Abstract

STEPSCAN differential scanning calorimetry, a form of temperature-modulated differential scanning calorimetry (DSC), was used to study the thermal transitions occurring during the heating of chocolate of varying thermal histories. Conventional DSC thermograms acquired during heating of chocolate can be complex, with the observation of a series of overlapping endothermic and exothermic events. STEPSCAN DSC was used to deconvolute the total heat flow into reversing (rapid) and nonreversing (slow) components, which were assigned to melting and recrystallization events, respectively. Such a separation is usually difficult using conventional DSC. The recrystallization events were more pronounced in rapidly cooled samples where the polymorphic form V had been nucleated through tempering. Because of the presence of artifacts, STEPSCAN can only provide a crude separation of reversing and nonreversing signals in this system. The general applicability and limitations of STEPSCAN DSC as well as the effects of prenucleation and rate of cooling of chocolate are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cocoa butter exhibits polymorphism, i.e., the ability to exist in several crystalline forms. Six polymorphic states are generally recognized for cocoa butter and are identified as forms I to VI.1 These forms can be assigned to the polymorphs α, β′, and β, based on the lateral packing. The formation of polymorphic form V of cocoa butter has long been accepted as optimal for chocolate manufacture due to its melting point (∼28–32°C depending on chocolate composition) occurring above typical room temperature but below physiological temperature. This makes it solid under ambient conditions but able to melt in the mouth and exhibit the sensory properties desirable of chocolate.2 Form V also gives the desirable gloss and snap associated with good-quality chocolate and good demolding properties.3 The presence of lower forms is known to compromise the final product quality by producing chocolate, which melts at low temperatures, has difficulties in demolding, and eventually exhibits fat bloom—a whitish discoloration caused by recrystallization into more stable higher melting temperature forms.2

Differential scanning calorimetry (DSC) is an important technique for the study of the melting and crystallization behavior of confectionery fats, cocoa butter, and pure triacylglycerols.4 – 7 It provides information on the “quality” of the chocolate, which can be related to processing conditions such as the level of tempering and final cooling rate of the product. However, the interpretation of a DSC thermogram is often complex due to various underlying transformations, such as melting and recrystallization, occurring concurrently during heating. Several weak, broad, and overlapping transitions are often seen for chocolate and other foods.8 , 9 It has been reported that modulated DSC techniques have the ability to separate thermograms into reversing (melting) and nonreversing (kinetic/crystallization/recrystallization) traces.

To increase the sensitivity (i.e., signal-to-noise) for the detection of a weak transition, either the sample mass or the scan rate can be increased. To obtain a higher resolution to separate transitions occurring at similar temperatures, either smaller samples are used or the heating rate is decreased. Therefore, increased sensitivity is usually at the expense of the resolution and vice versa.9 The aim of this study was to examine the potential for the use of STEPSCAN DSC to obtain enhanced information regarding the phase behavior of chocolate without necessarily compromising on sensitivity or resolution. This was achieved by comparing the transformations occurring during the heating of chocolate produced by different cooling regimes from a tempered or untempered state using conventional and STEPSCAN DSC.

Temperature-modulated differential scanning calorimetry

Temperature-modulated differential scanning calorimetry (TMDSC) techniques have been recently developed to offer a better understanding of thermal phase transitions particularly in the study of polymers.10 In contrast to conventional DSC, where a linear and constant heating rate is applied, TMDSC uses a periodic temperature modulation over a linear heating or cooling profile. It is claimed to be capable of giving accurate heat capacity measurements and separating underlying kinetic and thermodynamic phenomena with better resolution and sensitivity. Two main types of TMDSC have evolved. One uses a sinusoidal wave modulation and the other uses isothermal heat/cool segments, for example, STEPSCAN (Perkin Elmer Inc).

The theory and principles of TMDSC using sinusoidal modulation can be found in articles by Reading, Schawe, and Wunderlich.11 – 14 Reading13 proposed that the resultant modulated heat flow can be deconvoluted by using a Fourier transform to give reversing and nonreversing components.13 The reversing component is calculated from the periodic part of the heat flow and provides information on events that are thermodynamically reversible in a given time.15 The nonreversing component is the difference between the underlying heat flow and the reversing component.

The temperature program according to Reading et al. 13 is expressed as:

where T 0 is the starting temperature, b is the heating rate, B is the amplitude of temperature modulation, and ω is the frequency.

According to the same authors, assuming the temperature modulation is small and that over the interval of modulation the response of the kinetic process to temperature is approximately linear, the heat flow equation can be written as:

where f′(t,T) is the average underlying kinetic function once the effect of the sine wave has been subtracted, C is the amplitude of the kinetic response to the sine wave modulation, and [b + Bcos (ωt)] is the measured quantity dT/dt.

In temperature-modulated experiments using the sine wave function, there are two main methods to analyze the resulting modulated heat flow: the reversing/nonreversing heat flow approach as described by Reading et al. 16 and the complex heat capacity approach proposed by Schawe.11

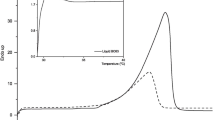

STEPSCAN DSC, as provided by Perkin Elmer, is a simplified version of TMDSC and does not involve complex Fourier transform for the deconvolution of the heat capacity data.17 The temperature program consists of periodic short heating rates and isothermal segments. The isothermal holds continue until the heat flow rate falls below a predetermined value (or criterion). The thermodynamic component is the heat flow response to the heating (or cooling) segment and reflects the so-called reversing changes of the sample. The nonreversing change is obtained from the heat flow at the end of the isothermal segment and is sometimes known as the Iso-K (kinetic) baseline (see Figure 1). The interpretation of results is similar to TMDSC, and the reversing thermodynamic or C p signal (reversible under the experimental conditions) and nonreversing (Iso-K baseline, kinetic) contributions can be directly and simply extracted from the data as described in Eq. 3.13 , 17

where dH/dt is the overall heat flow, C p the heat capacity, dT/dt the heating rate, and f (t,T) is the kinetic response that is a function of time and temperature. By treating the f(t,T) as an effective offset or baseline, this can be removed and the heat capacity on heating calculated as the heat flow divided by the heating rate:13 , 17

Materials and methods

Sample preparation

The experiments were performed using samples of commercial milk chocolate (composition: 47% sugar, 17% milk nonfat solids, 17% cocoa butter, 7% milk fat, 5% cocoa solids, 5% vegetable fats, and emulsifiers). Because the prior thermal history of the chocolate would have a significant effect on its melting behavior (polymorphic transformation), the chocolate was melted and retempered to produce samples of known thermal histories. Tempering was carried out to nucleate the form V polymorph in a purpose-built, laboratory-scale tempering machine under continuous shear. The tempering profile used was as follows: melt at 55°C and maintain under shear for 20 min to melt out all fat crystals. This was followed by cooling to 22°C at a rate of ∼2°C min−1 then holding for 8 min to induce crystallization and finally reheating to 28°C and holding for 6 min to melt lower melting temperature polymorphs, leaving the mixture with only the high melting polymorph, form V. The importance of shear in the production of tempered samples is well known and has been discussed by several authors.18 – 21 Shearing is believed to enhance nucleation through the alignment of triglyceride molecules (primary nucleation), break up crystallites creating a greater number of seed crystals and thus initiate secondary nucleation, and enhance growth by improving mass transfer through the decrease of the thickness of the diffusion limiting stagnant film around nuclei.

When tested with a Grant Tempermeter® (Cambridge, UK) and from DSC (described subsequently) and X-ray diffraction (XRD; not shown) results, this tempering profile was found to produce chocolate seeded with form V crystals.

Differential scanning calorimetry

Thermal analysis was performed using a Pyris Diamond DSC (Perkin Elmer, UK), calibrated for temperature and heat flow using indium. The preparation of the pans was carried out in a temperature-controlled environment with all instruments being maintained at 28°C. To minimize uncontrolled cooling of the chocolate during the transfer of the sample from the temperer to the DSC apparatus, the sample weight (between 15 and 25 mg) was determined after the completion of the experiment and used to normalize the heat flow data. For tempered samples, the chocolate was immediately transferred from the temperer, sealed into 50 μL aluminum pans, and inserted in the calorimeter held at 28°C. The entire sample transfer procedure was carried out in less than 60 s. The samples were then cooled at 1°C min−1 to favor the growth of form V seed crystals or 10°C min−1 to simulate rapid cooling to produce lower melting polymorphic forms. The final temperature at the end of cooling was fixed at −30°C. Once at −30°C, the samples were held for 2 min and were then heated to 50°C linearly at 2°C min−1 (to match the underlining heating rate of the STEPSCAN experiment) to obtain conventional DSC thermograms and in STEPSCAN mode using the following parameters: amplitude (step size) of 2°C, heating rate of 150°C min−1, an isothermal time of 5 min and equilibrium criterion (±0.01 mW), giving an overall underlying heating rate of approximately 2°C min−1.

The data was analyzed using Pyris version 7.0 software provided by Perkin Elmer. Untempered chocolate samples produced by melting chocolate in DSC pans at 50°C in the calorimeter were used as controls to assess the role of tempering. These untempered samples were produced in the absence of shear, as the aim was to produce samples that had no nuclei of any polymorph of cocoa butter. The samples were cooled at 10°C min−1 to −30°C to simulate rapid cooling. Following rapid cooling, these samples were warmed to 50°C linearly at 2°C min−1 and in STEPSCAN mode using the same parameters as for the tempered samples (see above).

Many experiments with numerous replications (typically greater than five) were carried out under various cooling and heating rates. Examples showing typical traces have been selected from the data set. Although the relative magnitude of the endothermic and exothermic events observed varied between replications, the number of these events and the temperature at which they occurred were reproducible to within ±0.4°C. This point is further discussed in Results and discussion.

Results and discussion

Modulated methods and artifacts

When using temperature-modulated methods, it is important to decide on the limits of applicability. Schawe and Hohne22 gave clear guidelines as to when the reversing and nonreversing signals may be accurately separated for temperature profiles having a sine wave oscillation of temperature superimposed on a linear temperature ramp. Briefly, these authors stated that for kinetically restricted transformations/reactions, such as cold crystallization processes in polymers, the approximate equation (Eq. 5) must apply to measure the reversing signal accurately from the oscillatory heat flow response and to allow the calculation of the nonreversing signal by subtracting the reversing component from the total heat flow:22

where β 0 is the underlying heating rate, H r is the partial enthalpy of reaction, α is the degree of the reaction, ω 0 is the frequency of modulation, and T a is the temperature amplitude of modulation.

This equation is an approximation in the sense that the reaction must be fast enough to be in equilibrium with the temperature change and that the amplitude of temperature modulation must be sufficiently small that high terms in the temperature-dependent expansion of the reaction rate can be neglected.

However, the method of calculating signals is completely different in STEPSCAN and Eq. 5 does not apply directly. As Figure 1 shows, the nonreversing signal can more correctly be labeled the slow component, and is the power offset at the end of the isotherm, whereas the reversing trace is calculated from the amount of heat required to raise the sample temperature by a given amount; a conventional heat capacity measurement. Although the exact details of the algorithm, which is proprietary, are not available, the limitations of the method can be mapped experimentally. This was performed on tripalmitin and chocolate and the conclusions are described below. To avoid artifacts and achieve at least an approximate separation into reversing or rapid and nonreversing or slow signals, it is important to choose appropriate values for the (1) amplitude, (2) isotherm length, and (3) step rate (see Figure 1).

-

(1)

The use of large values for the temperature step leads to widened peaks and impaired resolution, due almost certainly to an averaging procedure. To preserve the resolution, small steps should be chosen. This is particularly important, for example, when studying pure triacylglycerols where transitions occur over a narrower temperature range than in the case of a mixed system like chocolate. However, the overall sensitivity is impaired by small values, with 1°C to 2°C producing less noise compared with 0.5°C.

-

(2)

The isotherm length is a crucial parameter. As Figure 2 (top) shows, too short a choice leads to reversing signal appearing in the nonreversing trace and inaccuracies appearing in the calculation of C p. However, as shown on Figure 2 (bottom), for tripalmitin, which exhibits rapid recrystallization, if the choice of isotherm is long compared with the rate of recrystallization, then the isokinetic baseline gives misleading estimates of the process. A choice of smaller amplitude steps can help in such situations. In fact, in chocolate, the recrystallization events are sufficiently fast that the STEPSCAN method, within the limits of the instrumentation, can only provide an approximation to the transformation.

-

(3)

The rate of temperature increase of the step was found to have little effect. This was expected as the calculation of C p was simply made from the heat flow produced in response to the overall increase in temperature.

The effect of isothermal time on the heat flow signal (top). Too short a time leads to the C p or reversing signal appearing in the isokinetic or nonreversing trace. The distortions (bottom) can arise in the nonreversing trace when the transformation is rapid. This trace is for the tripalmitin (temperature step = 0.5°C, isotherm length = 1 min, and heating rate for the step = 150°C min−1), which rapidly transforms from the α to the β polymorph. Too long an isothermal time results in the heat flow of the reaction being “missed.”

Before carrying out STEPSCAN experiments, it was necessary to vary the experimental parameters on chocolate samples to obtain the set of conditions that would lead to the optimal results and minimize the influence of artifacts. As has been discussed above, the choice of parameter value to optimize one feature, for instance the separation of reversing and nonreversing signals where long isothermal time could be in conflict with the value required to optimize another feature, e.g., the accurate recording of the nonreversing signal (short isothermal time). A compromise set of parameters was chosen as follows: a step size of 2°C, a step heating rate of 150°C min−1, and an isothermal time of 5 min. These parameters will only be applicable for these samples and must be optimized for other systems.

It may have been possible, by judicious manipulation of the criterion for equilibration, which is the STEPSCAN parameter responsible for deciding when to move to the next heating step, to minimize some of the artifacts involved, particularly those associated with the length of the isotherm. However, in the absence of more detailed information on the operation of the parameter, this was not pursued.

Slow cooling experiments

The thermograms acquired using conventional DSC by heating at 2°C min−1 on tempered chocolate, which had been cooled to −30°C at 1°C min−1, showed a series of endotherms, the main one having a peak temperature of ∼28°C. A typical result is shown in Figure 3. The melting temperature of form V of cocoa butter is reported as 33.8°C.1 However, this value is usually depressed by the presence of other fats such as milk and vegetable fats.23 In this formulation of chocolate, milk fat contributed ∼7% of the total ingredient list. It is therefore highly likely that the major melting event occurring at 28°C is that of the form V polymorph. The thermogram indicates that for tempered chocolate at a low cooling rate, the kinetics favor the growth of form V rather than the nucleation and growth of lower forms. This is in agreement with current manufacturing practice. Other minor melting events are observed at temperatures (peak) of ∼9°C, 14°C, and 19°C. These are attributed to low-melting-point triacylglycerols present in the fat fraction of chocolate solidifying due to the sample of chocolate being cooled to −30°C. These triacylglycerols would normally be in the liquid phase at room temperature. STEPSCAN was used to facilitate the assignment of thermal events on the thermograms.

Figure 4 shows the processed STEPSCAN thermogram deconvoluted into the reversing and nonreversing heat flow components. The total heat flow trace was only broadly similar to that obtained by conventional DSC (Figure 3). The reversing component showed similar melting endotherms to those in Figure 3, namely at peak temperatures of 5–9°C, 24°C, and 29°C. The nonreversing trace showed evidence of exothermic heat flow at ∼11°C, 22°C, and 26°C, suggesting that crystallization events overlapped some of the melting events. This observation, which cannot be unequivocally implied using conventional DSC, is of significance, as it could lead to a range of artifacts in conventional DSC analysis of chocolate. Distortion of melting endotherms could lead to the underestimation of latent heat of melting, as the measured values reflect the overall sum of endothermic and exothermic heat components, together with errors in estimating peak temperatures.

However, there are still significant artifacts present on the STEPSCAN thermograms. The resolution is lower on Figure 4 as compared with Figures 3 and 5, due to the large step amplitude (2°C); however, both of the major melting peaks on Figures 3 and 4 are probably composite peaks composed of at least two underlying melting peaks. It is also worth noting that the peak temperature of the main melting endotherm (occurring at ∼24°C) in both the reversing and the total heat flow of the STEPSCAN data is shifted to slightly lower values compared with the conventional DSC. This is thought to be due to the fact that the calibration is applied to the thermal data when the heating has stopped during the isothermal hold. A small increment should be added to temperature onset values in this case typically of the order of 0.5°C for a 10°C min−1 calibration. The issue of calibration is complex and there has been no accepted protocol on what calibration should be applied when using STEPSCAN DSC. The difficulty is in the choice of time–temperature profile for the calibration and a suitable standard. In this study, a calibration performed at a constant heating rate of 2°C min−1 was used. This rate matches the underlying heating rate of the STEPSCAN time–temperature profile.

Rapid cooling experiments

To assess the impact of rapid cooling on the DSC melting thermogram, tempered chocolate was cooled in the calorimeter at a rate of 10°C min−1. Cooling at this rate would be expected to lead to the formation of lower melting temperature polymorphs.24

The main difference in the melting behavior of the rapidly cooled tempered chocolate was the presence of suspected exotherms centered at ∼13°C and 28°C (Figure 5). This pattern suggested that at a cooling rate of 10°C min−1, a significant fraction of chocolate crystallized into low-melting-point polymorphs, which melted on heating and subsequently recrystallized into higher-melting-temperature ones, which then melted at temperatures comparable with those of the higher-melting-temperature polymorphs obtained on slow cooling (Figure 3). It is worth noting, however, that the rapid cooling experiments exhibited a high degree of variability at higher heating rates. The pronounced recrystallization exotherms were observed in approximately one sample out of three at rates >10°C min−1 in conventional DSC runs. This variability is unlikely to be due to variation in the initial degree of temper of the chocolate because the samples were uniformly sheared in the temperer to evenly distribute form V nuclei throughout the sample. Furthermore, increasing sample size to increase the number of nuclei in a given DSC pan and address potential heterogeneity in nuclei had no significant impact. A more likely explanation, therefore, is the inverse relationship between heating rate and time being allowed for recrystallization events to proceed. A lower heating rate would allow more time for the system to convert to higher forms over a wider temperature range. This is indeed the case as the STEPSCAN experiments, which incorporate an isothermal hold time, carried out on rapidly cooled chocolate samples (discussed below), showed the recrystallization event in every run.

STEPSCAN thermograms for a tempered chocolate sample that was cooled at 10°C min−1 are shown in Figure 6. The results clearly show the large nonreversing heat flow component centered at ∼12°C relating to a recrystallization exotherm. The nonreversing curve shows multiple, albeit small, crystallization events occurring at temperatures of ∼7°C, 12°C, 17°C, 22°C, and 26°C, which cannot all be detected in the conventional DSC trace. The observation of multiple crystallization events indicates that transformation processes are complex. The melting events are also clearly separated out, and, hence, it is possible to calculate the crystallization and melting enthalpies involved from the nonreversing and reversing traces, respectively. Such a calculation, although possible, is of little quantitative value due to inaccuracies in the nonreversing trace and the fact that the melting enthalpy of cocoa butter is strongly dependent on its polymorphic form,25 which is not known accurately without recourse to simultaneous XRD.

It is, however, interesting to compare the melting enthalpies obtained from the conventional and STEPSCAN DSC analysis. The overall endothermic melting enthalpy obtained by integrating the conventional DSC thermogram for the tempered chocolate cooled at 1°C min−1 over the temperature range −10°C and 40°C was 31 J g−1. This value is comparable with that obtained from the equivalent total (reversing + nonreversing) STEPSCAN thermogram (34 J g−1) but smaller than that obtained from the reversing component of the thermogram (40 J g−1). The difference between the reversing STEPSCAN and the conventional DSC values reflects the inability of the latter to separate exothermic contributions from the crystallization events discussed above. Additionally, milk fat and sugar do not contribute to the enthalpy. The net result is to cause the recorded values of between 30 and 40 J g−1 to be much less than the values for pure cocoa butter. For example, the ΔH m of form II of cocoa butter (T m = 23.3) is ∼86 J g−1 while that of form V (T m = 33.9°C) is ∼137 J g−1.

The effect of tempering on recrystallization

While the transformation on heating of lower- to higher-melting-point polymorphs is significant, even in chocolate cooled slowly (1°C min−1), it is not clear whether the existence of higher-form nuclei (as a result of tempering) plays any role in this transformation. To answer this question, conventional and STEPSCAN DSC experiments were performed on untempered chocolate samples in rapid cooling conditions (10°C min−1). When comparing the result of conventional DSC melting of the untempered to tempered chocolate (Figure 7), it was clear that the untempered chocolate crystallized largely into an intermediate-melting-point polymorph believed to be form II (confirmed by XRD, results not shown), which had a peak temperature of ∼17°C. Minor melting endotherms where observed at −11°C and 25°C. There was no evidence of any higher forms (forms V and VI). The absence of a crystallization exotherm in the conventional DSC thermogram of the untempered sample was the most striking difference when compared with the behavior of the tempered sample, suggesting that the existence of nuclei is necessary for the recrystallization process. The free energy of formation of nuclei of the higher forms, despite being the most stable, is high. Furthermore, there is insufficient time during a scan (STEPSCAN or conventional) for nucleation to occur.

STEPSCAN was performed on a sample of untempered chocolate cooled at 10°C min−1 to test the above proposal, i.e., the absence of recrystallization in nonnucleated systems. The results were compared with those obtained on the nucleated/tempered system (Figure 8). Although some evidence of multiple recrystallization events can be seen on the nonreversing trace, they were of a much smaller magnitude compared with the results obtained with tempered chocolate under the same experimental conditions and time frame. This confirms the suggestion made above that nuclei of a higher form (form V in this instance) are required for well-defined recrystallization to take place.

Conclusion

STEPSCAN is a useful addition to DSC and offers additional information in the thermal analysis of tempered and untempered chocolate. The technique demonstrated that even in slowly cooled tempered chocolate, there is formation of low-melting-point polymorphs. This is more pronounced for rapidly cooled chocolate. These low-melting polymorphs melt on heating and the liquid formed is consumed in the growth of existing high-melting-point nuclei. This finding questions the validity of DSC-determined melting enthalpies and temperatures of polymorphs of mixed systems.

However, the isokinetic (nonreversing) recording of kinetic processes is poor if the process is fast or if incorrect parameters are chosen; nevertheless, the information even if approximate is useful. There are further limitations to the technique. A STEPSCAN measurement generally requires more time than conventional DSC because a lower underlying heating rate is normally used. Moreover, care and time must be taken in determining the STEPSCAN parameters (step size, isothermal time, and step heating rate) and interpreting their effect on the results.

References

R.L. Wille and E.S. Lutton, J Am Oil Chem Soc, 43, 491–496 (1966).

J. Schlichter-Aronhime and N. Garti, Solidification and polymorphism in cocoa butter and the blooming problems. In: Crystallisation and Polymorphism of Fats and Fatty Acids, edited by N. Garti, K. Sato (Marcel Dekker, Inc., New York 1988), pp. 363–391

R.B. Nelson, Enrobers, moulding equipment and coolers. In: Industrial Chocolate Manufacture and Use, 3rd edn., edited by S.T. Beckett (Blackwell Science, Oxford 1999), pp. 259–286

G. Keller, F. Lavigne, C. Loisel, M. Ollivon and C. Bourgaux, J Therm Anal 47, 1545–1565 (1996).

C. Loisel, G. Keller, G. Lecq, C. Bourgaux and M. Ollivon, J Am Oil Chem Soc 75, 425–439 (1998).

G. Spigno, G. Pagella and D.M. De Faveri, Ital J Food Sci 13, 275–284 (2001).

P. Robinson and W.J. Sichina, Characterization of chocolate using power compensated DSC. In: PerkinElmer Technical Note; PETech–43 1 (2000).

P. De Meuter, H. Rahier and B. Van Mele, Int J Pharm 192, 77–84 (1999).

E. Verdonck, K. Schaap and L.C. Thomas, Int J Pharm 192, 3–20 (1999).

B.B. Sauer, W.G. Kampert, E. Neal Blanchard, S.A. Threefoot and B.S. Hsiao, Polymer 41, 1099–1108 (2000).

J.E.K. Schawe, Thermochim Acta 260, 1–16 (1995).

B. Wunderlich, A. Boller, I. Okazaki and K. Ishikiriyama, Thermochim Acta 305, 125–136 (1997).

M. Reading, A. Luget and R. Wilson, Thermochim Acta 238, 295–307 (1994).

Y. Kraftmakher, Modulation Calorimetry (Springer, New York 2004).

L.M.W.K. Gunaratne, R.A. Shanks and G. Amarasinghe, Thermochim Acta 423, 127–135 (2004).

P.S. Gill, S.R. Sauerbrunn and M. Reading, J Therm Anal 40, 931–939 (1993).

M. Sandor, N.A. Bailey and E. Mathiowitz, Polymer 43, 279–288 (2002).

A.G.F. Stapley, H. Tewkesbury and P.J. Fryer, J Am Oil Chem Soc 76, 677–685 (1999).

S.D. MacMillan, K.J. Roberts, M.A. Wells, M.C. Polgreen and I.H. Smith, Cryst Growth Des 3, 117–119 (2003).

G. Mazzanti, S.E. Guthrie, E.B. Sirota, A.G. Marangoni and S.H.J. Idziak, Cryst Growth Des 3, 721–725 (2003).

C. Loisel, G. Keller, G. Lecq, B. Launay and M. Ollivon, J Food Sci 62, 773–780 (1997).

J.E.K. Schawe and G.W.H. Hohne, Thermochim Acta 287, 213–223 (1996).

S.Y. Reddy, N. Full, P.S. Dimick and G.R. Ziegler, J Am Oil Chem Soc 73, 723–727 (1996).

J.W. Hagemann, Thermal behaviour and polymorphism of acylglycerides. In: Crystallisation and Polymorphism of Fats and Fatty Acids, edited by N. Garti and K. Sato (Dekker, New York 1988), pp. 10–87

W.R. Rudnicki and M. Niezgódka, Modelling phase transitions in chocolate. 4th International Symposium on Confectionery Science, Hershey, PA, USA (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baichoo, N., MacNaughtan, W., Mitchell, J.R. et al. A STEPSCAN Differential Scanning Calorimetry Study of the Thermal Behavior of Chocolate. Food Biophysics 1, 169–177 (2006). https://doi.org/10.1007/s11483-006-9018-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-006-9018-z