Abstract

“Green development” has become the way for countries around the world to strengthen industries, and it is an important part of China’s high-quality economic development. The key for China to strike a balance between economic growth and environmental management is to optimize green total factor productivity (GTFP). This paper measures the GTFP of industry in 30 provinces of China from 2003 to 2019, based on the perspective of energy and carbon emission constraints. It empirically examines the spatial disequilibrium and dynamic evolution of industrial GTFP in China using Dagum Gini coefficients, Kernel density estimation, and Markov chain analysis. The study finds that, (1) although China’s industrial GTFP is not high, it shows an increasing trend. The industrial GTFP in the southern region is higher than that in the northern region. (2) Technical efficiency is the shortcoming of China’s industrial GTFP improvement. Technological progress is the main driving force of China’s industrial GTFP improvement. (3) The relative and absolute differences in China'’ industrial GTFP, technical efficiency, and technological progress have all shown a widening trend. Regional differences between the southern and northern regions are the main source of relative differences in industrial GTFP, technical efficiency, and technological progress. (4) China’s industrial GTFP shows a clear “club convergence” phenomenon and the “Matthew effect.” However, after the introduction of the spatial factor, the “club convergence” phenomenon and the “Matthew effect” have weakened. The driving effect of industrial GTFP on neighboring provinces is stronger in the south than in the north. This paper enriches the analysis of industrial GTFP and provides an important basis for the coordinated regional development of Chinese industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In 2018, global carbon emissions reached 34.05 billion tons, three times higher than in 1965. Global per capita carbon emissions grew to 4.42 tons per person in 2018, an increase of 20% compared to 1971. Economic growth in countries such as China and Japan has contributed to the rapid increase in carbon emissions in Asia, which is gradually becoming the world’s largest carbon emitting region. By 2020, China will account for 30.7% of the global carbon emissions, becoming the world’s largest carbon emitter. Therefore, it is of profound significance to study China’s industrial GTFP.

From the beginning time of reform and open, China’s economy is growing at a high speed. But it is more difficult to maintain economic growth than to start economic growth. However, the rapid economic growth over the past four decades has also brought serious environmental problems, and the problem of unbalanced and insufficient development is more prominent, hindering further economic growth. The 14th Five-Year Plan for National Economic and Social Development of the People’s Republic of China and the Outline of Vision 2035 state that China has shifted to a high-quality development stage, with significant institutional advantages and strong development resilience. In September 2020, China clearly set out the targets for “carbon peaking” by 2030 and “carbon neutral” by 2060. Under the new situation, the essence of promoting high-quality economic development is to improve energy efficiency and reduce environmental pollution in parallel with economic development, that is, to improve GTFP. Therefore, China’s economic development has put forward higher requirements for industrial GTFP.

The report of the 20th National Congress of the Communist Party of China stated that accelerating the construction of a new development pattern and making efforts to promote high-quality development to improve total factor productivity. The report also emphasized accelerating the green transformation of development methods, implementing comprehensive conservation strategies, developing green and low-carbon industries, advocating green consumption, and promoting the formation of green and low-carbon modes of production and lifestyles. Combined with China’s actual national conditions, in the context of global sustainable development, China needs to rely on the green development system to integrate into the global sustainable development trend. In the face of the severe ecological crisis, a green economy oriented towards quality and efficiency is the strategic choice to seize the economic high ground. A green economy requires economies to adhere to green development, use green technologies, build green development systems, emphasize high quality and green supply in the production chain, and increase the country’s economic adaptive capacity.

President Xi pointed out that China’s regional development is in a good situation. The regional economic development divergence trend is obvious; the Yangtze River Delta, the Pearl River Delta, and other regions have initially embarked on the track of high-quality development. The growth of some northern provinces slowed down, and the national economic center shifted to the south. Since the reform and opening up, the gap between the north and the south has further widened to a large extent, with the total economic output of the north accounting for about 46% in 1978 and the total economic output of the northern regions accounting for about 35% in 2020. Due to different asset endowments and development characteristics, regional economic development is also different. Industrialization took place first in the north, with economic development ahead of the south. But since China began to reform and open up in 1978, China has put forward the policy of establishing a socialist market economy so that the market plays a fundamental role in the allocation of resources. Fujian and Guangdong provinces became the first pilot provinces and carried out market-oriented economic reforms. Six special economic zones, including Shenzhen, Zhuhai, Xiamen, Shantou, and Hainan Island, were established to actively explore and promote market-oriented reforms around the socialist market economy. As industry in the north is mainly “heavy industry,” in the south is mainly “light industry.” The north is heavily affected by economic fluctuations and external shocks, making transformation and upgrading more difficult. Environmental pollution is more serious in heavy industry in the north, and green development is difficult and tortuous. In contrast, the southern region is closer to the market demand, the level of technological innovation is relatively high, and the effect of environmental management is relatively good. China’s economic center has shifted southward, widening the gap between north and south.

The promotion of China’s industrial GTFP requires not only theoretical research, but also quantitative analysis. Existing research on industrial GTFP measurement and analysis has been relatively rich, but there are still some aspects that need to be expanded. The main contributions of this paper are as follows: Firstly, by constructing a scientific measure of industrial GTFP for China’s sub-provinces and north–south regions with industrial value added as the desired output, sulfur dioxide and carbon emissions as non-desired outputs, and capital, labor, and energy as production inputs, which more closely match the real situation of China’s industrial efficiency. Secondly, the Dagum Gini coefficient decomposition method is used to explore the spatial differences and sources of China’s industrial GTFP. This method can identify the GTFP improvement potential of 30 provinces in China and the sources of north–south differences. Thirdly, the Kernel density estimation method is applied to characterize the dynamics of the distribution of industrial GTFP in China and its evolutionary trends and to understand the spatial and temporal dynamics of absolute differences in industrial GTFP in China. Fourthly, the spatial Markov chain is used to examine the specific patterns of the dynamic evolution of industrial GTFP. This study provides a reference for enhancing industrial GTFP, promoting regional coordinated development of industrial GTFP, and formulating policies related to achieving green low-carbon development, and provides a theoretical basis for formulating targeted environmental regulation policy intensity in the process of ecological civilization construction.

Literature review

In 2021, the Ministry of Industry and Information Technology of China formulated the Notice on the “14th Five-Year” Industrial Green Development Plan, which clearly pointed out the need to create a green and low-carbon system with low energy resource consumption, low environmental pollution, and high economic growth quality. In the past 10 years, the Chinese government has formulated a large number of environmental regulations and policies, such as reducing sulfur dioxide and nitrogen oxides (NOx) and carbon dioxide emissions. But China’s energy consumption per unit of GDP and emission pressure are still relatively high (Xu et al. 2014; Wang et al. 2013; Hang et al. 2021). In the context, measuring and analyzing energy and environmental efficiency is of great significance for studying the status quo and trends of energy consumption, pollution emissions, and economic growth in China’s industrial sector (Wang and Wei 2016). Total factor productivity is usually used to measure the quality of economic growth. It can evaluate economic efficiency from the perspective of factor input and economic output and decompose the sources of economic efficiency growth (Krugman 1994). However, the process of economic growth is usually accompanied by the consumption of resources, which will cause damage to the natural environment to a certain extent. The damage is difficult to be accurately evaluated (Ma and Hong 2004). The research shows that green dynamic capability and environmental protection strategy play an indispensable role in promoting green vision and environmental performance, addressing climate change, preventing environmental pollution, and alleviating energy constraints (Yu et al. 2022; Latif et al. 2022). Advocating environmental awareness, green entrepreneurship orientation, sustainable investment concepts, and dynamic management decisions are crucial to promote green industrial development (San et al.2022; Zhu et al. 2020; Al 2021; Gebauer 2011; Tunio et al. 2021). Therefore, GTFP includes energy and environmental constraints, one of the important indicators to consider environmental protection, energy consumption, and the quality of economic growth (Chen and Golley, 2014; Mahlberg and Luptacik, 2014; Wang and Feng, 2015; Yin et al. 2019).

To analyze input–output efficiency that includes unfavorable factors, scholars commonly use the directional distance function (DDF) and Malmquist Luenberger (ML) index to measure the total factor productivity including expected output and non-expected output (Chung et al. 1997; Färe et al. 2001; He et al. 2013; Arabi et al. 2014). However, the method is limited to the solvability of linear function. On this basis, Oh (2010) applied the GML index containing global ideas to the measurement of environmental non-expected input–output models, taking the sum of input and output of each period as a common reference set, which can measure the efficiency of production technology with cyclic accumulation characteristics. Referring to previous studies, in order to more realistically assess the changes in the quality of economic growth in China’s industrial sector, we add industrial energy consumption and non-expected output that have adverse effects on the environment on the basis of the traditional total factor productivity input–output index. The GTFP systematically evaluates the actual efficiency of input and output of China’s industrial sector under energy and environmental constraints.

There are significant regional differences in China’s economic growth (Golley 2002; Liu et al. 2016; Hu et al. 2005). Studies have found that there are multiple difficulties in China, such as resource depletion, environmental degradation, and lack of advanced technology. The higher the dependence on traditional energy, the lower the energy efficiency (Dan 2007). In China, economically developed cities have higher energy and emission efficiency. There is still a significant imbalance in industrial development across the country (Wang and Wei 2014), and the imbalance is also reflected in the industrial water efficiency (Shi et al. 2021). In addition, the inefficient use of foreign resources (Wang et al. 2016), low industrial concentration, imperfect financing systems, and advanced technology gaps further restrict the growth of industrial efficiency in the central and western inland regions of China (Tian and Lin 2018).

In recent years, China’s economic center has been moving southward and the development gap between the north and the south has been widening, which has become a new feature of China’s regional development (Huang et al. 2021). China’s industrial layout has long exhibited the characteristics of southern light and north heavy, the industrial layout in the north is dominated by heavy industry (Xue et al. 2018), while the south is more focused on the development of light industry. The main reason is that natural resources such as coal, iron ore, and oil are mainly located in northern of China. The southern region has better labor, transportation, and trade conditions, so it is more inclined to develop light industries that are less dependent on natural resources. Affected by factors such as politics, economic system reform, technology introduction, and industrial structure, after the reform and opening up, the level of economic development in the north and south of China has gradually differentiated (Wu 2001; Barbieri et al. 2012). Especially since the twenty-first century, the focus of China’s industrial energy consumption has gradually shifted from coastal areas to inland areas (Zhou et al. 2016), the carbon emission reduction potential and new energy development also have significant regional differentiation (Pan and Dong 2022; Cui et al. 2021). With the exposure of energy consumption, environmental pollution, lagging industrial upgrading, and overcapacity issues, resource-based cities in northern China are facing a more severe transformation dilemma (Chen et al. 2017). Some scholars have done a lot of quantitative analysis on the input–output efficiency of China’s sub-regions and industries (Liang et al. 2007; Chen et al. 2020a, b; Xu and Lin 2016; Jiang et al. 2019; Wei et al. 2019; Li et al. 2022), but few articles have conducted in-depth analysis of the internal mechanism of the formation of regional differences in China’s industrial efficiency. Therefore, based on previous studies, this paper re-measures industrial GTFP and decomposes its regional differences to clarify the sources of regional differences as well as their dynamic evolution.

Research methods and data

Research methods

GML index

In order to estimate the growth of environmentally sensitive industrial production efficiency, the production efficiency including both expected and unexpected outputs to evaluate the industrial GTFP should be defined (Chen and Golley 2014; Oh and Heshmati 2010; Tao et al. 2017). With reference to previous studies (Chung et al. 1997; Oh 2010), defining \(k= 1,\dots ,K\) decision-making units (DMUs), \(s = 1,...t...T\) time periods. Each DMUs use \(N\) types of inputs \(x(x\in {R}_{N}^{+})\) to obtain \(M\) types of expected output \(y(y\in {R}_{M}^{+})\) and \(I\) type of non-expected output \(b(b\in {R}_{I}^{+})\). The production possibility set (PPS) under environmental constraints can be defined as \(P(x)=\{(y,b)|x\to (\mathrm{production})(y,b)\}\). The directivity distance function DDF is introduced, which represents the distance from each unit to the front surface:

In the formula, \(\beta\) is the expansion ratio of the expected output and the contraction ratio of the non-expected output and g is the direction vector, which represents the direction of the increase or decrease in expected and non-expected output. The environmental production technology set of the same period is defined as \({P}^{t}({x}^{t})=\{({y}^{t},{b}^{t})|{x}^{t}\to (\mathrm{production})({y}^{t},{b}^{t})\}\), so the global green production technology for the inter-period construction of the technological frontier is defined as \({P}^{G}={P}^{1}\cup {P}^{2}\cup \cdots \cup {P}^{T}\), and the distance between the decision-making units in different periods and the common frontier can be calculated. The DDF (\({D}^{G} = \max \{\beta :(y + \beta y, b-\beta b)| \in P|(x)\}\)) is defined on the global technology set \({P}^{G}\). The GML of the decision-making unit in period t to t + 1, as shown in Eq. (2).

Furthermore, the GML index can be decomposed into the form of a product of EC and TC, which are used to evaluate the position change (EC) of each decision-making unit to the production boundary and production efficiency to changes in production technology boundaries (TC) (Pastor and Lovell, 2005; Oh, 2010; Fan et al. 2015).

When the obtained \(GM{L}^{t,t+1}>\) 1, it means the GTFP growth; when the \({EC}^{t,t+1}>\) 1, it means technical efficiency is improved; when the \({TC}^{t,t+1}>\) 1, it means technological progress, and equal to 1 means that the index has not changed, and vice versa, since the GML index reflects changes in the growth of GTFP. This article draws on related research (Lin and Chen 2018) and uses the cumulative multiplication method to calculate the final GTFP.

Dagum Gini coefficient

We use the Dagum Gini coefficient decomposition method to analyze the regional differences in China’s industrial GTFP, and decompose the regional differences into three parts: intra-regional differences, inter-regional differences, and ultra-variable density contributions. First, calculate the Gini coefficient; the formula isFootnote 1:

Then, we measure the overall difference, intra-regional difference, inter-regional difference, and hypervariable density of China’s industrial GTFP.

Kernel density estimation

Kernel density estimation uses continuous density curves to estimate the probability density of random variables (Zeng et al. 2022). Compared with other estimations, its model dependence is weaker and its robustness is stronger. Assuming \(f(x)\) is the density function of random variable \(x\), the formula is as follows:

\(N\) is the total number of observations; \({X}_{\mathrm{i}}\) represents the observations with independent and identical distribution characteristics; \(\overline{x}\) represents the mean of all observations; \(K(x)\) is the kernel density function, as in Formula (14); and \(h\) is the broadband; if the broadband is larger, it means that the smoother the density function image, the lower the accuracy of the estimation. On the contrary, if the bandwidth is smaller, the density function is less smooth and its accuracy is higher. The Gaussian check used in this paper estimates the dynamic evolution of industrial GTFP across the country and the two major regions.

Spatial Markov chain

The traditional Markov chain discretizes continuous data into K types. Under the condition that both time and state are discrete, we calculate the probability distribution and evolution trend of each type, and obtain a K × K probability transfer matrix to reveal the laws of the development level of GTFP of different industries in different regions over time. \({p}_{\mathrm{ij}}\) represents the probability that a region will change from type i at time t to type j at t + 1, which can be estimated according to \({p}_{ij}={~}^{{n}_{ij}}\!\left/ \!{~}_{{n}_{ij}}\right.\). \({n}_{\mathrm{ij}}\) represents the sum of the number of provinces transferred from type i at time t to type j at time t + 1. \({n}_{\mathrm{i}}\) is the sum of the number of zones of type i for all time periods. The spatial Markov chain introduces the “spatial lag” into the traditional Markov chain. We analyze the influence of the development level of the industrial GTFP in the neighborhood on the transfer probability of the industrial GTFP in the region. We construct the economic distance matrix \(\mathrm{W}={W}_{1}*E\), where \({W}_{1}\) represents the geographic weight matrix, E is the economic difference matrix, and d is the spherical distance between the two provincial capitals. \({\overline{y} }_{\mathrm{m}},{\overline{y} }_{\mathrm{n}}\) represent the per capita GDP of m and n provinces in the sample period (Chen et al. 2020a, b).

Indicators and data processing

We measure the industrial GML index, EC index, and TC index based on the industrial input–output data of various provinces and cities in China from 2003 to 2019, and consider the labor and capital input of each province while also considering the “expected” output and “non-expected” output of the industry.

Input indicators

With reference to the research design of Xiao et al. (2022), we use the perpetual inventory method to estimate the total value of fixed assets in the industrial sector as the total capital stock, as the GTFP capital investment for the industrial sector. As for labor input, this article uses the average number of workers used by Chinese industrial enterprises above designated size as the proxy variable of labor input. In addition, energy consumption is also included in the input index. As part of the energy statistics data is missing, the energy consumption data of this article mainly adopts industrial energy consumption accounted for most of the former three kinds of the total energy consumption (coal, oil, natural gas). According to the various energy on the China national energy bureau disclosure of standard coal reference coefficient method, the equivalent industry terminal energy consumption of industrial energy of standard coal, and carry on the summary, to estimate the total energy consumption of China's industrial sector.

Output indicators

We choose industrial added value as a measure of the expected output in the industrial production process and use 2002 as the base period for deflation. At the level of industrial non-expected output indicators, a large amount of industrial waste is produced in the industrial production process, which will pollute the environment. Among them, sulfur dioxide is one of the most important causes of air pollution (Li et al. 2018). At the same time, the large amount of carbon dioxide produced by the industrial production department will also have an adverse effect on the atmospheric environment; excess carbon emissions pose a serious challenge to global warming and environmental governance (Cui et al. 2021). Therefore, we choose industrial sulfur dioxide emissions and carbon emissions as bad output, with reference to related studies (Fan et al. 2015). We choose the measured carbon emission factors in the production process as a proxy variable for carbon emissions, as provided by the official Chinese database (CEADs), according to the IPCC subsector emission calculation method.

Indicators and data sources

The data is selected from the National Bureau of Statistics of China, China Statistical Yearbook, China Industrial Economic Statistical Yearbook, China City (Town) Life and Price Yearbook, and EPS database.

Regional differences and sources of industrial GTFP in the north and south regions

The overall difference of China’s industrial GTFP

The overall difference

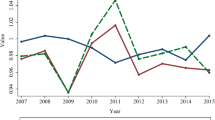

Figure 1 reveals the size and trend of changes in China’s industrial GTFP, technical efficiency, and overall differences in technological progress. Figure 1 describes that (1) from the perspective of changing trends, the Gini coefficient of China’s industrial GTFP shows an increasing trend in fluctuations. In 2003, the Gini coefficient of industrial GTFP was 0.063, which has been on the rise since then. It reached the maximum value of 0.1336 in 2019, with an average annual growth rate of 7.00%, indicating that the regional difference in industrial GTFP has further expanded; the technical efficiency Gini coefficient was 0.0726 in 2003, and it has shown steady growth since then. In 2012, the Gini coefficient reached the maximum value of 0.146, and the overall difference in technical efficiency expanded. After 2012, the Gini coefficient declined in fluctuations, and fell to 0.139 in 2019. The Gini coefficient of technical progress shows an upward trend throughout the sample period, from 0.077 in 2003 to 0.116 in 2019, with an average annual growth rate of 3.129%. Therefore, during the 2003–2019 observation period, China’s industrial GTFP, technical efficiency, and regional differences in technological progress showed an expanding trend. Among them, the regional differences in industrial GTFP expanded the most, followed by technical efficiency and technological progress. The widening of the difference is the smallest. (2) From the perspective of numerical value, the Gini coefficient of China’s industrial GTFP is relatively small, between 0.063 and 0.1336, with an average value of 0.104; the Gini coefficient of technical efficiency is relatively large, between 0.073 and 0.146, with an average value 0.126; the Gini coefficient of technological progress is between the total factor productivity of industrial green and the Gini coefficient of technical efficiency, with an average value of 0.113. It can be seen that among the three, the regional difference in technical efficiency is the largest, followed by technological progress, and industrial green. The regional differences in factor productivity are the smallest. (3) From the perspective of fluctuations, the dynamics of the Gini coefficient of industrial GTFP, technical efficiency and technological progress are similar. However, the relative position changed in 2015. Before 2015, the regional difference in technological progress was always higher than the regional difference in industrial GTFP, but after 2015, the regional difference in industrial GTFP has expanded and is higher than the regional difference in technological progress. The possible reasons are energy-saving and emission reduction policies in 2015 and special green development activities; in 2017, China proposed a “high-quality development” strategy to establish a sound, green, and low-carbon circular economy system, so it has a certain impact on regions where industries rely on high energy consumption and high pollution to develop, forming regional differences (Table 1).

Regional differences

Figure 2 further reveals the size and evolution of regional differences in China’s industrial GTFP, technical efficiency, and technological progress. China’s industrial GTFP differs from region to region. During the sample period, the Gini coefficient in the industrial GTFP region of the northern region showed an upward trend. The Gini coefficient increased from 0.404 in 2003 to 0.135 in 2019, with an average annual growth rate of 14.625%, indicating that the industrial rate in the northern region is full of factors. The regional difference in productivity has shown an expanding trend; the Gini coefficient in the southern industrial GTFP region has shown an upward trend. The Gini coefficient has risen from 0.0830 in 2003 to 0.1056 in 2019, roughly showing a trend of “rising-falling-rising.” From 2003 to 2009, the Gini coefficient rose in volatility, reaching its maximum value in 2009, and then slowly declining from 2009 to 2016. It began to rise from 2001 to 2019, with an overall average annual growth rate of 1.703%. In terms of numerical value, the Gini coefficient in the northern region (0.101) is slightly larger than that in the southern region (0.099), indicating that the regional difference in GTFP of the northern industry is larger than that in the southern region.

Technical efficiency varies from region to region. During the observation period, the Gini coefficient in both the northern and southern regions of technical efficiency shows an increasing trend. The Gini coefficient in the technical efficiency region of the northern region increased from 0.1026 in 2003 to 0.1872 in 2019, with an average annual growth rate of 5.155%, indicating that the technical efficiency gap between provinces in the northern region has further widened. The Gini coefficient in the technical efficiency region of the southern region increased from 0.0352 in 2003 to 0.0725 in 2019, with an average annual growth rate of 6.606%. The fluctuations showed a trend of “rising-falling-rising.” It rose in fluctuations from 2003 to 2009, and in 2009 the Gini coefficient was 0.0896. The Gini coefficient declined in fluctuations from 2009 to 2014. In 2014, the Gini coefficient was 0.0496, and the Gini coefficient for 2014–2019 decreased. In 2019, the Gini coefficient was 0.0725. In terms of the value of the Gini coefficient, the Gini coefficient in the technical efficiency region of the northern region is higher than that of the southern region, indicating that the difference in technical efficiency between provinces in the northern region (0.166) is higher than that in the southern region (0.166).

During the observation period, the Gini coefficient in both the northern and southern regions of technological advancement shows a significant growth trend. The Gini coefficient in the technological advancement area of the northern region shows a trend of “rising-falling-rising,” and the corresponding regional differences have undergone a process of “expanding-shrinking-expanding,” increasing from 0.0739 in 2003 to 0.110 in 2011 and dropping to 2016. The annual growth rate of 0.115 increased to 0.133 in 2017, and decreased to 0.118 in 2019, with an average annual growth rate of 2.326%. The Gini coefficient in the technological progress area of the southern region shows a trend of “rising-falling-rising,” rising from 0.0768 in 2003 to 0.119 in 2017, falling to 0.098 in 2010, and rising to 0.105 in 2019, with an average annual growth rate of 2.326%. From the perspective of the Gini coefficient in the technological advancement area, the Gini coefficient in the technological advancement area in the north (0.116) is higher than the Gini coefficient of the technological advancement in the south (0.100), indicating that the regional difference in technological advancement in the north is higher than that in the south. In summary, the regional differences in industrial GTFP, technical efficiency, and technological progress in the northern region are higher than those in the southern region, and they are all showing an expanding trend (Table 2).

Differences between regions

From the perspective of the size of the Gini coefficient between regions, as of 2019, the regional difference in technical efficiency is the largest (0.136), followed by the regional difference in industrial GTFP (0.109), and the regional difference in technological progress is the smallest (0.117). It shows that the main reason for the difference in total factor productivity between north and south industries is the large difference in technical efficiency. From the perspective of the change trend of the Gini coefficient between regions, industrial GTFP, technical efficiency, and technological progress all show different degrees of growth. The inter-regional Gini coefficient of industrial GTFP increased from 0.064 in 2003 to 0.148 in 2019, with an average annual growth rate of 8.059%; the inter-regional Gini coefficient of technical efficiency increased from 0.076 in 2003 to 0.152 in 2019, with an annual average. The growth rate was 6.246%; the Gini coefficient between regions of technological progress increased from 0.079 in 2003 to 0.120 in 2019, with an average annual growth rate of 3.244%. Therefore, regardless of the size of the Gini coefficient or the growth rate between regions, technical efficiency is the main source of regional differences in industrial GTFP (Fig. 3) and (Table 3).

Sources of regional differences and contribution rate

The source of difference in industrial GTFP

The inter-regional differences include the contribution rate of the net difference between the far and near super-variables and the contribution rate of the inter-regional super-variable density. According to Table 4, regional differences are the main source of unbalanced industrial GTFP distribution, with an average contribution rate of 52.169%. In the inter-regional contribution, the inter-regional ultra-variable net value shows an increasing trend in fluctuations, with a contribution rate ranging from 0.560 to 23.934%, and an average contribution rate of 10.103%, indicating that the net difference between different regions is becoming more and more serious. An important reason for the imbalance of industrial GTFP. The contribution rate of inter-regional hypervariable density is between 27.415 and 52.933%, and the average contribution rate is 42.066%. It shows a downward trend during the observation period, which means that the overlap between different regions has improved, but for industrial GTFP, the impact of differential production is still great. The contribution rate of the regional difference in industrial GTFP is between 44.581 and 49.179%, and the average contribution rate is 47.831%. It shows a downward trend during the observation period, indicating that the regional difference has a weak impact on the difference in industrial GTFP. Among the regional differences, the contribution rate of the regional difference in the southern region was higher than that in the northern region before 2011. After 2011, the contribution rate of the regional difference in the northern region was greater than the regional difference in the southern region. There is a large difference in industrial green total factor productivity, and there is a significant difference among provinces in the northern region.

Sources of differences in technical efficiency

Regional differences are the main source of differences in technical efficiency, with a contribution rate ranging from 51.749 to 55.970%, with an average contribution rate of 53.978%. Among the regional differences, the contribution rate of ultra-variable density is far greater than the contribution rate of ultra-variable net value, ranging from 28.017 to 55.431%, with an average contribution rate of 43.014%, indicating that the overlap between different regions is an important source of differences in technical efficiency. However, the contribution rate of hypervariable density shows a downward trend during the observation period, which means that the overlap between different regions has improved. The contribution rate of hypervariable net value ranges from 0.5393 to 25.339%, with an average contribution rate of 10.964%, and it shows an upward trend during the observation period, indicating that the problem of net differences in different regions is becoming more and more serious. The contribution rate of the regional difference in technical efficiency is between 44.03 and 48.251%, and the average contribution rate is 46.022%. It shows a downward trend during the observation period, indicating that the influence of the regional difference on the difference in technical efficiency has been weakened. Among the intra-regional differences, the contribution rate of the intra-regional differences in the northern region is far greater than the intra-regional differences in the southern region.

Sources of differences in technological progress

The main sources of differences in technological progress are regional differences, with a contribution rate ranging from 50.991 to 52.866%, with an average contribution rate of 51.884%. Among the contribution rates of regional differences, the contribution rate of super-variable density is far greater than the contribution rate of super-variable net value, the contribution rate is between 31.455 and 50.311%, and the average contribution rate is 41.129, indicating that the overlap between different regions is the problem of technological progress.

The main source of difference

The contribution rate of hypervariable net value ranges from 0.728 to 21.411%, with an average contribution rate of 10.755%, and it shows an increasing trend during the observation period, indicating that the net difference between different regions is becoming more and more serious. The contribution rate of regional differences in technological progress is slowly declining, with the contribution rate ranging from 47.134 to 49.009%, with an average contribution rate of 48.116%. In the contribution rate of intra-regional differences, the contribution rate in the northern region is greater than that in the southern region and has become the main source of the total contribution rate of intra-regional differences.

The dynamic evolution of China’s industrial GTFP

In order to analyze the absolute difference characteristics of GTFP in the country and the two regions in more depth, we use nuclear density to analyze the absolute difference in industrial GTFP in China and the north and south regions through the three-dimensional distribution map of industrial GTFP, variation trends, ductility, and polarization trends.

The dynamic distribution of the national overall industrial GTFP

According to the results of nuclear density estimation, Table 5 reveals the evolution characteristics of the distribution dynamics of industrial GTFP, technical efficiency, and technological progress in the north and south of China. Figure 4, Fig. 5, and Fig. 6 describe the dynamic evolution of the distribution of GTFP, technical efficiency, and technological progress in the country’s overall industrial green, northern region and southern region. From the perspective of the evolution of the distribution position, the industrial GTFP exhibits “shift right-shift left-shift right,” corresponding to the ups and downs of industrial GTFP during the sample period, which shows that in the sample period the GTFP of the domestic industry continues to increase. From the perspective of the evolution of the main peak distribution, during the observation period, the height of the main peak of industrial GTFP decreased, the width expanded, from “tip and narrow” to “flat and flat,” indicating the absolute difference in industrial GTFP expand. From the perspective of the extension of the distribution, there is a long tail on the right side of the industrial GTFP distribution map, indicating that there are provinces with higher industrial GTFP. In addition, the ductility of the industrial GTFP distribution has shown a broadening trend, indicating that provinces with higher industrial GTFP have achieved further development, showing the phenomenon of “the strong are stronger.” From the perspective of polarization, the overall national industrial GTFP is in a state of polarization, which further shows that China’s industrial GTFP is characterized by significant spatial imbalance.

The dynamic evolution of the national overall technical efficiency distribution. From the perspective of the evolution of the distribution position, the technical efficiency presents “right shift-left shift-right shift,” and the overall performance is left shift, indicating that the technical efficiency has a downward trend during the observation period. It is different from the descriptive statistical analysis, mainly because: the descriptive statistical analysis of the technical efficiency of the southern region uses the mean value of all southern provinces, while the nuclear density distribution map is measured by the absolute value of each southern province. From the perspective of the evolution of the distribution of the main peak, during the observation period the height of the main peak of technical efficiency decreases, the width expands, from “pointy and narrow” to “flat and flat,” indicating that the absolute difference in technical efficiency has further expanded. From the point of view of the ductility of the distribution, the technical efficiency distribution map has the phenomenon of right tailing and narrowing of the extension, indicating that the overall technical efficiency of the country has higher technical efficiency provinces. From the perspective of polarization, the country’s overall technical efficiency has a less obvious “polarization” situation, which shows that China’s technical efficiency has significant spatial imbalance characteristics.

The distribution of overall technological progress in the country is dynamically evolving. From the perspective of the evolution of the distribution position, the technological progress showed “left shift-right shift-left shift-right shift,” and finally the overall appearance “right shift,” indicating that the level of technological progress has further improved during the observation period. From the perspective of the evolution of the distribution of the main peaks, during the observation period, the height of the main peak of technological progress has decreased, the width has expanded, from narrow to flat, indicating that the absolute difference in the level of technological progress has further expanded. From the perspective of the ductility of the distribution, technological progress has a right tail and extension, and the number of provinces with higher technological progress has increased. There is no obvious polarization phenomenon in the distribution map of technological progress.

The dynamic distribution of industrial GTFP in the north and south regions

Northern region

From the perspective of the evolution of the distribution position, the industrial GTFP in the northern region shows a “right shift-left shift-right shift” trend, indicating that the northern industrial GTFP has experienced an “increase–decrease-increase” trend, and the overall performance of industrial GTFP is increased. The technical efficiency distribution map in the northern region shows “shift right-shift left-shift right-shift left,” and the overall shift is left. Correspondingly, the technical efficiency has experienced a change trend of “growth-decline-growth-decrease.” The technological progress distribution map presents a “shift left-shift right-shift left” change trend, and the overall performance is shifted right, indicating that the level of technological progress has further improved during the observation period.

From the perspective of the evolution of the distribution of the main peaks, the GTFP, technical efficiency, and technological progress of the north industries during the observation period decreased in the height of the main peaks, expanded in width, and changed from “sharp and narrow” to “flat and flat,” indicating the three factors. The absolute difference widens. From the perspective of the scalability of the distribution, the distribution maps of industrial GTFP and technological progress both show a tailing and extension and widening phenomenon, indicating that there are provinces with higher levels of industrial GTFP and technological progress, and has increased in number. Although the technical efficiency distribution map is trailing to the right, the extension is narrowed, indicating that there are provinces with higher levels of technical efficiency, but the number is decreasing. From the perspective of polarization, during the sample period, the northern industrial GTFP, technical efficiency, and technological progress have all turned into obvious polarization phenomena, indicating the imbalance of industrial GTFP, technical efficiency and technological progress in the northern region.

Southern region

From the perspective of the evolution of the distribution position, the distribution map of industrial GTFP in the southern region shows “shift right-shift left-shift right,” which corresponds to the change trend of “increase–decrease-decrease” in industrial GTFP, and finally realized to improve the total factor productivity of the industrial rate. The technical efficiency distribution map presents a “shift left-shift right-shift left-shift right” situation, and the overall performance is shifted right, indicating that the technical efficiency has improved during the observation period. The distribution map of technological progress roughly presents a “shift left-shift right” trend, indicating that technological progress has experienced a decline-rise trend, and the overall performance is an increase in technological progress.

From the perspective of the evolution of the distribution of the main peak, similar to the performance in the north, the southern industrial GTFP, technical efficiency, and technological progress during the observation period decreased in the height of the main peak, expanded in width, and changed from “sharp and narrow” to “flat and flat,” indicating that the absolute difference between the three has widened. From the perspective of the extension of the distribution, there is a long tail on the right side of the industrial GTFP and technological progress distribution map, indicating that there are provinces with higher industrial GTFP and technological progress in the southern region. The ductility of the distribution of both shows a broadening trend, indicating that the level of provinces with relatively high levels of industrial GTFP and technological progress has increased, and the level has improved. The technical efficiency distribution map shows a tail to the right but the extension narrows, indicating that there are provinces with a higher level of technical efficiency, but the number of provinces is decreasing. From the perspective of polarization, during the sample period, industrial GTFP and technological progress showed obvious polarization, and the characteristics of uneven development level were obvious. There is no obvious polarization in the technical efficiency distribution map.

The spatial and temporal laws of China’s industrial GTFP level transfer

We use Kernel density estimation to describe the dynamic distribution of China’s industrial GTFP and show the unbalanced characteristics and evolution trend of industrial GTFP. However, the disadvantage of the method is that it cannot reveal the specific transfer law of regional industrial GTFP level, nor can it explain the probability and direction of transfer of China’s industrial GTFP level between regions. We use the Markov chain method to explore the specific transfer law of China’s industrial GTFP level from two perspectives of time and space. We divide the differences in the level of industrial GTFP of the three provinces from 2003 to 2019 into four levels: low, medium low, medium high, and high (expressed as L, ML, MH and H respectively), set the time span as 1 year (t = 1), and solve the traditional Markov transfer matrix (as shown in Table 6).

As a whole, (1) the industrial GTFP shows an obvious phenomenon of “club convergence.” In the transfer matrix, the probability value on the main diagonal is significantly higher than that on the non-diagonal. The mean value of diagonal probability value is 0.8445, which indicates that it is more likely that China’s industrial GTFP will remain stable. In the transition matrix, the probabilities of LL and HH are relatively large. In the initial stage, the probability of the low level of industrial GTFP remaining in the initial state is 0.96, and the probability of transferring to the high level is 0.04, indicating that the low level of industrial GTFP cannot break the path dependence of the original development mode due to the constraints of resource endowment and economic stock. The probability of maintaining the high level of industrial GTFP in the initial state is 0.9043, but there is also a probability of 0.0957 transferring to the low level. (2) Most of the transfer probabilities on both sides of the diagonal of the matrix are not 0, which indicates that the development level of industrial GTFP in the city is more likely to shift upward or downward within a year, while the possibility of jump transfer is small, which indicates that it is difficult for industrial GTFP to make a large leap. (3) The upward transition probability (0.2898) of the transition matrix is slightly larger than the downward transition probability (0.2159), indicating that there are relatively more provinces with higher industrial GTFP. In terms of different regions, the average probability of the transition matrix diagonal in the northern region is 0.8776; the upward transition probability of the transition matrix (0.2272) is slightly smaller than the downward transition probability (0.2623), indicating that relatively few provinces in the northern region have improved industrial GTFP. The average probability of the transition matrix diagonal in the southern region is 0.8118; the upward transition probability of the transition matrix (0.5907) is greater than the downward transition probability (0.162), indicating that there are relatively more provinces in the southern region with higher industrial GTFP. Compared with the northern region, the industrial GTFP level in the southern region is higher.

The traditional Markov chain describes the transition characteristics of industrial GTFP level over time. However, under the market economy system, its state transfer is not independent in space, and there are spatial interaction and spatial spillover effects in the industrial development of various regions. Therefore, we introduce spatial factors, construct spatial Markov chains, and further analyze the spatial transfer law of industrial GTFP (see Table 7). When the industrial GTFP level of neighboring provinces is at a low level, the probability of upward transfer of low-level provinces is 0.0588, the probability of upward transfer of medium and low-level provinces is 0.0833, and the probability of upward transfer of medium and high-level provinces is 0.1176. When the industrial GTFP level of the neighboring provinces is at the middle and low level, there is no low-level province, the probability of upward transfer of the middle and low-level provinces is 0.0870, and the probability of upward transfer of the middle and high-level provinces is 0.3333. When the neighboring provinces are in the middle and high level, the probability of upward transfer of the low-level provinces is 0.0408, the probability of upward transfer of the middle- and low-level provinces is 0.0408, and the probability of upward transfer of the middle and high-level provinces is 0.1778. When the neighboring provinces are high-level, the low-level provinces do not transfer, the probability of the middle and low-level provinces transferring upward is 0.2381, and the probability of the middle and high-level provinces transferring upward is 0.3056. The above results show that the driving effect of neighbors at different levels is different. It generally shows that the higher the neighbor level, the stronger the driving force. Take the medium and high level as an example, the upward transfer probability driven by the low level, the medium and low level, the medium and high level, and the high level neighbor is 0.0833, 0.0870, 0.1864, and 0.2381 in turn.

Spatial characteristics of horizontal transfer of industrial GTFP in northern China. (1) When the neighboring provinces are low-level and low-medium-level, there are no low-level and high-level provinces, and the probabilities of the upward transition of the low-medium-level provinces are 0.0909 and 0, respectively. (2) When the neighbors are medium–high-level, the middle-low-level provinces are upwards. The probability of transfer is 0.0714, of which there is a jump transfer with probability 0.0238, which is transferred from low-medium level to high-level. (3) When the neighbor is high, the probability of the upward transfer of the middle and low provinces is 0.1667, and the probability of the upward transfer of the middle and high provinces is 0.1579. Spatial characteristics of horizontal transfer of industrial GTFP in southern China. (4) When the neighbor is low level, the probabilities of upward transition of provinces at each level (L, ML, MH) are 0.0588, 0.2500, and 0.4000, respectively. (5) When the neighbor is medium and low level, the probabilities of upward transition of provinces at each level (L, ML, MH) are 0, 0.2222, and 0, respectively. (6) When the neighbor is in the middle and high level, the probabilities of upward transition of provinces at each level (L, ML, MH) are 0.0606, 0.2564, and 0.2286 respectively. (7) When the neighbor is at a high level, the probabilities of the provinces at each level (L, ML, MH) shifting upward are 0, 0.1250, and 0.5000 in turn. The higher the level of industrial GTFP in the southern region, the greater the probability of upward transition and the greater the probability of diagonal versus off-diagonal, showing the phenomenon of obvious “Matthew effect” and “club convergence.” It can be seen from the above that the industrial GTFP presents the phenomenon of club convergence and the “Matthew effect,” but after the introduction of spatial factors, the phenomenon of “club convergence” and the “Matthew effect” has weakened. Compared with the northern regions, the industrial GTFP in the southern region has a stronger driving effect on the neighboring provinces.

Conclusions and policy recommendations

By taking the capital stock, labor, and energy consumption as production inputs, industrial added value as expected output, and industrial sulfur dioxide and production carbon emissions as unexpected output, we calculate the industrial GTFP of 30 provinces in China from 2003 to 2019, and decompose it into technical efficiency and technological progress index. Then, we empirically study the spatial imbalance and trend evolution of industrial GTFP level by using the Dagum Gini coefficient, kernel density estimation and Markov chain analysis.

The research indicates that: (1) During the observation period from 2003 to 2019, the regional differences in total factor productivity, technical efficiency, and technological progress of China’s industrial green industry showed an expanding trend; the regional differences in total factor productivity, technical efficiency, and technological progress of industry in the north were higher than those in the south; the main source of differences in industrial total factor productivity, technological efficiency, and technological progress. (2) The absolute difference in total factor productivity, technical efficiency, and technological progress of China’s overall industry is expanding, and similar changes also exist in the northern and southern regions. (3) Industrial GTFP presents “club convergence” phenomenon and “Matthew effect.” However, after introducing spatial factors, the phenomenon of “club convergence” and “Matthew effect” have weakened. The driving effect of industrial GTFP in the south on neighboring provinces is stronger than that in the north.

The following recommendations are made based on the above findings in order to promote industrial GTFP and synergistic and balanced regional growth.

First, improving industrial GTFP requires accelerating the pace of emission reduction, guiding green technology innovation, and promoting the adjustment of industrial structure and energy structure. The government should vigorously develop renewable energy, balance economic development, and green transformation. (1) The government should improve the intellectual property protection system to improve China’s innovation level. According to the 2018 International Intellectual Property Index Report, China’s intellectual property index in 2018 ranked only 25th among 50 economies. Intellectual property is an important guarantee for innovation. (2) According to the data released by the National Bureau of Statistics, China’s GDP has reached 1,015,986.2 billion yuan in 2020, of which R&D expenditure has reached 2442.6 billion yuan, accounting for 2.4%. However, China’s overall ranking in the global innovation index in 2020 is 14 (National Innovation Index Report 2020), and the contradiction between higher R&D investment and relatively low innovation level is more prominent. The investment structure of basic, application, and experimental research is seriously unbalanced. Only 6.03% of the capital is invested in core, high-tech, and basic research and development, accounting for about 130 billion yuan, a very low proportion. The experimental research accounts for more than 80%, the long-term investment in basic research is low, and the core technology has bottlenecks. (3) Promote the deep integration of industry, education, and research. Innovation institutions are the pillar of innovation activities and need to be carried out on the platform. China is actively promoting the scientific and technological innovation mode of integration of industry, university, and research. At present, it has entered the mode of deep integration of industry, university, and research. In China, it has gradually formed an innovation alliance with enterprises as the main body, market as the guidance, and deep integration of industry, university, and research. The purpose is to establish an innovation system with enterprises as the main body, market orientation, and deep integration of industry, university, and research, and improve innovation efficiency and quality.

Secondly, in view of the regional heterogeneity of industrial GTFP level, we can correctly grasp the structural source and formation mechanism of industrial GTFP level differences between different regions, so as to quickly and effectively promote the coordinated development of industrial GTFP according to local conditions. As industries in the north are mainly “heavy industries,” they are more affected by economic fluctuations and external shocks, and it is more difficult to transform and upgrade. Moreover, the heavy industries in the north are more serious about environmental pollution, making green development difficult and tortuous. The southern region, on the other hand, is closer to market demand, with relatively easy industrial transformation, relatively high levels of technological innovation, and relatively good environmental management. From the analysis results, it is also clear that the GTFP, technical efficiency and technological progress index of industry in the north are lower than those in the south. Therefore, on the one hand, China should focus on supporting the industrial development of the northern regions and speed up industrial restructuring. In order to give full play to the industrial demonstration role of the rich resources in the north and the advanced technology level and standards of state-owned enterprises, China should develop clean energy and renewable energy, improve resource utilization efficiency, and stimulate new vitality and motivation of enterprises; On the other hand, China should increase green investment in the north, vigorously develop advanced manufacturing and new energy industries, reduce the negative impact of industrial capital upgrading on the environment through the development of advanced manufacturing, actively carry out environmental management, and comprehensively promote the improvement of GTFP in the north. Secondly, the southern region should give full play to its regional advantages, promote coordinated development among regions, optimize resource allocation, and form a core region driven by radiation. The southern region will play a good exemplary role, be a good leader, and stimulate and help the industrial transformation and development of the northern region, so that advanced production technology and management experience can be spread to the northern region with low efficiency value.

Thirdly, green development should be included in the assessment of economic development, and an assessment system that incorporates resource and environmental indicators and related elements into the assessment should be developed to further improve and perfect environmental regulations. The new development concept calls for “innovation, coordination, green, openness and sharing,” of which green development is an important part, and it is also a necessary way for China to integrate into the global trend of sustainable development based on green development. Under the new development concept, green development has been emphasized, and green development has been made an important part of the economic development assessment, and enterprises and regions that have made outstanding contributions to green development have been given awards to encourage green development. At present, China’s environmental regulation system is not perfect, the industry standards and norms are not clear, and the operation of the carbon trading market is not standardized. Therefore, it is necessary to improve and perfect the environmental regulation system, promote the standardized operation of the trading market, and achieve the purpose of reducing emissions.

Data availability

The datasets and materials used and/or analyzed during the current study are available from the corresponding authors on reasonable request.

Notes

See Dagum (1997) for a detailed explanation of the formula.

References

Al HM (2021) The dynamic evolution of synergies between BIM and sustainability: a text mining and network theory approach. J Build Eng 37:102159

Arabi B, Munisamy S, Emrouznejad A, Shadman F (2014) Power industry restructuring and eco-efficiency changes: a new slacks-based model in Malmquist-Luenberger Index measurement. Energy Policy 68:132–145

Barbieri E, Tommaso M, Bonnini S (2012) Industrial development policies and performances in Southern China: beyond the specialised industrial cluster program. China Econ Rev 23(3):613–625

Chen JD, Wu YY, Wen J, Cheng SL, Wang JL (2017) Regional differences in China’s fossil energy consumption: an analysis for the period 1997–2013. J Clean Prod 142(2):578–588

Chen MH, Zhang XM, Liu YX, Zhong CY (2020a) Dynamic evolution and trend forecasting of green TFP growth - an empirical study based on five major urban agglomerations in China. Nankai Econ Stud 01:20–44

Chen SY, Golley J (2014) “Green” productivity growth in China’s industrial economy. Energy Econ 44:89–98

Chen YB, Yin GW, Liu K (2020b) Regional differences in the industrial water use efficiency of China: the spatial spillover effect and relevant factors. Resour Conserv Recycl 167:105239

Chung YH, Färe R, Grosskopf S (1997) Productivity and undesirable outputs: a directional distance function approach. J Environ Manag 51(3):229–240

Cui Y, Khan SU, Deng Y, Zhao NJ (2021) Regional difference decomposition and its spatiotemporal dynamic evolution of Chinese agricultural carbon emission: considering carbon sink effect. Environ Sci Pollut Res 28(29):38909–38928

Dagum CA (1997) New approach to the decomposition of the gini income inequality ratio. Empir Econ 22(4):515–531

Dan S (2007) Regional differences in China’s energy efficiency and conservation potentials. Chin World Econ 01(77):100–119

Fan M, Shao S, Yang L (2015) Combining global Malmquist-Luenberger index and generalized method of moments to investigate industrial total factor CO2 emission performance: a case of Shanghai (China). Energy Policy 79:189–201

Färe R, Grosskopf S, Pasurka C (2001) Accounting for air pollution emissions in measures of state manufacturing productivity growth. J Reg Sci 41(3):229–240

Gebauer H (2011) Exploring the contribution of management innovation to the evolution of dynamic capabilities. Ind Mark Manage 40(8):1238–1250

Golley J (2002) Regional patterns of industrial development during China’s economic transition. Blackwell Publishers Ltd 10(3):761–801

Hang Y, Wang F, Su B, Wang YZ, Zhang W, Wang QW (2021) Multi-region multi-sector contributions to drivers of air pollution in China. Earth’s Future 9(6):e2021EF002012

He F, Zhang QZ, Lei JS, Fu WH, Xu XN (2013) Energy efficiency and productivity change of China’s iron and steel industry: accounting for undesirable outputs. Energy Policy 54:204–213

Hu JL, Sheu HJ, Lo SF (2005) Under the shadow of Asian Brown Clouds: unbalanced regional productivities in China and environmental concerns. Int J Sust Dev World 12(4):429–442

Huang HY, Wang FR, Song ML, Balezentis T, Streimikiene D (2021) Green innovations for sustainable development of China: analysis based on the nested spatial panel models. Technol Soc 65(4):101593

Jiang T, Huang S, Yang J (2019) Structural carbon emissions from industry and energy systems in China: an input-output analysis. J Clean Prod 240:118116.1-118116.13

Krugman P (1994) The Myth of Asia’ s Miracle[J]. Foreign Aff 73(6):62–78

Latif B, Gunarathne N, Gaskin J, Ong TS, Ali M (2022) Environmental corporate social responsibility and pro-environmental behavior: the effect of green shared vision and personal ties. Resour Conserv Recycl 186:106572

Li N, Pei XD, Huang YZ, Qiao JQ, Zhang YJ, Jamali RH (2022) Impact of financial inclusion and green bond financing for renewable energy mix: implications for financial development in OECD economies. Environ Sci Pollut Res 29(17):25544–25555

Li N, Wang Z, Zhang ZC (2018) Influence of plant structure and flow path interactions on the plant purification system: dynamic evolution of the SO2 pollution. Environ Sci Pollut Res 25(35):35099–35108

Liang QM, Fan Y, Wei YM (2007) Multi-regional input-output model for regional energy requirements and CO2 emissions in China. Energy Policy 35(3):1685–1700

Lin BQ, Chen ZY (2018) Does factor market distortion inhibit the green total factor productivity in China? J Clean Prod 197:25–33

Liu GT, Wang B, Zhang N (2016) A coin has two sides: which one is driving China’s green TFP growth? Econ Syst 40(3):481–498

Ma Z, Hong L (2004) Clarity and tradability of property rights is the basis for proper pricing of environment and resources. China Price 2:49–51

Mahlberg B, Luptacik M (2014) Eco-efficiency and eco-productivity change over time in a multisectoral economic system. Eur J Oper Res 234(3):885–897

Oh D (2010) A global Malmquist-Luenberger productivity index. J Prod Anal 34(3):183–197

Oh D, Heshmati A (2010) A sequential Malmquist-Luenberger productivity index: environmentally sensitive productivity growth considering the progressive nature of technology. Energy Econ 32(6):1345–1355

Pan YL, Dong F (2022) Dynamic evolution and driving factors of new energy development: fresh evidence from China. Technol Forecast Soc Chang 176:121475

Pastor JT, Lovell CAK (2005) A global Malmquist productivity index. Econ Lett 88(2):266–271

San OT, Latif B, Di Vaio A (2022) GEO and sustainable performance: the moderating role of GTD and environmental consciousness. J Intellect Cap 23(7):38–67

Shi CF, Zeng XY, Yu QW, Shen JY, Li A (2021) Dynamic evaluation and spatiotemporal evolution of China’s industrial water use efficiency considering undesirable output. Environ Sci Pollut Res 28(16):20839–20853

Tao F, Zhang HQ, Hu J, Xia XH (2017) Dynamics of green productivity growth for major Chinese urban agglomerations. Appl Energy 196:170–179

Tian P, Lin BQ (2018) Regional technology gap in energy utilization in China’s light industry sector: Nonparametric meta-frontier and sequential DEA methods. J Clean Prod 178:880–889

Tunio RA, Jamali RH, Mirani AA et al (2021) The relationship between corporate social responsibility disclosures and financial performance: a mediating role of employee productivity. Environ Sci Pollut Res 28(9):10661–10677

Wang H, Liu HF, Cao ZY, Wang BW (2016) FDI technology spillover and threshold effect of the technology gap: regional differences in the Chinese industrial sector. Springerplus 5(1):323

Wang K, Wei YM (2014) China’s regional industrial energy efficiency and carbon emissions abatement costs. Appl Energy 130:617–630

Wang K, Zhang X, Wei YM, Yu SW (2013) Regional allocation of CO2 emissions allowance over provinces in China by 2020. Energy Policy 54(1):214–229

Wang K, Wei YM (2016) Sources of energy productivity change in China during 1997–2012: a decomposition analysis based on the Luenberger productivity indicator. Energy Econ 54:50–59

Wang ZH, Feng C (2015) Sources of production inefficiency and productivity growth in China: a global data envelopment analysis. Energy Econ 49:380–389

Wei W, Zhang WL, Wen J, Wang JS (2019) TFP growth in Chinese cities: the role of factor-intensity and industrial agglomeration. Econ Model 91:534–549

Wu D (2001) A study on North-South differences in economic growth. Geogr Res 20(2):238–246

Xiao SY, Wang SS, Zeng FH, Huang WC (2022) Spatial differences and influencing factors of industrial green total factor productivity in Chinese industries. Sustainability 14(15):9229

Xu B, Lin BQ (2016) Regional differences in the CO2 emissions of China’s iron and steel industry: Regional heterogeneity. Energy Policy 88:422–434

Xu SC, He ZX, Long RY (2014) Factors that influence carbon emissions due to energy consumption in China: Decomposition analysis using LMDI. Appl Energy 127(15):182–193

Xue Y, Wen ZZ, Jie F, Jian HY, Hong YZ (2018) Transfers of embodied PM 2.5 emissions from and to the North China region based on a multiregional input-output model. Environ Pollut 235:381–393

Yin JY, Cao YF, Tang BJ (2019) Fairness of China’s provincial energy environment efficiency evaluation: empirical analysis using a three-stage data envelopment analysis model. Nat Hazards 95(10):343–362

Yu DN, Tao S, Hanan A, Ong TS, Latif B, Ali M (2022) Fostering green innovation adoption through green dynamic capability: the moderating role of environmental dynamism and big data analytic capability. Int J Environ Res Public Health 19(16):10336

Zeng P, Wei X, Duan Z (2022) Coupling and coordination analysis in urban agglomerations of China: urbanization and ecological security perspectives. J Clean Prod 365:132730

Zhou X, Zhang M, Zhou MH, Zhou M (2016) A comparative study on decoupling relationship and influence factors between China’s regional economic development and industrial energy–related carbon emissions. J Clean Prod 142(2):783–800

Zhu XW, Du JG, Boamah KB, Long XL (2020) Dynamic analysis of green investment decision of manufacturer. Environ Sci Pollut Res 27(14):16998–17012

Acknowledgements

The authors are grateful to all the people who helped complete this research and to the anonymous reviewers for their suggestions for improving the manuscript.

Funding

This research was supported by the National Social Science Fund’s major project “Research on the Formation Mechanism, Dynamic Evaluation and Policy Synergy of China’s Economic Resilience under the New Development Pattern” (21&ZD072).

Author information

Authors and Affiliations

Contributions

SW, SX, and XL contributed to the study conception and design. SW and SX participated in material preparation, data collection, and analysis. SW wrote the first manuscript draft. QZ helped revise and improve the manuscript draft. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Eyup Dogan

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Xiao, S., Lu, X. et al. North–south regional differential decomposition and spatiotemporal dynamic evolution of China’s industrial green total factor productivity. Environ Sci Pollut Res 30, 37706–37725 (2023). https://doi.org/10.1007/s11356-022-24697-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24697-9