Abstract

This article predicts the operational temperature of a 1-MWp rooftop photovoltaic (PV) system installed on buildings of GITAM University, Andhra Pradesh, India, using various temperature models. In the process of photovoltaic conversion, the operating temperature plays a key role, where the module efficiency and output power of the PV module are linearly dependent on temperature. Various temperature models are presented in the literature with simplified working formulas to find the module temperature involving environment and PV system parameters. This study adopts four models NOCT (normal operating cell temperature), Fiaman, Scandia and arbitrary mounting model (AMM), to assess the power, module temperature of the photovoltaic plant and identify the best model to suit the present study location. Their precision is evaluated on a seasonal day (winter, summer, monsoon and autumn) from the measured data. It is observed that winter, summer, monsoon and autumn days have hourly average module temperatures of 45.4 °C, 48.1 °C, 48.2 °C and 45.3 °C, respectively. Results show the highest average DC voltage of 231.2 kW on a summer day with an hourly module temperature of 48.1 °C recorded. The slightest error values of 3.71% MBE, 5.8% NRMSE, 1.89% TS and 0.03% WMBE are noted with the arbitrary mounting temperature model. This study is helpful to validate that the AMM model is best suited for PV simulation in coastal regions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Renewable energy is an essential focus for energy production worldwide since the greenhouse gas (CH4, O3, CFC and mainly CO2) emissions into the atmosphere are causing high environmental pollution with fossil fuels. Concurrently, the gases and the radioactive waste released from nuclear power plants remain active for years, making the environment worse. Scientists and engineers are searching for safe, clean, renewable energies from the perspectives of global warming and natural gas shortages, where solar energy is considered to be the most promising amongst the available renewable energy methods because of its advantages in energy production, operation and maintenance. Over few years, potential research has been underway on solar PV system study, deployment, maintenance and performance. The articles (Dawn et al. 2016; Vishnupriyan and Manoharan 2017) highlighted the feasibility of installing rooftop PV plants and their performance investigations mathematically and with software simulation tools. Many articles (Kawajiri et al. 2011; Pendem and Mikkili 2018; Kumar et al. 2018) specify that the performance of the PV system relies on parameters such as solar irradiation, wind speed, ambient temperatures, material and mounting of PV module and module temperatures.

Temperature plays a significant role in a PV system’s energy yields and efficiency in all the abovementioned parameters. The article (Malvoni et al. 2020) presented the effect of geographical variations (solar radiation, temperature of air, wind speeds) on performance. Also, it focused on the module temperature variation of − 20% to 5% which is observed from the parameters mentioned above in different locations. The effect of temperature on the PV efficiency on PV arrays mounted on free-standing frames, PV-thermal collectors and building-integrated photovoltaic arrays was discussed (Al-Maghalseh 2018). The article confirms that the performance ratio is higher due to low temperatures in high altitudes.

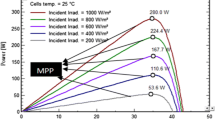

The temperature distribution on the surface of the PV modules considering the effects of irradiance, heat transfer coefficient and ambient temperature is assessed through a comparative study of different solar modules through the finite element method in (Atsu and Dhaundiyal 2019). It is stated that the temperature of the module is increased in a range of 0.67–4.16%, with an increase in the ambient temperature of 10%. The performance of an 11.2-kWp rooftop grid-connected PV system is studied for three different seasons in a year (Sharma and Goel 2017). It is noted that the lowest efficiency and high performance ratio (PR) are observed during high temperatures and vice versa. A variation of 0.2–1.0% in the efficiency and 1–10% PR values are observed. The performance of a 200-kW roof-integrated PV system predicted using PVsyst simulation tool shows an approximate degradation rate of − 0.6% to − 5% for a PV array, whereas the energy loss was − 26.5% (Kumar et al. 2019a, b). The study (Amelia et al. 2016) on the effect of temperature on the PV panel output specifies that the output power and efficiency decrease with an increase in module temperatures. The impact of cell temperature on electrical efficiency and thermal comfort is examined on a 5.25-kWp building-integrated installed system in a time interval of 30 min in a day under tropical weather conditions by estimating its overall performance (Pillai et al. 2014). The performance of monocrystalline, polycrystalline and amorphous modules installed on rooftops of an educational institute in Morocco is studied in Karami et al. (2017). The results exhibited a maximum PR of 72.10%, 91.53% and 86.20%, achieved on cloudy days due to low temperature and high wind speed. In contrast, minimum PR values and PV module efficiency on a quiet sunny day and rainy day affect the energy generated.

All the articles addressed (Dawn et al. 2016; Vishnupriyan and Manoharan 2017; Kawajiri et al. 2011; Pendem and Mikkili 2018; Malvoni et al. 2020; Al-Maghalseh 2018; Sharma and Goel 2017; Kumar et al. 2019a, b; Karami et al. 2017) are stating that module temperatures play a vital role in the performance of the solar PV system. There are various models proposed to estimate module temperatures (Correa-Betanzo et al. 2018; Almaktar et al. 2013) to evaluate the performance of PV systems. A mathematical model based on the critical component analysis and a basic analytical model was investigated to determine the PV module temperature from geometric data (environmental temperature, global solar irradiation in the array plane and wind speed) at different climate regions (Koehl et al. 2011). In the article by Ciulla et al. (2013), an artificial neural network approach is adopted to predict the module temperatures, where the results are compared with experimental data. The performance of 32.7 kWp capacity BAPV and BIPV configurations is compared with three different technologies crystalline, CIS and CdTe using PVGIS (Mohammed et al. 2019). The losses of 2.8%, − 1 to − 5% and − 7.4 to − 13.6%, are observed due to the angle of incidence, spectral effects and change in irradiance and module temperatures. It is shown that in the mentioned technologies, CdTe cells exhibited better performance. A comparative study (Olukan and Emziane 2014) presents 16 temperature models considering monthly mean metrological data. The module temperature variation is investigated with a change in solar irradiation from 100 to 1000 W/m2 and various ambient temperature changes. A shift in module temperatures of 31.8 °C to 66 °C is observed for the presented PV models in various months. The performance variations for each model were highlighted, stating the suitability of that particular model for optimal sizing, designing of PV systems. Article by Kaplanis and Kaplani (2019) elaborately presented the prediction models to find the steady-state module temperatures. A deviation of < 3% is recorded in module temperatures, and a 5–25% deviation in output power is observed compared with six familiar models. Furthermore, a mathematical algorithm approach is developed to predict transient and steady module temperatures, in which < 5% deviation is observed.

The importance of using simulation tools for technical sizing of solar PV systems is investigated in light of such modelling and analysis. A study of six simulation tools, PV Watts, PVGIS, PV-Online, PV*SOL, PVsyst and System Advisor Model (SAM), used for technical sizing of solar PV facilities is conducted by the author Kumar (2017). The article Mukisa et al. (2019) addressed the challenges and issues in selecting the suitable PV models widely used in simulation software. RETScreen, SAM, PVsyst and PVSS software are used to predict the errors in cell temperature and module power. From all the mentioned softwares and models, SAM’s NOCT model ranked as a good choice for estimating module temperatures. PV-Online simulation programme is used to estimate grid feed-in electricity of a roof-integrated Si-amorph PV system based on orientation, tilt angle and available roof surface area (Kumar et al. 2017). The authors mentioned that the PV array’s performance ratios (PRs) are almost twice as high in the case of a horizontal roof, at 78%.

Several combinations of temperature models were selected to estimate the cell temperature of different PV systems and identify the best suitable model considering the monthly mean solar irradiation data on horizontal surfaces (Araneo et al. 2014). The statistical indicators (MBE, RMSE, R2) are calculated from estimated and measured data, and temperature statistics for combinational models were tabulated. In the article Almaktar et al. (2013), new mathematical models were proposed to estimate module temperatures for poly and monocrystalline modules in tropical climatic conditions. Statistical error tests (MBE, RMSE, MPE) were performed for the best model. The hourly PV module temperature for a mono PV system is estimated at 2.23 (MBE) and 2.88 (RMSE), and MPE was 6.26%, whereas polycrystalline PV module was 2.65 (MBE), 3.42 (RMSE), and 6.3% for MPE. The precision of module temperatures is correlated with climate conditions in Indian sites for three different PV technologies in Mohammed et al. (2019). It is concluded that the Faiman correlation is the best module temperature estimation model that exhibited low RMSE values of 4.2 °C, 4.1 °C and 4.3 °C for the mc-Si, HIT and a-Si module technologies, respectively, under mid-temperature ranges and an RMSE of 6.6 °C, and 6.2 °C for mc-Si and a-Si technologies for high-temperature ranges.

In this connection, this article presents an impact evaluation of four module temperature models on the energy yield of a PV system. The assessment considers the atmospheric conditions such as site solar irradiation, wind speed at the location, ambient temperatures and the specifications of the solar PV modules installed. Seasonal assessment is made based on the coastal climatic changes. The performance parameters such as energy yield, PV array efficiency and performance ratio were assessed. The experimental validation is carried out on a specific day of the four seasons in a year (winter, summer, monsoon and autumn). The existing statistical parameters, mean bias error (MBE), the root mean square error (RMSE), normalised root mean square error (NRMSE), weighted mean bias error (WMBE), standard deviation (SD) and the coefficient of determination (R2), are estimated and also the comparison between the measured and estimated temperatures is highlighted. This article attempts to present the energy performance, module temperature prediction and comparison for a rooftop PV system installed on the free spaces of the buildings in an educational institute in Rushikonda, Andhra Pradesh, India, in coastal climatic conditions. The article is sectionalised as follows: statistical assessment of PV models; brief explanation of the existing temperature models; and a case study of 1 MWp solar PV system installed in GITAM University, India, followed by results and discussion along with the comparison of outcomes taking into account current literature. Finally, the concluding points are outlined.

Statistical assessment of the PV models

Statistical methods have been developed for measuring and quantifying errors across a wide range of parameters. Experts have developed various formulas (error matrices) for reporting the accuracy of the temperature models (Almaktar et al. 2013). This assessment focuses on finding the relative error (statistical indicators) between module temperature from the forecasted temperature models with the measured temperatures. Extensively used matrices statistically like mean bias error (MBE), the root mean square error (RMSE), normalised root mean square error (NRMSE), weighted mean bias error (WMBE), standard deviation (SD) and the coefficient of determination (R2) are calculated for all the four temperature models (del Cerro et al. 2021; Hajjaj et al. 2018; Assoa et al. 2017).

Mean bias error (MBE) is the ratio of the sum of the difference between the measured and calculated module temperatures over some time to the number of measurements recorded over that period.

where Txm is the measured temperature value, Txcal is the calculated temperature value at xth time interval and N is the total measurements recorded. The positive and negative MBE values present an overestimation and underestimation of the calculated and measured values, respectively.

Root mean square error (RMSE) is the square root of the average of the squared temperature errors measured over a definite time interval, where the temperature error is the difference between the measured and estimated module temperature values. Root mean square error is widely used in climate research, forecasting and regression to check experimental outcomes. RMSE provides details on the output of the forecasted data set in the short term.

Normalised root mean square error (NRMSE) measures the sum of the absolute difference between the measured and calculated module temperatures over time to the measured module temperature and the number of measurements recorded over that period. NRMSE generally offers better predictive knowledge compared with MBE and RMSE.

NRMSE provides a standard performance assessment and high accuracy of the predicted model for smaller TS values. TS is mainly evaluated if the expected temperature value is significantly different from the calculated value. The smallest TS value gives more accuracy to the predicted temperature value.

Standard deviation (SD) indicates the difference between expected temperature values and ground-level measurement values. The RMSE and MBE values are calculated from Eqs. 1 and 2.

Weighted mean bias error (WMBE) is expressed as:

where Gx is the solar irradiation at the xth interval.

The most popular dependency measure between two quantities is Pearson’s coefficient of correlation or simply “the coefficient of correlation”. The square of the Pearson’s coefficient of correlation is named as coefficient of determination and expressed as:

This measures how well the model replicates the observed outcomes based on the proportion of total variance of outcomes described by the model. R2 provides a linear fit between the measured and calculated values. There are several definitions for R2 where the value ranges between 0 and 1. In some cases, R2 can yield negative values, depending on the computational purpose.

Temperature models of PV system

Several studies have been carried out to evaluate the impact of temperature on the total energy yield and module efficiency of PV arrays. Few studies show degradation of up to 12% in the conversion efficiency due to temperature variations (Correa-Betanzo et al. 2018). It is a well-known fact that the module temperature not only changes with solar irradiation but is also influenced by air temperature and wind speed. Various temperature models are being proposed to estimate the PV module temperatures at different weather conditions (Sarkar 2016; Bhattacharya et al. 2014; D’Orazio et al. 2013; Armstrong and Hurley 2010; Huld and Amillo 2015). This section discusses four temperature models to estimate the module temperature of the 1 MWp solar PV plant.

NOCT model

A standard working cell temperature or normal operating cell temperature (NOCT) model is commonly used to determine the module temperature (Tcell) (Correa-Betanzo et al. 2018). The parameters affecting the module temperature are atmospheric air temperature (Tair), solar irradiation (G) at the location and the nominal operating temperature (TNOCT) of the solar module, ignoring the wind velocity. The module temperature (Tcell) is calculated using:

In many studies, the air temperature of 20 to 25 °C and solar radiation of 800–1000 W/m2 are considered from standard references. However, the air temperature and solar radiation are not constant in any specific field applications. Hence these parameters are considered from the real-time data at the present study location. The PV arrays in this study operate at a NOCT of 44 °C. It can be noted that the module temperatures change with solar irradiation, but the wind speeds also have to be considered. As this approach neglects the wind speeds, three other models are considered for further assessment considering the wind velocity (based on the available real-time geographical data).

Faiman model

The second one is the Faiman model; it is based on the heat loss coefficients (Uo and U1) of the PV modules and also on the wind speed (Faiman 2008). As polycrystalline PV modules are used in the present study, the parameters Uo and U1 values are considered 25 W/m2K and 6.84 W/m3K, respectively (Correa-Betanzo et al. 2018). The module temperature is estimated from the equation given by:

The seasonal wind speed (Wspeed) is identified at about 50 m from the sea level. The wind speed changes with the height of the mounting of the PV arrays. A more accurate formula to precisely calculate the wind speed is considered for the required height from the measured height based on the following equation (Gökmen et al. 2016):

where Wref is the known wind speed (m/s) measured at a reference height href from the ground (href = 50 m in the present study), Wspeed is the wind speed (m/s) calculated to the required height of the installed PV array, h is the PV array installed height (m) for which the wind speed has to be recalculated, and n is a power-law exponent which is a variable quantity.

Sandia model

The third model is the Sandia model, which is a frequently used temperature model considering some empirical parameters from PV array materials and type of mounting is given by Correa-Betanzo et al. (2018):

The coefficients a and b are related to the module temperatures for certain solar irradiation values and wind speeds which are derived empirically as a = − 3.56 and b = − 0.75.

Arbitrary Mounting Model (AMM)

The fourth one is the arbitrary mounting model (AMM) (Kumar et al. 2019a, b), considering the mounting coefficient of the rooftop models as well as the regular geographical parameters such as solar radiation, wind speed and air temperatures. The expression used to calculate the module temperature (TMod) is:

The term ic is the mounting coefficient for roof-integrated PV arrays, considered 1.8 in the present study. The module temperatures of the PV arrays in the installed PV plant are estimated for each instant of time, selecting the temperature model atmospheric conditions, and taking into account the essential characteristics of the polycrystalline PV module.

Case study of 1 MWp PV plant

The case study presented in this article is a 1-MWp solar PV plant mounted on the rooftops of educational institute buildings (GITAM deemed to be university), geographically situated in the coastal region (latitude 17° 48′ 8.208'' N and longitude 83° 23′ 6.54'' E) of Andhra Pradesh, India (Thotakura et al. 2020). The study location Visakhapatnam has a tropical wet and dry climate. The average annual temperature is about 28 to 30 °C, with an average monthly temperature varying between 8 and 9 °C. The weather position in the PV plant location is sectionalised into four seasons, summer, monsoon, autumn and winter. During May, the summer season will have the hottest and highest temperatures ranging between 40 and 46 °C. The coldest month is January, and the lowest average temperature is observed at 16 °C. September to be the wettest month with an average precipitation of 201.7 mm and annual precipitation of 1045.4 mm per year. The highest wind speeds were 10 m/s in November, and yearly wind speeds were 5.4 m/s. The average sunshine in a day is observed to be 9 h.

The institute has installed the 1-MWp grid integrated solar plant in the free spaces of the rooftops of various buildings to harness the renewable energy from the sun, and the energy produced from the power plant is fed into the grid through the campus substation. The PV plant composes of 3078 PV modules made with polycrystalline technology (3.2 mm, high transmission, AR–coated tempered glass, silver anodised aluminium alloy frame 1056 mm × 992 mm × 30 mm) with a rated current and voltage of 8.73 A and 37.2 V, with 325 Wp capacity, mounted with a structure tilt of 10° towards the south. Manufacture specification for the temperature coefficient for maximum power is − 0.41%/°C, temperature coefficient of Voc is − 0.32%/°C and maximum operational temperature varies between − 40 °C and + 85 °C. The PV plant is operated with a combination of 23 PV arrays installed on 15 building terraces.

Maximum power point tracking (MPPT) empowered conditioning units are connected to the outputs of the PV arrays, usually inverters. A total of 23 inverters of KACO manufacturer are used, with 20 kWp and 50 kWp capacities, with a maximum DC operating current of 108 A, the output voltage of 400–480 V and efficiency > 98%. Each PV array comprises two MPPT systems connected. Each MPPT system has a specific number of modules and strings (for example, 19 M × 2 S specifies 19 PV modules connected in two strings). Table 1 describes the total capacity of PV arrays, full strings (S) and modules (M) in each array and the PV array area. The schematics in Fig. 1 show the power plant units installed on the rooftops of the institute.

Results and discussion

This section discusses the review of the performance results monitored and the degradation rates assessed using the four temperature models. To understand the temperature variations and performance of the PV plant, the data is monitored on a specific day (preferably highest temperature) in the seasons of winter, summer, monsoon and autumn. The hourly average (6.45 am to 6.45 pm) solar radiation and air temperature data are considered, along with average wind velocities of 4.67 m/s, 5.59 m/s, 6.06 m/s and 4.55 m/s during the four seasons (NASA 2021), respectively, measured 50 m above the sea level.

Solar irradiation and air temperatures

The solar irradiation and ambient air temperatures measured between 6.45 am and 6.45 pm on an hourly basis on a typical day of a season are discussed in this section and are presented in Figs. 2 and 3. The highest solar irradiation occurred during winter (6.634 kWh/m2) in a day in the given time slot, whereas the lowest was recorded in monsoon (4.761 kWh/m2). The hourly variation in solar irradiation of 114 to 955 W/m2 is noted on a winter day; it ranges between 72 and 870 W/m2 in the summer season, during monsoon 6 to 649 W/m2 and in autumn, it is observed as 15 to 772 W/m2 (NASA 2021). Regarding the ambient air temperature, the highest temperature 45.3 °C is observed on a summer day and the lowest temperature of 25.1 °C on a winter day. It is observed that there is a variation of ± 2 °C temperature in a day from morning to evening. The average temperatures of 25.5 °C, 29.9 °C, 29.8 °C and 28.1 °C are observed in winter, summer, monsoon and autumn days, respectively.

Wind speeds

Wind speed is an essential factor to estimate the temperature models. As the 23 PV arrays are arranged on buildings of different heights, the wind speed on all the arrays is calculated individually using Eq. (10). The average wind velocity of 4.67 m/s, 5.59 m/s, 6.06 m/s and 4.55 m/s are noted in the four seasons (winter, summer, monsoon and autumn) at a reference height (50 m above the sea level) (NASA 2021). Figure 4 indicates the wind speeds on the 23 PV arrays calculated individually, installed on different heights. It is spotted that a variation from 4.31 to 5.04 m/s is observed between the 23 PV systems during winter, in monsoon 5.18 to 6 m/s, during monsoon 5.6 to 6.49 m/s and in autumn between 4.19 and 4.92 m/s. In all four seasons, the change in wind velocity between the PV arrays is 0.6 to 1 m/s.

Module temperatures

The minimum, maximum and average temperatures in a day of the four seasons for the 23 PV systems are discussed in this section. On a winter day, the PV system minimum temperature is varied between 18 and 36.4 °C; maximum temperature ranges from 49.2 to 56.2 °C and an average temperature of 41.5 °C to 48.1 °C is observed; in the summer day, the minimum, maximum and average temperatures are varied between 33.3 and 39.0 °C, 48.9 and 62.5 °C and 43.6 and 51.2 °C, respectively; for monsoon day, a range of 30.1 to 40.4 °C of minimum, 48.2 to 60.4 °C maximum and 43.5 to 51.6 °C of average temperatures are recorded. Lastly, during the autumn season, the variation of minimum, maximum and average temperatures is observed as 29.1 to 38.1 °C, 45.5 to 57.6 °C and 41.5 to 48.7 °C, respectively. The maximum module temperature recorded in 23 PV arrays for all the seasons is shown in Fig. 5. The hourly temperatures of all the 23 PV systems are noted from 6.45 am to 6.45 pm, and the graphical notation on an autumn day is presented in Fig. 6. Overall, a minimum module temperature of 18 °C is observed during a winter day, and a maximum temperature of 62.5 °C is recorded during summer.

Total power output

The generated output power of a solar PV system depends on many atmospheric parameters, but mainly on ambient air temperature, solar irradiation and wind speeds. This section discusses the power output of the 1-MWp solar PV plant along with the minimum, maximum and average power generated by each PV system connected to the plant. The hourly variation of output DC power production on a selected day of the four seasons is presented in Fig. 7. It is observed that at 12.45 pm, the highest solar radiation and power outputs are recorded on winter, summer and monsoon days, whereas in autumn, peak values are noted during 11.45 am. On a winter day, 8620.558 kW of DC power is generated for solar radiation of 955 W/m2; during summer 8784 0.087 kW is generated at solar radiation of 870 W/m2; on a monsoon day, it is observed that the highest power output achieved is 8009.578 kW at solar radiation of 649 W/m2, whereas autumn for the highest value of solar radiation 772 W/m2, the DC power recorded is 6762.829 kW. It is noticed that a higher value of solar radiation indicated a more DC output power production. The average hourly power in winter, summer, monsoon and autumn days is 5825.05 kW, 5984.07 kW, 6954.4 kW and 4538.39 kW, respectively.

As mentioned, the 1-MWp solar PV plant is built with 23 PV systems, the hourly minimum, maximum and average DC power generation of all the 23 PV systems seasonally is recorded, and the hourly average DC power output is presented in Fig. 8. During the winter season, the range of minimum, maximum and average power observed between the 23 PV systems is 0.51 to 2.75 kW, 144.91 to 535.97 kW and 73.41 to 284.93 kW, respectively; in summer, the variation of 1.28 to 8.75 kW, 195.37 to 555.56 kW and 103.69 to 297.35 kW of minimum, maximum and average values, respectively, is noted; on monsoon day, the range of 2.18 to 36.7 kW, 176.18 to 473.61 kW and 97.50 to 294.84 kW of minimum, maximum and average power outputs is observed. In contrast, on the autumn day, the variation of + 57.09 kW, + 320.1 kW and 158.29 kW is noted for the smallest of minimum, maximum and average values of DC power output. As it is known, the power output of the solar PV systems will depend on solar irradiation and ambient temperatures. And these two values vary from season to season, as well as specific times during a day. Hence, highest DC power output is observed during the mid-day (11 am–12 pm) in summer and at 4 pm on a monsoon day.

Predicted temperature models

With the four models discussed in the “Temperature models of PV system” section, the temperature in the 23 PV arrays is calculated for a selected day in a season. For predicting the module temperatures with various models, the parameters mainly required are the ambient air temperatures, wind speeds and solar irradiation. These parameters are collected from the source (NASA 2021) to validate the models. The first model, i.e. NOCT model, considers only the ambient air temperatures and solar irradiation, and all the 23 PV systems will have a similar value. The minimum, maximum and average temperatures calculated with NOCT model during winter are 24.7 °C, 54.2 °C and 40.8 °C; in summer, 30 °C, 56.5 °C and 44.5 °C; during monsoon, 29.5 °C, 49.5 °C and 40.8 °C and in autumn, 27.5 °C, 51.5 °C and 40.5 °C, respectively.

The following three models, namely Faiman, Sandia and arbitrary mounting models, additionally consider the wind speed, which changes concerning the height of the PV system displayed in Fig. 4, hence each of the PV systems will exhibit different module temperatures. From the recorded values, in the Faiman temperature model, the minimum temperatures are in the range of 27 to 30 °C with the least value during winter and autumn days, maximum values and averages vary between 39 and 45 °C and 35 to 38 °C, respectively, with the highest value during the summer season. Sandia temperature models exhibit a minimum temperature of 24.7 °C during the winter season, a maximum and average temperatures of 30.6 °C and 30.2 °C during the summer season with variations of ± 3 to 5 °C with the remaining values. The arbitrary mounting model predicts minimum and maximum temperatures of 24.7 °C and 56.9 °C in winter and the highest average of 44.4 °C during summer, with variations of ± 4 to 5 °C.

Comparison of monitored and predicted temperature values

The module temperatures are calculated from the four temperature models and compared with the measured cell temperature for all the 23 PV systems. It is observed that the measured module temperatures are in the range of 30 to 55 °C in all seasons. In contrast, the calculated temperatures using the NOCT model are in the range of 24 to 56 °C, with Faiman model 27 to 43 °C, Sandia model 25 to 31 °C and using the arbitrary mounting model is 29 to 56 °C based on the seasonal variation. Table 2 presents the comparison of the average module temperatures of the temperature models with the measured values for the 1-MWp Solar PV plant.

The relative error calculations (statistical error matrices) between the measured and calculated temperature values are implemented for better evaluation of the prediction models. Based on the prediction models, mean bias error, root mean square error, normalised root mean square error, TS, standard deviation, weighted mean bias error and coefficient of determination are calculated for each PV system of the 1-MWp plant, and the summary of it is presented seasonally in Fig. 9a–d. Table 3 shows the numerical values on an autumn day. Figure 10a–f represents the error calculations of individual 23 PV arrays in all four seasons using the arbitrary mounting model. Similarly, the error calculation is performed with the other three temperature models. Noting the least error values, 3.71% MBE is observed with AMM on a winter day, 6.04% RMSE is seen in the NOCT model during a summer day, 5.8% of NRMSE is found with AMM during a summer day, 1.89% of TS is noted with AMM on a winter day and an SD of 2.51% is observed by Faiman model on a summer day. In contrast, the lowest WMBE of 0.03% is witnessed by AMM.

For the sake of accuracy, the influence of the variation of the seasons on the four predicted models has been tested, and ranking based on the NRMSE values, AMM is the best for PV simulation during winter and autumn with 8.69% and 9.13%, respectively. In summer and monsoon, the NOCT model has the best value with 4.6% and 15.32%, respectively. Out of all the four models considered, the AMM model can be recognised as the most acceptable model for our region of analysis. It is observed that AMM has exhibited the lowest MBE, RMSE, NRMSE, TS, and WMBE (error values ranging between 0.27 and 9.13) during the winter and autumn days compared to others. The difference in atmospheric temperature and solar spectrum in a year is the cause of the deviation between the seasons. Each prediction model is a regression equation that better predicts cell temperature and solar irradiation in a particular range.

Conclusion

Like other weather parameters, temperature is one that adversely affects the solar PV plant performance irrespective of installation type. Given the high deployment of rooftop solar PV systems and their uncertain operation has pushed the authors to have mandate understanding over the role of temperature on the solar PV performance and how the ambient temperatures would affect the PV module temperature. In this study, the accuracy of four temperature models to predict the module temperature of a 1-MWp solar PV plant is identified considering the highest temperature day (on a selected day) of winter, monsoon, summer and autumn seasons. Data monitoring is followed by the performance analytics of an installed rooftop solar PV plant exposed to coastal weather conditions. The following were the concluding observations from this study:

-

The hourly average module temperatures of 45.4 °C, 48.2 °C, 48.3 °C and 45.4 °C are observed in winter, summer, monsoon and autumn days, respectively, suggesting that irrespective of season, temperature has a negative effect on the PV plant performance.

-

It was observed that there is a considerable impact of temperature on the performance of the solar plant and the observed average DC power output of solar PV plant on winter, summer, monsoon and autumn days as 227.47 kW, 231.21 kW, 217.5 kW and 182.3 kW, respectively.

-

The least error values are identified as 3.71% MBE with the AMM model on a winter day, 6.04% RMSE in the NOCT model during a summer day, 5.8% of NRMSE on a summer day with the AMM model and 1.89% of TS and 0.03% of WMBE with AMM during summer and winter days, respectively.

The analysis of seasonal effect for a precise simulation based on the monitored data suggested that all models can be used; however, coming to more accuracy, the AMM model is well-suited for the given weather conditions. Overall, the results show that the AMM model best understands the temperature-influenced PV power plant performance analytics.

Data availability

Supplementary data to this article will be provided on request.

References

Al-Maghalseh M (2018). Experimental study to investigate the effect of dust, wind speed and temperature on the pV module performance. Jordan J Mech Ind Eng 12(2).

Almaktar M, Rahman HA, Hassan MY, Rahman S (2013) Climate-based empirical model for PV module temperature estimation in tropical environment. Appl Solar Energy 49(4):192–201. https://doi.org/10.3103/S0003701X13040026

Amelia A, Irwan Y, Leow W, Irwanto M, Safwati I, Zhafarina M (2016) Investigation of the effect temperature on photovoltaic (PV) panel output performance. Int J Adv Sci Eng Inf Technol 6(5):682–688. https://doi.org/10.18517/ijaseit.6.5.938

Armstrong S, Hurley W (2010) A thermal model for photovoltaic panels under varying atmospheric conditions. Appl Therm Eng 30(11–12):1488–1495. https://doi.org/10.1016/j.applthermaleng.2010.03.012

Araneo R, Grasselli U, Celozzi S (2014) Assessment of a practical model to estimate the cell temperature of a photovoltaic module. Int J Energy Environ Eng 5(1):1–16. https://doi.org/10.1007/s40095-014-0072-x

Assoa YB, Mongibello L, Carr A, Kubicek B, Machado M, Merten J, Misara S, Roca F, Sprenger W, Wagner M (2017) Thermal analysis of a BIPV system by various modelling approaches. Sol Energy 155:1289–1299. https://doi.org/10.1016/j.solener.2017.07.066

Atsu D, Dhaundiyal A (2019) Effect of ambient parameters on the temperature distribution of photovoltaic (PV) modules. Resources 8(2):107. https://doi.org/10.3390/resources8020107

Bhattacharya T, Chakraborty AK, Pal K (2014) Effects of ambient temperature and wind speed on performance of monocrystalline solar photovoltaic module in Tripura, India. J Sol Energy 2014. https://doi.org/10.1155/2014/817078

Ciulla G, Lo Brano V, Moreci E (2013). Forecasting the cell temperature of PV modules with an adaptive system. Int J Photoenergy 2013https://doi.org/10.1155/2013/192854

Correa-Betanzo C, Calleja H, De León-Aldaco S (2018) Module temperature models assessment of photovoltaic seasonal energy yield. Sustainable Energy Technol Assess 27:9–16. https://doi.org/10.1016/j.seta.2018.03.005

Dawn S, Tiwari PK, Goswami AK, Mishra MK (2016) Recent developments of solar energy in India: perspectives, strategies and future goals. Renew Sustain Energy Rev 62:215–235. https://doi.org/10.1016/j.rser.2016.04.040

del Cerro RTG, Subathra M, Kumar NM, Verrastro S, George ST (2021) Modelling the daily reference evapotranspiration in semi-arid region of South India: a case study comparing ANFIS and empirical models. Inf Process Agric 8(1):173–184. https://doi.org/10.1016/j.inpa.2020.02.003

D’Orazio M, Di Perna C, Di Giuseppe E (2013) Performance assessment of different roof integrated photovoltaic modules under Mediterranean climate. Energy Procedia 42:183–192. https://doi.org/10.1016/j.egypro.2013.11.018

Faiman D (2008) Assessing the outdoor operating temperature of photovoltaic modules. Prog Photovoltaics Res Appl 16(4):307–315. https://doi.org/10.1002/pip.813

Gökmen N, Hu W, Hou P, Chen Z, Sera D, Spataru S (2016) Investigation of wind speed cooling effect on PV panels in windy locations. Renewable Energy 90:283–290. https://doi.org/10.1016/j.renene.2016.01.017

Hajjaj C, Merrouni AA, Bouaichi A, Benhmida M, Sahnoun S, Ghennioui A, Zitouni H (2018) Evaluation, comparison and experimental validation of different PV power prediction models under semi-arid climate. Energy Convers Manage 173:476–488. https://doi.org/10.1016/j.enconman.2018.07.094

Huld T, Amillo AMG (2015) Estimating PV module performance over large geographical regions: the role of irradiance, air temperature, wind speed and solar spectrum. Energies 8(6):5159–5181. https://doi.org/10.3390/en8065159

Kaplanis S, Kaplani E (2019) A new dynamic model to predict transient and steady-state PV temperatures taking into account the environmental conditions. Energies 12(1):2. https://doi.org/10.3390/en12010002

Karami E, Rafi M, Haibaoui A, Ridah A, Hartiti B, Thevenin P (2017) Performance analysis and comparison of different photovoltaic modules technologies under different climatic conditions in Casablanca. J Fundam Renew Energy Appl 7(03):1–6. https://doi.org/10.4172/2090-4541.1000231

Kawajiri K, Oozeki T, Genchi Y (2011) Effect of temperature on PV potential in the world. Environ Sci Technol 45(20):9030–9035. https://doi.org/10.1021/es200635x

Koehl M, Heck M, Wiesmeier S, Wirth J (2011) Modeling of the nominal operating cell temperature based on outdoor weathering. Sol Energy Mater Sol Cells 95(7):1638–1646. https://doi.org/10.1016/j.solmat.2011.01.020

Kumar NM (2017) Simulation tools for technical sizing and analysis of solar PV systems. In Proceedings of the 6th World Conference on Applied Sciences, Engineering and Technology (WCSET-2017) 201 218–222

Kumar NM, Das P, Krishna PR (2017) Estimation of grid feed in electricity from roof integrated Si-amorph PV system based on orientation, tilt and available roof surface area. In 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT) (pp.588–596).IEEE. https://doi.org/10.1109/ICICICT1.2017.8342629

Kumar NM, Subathra MP, Moses JE (2018) On-grid solar photovoltaic system: components, design considerations, and case study. In 2018 4th International Conference on Electrical Energy Systems (ICEES) (616–619). IEEE. https://doi.org/10.1109/ICEES.2018.8442403

Kumar NM, Gupta RP, Mathew M, Jayakumar A, Singh NK (2019a) Performance, energy loss, and degradation prediction of roof-integrated crystalline solar PV system installed in Northern India. Case Stud Therm Eng 13:100409. https://doi.org/10.1016/j.csite.2019.100409

Kumar NM, Sudhakar K, Samykano M (2019b) Performance comparison of BAPV and BIPV systems with c-Si, CIS and CdTe photovoltaic technologies under tropical weather conditions. Case Stud Therm Eng 13:100374. https://doi.org/10.1016/j.csite.2018.100374

Malvoni M, Kumar NM, Chopra SS, Hatziargyriou N (2020) Performance and degradation assessment of large-scale grid-connected solar photovoltaic power plant in tropical semi-arid environment of India. Sol Energy 203:101–113. https://doi.org/10.1016/j.solener.2020.04.011

Mohammed H, Gupta R, Sastry O, Magare D (2019) Assessment of different correlations to estimate distinct technology PV module operating temperature for Indian site. Energy Sci Eng 7(3):1032–1041. https://doi.org/10.1002/ese3.332

Mukisa N, Zamora R, Lie T (2019) Analysis of solar cell temperature models used in solar photovoltaic simulating softwares. 2019 IEEE PES GTD Grand International Conference and Exposition Asia (GTD Asia), IEEEhttps://doi.org/10.1109/GTDAsia.2019.8715916

NASA. Prediction of worldwide energy resources. The power project. Available on https://power.larc.nasa.gov. Accessed 28 Jan 2021.

Olukan TA, Emziane M (2014) A comparative analysis of PV module temperature models. Energy Procedia 62:694–703. https://doi.org/10.1016/j.egypro.2014.12.433

Pendem SR, Mikkili S (2018) Modeling, simulation and performance analysis of solar PV array configurations (series, series–parallel and honey-comb) to extract maximum power under partial shading conditions. Energy Rep 4:274–287. https://doi.org/10.1016/j.egyr.2018.03.003

Pillai R, Aaditya G, Mani M, Ramamurthy P (2014) Cell (module) temperature regulated performance of a building integrated photovoltaic system in tropical conditions. Renewable Energy 72:140–148. https://doi.org/10.1016/j.renene.2014.06.023

Sarkar MNI (2016) Effect of various model parameters on solar photovoltaic cell simulation: a SPICE analysis. Renewables Wind, Water, Solar 3(1):1–9. https://doi.org/10.1186/s40807-016-0035-3

Sharma R, Goel S (2017) Performance analysis of a 11.2 kWp roof top grid-connected PV system in Eastern India. Energy Rep 3:76–84. https://doi.org/10.1016/j.egyr.2017.05.001

Thotakura S, Kondamudi SC, Xavier JF, Quanjin M, Reddy GR, Gangwar P, Davuluri SL (2020) Operational performance of megawatt-scale grid integrated rooftop solar PV system in tropical wet and dry climates of India. Case Stud Therm Eng 18:100602. https://doi.org/10.1016/j.csite.2020.100602

Vishnupriyan J, Manoharan P (2017) Demand side management approach to rural electrification of different climate zones in Indian state of Tamil Nadu. Energy 138:799–815. https://doi.org/10.1016/j.energy.2017.07.140

Author information

Authors and Affiliations

Contributions

Conceptualization: Sandhya Thotakura; data curation: Sandhya Thotakura; formal analysis and investigation: Sri Chandan Kondamudi; writing: Sandhya Thotakura and Sri Chandan Kondamudi; writing—review and editing: Sandhya Thotakura and Sri Chandan Kondamudi; supervision: Sandhya Thotakura.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thotakura, S., Kondamudi, S.C. Operating temperature prediction and comparison for rooftop PV arrays in coastal climates of India. Environ Sci Pollut Res 29, 43532–43545 (2022). https://doi.org/10.1007/s11356-022-20068-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20068-6