Abstract

The diffusion coefficient of the water component in a freeze-concentrated matrix is a useful parameter for predicting and controlling the recrystallization rate of ice crystals in sugar solutions relevant to frozen desserts. Herein, application of molecular dynamics (MD) for estimating the water diffusion coefficient in a freeze-concentrated matrix of sugar solutions is described. Diffusion coefficients evaluated using MD with the optimized potentials for liquid simulations all atom force field and water models of three types (simple point charge, simple point charge extended, and transferable intermolecular potential-4 point) show a good positive linear relation with measured values, indicating that the MD methods used in this study are useful for predicting differences in water diffusion coefficients in a sugar freeze-concentrated matrix. Furthermore, similarly to measured values, the estimated diffusion coefficients show a good positive correlation with recrystallization rates of ice crystals, which suggests that MD is useful to predict differences in recrystallization rates of ice crystals in frozen sugar solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recrystallization of ice crystals in frozen foods is characterized by an increased average size of ice crystals after completion of water solidification.1,2 Recrystallization causes deterioration during storage and distribution in frozen foods. For example, for ice cream, the increased size of ice crystals in ice cream brings about a coarse, grainy, and icy texture, destroying its preferred creamy and smooth texture.2,3 Recrystallization in frozen meat damages the cell structure, causing drip loss after thawing. Consequently, the recrystallization process has been considered as an important phenomenon to be controlled for proper storage and distribution of frozen foods. Storage experiments examining frozen foods4–13 and model systems14–21 have been conducted to elucidate the recrystallization rates of ice crystals under various experimental conditions. However, these storage experiments are generally time-consuming because storage for days to months is often needed to observe distinct recrystallization process. For example, Martini and Zaritzky5 conducted a maximum storage period of 5 months to examine the recrystallization rate in frozen beef. Consequently, it is unreasonable to try examining many of the recrystallization rates of frozen foods in the markets using storage experiments. To understand recrystallization in various frozen foods under various storage conditions better, a more systematic approach is necessary. Finding a common mechanism accounting for different recrystallization rates will enable prediction and control of recrystallization behavior for widely various frozen foods under various conditions.

Recently, we showed that the diffusion coefficient of the water component in a freeze-concentrated matrix is a useful parameter for predicting and controlling recrystallization of ice crystals in sugar solutions relevant to frozen desserts.21 That is to say, knowing the water diffusion coefficient in a freeze-concentrated matrix would engender prediction of recrystallization rate of ice crystals and save time-consuming storage experiments. Very recently, Budke et al.22 also have shown the correlation between ice recrystallization rate and water diffusion coefficient in sucrose solutions containing synthetic antifreeze glycoprotein analogues.

A useful method to measure the water diffusion coefficient is NMR, such as pulse field gradient stimulated gradient echo proton NMR (PFGSTE 1H-NMR).23 This method, however, requires expensive equipment. The running cost for operating the related devices is also high. Consequently, it is not widely used.

Molecular dynamics (MD) simulation can predict the structure and dynamics of various systems, including gases, liquids, solids, solutions, and glass.24 In this simulation method, atoms and molecules are allowed to interact according to the laws of physics, e.g., Newton’s laws of motion. By analyzing a molecular or atomic trajectory, physical properties of simulation systems such as viscosity and diffusion coefficient can be calculated. Recent rapid progress in computer technology and simulation techniques has enabled the use of MD with lower cost and shorter computational time. Regarding the properties of water, several water models adapted to MD simulation have been developed.

Reportedly, MD simulation using some of these models can reproduce experimental water properties such as the diffusion coefficient,25 density maximum temperature,26,27 dielectric constant,28 and expansion coefficient,29 although no water model reproduces many water properties simultaneously. Furthermore, force fields for MD of organic molecules30 and biomolecules31–33 such as proteins, carbohydrates, lipids, and others have been developed. The theoretical backbone for MD simulation of widely various aqueous organic solutions is being established. In fact, MD simulations of several sugar solutions were conducted to probe molecular interpretation for their functions as cryoprotectants and protein stabilizers.34–38 For example, Ekdawi-Sever et al. performed MD simulations to compare measured and simulated water diffusion coefficients in aqueous solutions of sucrose or trehalose at room temperature or above.38 They concluded that simulated water diffusion coefficients in both disaccharides solutions were in good agreement within 30% with measured ones.38 From these aspects, the diffusion coefficient of water molecules in freeze-concentrated matrix of frozen foods might be evaluated using MD simulation. In addition, using diffusion coefficient by MD simulation might enable prediction of the recrystallization rates of ice crystals. However, most water models and force fields described above are presumed to be used for simulations at or near room temperature.

Few reports to date have described MD simulation of aqueous organic solutions at subzero temperatures. Therefore, no information is available about whether MD simulation is useful to predict the water diffusion coefficient of a freeze-concentrated matrix or not at subzero temperatures. No reported study has investigated the correlation between simulated diffusion coefficient of water molecules in freeze-concentrated matrix and experimental recrystallization rate either. Our objective is to provide reliable information related to the relation between previous experimental recrystallization rate21 and diffusion coefficient of water molecules obtained using a MD simulation in the freeze-concentrated matrix in various sugar (mono and disaccharide) solutions having relevance to frozen desserts.

Materials and Methods

Simulation System

Table 1 presents details of the sugar solutions examined in this study. The concentration and ice content are shown in weight percent. The measured values of the recrystallization rate and diffusion coefficient of water molecule in a freeze-concentrated matrix (by PFGSTE 1H-NMR) were obtained from a previous study.21

Molecular structure data of the sugars for MD simulation were obtained from the Hetero-compound Information Centre, Uppsala (HIC-Up; http://xray.bmc.uu.se/hicup/). The force field potential parameters for the sugar molecules were from the optimized potentials for liquid simulations all atom (OPLS-AA) force field optimized for carbohydrates.39. The OPLS-AA includes bonded interaction terms representing the energy of deformation of bond length, bond angle, and dihedral angles and non-bonded terms: the Lennard–Jones potential (van der Waals interaction) and electrostatic potential between atom-based charge. The OPLS-AA was also used in a preceding study38 for the prediction of water diffusion coefficient in sugar solutions at room temperature or above with success. As a water model, simple point charge (SPC)40, SPC extended (SPC/E),41 and transferable intermolecular potential-4 point (TIP4P)42 were selected because they have been often used in the simulation in organic solutions.

The initial model of freeze-concentrated matrix (Table 1) was constructed as follows. Sugar molecules and water molecules were located in a cubic unit cell with a periodic boundary condition. The amounts of sugar and water per unit cell were arranged so that the sugar concentration was the same as that in freeze-concentrated matrix (Table 1). This procedure was done using the MD program suite Groningen Machine for Chemical Simulations (GROMACS).43 Table 2 presents details of the simulated system. Initial cell sizes were set so that the system densities were equal to reported ones of real solutions at 20 °C.44

MD Simulation

All MD simulations were done using the MD program suite, GROMACS,43 on a home-built PC equipped with a quad-core processor Core 2 Quad (Intel Corp.).

First, the initial system was energy-minimized using the steepest descent method, with a bond and angle of the sugar molecule flexible. Then, similarly to the method used by Roberts and Debenedetti,35 the initial velocity of each atom was assigned from a Maxwell–Boltzmann distribution at 450 K and MD simulation, with NVT ensemble performed for 100 ps of simulated time to randomize the system. The system was then cooled to the simulation temperature shown in Table 1 and equilibrated for 500 ps with the NPT ensemble. Subsequently, production MD simulation with the NPT ensemble was carried for 4,000 ps of simulation time for the evaluation of the water diffusion coefficient.

The cutoff distance used for the van der Waals interactions was 0.7 nm. Long-range electrostatic interactions were calculated using the particle mesh Ewald method.45,46 Temperature control was done using the Nosé–Hoover method.47,48 The system pressure was set to 1 atm using the Parrinello–Rahman approach during simulations using NPT ensemble.49 The time step of simulations was 0.5 fs (5 × 10−16 s). The resultant trajectory data were saved at every 250 steps (125 fs; 1.25 × 10−14 s).

From the trajectory data of water molecules, the diffusion coefficient of water molecules was calculated based on the Einstein relation24 as shown below.

In that equation, D signifies the diffusion coefficient, t stands for the time of production MD simulation, n denotes the number of water molecules, and r(t) is the position of center of mass of water molecules at time t. This calculation was performed using the command of g_msd on GROMACS. g_msd gathered the mean square displacement of the center of each water molecules with the time interval of 125 fs (1.25 × 10−14 s) to 3,500 ps from the 4,000 ps production MD simulation. Then, the diffusion coefficient of water molecules was calculated by least squares fitting a straight line to the relation between the mean square displacement and the time interval.

Results

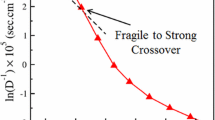

Relationship Between the Mean Square Displacement of Water Molecules and Time Interval

Figure 1 shows a typical plot of the mean square displacement of water molecules vs. time interval. It gives a straight line. This indicates that the simulation system was stabilized enough after the equilibrium process of 500 ps, and the water diffusion coefficient was evaluated from the slope of the plot.

Comparison of Simulated Diffusion Coefficients to Measured Ones

Figure 2 presents a plot of the diffusion coefficients evaluated using MD simulation as a function of the measured ones using PFGSTE 1H-NMR in a previous study.21 It shows a good linear relation with the correlation coefficient \( {R^{\text{2}}} = 0.{\text{899}} - 0.{\text{947}} \) for all water models used. In particular, the calculated diffusion coefficients with the SPC/E water model were close to those measured using PFGSTE 1H-NMR for all solutions examined in this study.

Plots of diffusion coefficients evaluated using the molecular dynamics (MD) simulation as a function of the value measured using pulse field gradient stimulated gradient echo proton NMR (PFGSTE 1H-NMR) in a previous study.21 The solid lines represent results of linear fitting. The broken line represents points where the measured diffusion coefficients are equal to the simulated ones. Water model: Square simple point charge (SPC), triangle transferable intermolecular potential-4 point (TIP4P), circle simple point charge extended (SPC/E)

Correlation Between Simulated Diffusion Coefficients and Recrystallization Rates

In Figure 3, the experimental recrystallization rates obtained in a previous study21 are shown as a function of the diffusion coefficients of water molecules obtained using the MD simulation. The experimental recrystallization rates correlated well with the diffusion coefficients obtained using the MD simulation for all water models examined; increasing the diffusion coefficient increased the recrystallization rate. The result of fitting to a linear function showed reasonable agreement \( \left( {{R^{\text{2}}} = 0.{\text{948}} - 0.{\text{984}}} \right) \).

Correlation between the recrystallization rate 21 and simulated diffusion coefficient. Solid lines represent results of linear fitting. Water model: square simple point charge (SPC), triangle transferable intermolecular potential-4 point (TIP4P), circle simple point charge extended (SPC/E)

Discussion

In general, physical properties, such as the diffusion coefficient of molecules obtained using the MD simulation, depend upon the type of molecular model and force field.24 The result portrayed in Figure 2 shows clearly that a good linear relation was obtained between measured and simulated values for all water models used in this study, although the values of diffusion coefficients mutually differed. That fact indicates that the combinations of the OPLS-AA force field and the water models used herein are useful to predict the difference of diffusion coefficients of water molecules in sugar solutions at subzero temperatures. Among them, the combination of OPLS-AA and SPC/E water model was best because it reproduced diffusion coefficients close to the measured ones. The performance of three water models used in this study for reproduction of water diffusion coefficient in pure liquid state has been discussed by preceding studies.50,51 According to the paper of Mahoney and Jorgensen,50 the diffusion coefficient calculated using SPC model at 25 °C and 1 atm was significantly larger than the measured one. Using TIP4P model showed improvement, but the value of calculated diffusion coefficient was still significantly larger.50 They reported that the SPC/E was the closest to the measured one.50 The simulated water diffusion coefficients in various sugar solutions in this study also shows same tendency, suggesting that the superiority of SPC/E over SPC and TIP4P for reproducing water diffusion coefficient still retains in the sugar solutions.

A prior study showed experimentally that the ice crystal recrystallization rate in frozen sugar solutions has a good linear relation with measured diffusion coefficients of water molecules in freeze-concentrated matrices.21 Therefore, the diffusion coefficient of water molecules in a freeze-concentrated matrix is an important parameter for predicting the recrystallization rate of ice crystals. However, few experimental methods exist to measure the diffusion coefficient of water molecules aside from NMR, which is very expensive. The result portrayed in Figure 3 shows that the diffusion coefficient obtained using MD simulation reproduced the tendency displayed by NMR. The price of the PC used for simulation was about the same as that of high-end PC in the consumer products market. As demonstrated, the MD simulation is useful for predicting difference in recrystallization rate of ice crystals in various sugar solutions with superior cost performance.

Apart from the MD simulation, He et al.52 proposed the theoretical model based on the free volume models for water diffusion coefficient in solutions of glycerol fructose, sucrose, and trehalose, respectively. Their model provided the diffusion coefficient at the function of temperature and concentration of solute. However, in order to use their model equation, it is necessary to know preliminarily many values parameters (e.g., the activation energy ΔE for a water molecule to overcome the attractive forces from the surrounding molecules, the preexponential factor D 0, the ratio of the molar volume of the jumping unit of water to that of solute ξ, and the two free volume parameters K 12 and K 22). Since these parameters have to be determine by fitting to the available experimental data now (example, water diffusion coefficient itself), their model is not applicable for the solutions that have no available experimental data. On the contrary, the MD simulation can evaluate the water diffusion coefficient in solution directly without experiment data if adequate force field is available, although it does not directly provide the temperature and solute concentration dependence of water diffusion coefficient in solutions.

In realistic situations of frozen dessert productions, freezing and storage conditions such as temperature, freezing rate, and type of freezing machine are varied. In addition, sample composition is generally more complicated. For example, a polysaccharide is included in most of ice cream mix as a stabilizer. These factors may affect recrystallization rate of ice crystals during storage11,15,16,18 and diffusion coefficient of water molecules in freeze-concentrated matrix. The mechanism accounting for different recrystallization rates by these factors and the method for the prediction of the difference of recrystallization rate should be also pursued because of its practical importance. The results obtained by this study would be a basis for this examination.

In conclusion, the MD simulation using the OPLS-AA force field and three water models (SPC, TIP4P, and SPC/E) reproduced actual differences in measured diffusion coefficients of water molecules in the freeze-concentrated phase among various sugar solutions. The diffusion coefficients simulated using SPC/E were the closest to the actual measurement values obtained using NMR. The simulated diffusion coefficients showed a good linear relation to observed recrystallization rates of ice crystals; the coefficients resembled the measured coefficients, which suggests that using MD simulation enables us to predict the difference in recrystallization rates of ice crystals in sugar solutions, as in frozen dessert foods, without time-consuming experiments.

References

O.R. Fennema, in Low-temperature preservation of foods and living matter, ed. by O.R. Fennema, W.D. Powrie, E.H. Marth (Marcel Dekker, New York, 1973)

R.W. Hartel, in The properties of water in foods: ISOPOW 6, ed. by D.S. Reid (Blackie, London, 1998)

R.W. Hartel, Crystallization in foods (Aspen, Gaithersburg, 2001)

A.E. Bevilacqua, N.E. Zaritzky, Ice recrystallization in frozen beef. J Food Sci 47, 1410 (1982)

M.N. Martino, N.E. Zaritzky, Ice crystal size modifications during frozen beef storage. J Food Sci 53, 1631–1649 (1988)

D.P. Donhowe, R.W. Hartel, Recrystallization of ice in ice cream during controlled accelerated storage. Int Dairy J 6, 1191 (1996)

D.P. Donhowe, R.W. Hartel, Recrystallization of ice during bulk storage of ice cream. Int Dairy J 6, 1209 (1996)

T. Hagiwara, R.W. Hartel, Effect of sweetener, stabilizer, and storage temperature on ice recrystallization in ice cream. J Dairy Sci 79, 735 (1996)

T. Miller-Livney, R.W. Hartel, Ice recrystallization in ice cream: interactions between sweeteners and stabilizers. J Dairy Sci 80, 447 (1997)

E. Ben-Yoseph, R.W. Hartel, Computer simulation of ice recrystallization in ice cream during storage. J Food Eng 38, 309 (1998)

R.L. Sutton, J. Wilcox, Recrystallization in ice cream as affected by stabilizers. J Food Sci 63, 104 (1998)

T. Hagiwara, H.-L. Wang, T. Suzuki, R. Takai, Fractal analysis of ice crystals in frozen food. J Agric Food Chem 50, 3085 (2002)

T. Hagiwara, R. Hayashi, T. Suzuki, R. Takai, Fractal analysis of ice crystals in frozen fish meat. Jpn J Food Eng 4, 11 (2003)

R.L. Sutton, A. Lips, G. Piccirillo, A. Szthehlo, Kinetics of ice recrystallization in aqueous fructose solutions. J Food Sci 61, 741 (1996)

R.L. Sutton, A. Lips, G. Piccirillo, Recrystallization in aqueous fructose solutions as affected by locust bean gum. J Food Sci 61, 746 (1996)

R.L. Sutton, D. Cooke, A. Russell, Recrystallization in sugar/stabilizer solutions as affected by molecular structure. J Food Sci 62, 1145 (1997)

R.L. Sutton, I.D. Evans, J.F. Crilly, Modeling ice crystal coarsening in concentrated disperse food systems. J Food Sci 59, 1227 (1994)

A. Regand, H.D. Goff, Structure and ice recrystallization in frozen stabilized ice cream model systems. Food Hydrocoll 17, 95 (2003)

A.K. Carrington, H.D. Goff, D.W. Stanley, Structure and stability of the glassy state in rapidly and slowly cooled carbohydrate solutions. Food Res Int 29, 207 (1996)

D.R. Martin, S. Ablett, A. Darke, R.L. Sutton, M. Sahagain, Diffusion of aqueous sugar solutions as affected by locust bean gum studied by NMR. J Food Sci 64, 46 (1999)

T. Hagiwara, R.W. Hartel, S. Matsukawa, Relationship between recrystallization rate of ice crystals in sugar solutions and water mobility in freeze-concentrated matrix. Food Biophys 1, 74 (2006)

C. Budke, C. Heggemann, M. Koch, N. Sewald, T. Koop, Ice recrystallization kinetics in the presence of synthetic antifreeze glycoprotein analogues using the framework of LSW theory. J Phys Chem B 113, 2865–2873 (2009)

J.E. Tanner, Use of the stimulated echo in NMR diffusion studies. J Chem Phys 52, 2523 (1970)

M.P. Allen, D.J. Tildesley, Computer simulation of liquids (Oxford University Press, New York, 1987)

Y. Wu, H.L. Tepper, G.A. Voth, Flexible simple point-charge water model with improved liquid state properties. J Chem Phys 124, 024503 (2006)

M.W. Mahoney, W.L. Jorgensen, A five-site model for liquid water and the reproduction of the density anomaly by rigid, nonpolarizable potential functions. J Chem Phys 112, 8910 (2000)

I.M. Svishchev, P.G. Kusalik, J. Wang, R.J. Boyd, Polarizable point-charge model for water: results under normal and extreme conditions. J Chem Phys 105, 4742 (1996)

S.W. Rick, Simulation of ice and liquid water over a range of temperature using the fluctuating charge model. J Chem Phys 114, 22763 (2001)

H. Nada, J.P.J.M. van der Eerden, An intermolecular potential model for the simulation of ice and water near the melting point: a six-site model of H2O. J Chem Phys 118, 7401 (2003)

W.L. Jorgensen, D.S. Maxwell, J. Tirado-Rives, Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J Am Chem Soc 118, 11225 (1996)

J.W. Ponder, D.A. Case, Force fields for protein simulations. Adv Prot Chem 66, 27 (2003)

T.E. Cheatham III, M.A. Young, Molecular dynamics simulation of nucleic acids: successes, limitations and promise. Biopolymers 56, 232 (2001)

A.D. MacKerell Jr., N. Banavali, N. Foloppe, Development and current status of the CHARMM force field for nucleic acids. Biopolymers 56, 257 (2001)

P.B. Conrad, J.J. de Pablo, Computer simulation of the cryoprotectant disaccharide α, α-trehalose in aqueous solution. J Phys Chem A 103, 4049 (1999)

C.J. Roberts, P.G. Debenedetti, Structure and dynamics in concentrated, amorphous carbohydrate-water systems by molecular dynamics simulation. J Phys Chem B 103, 7308 (1999)

M. Umemura, S. Hayashi, T. Nakagawa, H. Urakawa, K. Kajiwara, Structure of water molecules in aqueous solutions of di-and penta-D-glucopyranoses using molecular dynamics simulation. J Mol St (Theochem) 639, 69 (2003)

M. Rampp, C. Buttersack, H.-D. Lüdemann, c,T- Dependence of the viscosity and the self-difusion coefficients in some aqueous carbohydrate solutions. Carbohydr Res 328, 561 (2000)

N. Ekdawi-Sever, J.J. de Pablo, E. Feick, E. von Meerwall, Diffusion of sucrose and α, α-trehalose in aqueous solutions. J Phys Chem A 107, 936 (2003)

W. Damm, A. Frontera, J. Tirado-Rives, W.L. Jorgensen, OPLS all-atom force field for carbohydrate. J Comput Chem 18, 1955 (1997)

H.J.C. Berendsen, J.P.M. Postma, W.F. van Gunsteren, J. Hermans, in Intermolecular forces, ed. by B. Pullman (Reidel, Dordrecht, 1981), p. 331

H.J.C. Berendsen, J.R. Grigera, T.P. Straatsma, The missing term in effective pair potentials. J Phys Chem 91, 6269 (1987)

W.L. Jorgensen, J.D. Madura, Temperature and size dependence for Monte Carlo simulations of TIP4P water. Mol Phys 56, 1381 (1985)

D. van der Spoel, E. Lindahl, B. Hess, G. Groenhof, A.E. Mark, H.J.C. Berendsen, GROMACS: fast, flexible and free. J Comp Chem 26, 1701 (2005)

Lide DR (ed) (2003) CRC handbook of chemistry and physics, 84th edn. CRC, Boca Raton

T. Darden, D. York, L. Pedersen, Particle mesh Ewald: an N-log(N) method for Ewald sums in large systems. J Chem Phys 98, 10089 (1993)

U. Essmann, L. Perera, M.L. Berkowits, T. Darden, H. Lee, L.G. Pedersen, A smooth particle mesh Ewald potential. J Chem Phys 103, 8577 (1995)

S. Nosé, A molecular dynamics method for simulations in the canonical ensemble. Mol Phys 52, 255 (1984)

W.G. Hoover, Canonical dynamics: equilibrium phase space distributions. Phys Rev A 31, 1695 (1985)

M. Parrinello, A. Rahman, Polymorphic transitions in single crystals: a new molecular dynamics method. Appl Phys 52, 7182 (1981)

M.W. Mahoney, W.L. Jorgensen, Diffusion constant of the TIP5P model of liquid water. J Chem Phys 114, 363 (2001)

C. Vega, J.L.F. Abascal, M.M. Conde, J.L. Aragones, What ice can teach us about water interactions: a critical comparison of the performance of different water models. Faraday Discuss 141, 251 (2009)

X. He, A. Fowler, M. Toner, Water activity and mobility in solutions of glycerol and small molecular weight sugars: implication for cryo- and lyopreservation. J Appl Phys 100, 074702 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hagiwara, T., Sakiyama, T. & Watanabe, H. Estimation of Water Diffusion Coefficients in Freeze-Concentrated Matrices of Sugar Solutions Using Molecular Dynamics: Correlation Between Estimated Diffusion Coefficients and Measured Ice-Crystal Recrystallization Rates. Food Biophysics 4, 340–346 (2009). https://doi.org/10.1007/s11483-009-9132-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-009-9132-9