Abstract

The effect of functional ingredients (carrot juice, whole soy flour, and whole kamut flour) and storage (180 days) on physicochemical properties (texture and amylopectin recrystallization) and water status (moisture content, water activity, ice melting peak thermal properties, and proton nuclear magnetic resonance (1H NMR) mobility) of tortillas has been studied. Different formulations significantly changed the parameters studied during storage resulting in larger changes than in the standard formulation (STD) that, therefore, may be considered the most stable product. The properties of whole kamut tortillas were very similar to those of standard sample while the formulation that contained carrot juice lead to an increased system rigidity observable both at macroscopic (textural properties), macromolecular (significantly reduced), and molecular (1H FID) levels. A decrease of moisture content, water activity, endothermic transition ~0 °C, and an increase of 1H NMR mobility (1H T2 pop A and C) were observed in soy-containing products [(soy enriched (SOY) and carrot, soy, and kamut (CSK)]. SOY and CSK had very low water activity, presented the highest 1H NMR molecular mobility and underwent the most marked changes during storage suggesting that water activity cannot be taken as a sole indicator of food stability as very important modifications occurred in tortillas at molecular level.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The interest of the food industry in producing food able to improve the nutritional quality of the diet and to preserve consumers from the risk of nutrition-related diseases is rising faster than ever. In particular, a large interest is focused on functional food, products able to affect beneficially one or more target functions in the body beyond adequate nutritional effects, in a way relevant to improved state of health and wellbeing, reduction in risk of diseases, or both1. The beneficial effects overdraw by functional food is undoubtedly reached by the inclusion of functional ingredients in staple foods, such as tortillas, whose consumption is wide-spread in South America and is becoming more popular also in North America where tortillas' industry is one of the fastest growing segments of the baking industry2,3

Nutritionally improved tortillas were developed in our laboratory starting from a standard wheat tortilla production procedure and incorporating ingredients with well-documented nutritional functionality such as carrots, soy, and whole meal kamut4. Changes in formulation are known to significantly affect product properties and stability and, therefore, fresh tortillas were previously characterized for their physicochemical and nutritional properties as well as for sensory acceptability4,5. The substitution of part of the water with carrot juice in the tortilla formulation altered significantly macroscopic (i.e., reduction of water activity and moisture content) and thermal properties (i.e., lower “frozen water” content) but only marginally the molecular attributes (proton nuclear magnetic resonance (1H NMR) mobility) of the product. Inclusion of soy flour in tortillas formulation significantly affected the water status indicators at all time-space domains considered (e.g., lower moisture content, water activity, and “frozen water” content, higher 1H T2 NMR mobility) while the substitution of wheat flour with whole kamut flour did not alter the properties considered. It was found that the simultaneous combination of carrot juice, soy, and wholemeal kamut flours resulted in a very interesting product that reflected the distinctive contribution of each specific ingredient from a physicochemical stand point, was perceived as the most acceptable by the consumers and had the highest total antioxidant capacity and lowest glycemic index4.

During storage, tortillas undergo a staling process, resulting in texture deterioration and quality loss. Staling of bakery products is a complex phenomenon in which multiple mechanisms (including starch retrogradation, water redistribution, changes in polymers plasticization) take place simultaneously6. To preserve tortillas quality is, therefore, important to thoroughly understand the phenomena causing the textural changes to intelligently engineer product formulation and/or processing to extend tortillas' shelf-life. Tortillas staling has previously been characterized following textural changes (e.g., firmness and stiffness increase, decreased rollability7,8, and sensory acceptance7), focusing on water properties (e.g., “freezable water” decrease), starch retrogradation9,10, and mechanical properties10.

Water status and water availability in the food matrixes have to be taken in consideration as key factors in stability and quality of food, and they should be studied with multiple analytical techniques to portray the role of water in a product at different time-space domains. Water activity and water content can provide averaged, long-term macroscopic water state information while thermal analysis (e.g., differential scanning calorimetry) supplies an insight on the shorter range, macromolecular water state window. NMR spectroscopy is an available tool to focus on faster and shorter-range water molecular properties. 1H NMR has been extensively applied to the study of bread staling but that has also been specifically applied to study the effect of glycerol and high pressure processing in corn tortillas (1H cross-relaxation NMR and 1H T1 and T2 relaxation times)11. The objective of this work was to study how functional ingredients added to a standard wheat tortilla formulation altered the physicochemical properties and, in particular, the water status during long-term storage (180 days) of nutritionally enhanced tortillas.

Materials and Methods

Five prototypes of tortillas, wheat based (standard, STD), carrot enriched (CAR), soy enriched (SOY), kamut (KAM), and one containing simultaneously carrot, soy, and kamut (CSK) were produced as previously reported4. Shortly, ingredients were mixed in a Kitchen Aid (St. Joseph, MI, USA) to produce a dough that was divided into 40-g pieces, allowed to rest for 30 min, laminated to obtain round tortillas (1.30 ± 0.10 mm thickness), cooked at 350 °C on a glass ceramic skillet (Schott Ceran, Germany) for a total of 30 s, cooled to room temperature, and then packed under vacuum in polyethylene pouches. Formulation and composition of tortillas prototypes can be found in Table 1. Batches of six tortillas were produced on two different days for each prototype. Tortillas were stored at room temperature (17–20 °C) up to 180 days and analyzed at days 7, 14, 30, 90, and 180.

Samples used for product characterization were extracted from the central part (3 cm diameter) of each tortilla. The upper and lower tortillas' surfaces were removed and only the central core of the product was used for all analyses except for the texture tests.

Force at Rupture

Force at rupture, (N) was measured using a two-dimensional extensibility test7 as with a TA.XT2 Texture Analyzer equipped with a 25 kg load cell (Stable Micro Systems, Goldalming, UK). Test speed was adjusted to 1.0 mm/s. For each storage time, duplicated analysis was carried out on 12 tortillas for each type.

Amylopectin Recrystallization

A differential scanning calorimeter (DSC Q 100 TA Instruments, New Castle, DE, USA) was used to follow recrystallized amylopectin5,12. Indium and mercury were used to calibrate the DSC and an empty pan was used as reference. Tortilla samples (4–5 mg) were placed into hermetically sealed stainless steel pans in small pieces making full the pans deep (Perkin Elmer, Somerset, NJ, USA), equilibrated at −50.00 °C and heated to 120 °C with a heating rate of 5 °C/min. Thermograms were analyzed with a Universal Analysis Software, Version 3.9A (TA Instruments, New Castle, DE). Duplicated analyses on two tortillas for each batch were carried out at each storage time for a total of eight DSC determinations for each tortilla prototype.

Water Status

Moisture content (MC) of tortillas was determined from weight loss by oven drying at 105 °C to constant weight. For each storage time, duplicated analyses on three tortillas for each batch were carried out for a total of 12 MC determinations for each tortilla prototype.

Water activity (aw) of tortilla samples was measured at 25 °C using Decagon Aqualab Meter Series 3TE (Pullman, WA). Tortillas were broken into small pieces immediately before water activity measurement. Duplicated analyses on two tortillas for each batch were carried out at each storage time for a total of 8 water activity determinations for each tortilla prototype.

Ice melting peak properties were studied through the analysis of the DSC endothermic peak around 0 °C13 (refer to the “Materials and Methods” “recrystallized amylopectin” section for experimental conditions).

1H NMR mobility: a low resolution (20 MHz) 1H NMR spectrometer (the miniSpec, Bruker Biospin, Milano, Italy) was used to study proton molecular mobility by measuring the free induction decay (FID) and transverse (T2) relaxation time. Three grams of tortilla (10 mm high) were placed into a 10 mm NMR tube that was then sealed with parafilm to prevent moisture loss during the NMR experiment. All measurements were made at 25.0 ± 0.1 °C. FID was acquired using a single 90° pulse, followed by dwell time of 7 μs and a recycle delay in the 0.1–0.5 s range (depending on sample properties). 1H T2 (transverse relaxation times) was obtained with a Carr Purcell Meiboom Gill pulse sequence14,15 using a recycle delay in the 0.1–0.5 s range (depending on system mobility and always as ≥5 T1) and interpulse spacing of 0.04 ms. 1H T2 curves were analyzed as quasi-continuous distributions of relaxation times using a UPEN software16,17. Duplicated analyses on two tortillas for each batch were carried out for a total of eight NMR determinations for each tortilla prototype for each storage time.

Statistical Analysis

Means and standard deviations (SD) were calculated with SPSS statistical software (Version 12.0, SPSS Inc., Chicago, IL, USA). The effect of formulation (at the same storage time) and the effect of storage (for the same formulation) were identity with one-way analysis of variance and least significant difference test at a 95% confidence level (p < 0.05). The results obtained were reported in Table 1: small letters indicate significant differences among samples with different formulations; capital letters significant differences among samples with different storage time.

Results

Textural Properties of Tortillas During Storage

Textural properties of fresh tortillas indicated that STD and KAM were softer while CAR, SOY, and, more significantly, CSK were harder products4. These differences were previously related to the competition of the different solids (gluten, starch, sugars, proteins, fiber, etc.) for water resulting in different hydration and plasticization of polymers in those matrices4.

The changes on force at rupture of nutritionally enhanced tortillas are showed in Figure 1 while results of statistical analysis can be found in Table 2. All tortillas prototypes became more fragile during storage as shown by the lower amount of force necessary to break them (Figure 1) and their slightly lower extensibility before rupture (data not shown). Weakening of tortillas structure was quite fast in the first 7 days of storage and slower at longer storage times in all samples. It is interesting to observe that CAR underwent a particularly sharp force at rupture decrease between 0 and 7 days (Figure 1) while SOY and KAM softening leveled out at 14 days of storage. Force at rupture of STD and CSK on the contrary, continuously decreased (although at a slower rate after 14 days) during storage.

The force necessary to break tortillas during storage was formulation dependent: STD and KAM generally required the least amount of force to break them (p < 0.05; with the exception of KAM at 180 days) while the other tortillas (CAR, SOY, and CSK) were higher in force at rupture. SOY and CSK at days 90 and 180 were significantly higher in force at rupture than the other prototypes suggesting that these formulations were able to partially preserve the macrostructure during storage5.

Amylopectin Recrystallization in Tortillas During Storage

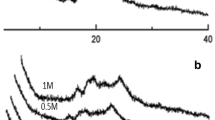

It is well known that amylopectin crystals melting can be easily observed in a DSC thermogram as an endothermic event occurring in the 60–80 °C range12. Fresh nutritionally enhanced tortillas displayed an endothermic peak at 60–80 °C that was attributed to either incomplete starch gelatinisation during baking (due to the short cooking time and/or limited water availability) and/or very fast amylopectin retrogradation5. Moreover, the amylopectin melting peak partially overlapped with the margarine melting peak5 not allowing for clear differentiation and quantification of the constituent events during storage. In addition, each event may have been affected by multiple factors (including interaction with other constituents, microstructural changes, phase transitions/separations) not allowing for prediction of amylopectin melting temperature range. It is here, therefore, provided only a qualitative and descriptive analysis of the changes in DSC peak lineshape (40–90 °C range, Figure 2) in relation to tortillas formulation and length of storage.

The overall area of the peak increased during storage in all samples, as commonly observed in staling of bakery products as result of amylopectin recrystallization18,19. The endothermic peak temperature range did not change in STD during storage, but it increased in the other tortillas due to a shift towards lower onset temperatures. The onset temperature shift was more marked in SOY and CSK (especially at 90–180 days of storage) than in CAR and KAM (Figure 2), and it was probably due to a phase separation or a change in crystalline structure of some margarine fractions.

Water Status in Tortillas During Storage

Water status of stored tortillas was investigated at different time-space domains in terms of moisture content, water activity, 0 °C DSC endothermic peak thermal properties and 1H NMR mobility to better understand the water redistribution among components during storage.

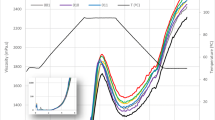

Moisture content of STD was ~28 g water/100 g sample at day 0, and it was not significantly different from KAM, while it was significantly lower in CAR (~26 g water/100 g sample) as well as in SOY (~25 g water/100 g sample) and CSK (24 g water/100 g sample) samples. The differences in moisture content were primarily due to the different amounts of water required by the recipe to obtain a processable product and, secondly, to the development of different water-solid interaction in products of different formulation5. Moisture content decreased during storage (Figure 3a and Table 2 for statistical significance) in all cases, especially in the first 7 days of storage and between 90 and 180 days in all products (Figure 3a). The moisture content decrease was mainly attributed to evaporation through the packaging material. Moisture content of SOY (from ~25 (day 0) to ~19 (day 7) g water/100 g sample) and CSK (from ~23 (day 0) to ~17 (day 7) g water/100 g sample) exhibited a large loss up to day 7 but at longer storage times (until 30 days) it significantly increased possibly because of water adsorption from the surrounding environment and/or a water redistribution in the matrix. However, since SOY and CSK tortillas showed identical trends in the moisture content changes during storage, the presence of soy (known to have high affinity for water and significantly change water status20,21) might be speculated to be responsible of this behavior by altering the water-matrix interaction. Opposite to our results, Clubbs et al.10 reported no significant changes in moisture content in corn tortillas (52.3 ± 0.2% w.b.) during 14 days of storage, but it must be taken in consideration that composition, process, packaging conditions, and storage time of tortillas were markedly different than those used in this study.

The reported differences in moisture content were reflected also on water activity parameter at day 0. STD and KAM were comparable in water activity (~0.94 and ~0.93, respectively), while aw of CAR and SOY tortillas was significantly lower; in CSK a synergic effect of the ingredients was likely responsible for the very low water activity measured in the product5. Water activity (Figure 3b and Table 2 for statistical significance) of STD tortilla at day 0 was ~0.94 and marginal changes were observed during storage. KAM showed a similar aw trend as STD until day 30, and then significantly decreased at longer storage times. CAR slightly increased water activity at day 7, remained constant until day 90, and returned to values comparable to those of the fresh product at 180 days (Table 2). Water activity of SOY did not have a constant trend showing alternating increase/decrease during storage indicating an alteration in the water status. Water activity of CSK generally increased until day 90 (from ~0.85 to ~0.88), and then drastically decreased (~0.78 at day 180).

Water status at macromolecular level was investigated by DSC ice melting peak analysis that is here carried out only qualitatively since the ice melting transition overlapped with melting of a fraction of margarine5 making impossible to predict possible changes (e.g., transition temperature range, interaction with other molecules, phase separation) in the contribution of each single constituent (ice and margarine) to the observed melting event during storage. Formulation of nutritionally enhanced tortillas significantly affected the frozen water content at day 0 as extensively reported in Serventi et al.5. In particular, FW content of STD was ~17% (g frozen water/100 g water) and ~8%, 11%, 29%, and 19% (g frozen water/100 g water) in CAR, SOY, KAM, and CSK, respectively. These FW contents differences were attributed to different water–solids interaction developed, due to the presence of different ingredients in the formulations. The representative DSC thermograms (−30 to +40 °C) for all tortillas during storage are reported in Figure 4 and show a progressive decrease of the overall area of the endothermic peak with increasing time. The FW reduction is often associated to the migration of a portion of water from gelatinized starch towards the more rigid amorphous and crystalline domains, as reported for corn tortillas10 and bread22–24. STD exhibited a clear endothermic peak during all storage indicating that after 180 days part of the water within the sample was still phase separable from the matrix. In SOY and CSK, the endothermic transition was not clearly observable after 7 days of storage (partly due to the significant moisture content loss, Figure 3a) and after 180 days in CAR and KAM indicating that the changes in formulation altered water redistribution at macromolecular level.

The molecular mobility characterization of tortillas was carried out with a 1H NMR mobility study by 1H FID, to study the less mobile protons fraction, and 1H T2 to focus on the more mobile detectable protons fraction. It must be emphasized that the 1H NMR analysis is not specific for water as the signal detected may arise from any proton present in the sample relaxing in the time frame characteristic of the experiment25–28.

FIDs decays of tortillas became progressively sharper in all samples with increasing storage time (Figure 5a for STD as an example) indicating 1H molecular rigidity increase and mobility loss of the more rigid protons (relaxing in about ~8 to ~15 μs), such as starch, proteins, and water tightly associated with those solids29. CAR and CSK had, respectively, the larger and the smallest 1H rigidity increase of this “solid-like” 1H fraction after 180 days of storage. No pronounced differences among FIDs of all tortillas were found up to 14 days of storage (Figure 4b), while at longer storage times the effect of formulation was more evident with, for example, CAR showing the fastest FID decay at day 180.

Proton T2 distributions of relaxation times were characterized by three 1H T2 populations (named pop A, pop B, and pop C, from the shorter to the longer relaxation time) in all tortillas (Figure 6a). The characteristic relaxation times (e.g., relaxation time at the peak maximum) and relative proton abundance of the three 1H populations during storage are shown in Figure 6b.

T2 distributions (a) and effect of storage on T2 and protons% (b) for all tortillas. 1H NMR T2 distributions of nutritionally enhanced tortillas during storage. 1H T2 relaxation time (above) and% of total 1Hs (below) of 1H population A (T2A), 1H population B (T2B), and 1H population C (T2C) of nutritionally enhanced tortillas

Pop A peak did not fall completely within the experimental limits (T2 ≥ 0.089 ms; = 2 interpulse spacing plus spectrometer dead time) for all samples and all storage time considered. For example, peak A of STD was only partially within the useful experimental range up to 14 days of storage and completely within the useful experimental range for storage times ≥ 30 days. Similarly, peak A of CAR and KAM was completely within the useful experimental range after 14 and 180 days, respectively. On the contrary, peak A was always completely inside the useful relaxation spectrum in SOY and CSK, suggesting that soy may have induced greater molecular mobility and, possibly, plasticization of constituents associated to the A protons fraction. It is interesting to note that peak A at ~0.13–0.16 ms (when fully within the useful experimental range; Fig. 6b), became broader and more tailored towards slower relaxation times in all samples (Fig. 6a) during storage. This peak lineshape change was more evident in STD, CAR, and KAM indicating a mobility increase of pop A protons due to storage. In SOY and CSK tortillas, this peak was broader and more abundant than in STD, CAR, and KAM until day 90; at day 180 it disappeared as it overlapped with the pop B peak. It could be concluded that this faster relaxing 1H T2 pop A was more mobile (within the experimental range at all storage times) and more “stable” (fairly constant in the relative abundance) during storage in soy-containing products as compared to the other tortillas up to 90 days.

1H T2 pop B was characterized by relaxation times in the ~0.8–6/8 ms range and peaking at ~2 ms in all samples at day 05 and it shifted towards faster relaxation times in all samples (Figure 6a, b) during storage indicating a decrease of mobility of this 1H population. Pop B was less represented in SOY and CSK samples (as previously discussed in Serventi et al.5). During storage this population slightly increased in relative abundance in STD, CAR and KAM up to 90 days and then decreased until the end of the storage. SOY and CSK samples had peak B alternately increasing and decreasing up to 90 days while at 180 days it overlapped with pop A.

The slowest relaxing (most mobile) 1H population (pop C) was centered at ~70 ms (representing ~8–12% of the total detectable protons) in STD, CAR and KAM and at ~100 ms (~22–32% of the total detectable protons) in SOY and CSK. This larger abundance of pop C in SOY and CSK was attributed primarily to the presence of soy proteins, although a margarine contribution was not excluded5. An increase in the width of the pop C towards faster relaxation times was observed in all samples during storage indicating heterogeneity increase of the protons belonging to this population.

In the scientific literature, several studies applied 1H NMR (low resolution) mobility for the study of tortillas, bread, dough and model systems (containing gluten and starch) but only few authors tentatively attributed the signals of the NMR spectra to the relative components. At the authors best knowledge, no scientific paper reporting the effect of storage probed with low resolution 1H NMR in tortillas has been published. However, the results reported in this study are consistent with some previous work relating to similar but not identical products (bread, dough, model systems).30–34 Based on these reports, the three 1H T2 populations found in tortillas were tentatively attributed to protons associated with the protein phase (e.g., gluten, pop A), protons associated with the starch amorphous phase (pop B) and protons in diffusive exchange between components (pop C). The changes of the three protons populations are the indication of a molecular water migration and redistribution between the protein and the starch phases during storage in all samples. In particular, it is hypothesized and tentatively speculated that protons migrate from the protein- to the starch-domain, as indicated by the simultaneous decrease (relative abundance) of pop A and increase of pop B up to 30 days of storage. Gray and Bemiller reported that the majority of experimental evidences suggest a gluten to starch transfer of water molecules as starch crystallizes during bread staling35.

Discussion

Tortillas of different compositions were compared and found to have significantly different physicochemical properties and water status during long term storage (180 days).

The STD tortilla was the product that underwent the smallest changes of all physicochemical and water status parameters considered during storage and, therefore, it may be considered the most stable tortilla.

KAM properties were very similar to those of STD probably because of the high similarity of the composition of the two products (Table 1); the little differences observed may be ascribable to the slightly higher fiber content of KAM that may have slightly altered fiber–water interactions and system dynamics during storage.

CAR tortilla was characterized by an increased system rigidity observable both at macroscopic (textural properties), macromolecular (significantly reduced endothermic transition ~0 °C) and molecular (1H FID) level.

SOY and CSK tortillas were very interesting products as they were characterized by the lowest water activity and moisture content but, at the same time, they had the highest 1H molecular mobility (e.g., 1H T2 pop A and C). SOY and CSK underwent the largest changes in water status parameters during storage, suggesting that water activity cannot be taken as a sole indicator of food stability as very important modifications were observed in the dynamics of the system at molecular level. Water dynamics and redistribution among different domains of the product are important aspects to be considered when studying food product stability.

Due to the complexity of the matrices considered, it is not yet possible to point out a single most important factor in defying system stability but it has been shown that it is very important to look at food systems with a very wide, multi-dimensional, and multi-analytical approach. Much more work has to be done by the food science community in this area to create scientific evidences to rule out the role of different factors (in particular water status parameters) in system dynamics, to fully understand the changes occurring in food materials during storage and how these can be related to product stability and consumers' acceptability.

References

G. Riccardi, B. Capaldo, O. Vaccaro, Curr. Opin. Clin. Nutr. Metab. Care 8(6), 630–635 (2005)

M. Cornell, Baking and Snack Magazine 20, 37–44 (1998)

Tortilla Industry Association (2010). Available at: http://www.tortillainfo.com/mediaroom/press/prrevenue03.htm. Accessed 08 June 2010

F. Scazzina, D. Del Rio, L. Serventi, E. Carini, E. Vittadini, Food Biophys. 3, 235–240 (2008)

L. Serventi, E. Carini, E. Curti, E. Vittadini, J. Sci, Food and Agriculture 89, 73–79 (2009)

R.D. Waniska, Cereal Foods World 44(7), 471–473 (1999)

F.P. Bejosano, S. Joseph, R.M. Lopez, N.N. Kelekci, R.D. Waniska, Cereal Chem. 82(3), 256–263 (2005)

B. Limanond, M.E. Castell-Perez, R.G. Moreira, J. Texture Studies 33(1), 35–44 (2002)

K. Seetharaman, N. Chinnapha, R.D. Waniska, P. White, J. Cereal Sci. 35(2), 215–223 (2002)

E.A. Clubbs, E. Vittadini, T.H. Shellhammer, Y. Vodovotz, J. Cereal Sci. 47, 162–171 (2008)

E. Vittadini, E. Clubbs, T.H. Shellhammer, Y. Vodovotz, J. Cereal Sci. 39, 109–117 (2004)

P.L. Russell, J. Cereal Sci. 1, 285–286 (1983)

D.S. Reid, J. Hsu, W. Kerr (1993) The glassy state in foods. In: J.M.V. Blanshard, P.J. Lillford (eds) Nottingham University Press, UK. pp. 123–132

H.Y. Carr, E.M. Purcell, Phys. Rev. 94, 630–638 (1954)

S. Meiboom, D. Gill, Rev. Sci. Instrum. 29, 688–691 (1958)

G.C. Borgia, R.J.S. Brown, P. Fantazzini, J. Magn. Reson. 132, 65–77 (1998)

G.C. Borgia, R.J.S. Brown, P. Fantazzini, J. Magn. Reson. 147, 273–285 (2000)

J. Longton, G.A. LeGrys, Stärke 33, 410–414 (1981)

P.H. Roulet, W.M. MacInnes, P. WŸrsch, R.M. Sanchez, A.A. Raemy, Food Hydrocolloids 2, 381–396 (1988)

G. Doxastakis, I. Zafiriadis, M. Irakli, H. Marlani, C. Tananaki, Food Chem. 77(2), 219–227 (2002)

T.L. Traynham, D.J. Myers, A.L. Carriquiry, L.A. Johnson, J. Am, J. Am. Oil Chem. Soc. 84(20), 151–155 (2007)

M.Y. Baik, P. Chinachoti, J. Agric, Food Chem. 49, 4031–4038 (2001)

P.D. Ribotta, A. le Bail, Lebensm. Wiss. Technol. 40(5), 879–884 (2007)

G. Kerch, F. Rustichelli, P. Ausili, J. Zicans, R.M. Meri, A Glonin. Eur. Food Res. Technol. 226(6), 1459–1464 (2008)

B. Halle, H. Wennerström, J. Chem. Phys. 75(4), 1928–1943 (1981)

S.J. Schmidt, H.M. Lai (1991) Water Relationships in Food-Advances in experimental medicine and biology. In: H. Levine, L. Slade (eds) Plenum Publishing Corporation, New York. pp. 405–452

I.J. Colquhoun, B.J. Goodfellow (1994) Spectroscopic Techniques for Food Analysis. In: R.H. Wilson (eds). VCH Publishers, New York. pp. 87–145

R.R. Ruan, P.L. Chen, P. Chinachoti, Y. Vodovotz, Bread Staling (CRC Press, Boca Raton, FL, USA, 2001), pp. 113–127

Y.R. Kim, P. Cornillon, Lebensm. Wiss. Technol. 34, 417–423 (2001)

S.B. Engelsen, M.K. Jensen, H.T. Pedersen, L. Norgaard, L. Munck, J. Cereal Sci. 33(1), 59–67 (2001)

X. Wang, S.G. Choi, W.L. Kerr, Lebensm. Wiss. Technol. 37(3), 377–384 (2004)

N.M. Sereno, S.E. Hill, J.R. Mitchell, U. Scharf, I.A. Farhat (2007) Magnetic resonance in food science: from molecules to man. In: I.A. Farhat, P.S. Belton, G.A. Webb (eds). RSC Publishing, UK. pp. 89–95

P.L. Chen, Z. Long, R. Ruan, T.P. Labuza, Lebensm. Wiss. Technol. 30(2), 178–183 (1997)

R. Ruan, S. Almaer, H.T. Huang, P. Perkins, P. Chen, R.G. Fulcher, Cereal Chem. 73(3), 328–332 (1995)

J.A. Gray, J.N. Bemiller, Comp. Rev. Food Sci. Food Safety 2(1), 1–21 (2003)

Acknowledgements

The authors would like to thank Greta Bonacini and Luca Serventi for performing part of the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

This research was partially funded by the Italian Ministry for University and Research, Program “Rientro dei Cervelli”, D.M. n.96, 23.04.2001 and by the Marie Curie IRG, Functional foods for space contract # MIRG-CT-2004-006676.

Rights and permissions

About this article

Cite this article

Carini, E., Curti, E. & Vittadini, E. Effect of Long-Term Storage on Water Status and Physicochemical Properties of Nutritionally Enhanced Tortillas. Food Biophysics 5, 300–308 (2010). https://doi.org/10.1007/s11483-010-9171-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-010-9171-2

, CAR

, CAR  , SOY

, SOY  , KAM

, KAM  , CSK

, CSK  ) at different storage times

) at different storage times