevented the vapor molecules from penetrating the composite film and also increased its tortuosity. This also confirmed that curcumin was perfectly dispersed in the PLA matrix by the twin-screw extruder. However, it should be noted that, in the case of the films formed by the addition of curcumin to PLA in concentrations of 10 phr and 20 phr, the permeability of oxygen gas molecules was higher, owing to the low tortuosity of these films. On the other hand, the WVP value remained unchanged for curcumin contents of up to 10 phr. In addition, since the mechanical properties deteriorated with addition of higher amounts of curcumin to PLA, the permeability of the resulting composite films to the vapor molecules increased [25].

FE-SEM Analyses

FESEM images were taken from top surfaces after the tensile test and are shown in Fig. 8. to evaluate the influence of curcumin content on PLA microstructure. A significant smooth surface was observed for pure PLA film. PC5 fractured surface shows the uniform distribution of curcumin content and plastic deformation without any plasticizer content to PLA matrix. Further, the increasing curcumin content for PC10 and PC20 films formed of rough fractured surfaces and become more brittle nature. The amorphous status of curcumin with PLA matrix observed as increasing curcumin content and deterioration of physical properties.

Conclusions

PLA/curcumin composite films were prepared using a twin-screw extruder and a hot-pressing machine. Based on the results of FTIR and thermogravimetric analyses, it was confirmed the curcumin was perfectly loaded in the PLA matrix by the extruder. The tensile properties of the composites films were tested and showed better improvement at 3% w/w addition of curcumin to PLA. The effect of physical properties clearly observed through FESEM analysis. The color and transparency properties of the films confirmed that they could block UV rays completely. Further, contact angle measurements revealed that the composite films were hydrophobic. In addition, the composite films exhibited good barrier properties for curcumin contents of up to 5 phr. Finally, the WVP value of the films decreased with an increase in the curcumin content till 10% w/w. These results confirmed that, the composite films synthesized with 5% w/w curcumin to PLA should be suitable for further study as a food packaging material to preservation and enhance shelf life of food products.

References

J.-W. Rhim, H.-M. Park, C.-S. Ha, ProgPolymSci 38(10), 1629–1652 (2013)

M. Llana-Ruiz-Cabello, S. Pichardo, A. Baños, C. Núñez, J.M. Bermúdez, E. Guillamón, S. Aucejo, A.M. Cameán, LWT-Food SciTechnol 64(2), 1354–1361 (2015)

J.-W. Rhim, S.-I. Hong, C.-S. Ha, LWT--Food SciTechnol 42(2), 612–617 (2009)

L. Cabedo, J. Luis Feijoo, M. Pilar Villanueva, J.M. Lagarón, E. Giménez, MacromolSymp 233(1), 191–197 (2006)

C.J. Weber, V. Haugaard, R. Festersen, G. Bertelsen, Food Addit Contam 19(S1), 172–177 (2002)

Z.Ö. Erdohan, B. Çam, K.N. Turhan, J Food Eng 119(2), 308–315 (2013)

Y.-n. Wang, Y.-x. Weng, Lei Wang. Polym. Test. 36, 119–125 (2014)

J.-W. Rhim, Food Res Int 51(2), 714–722 (2013)

M. Ramos, A. Jiménez, M. Peltzer, C. María, Garrigós. Food Chem 162, 149–155 (2014)

N. Luo, K. Varaprasad, G.V.S. Reddy, A.V. Rajulu, J. Zhang, RSC Adv. 2(22), 8483–8488 (2012)

O. Naksuriya, S. Okonogi, R.M. Schiffelers, W.E. Hennink, Biomaterials 35(10), 3365–3383 (2014)

M. Sampath, R. Lakra, PurnaSai Korrapati, and Balasubramanian Sengottuvelan. Colloids Surf B 117, 128–134 (2014)

G. Yakub, A. Toncheva, N. Manolova, I. Rashkov, V. Kussovski, D. Danchev, J. Bioact. Compat. Polym. 29(6), 607–627 (2014)

T.T.T. Nguyen, C. Ghosh, S.-G. Hwang, L.D. Tran, J.S. Park, J Mater Sci 48(7), 125–133 (2103)

B. Dhurai, N. Saraswathy, R. Maheswaran, P. Sethupathi, P. Vanitha, S. Vigneshwaran, V. Rameshbabu, Front. Mater. Sci. 7(4), 350–361 (2013)

Y. Chen, J. Lin, Y. Fei, H. Wang, W. Gao, Fibers Polym 11(8), 1128–1131 (2010)

H.-J. Kwon, J. Sunthornvarabhas, J.-W. Park, J.-H. Lee, H.-J. Kim, K. Piyachomkwan, K. Sriroth, D. Cho, Compos Part B Eng 56, 232–237 (2014)

A. González, C.I. Alvarez Igarzabal, Food Hydrocoll. 33(2), 289–296 (2013)

Hiserod, Richard D., Chi-Tang Ho, and Robert T. Rosen. In Species Ed. by Sara J. Risch, Chi-Tang Ho, (ACS Publications, Washington, 1997), p. 97

S. Shojaee-Aliabadi, M.A. Mohammadifar, H. Hosseini, A. Mohammadi, M. Ghasemlou, S.M. Hosseini, M. Haghshenas, R. Khaksar, Int J BiolMacromol 69, 282–289 (2014)

T.T.T. Mai, T.T.T. Nguyen, Q.D. Le, T.N. Nguyen, T.C. Ba, H.B. Nguyen, T.B.H. Phan, X.P. Nguyen, J.S. Park, Adv NatSci :NanosciNanotechnol 3(2), 025014 (2012)

M.P. Arrieta, J. López, S. Ferrándiz, A. Mercedes, Peltzer. Polym Test 32(4), 760–768 (2013)

M. Ramos, E. Fortunati, M. Peltzer, F. Dominici, A. Jiménez, M. del Carmen Garrigós, J.M. Kenny, Polym. Degrad. Stab. 108, 158–165 (2014)

R. Jagannathan, P. Mary, P.P. Abraham, J Phys Chem B 116(50), 14533–14540 (2012)

M. Żenkiewicz, J. Richert, Polym. Test. 27(7), 835–840 (2008)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Ranjeth Kumar Reddy T declares that he has no conflict of interest. Hyun-Joong Kim declares that he has no conflict of interest.

Rights and permissions

About this article

Cite this article

Ranjeth Kumar Reddy, T., Kim, HJ. Mechanical, Optical, Thermal, and Barrier Properties of Poly (Lactic Acid)/Curcumin Composite Films Prepared Using Twin-Screw Extruder. Food Biophysics 14, 22–29 (2019). https://doi.org/10.1007/s11483-018-9553-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-018-9553-4