Abstract

This paper presents a study of a 98.1 kW-PV system facing south at an inclined angle of 15º on the roof of a university building in Seoul, South Korea (latitude 37.63° N and longitude 127.1° E). The system performance was analyzed for 2 years from Sep. 2015 to Aug. 2017. The average electrical power output was 0.59 kWh/(m2·day) with a 16.9% average annual efficiency for the 1st year which further decreased to 0.58 kWh/(m2·day) with average annual efficiency of 17.6% in the 2nd year. The annual irradiance was 3.50 kWh/(m2·day) for the 1st year and 3.31 kWh/(m2·day) for the 2nd year with a total annual output generation of 105.4 MWh and 103.5 MWh, respectively. Average daily power generations were 2.93 and 2.89 kWh/(kWp·day) for 2 years, respectively, with an annual performance ratio range of 80 ~ 90%. Predicted module temperatures show a good correlation with measured temperatures. Predicted and measured output values show a strong correlation. During the 1st year at a maximum module temperature of 60ºC, power output loss was found to be 13.3%, while in the 2nd year at a maximum module temperature of 57ºC, the power output loss observed was 12.2%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

According to the US energy information system, nearly 98% of fossil fuel consumption by South Korea is dependent on imports from other countries due to inadequate domestic resources [1]. From KESIS (Korea Energy Statistical Information System) 2017 report, though the South Korean government is promoting the use of natural resources, only 4% of the total power is generated through renewable energy sources as shown in Fig. 1 [2]. Land availability in South Korea is limited, and for the installation of PV systems, a large flat surface area is required. To overcome the insufficient land area, PV systems can be installed on the rooftop of buildings for the generation of electricity [3]. The implementation of solar PV panels on the rooftop of university buildings is an effective and practical way to overcome insufficient space problems. Since solar energy is clean, sustainable, and imperishable, the generation of electricity using PV systems is expected to become a major energy generation source in the future.

Electrical output and efficiency are generally specified under STC (Standard Test Conditions). In recent years, many investigations have been carried out for the PV system in order to check the performance and behavior of the efficiency with respect to the environmental factors. A study showing the analysis and performance evaluation results of a 50-kW rooftop PV system installed on the dormitory rooftop of Chosun University in Daegu for the duration of 4 years from 2003 to 2006 [4]. A 50-kW system is divided into two sets of arrays comprising 25 kW each located on the rooftop of a dormitory. The values of PV array characteristics, PCS (Power Conditioning System) characteristics, and the system performance were analyzed. The study concluded that the PV array conversion efficiency ranged from the lowest of 9.19% in 2003 to the highest of 10.02% in 2004 with a performance ratio maximum percentage of 82.56% in 2005 to the minimum point of 75.09% in 2003. The PV array power output was recorded lowest in June 2006 with less than 3000 kWh to a maximum output of 8000 kWh in April 2005 [4]. Another study was performed for a 5-kW rooftop SPV power plant based in India which shows a detailed performance analysis based on the monitored data for 1 year and the effect of temperature analyzed [5]. The studies represented that average PV array efficiency and system efficiency were found at 11.34% and 10.02%, respectively. The plant showed a yearly yield of 7175.4 kWh/year, and the losses were reported to be an average of 14.54% [5]. A 5-kWp capacity hybrid connected PV solar system data was analyzed from September 2020 to August 2021 for an entire period of 1 year installed on the roof of a house in Iraq which shows the PV system energy yield of 8.9 GWh/year with a performance ratio and load efficiency of 0.66 and 0.92%, respectively. The annual array efficiency of the system was 12.6% [6]. Vashisht et al. [7] conducted a study on the analysis of a 20-kWp solar photovoltaic system set up on the roof-top of the Indian Institute of Science, Bangalore, India, particularly focused on the objective of the performance analysis of a solar plant based on the climatic conditions and to analyze the system in different seasons [7]. The system showed the average daily production of 80 kWh for the last 2 years which constituted 28.9 MWh for the annual yield. The capacity utilization factor and performance ratio of the system is around 16.5% and 85%, respectively. In summers with a module temperature greater than 45℃, the module efficiency shows a drop by 0.08% per degree rise in temperature which turns to 0.04% in monsoons with a module temperature of more than 35℃. In post-monsoon, when the module temperature is greater than 38℃, the efficiency reduces by 0.06% per degree rise in temperature. However, the winter shows a maximum efficiency at a module temperature of 55℃ with a lower efficiency drop due to the cool breeze and lower ambient temperature creating an intermittent natural cooling at the surface of modules [7]. Ibrahim studied the electrical characteristics of photovoltaic single-crystal silicon solar cells at outdoor measurements [8]. A study done by Ma et al. [9] presented a detailed review of the literature focused on the use of phase change material for PV module thermal regulation and electrical efficiency improvement. Seme et al. [10] presented the study of the energy production of different types and orientation effect of photovoltaic systems under outdoor conditions in Slovenia. Nishioka et al. [11] presented the study of 50 kW PV system output characteristics by a field test analysis in Japan focusing on module temperature. Bhattacharya et al. [12] studied the effects of ambient temperature and wind speed on the performance of monocrystalline solar photovoltaic modules in Tripura, India.

However, the PV performance under actual field conditions is different from STC and little work has been done that predicts power generation with PV module temperatures which are correlated by ambient conditions.

In the present study, the field performance of a 98.1 kW rooftop PV system was analyzed for 2 years from September 2015 to August 2017 for the PV system efficiency, power output, and module temperature. The power output based on the environmental parameters like ambient temperature and solar irradiance, module temperature, and weather conditions were predicted.

The results from the monitored data provide detailed information for system performance and efficiency and give site insight for the prediction of future projects and development. The performance analysis of the system on a daily, monthly, seasonal, and annual basis is based on the actual measurements, and the calibrated data is observed. The analysis is done to predict the effect of solar irradiance and ambient temperature on the output energy generation and efficiency of the PV system in different seasons throughout the 2 years. The calculation of the predicted module temperature and predicted output values is done to analyze the correlation between measured module temperatures along with the calculated output values of PV panels.

2 System introduction and measurement system

2.1 The PV system specification

The PV panels are installed on the rooftop of one of the buildings in a university located in Seoul, South Korea, as shown in Fig. 2. It is situated at latitude 37.63° north and longitude 127.1° east. The South Korean weather can be generally classified into four seasons spring (Mar.–May), summer (June–Aug.), fall (Sep.–Nov.), and winter (Dec.–Feb.). The installation was completed on Jan. 2014. Due to the scarcity of plain land in South Korea and in order to fulfill the clean electricity generation, the university administration and the energy department installed the 98.1-kW PV system on the building rooftop of the university. The PV panel PM318B01_327 used in this study is manufactured by AU Optronics Corporation (BenQ Solar) consisting of 96 mono-crystalline cells. There are a total of 300 PV panels with an overall area of 489 m2 with a single module area of 1.63 m2. The tilt angle of the PV panels is 15° from the horizontal surface. The specifications of the PV panel are listed in Table 1. Under STC, the system’s nominal electric output per area is 200.6 W/m2.

2.2 PV measurement system

The following parameters should be measured to perform PV system hourly, daily, monthly, and annual analysis: using hourly global solar irradiance, ambient temperature, and outdoor conditions. PV panels gain solar energy from the sun, and the output of the PV panel’s energy is transferred to the PCS (Power Conditioning System) or solar inverter. After being processed in the PCS, the electrical energy is delivered to the load.

The data is analyzed and recorded by a temperature sensor probe and pyranometer that is transferred to the data logger storage device for further analysis. Figure 3 shows the schematic diagram of the PV measurement system.

Table 2 shows the pyranometer and ambient temperature sensor which are used to measure solar irradiance and temperature. Solar radiance data collected by DIS-100 type pyranometer were transferred to the data logger through RS-485 communication. Since RTD sensors are known for a long-term stability with little oxidation and corrosion process, RTD sensors were installed on the top side of the panel for the measurement of ambient temperature continuously.

3 Monitored climatic and raw data of PV system

3.1 Monitored solar irradiance data on-site and Korea Meteorological Administration data

The on-site power output data is collected through the university energy administration department which is constantly monitoring and recording the data since the time of the installation of the PV system. In order to investigate the accurate functioning and reliability of on-site installed sensors, the measured data is compared with Korea Meteorological Administration (KMA) measured data [13]. Figure 4 represents the comparison of solar irradiance measured on-site and Korea Meteorological Administration (KMA) measured data [13]. The comparison is made for a duration of 1 year from Sept. 2015 to Aug. 2016. The highest solar irradiance was observed in May 2016 with the lowest monitored in Nov. 2015 for on-site as well for KMA data. From Fig. 4, it can be observed that on-site measured data shows slight differences from the KMA measured data. The possible reason behind this could be the location of the site and the type of sensors used including the error margins. Regardless of the slight difference of data measurement patterns, the month-to-month overall comparison of on-site irradiance data provides satisfactory results with KMA-measured irradiance data. Therefore, this monitored on-site data can be used as a reliable source for the analysis of the PV system.

3.2 Ambient air temperature and module temperature of the PV system

To check the temperature behavior of the PV panel module temperature in accordance with the environmental parameters such as ambient air temperature, monthly ambient and module temperatures from Sept. 2015 to Aug. 2016 are shown in Fig. 5. The monthly ambient air temperature was lowest in Jan. 2016 with an average temperature of −2.3 °C and varied to a maximum in Aug. 2016 which reached 29.8℃. However, the module temperature varied from −2.1 °C in Jan. 2016 and reached 32.3 °C in Aug. 2016. From Nov. 2015 to Feb. 2016, there was a slight difference between the module and the ambient temperature. The difference varied from 0.07 °C in Jan. 2016 to 0.56 °C in Feb. 2016. From Mar. 2016 towards the summer season, Aug. 2016, the difference between ambient and module temperatures elevated due to a lower efficiency of the PV panel which resulted in more heat dissipation. Due to a high ambient temperature, the module temperature rose significantly, whereas in winter, the cool breeze flowing around the panel lowered the temperature difference and the module temperature.

3.3 Monthly monitored solar irradiance data

Figure 6 shows the variation of solar irradiance falling on the PV panels on a monthly basis for the continuous duration of two consecutive years (Sept. 2015–Aug. 2017) to check the pattern and behavior of irradiance. From Jan. to May, the solar irradiance data for both years showed a rising pattern. However, in July, a sudden decrease can be seen for both years, as there were about 10 days which had less than 1.5 kWh/(m2·day) of solar irradiance in this particular month. Between Sept. 2016 and Sept. 2017, there was a difference of 0.83 kWh/(m2·day) of irradiance. From the data analysis, solar irradiance greater than 5 kWh/(m2·day) was observed for about half of the days in Sept. 2016, whereas in Sept. 2017, there were only 2 days with solar irradiance more than 5 kWh/(m2·day). The maximum and minimum values of irradiance were observed during 2015–2016 showing a larger variation in irradiance. Overall, the trend of seasonal solar irradiance for both years was showing a similar pattern.

3.4 Correlation between ambient temperature and module temperature

The hourly representation of measured data is considered due to the fact that the temperature level fluctuates significantly throughout the whole day. However, the daily average data represents the mean values of the ambient and module temperature which cannot be used and can be unreliable to predict the module temperature in variance with the ambient temperature change on an hourly basis. Therefore, the hourly correlation of both the temperatures is preferred over the daily average data. The linear relation between hourly measured ambient and module temperature from Sep. 2015 to Aug. 2016 is shown in Fig. 7. The Pearson correlation coefficient R value for the ambient and module temperature is observed to be 0.9527 which is given by Eq. (1). This value shows the measure of the linear association strength between ambient and module temperature, and this correlation provides the information of how well the data of two variables ambient and module temperature fits into this model. It is observed that with the increase in the ambient temperature, the module temperature increased linearly (R2 = 0.9076). With a higher R2 value of 0.9076, a very strong positive correlation and fairly closeness for ambient temperature and module temperature values can be observed. The mean absolute error is observed to be 3.571℃, which shows the average magnitude of the errors and provides the idea of how big an error can be expected from the forecast on average which is given by Eq. (2). The standard deviation value gives the measure of data dispersion in relation to the mean. The low standard deviation value of 5.33℃ shows the value of the data which is clustered around the mean and is given by Eq. (3). The minimum temperature recorded for the ambient air was −18ºC, which shows a module temperature of −19.9ºC, and the maximum ambient temperature was recorded at 43.1ºC, which shows the module temperature at the maximum of 59.7ºC.

Pearson correlation coefficient (R):

Mean absolute error (MAE):

Standard deviation (SD):

where N = number of data, x = measured data, and y = estimated value by estimation.

4 PV performance data

4.1 Monitored data

Table 3 shows monthly solar irradiance, ambient air temperature, module temperature, and power output during Sep. 2015–Aug. 2017. The raw data has been gathered on a daily basis. During Sep. 2015–Aug. 2016, the total solar irradiance measured for the complete 1-year duration was 627.1 MWh with a net output generation of 105.4 MWh and annual daily average specific yield Savg,d of 2.92 kWh/(kWp·day). For the 2nd year during Sep. 2016–Aug. 2017, the total solar irradiance measured was 589.6 MWh with a gross output generation of 103.5 MWh. The total irradiance and output generation in the 2nd year were less than in the first year. However, the PV thermal efficiency was greater in the 2nd year. As solar irradiance varies, the PV system power output changes considerably. From Table 3, it is clear that power output generation (kWh/day) is proportional to the solar irradiance intensity. In the 1st year (Sep. 2015–Aug. 2016), the maximum output was in May 2016 with 407.8 (kWh/day) where the maximum solar irradiance was 2375.2 (kWh/day). The minimum was in Nov. 2015 with just 809 (kWh/day). For the 2nd year, the maximum irradiance was measured in Jun. 2017 with 2267.2 (kWh/day) and the lowest was 920.2 (kWh/day) in Dec. 2016. The minimum module temperature was −2.10ºC during the 1st year which then increased to 0.72ºC in the 2nd year. However, in Aug. 2016, a maximum module temperature observed was 32.30℃. In the 2nd year, it reached 30.12ºC in Jul. 2017, a decrease of 2.18ºC from the previous year. Annual average output was 288 (kWh/day) in the 1st year and 284.1 (kWh/day) in the 2nd year.

4.2 Performance of the PV system

4.2.1 PV system efficiency

The PV system efficiency is defined as the ratio of the output energy generated in kWh to the incident solar irradiance (kWh) falling on the PV arrays with the total module area (m2) and is given in Eq. (4) [14].

In the above equation, E is electrical energy generated, H is incident irradiance per area on the PV module, and A is the area of the PV module [14].

4.2.2 Monthly efficiency, output energy generation, and solar irradiance

The efficiency of the PV system for each month from Aug. 2015 to Sept. 2017 is given in Table 4 with respect to solar irradiance and output. In the 1st year (Sep. 2015–Aug. 2016), a maximum efficiency of 18.97% was observed in Jan. 2016 which was just 1.13% less than the efficiency at STC. However, in the next year (Sep. 2016–Aug. 2017), the efficiency reached a maximum value of 19.87% in Feb. 2017. The lowest efficiency was recorded at 15.49% in Jul. 2016 as the monthly average temperature of the module was 29.8ºC which was 4.8ºC higher than the STC temperature. However, in the 2nd year, the lowest efficiency was observed in July 2017 when the module temperature reached 30.12ºC. As mentioned in PV specifications, the efficiency is 20.1% under STC and the annual efficiency measured under the real conditions was 16.89% which is 3.2% less than that of the STC efficiency for the first year. However, annual efficiency increased in the next year and reached 17.62%. The average annual efficiency increased by 4.3% in the 2nd year. Park et al. [4] studied performance of 50 kW PV system at Daegu in which the efficiency showed an increasing pattern for the first 2 years of analysis, which was 9.19% in 2003 and increased to 10.02% in 2004. The increase of the PV efficiency shows the same trend with the previous study by Park et al. [4].

4.2.3 Seasonal efficiency, output energy generation, and solar irradiance

The following parameters like solar irradiance, output energy, and efficiency are also analyzed on the seasonal basis. By comparing both years, obtained data shows in the general same level of efficiency trend for each season. Seasonal PV system performance behavior is shown in Table 5. The efficiency was observed highest in winter season and lowest in summer season for both years. During 2 years of data analysis, the output generation was highest during spring season as the maximum amount of solar irradiance was received by the PV panel and efficiency was 17 ~ 18% which was 1% lower than the peak efficiency received in winter season. However, the efficiency is better in winter due to lower ambient temperature and the energy is efficiently converted by the PV modules. In winter season, the efficiency reached 19.07% which is very near the STC efficiency. According to the data, the maximum efficiency obtained for the first year was 18.23% in winter which was followed by 19.07% in winter the next year. The maximum output energy generation was observed in spring season for both years.

4.2.4 System performance indices and comparison of PV system analysis

The PV system performance can be varied and shows different results based on the individual system configuration, capacity, and location. The system factors and the performance indices like performance ratio (%), final system yield, and PV system efficiency can be preferably used and compared to check the evaluation and performance of the PV systems. To check the system operation and proper working of the system which is the primary information about the system performance, these indices are considered important.

Final yield (Yf):

The final yield (Yf) kWh/(kWp·day) of the system is generated by Eq. (5). It is defined as the daily net energy output (Enet) generation of the PV system to the peak capacity Po (kWp) of the system. This is the characteristic parameter to check the comparison of the systems [15]. The unit of the final yield is kWh/(kWp·day).

Reference yield (Yr):

For the calculation of the PR factor, the reference yield (Yr) is to be considered which is given by Eq. (6).

The reference yield (Yr) is the ratio of the total in-plane solar irradiation (Iinc) to the reference irradiance (Iref) of the PV system. The solar irradiance level at the reference point is considered as (1 kW/m2) [15]. The unit of reference yield is kWh/(kWp·day).

Performance ratio (%):

The performance ratio is a dimensionless parameter which is used to check the total losses on a system during the conversion operation of rated DC power to output AC power. It is defined as the ratio of the final yield and the reference field by Eq. (7). To check the system operating conditions as expected and to identify the faults occurrence, this PR values are useful [15].

The PR values notify the working pattern of the plant as of the rated power. Higher PR values indicated that the plant is working near the rated power, whereas the lower PR values show the generation losses occurred by design or technical problems [15].

The performance of the current PV system is compared with the system installed in Daegu for the duration of 4 years from 2003 to 2006 is shown in Table 6. Here, the comparison is based on the three parameters which are final yield, performance ratio, and system efficiency.

4.2.5 Performance ratio, PV efficiency, and final yield analysis of two systems installed

The comparison of the current PV system is done with the system installed in Daegu for the duration of 4 years from 2003 to 2006 is shown in Table 6. For the PV system efficiency, the average annual efficiency was observed at 16.89% for the first year (2015–2016), and it increased by 0.73% in the next year which is 17.62% for (2016–2017). The efficiency range lies between 16 and 17% which represents the PV system efficiency generation is near the rated module efficiency of 20%. The average annual performance ratio for the current study was observed at 83.7% for the first year of operation and reached to 87.4% in the next year. The performance ratio range for the system is observed between 80 and 90% which represents the higher PR values and shows the system is working near the rated power. The maximum loss in PR is measured in July 2017 due to the power loss from high temperatures, and the maximum number of cloudy rainy days with solar irradiance ranges from 0.3 to 1.5 kWh/(m2·day). The PR of the plant varies from 76.8% in Jul. 2016 to 98.6% in Feb. 2017. The average annual PR of 83.7% and 87.4% for both years is higher than the system installed in Daegu which were 75.09 and 81.70% [4]. This study is conducted for the duration of 4 years from 2003 to 2006 in Daegu which also shows the same pattern of efficiency for the first 2 years. The study concluded that the PV array conversion efficiency ranges from the lowest of 9.19% in 2003 to the highest at 10.02% in 2004, and the performance ratio was observed to a maximum percentage of 82.56% in 2005 to the minimum point of 75.09% in 2003 [4]. The comparison of both the systems shows a similar result with the duration of time, the increase of PV efficiency trend, and the performance ratio of both the systems. The current PV system shows a high value of PR and the final yield results are. The final yield of the system is deduced with the help of measured collected data. The maximum final yield of 4.14 kWh/(kWp·day) is observed in the month of May 2016 and a minimum of 1.45 kWh/(kWp·day) in Nov. 2015 with an average annual final yield of 2.93 kWh/(kWp·day) for the first year of measured data. The average annual final yield for the second year is observed at 2.89 kWh/(kWp·day) with a maximum of 4.07 kWh/(kWp·day) in May 2017 and a minimum of 1.83 kWh/(kWp·day). The higher final yield in May is due to the high solar radiation and the same for the lower final yield in Nov. 2015 and Dec. 2016. For the system installed at Daegu, the average annual final yield of 3.40 kWh/(kWp·day) can be seen in 2003 which is reduced to 3.17 kWh/(kWp·day) in 2006. The final yield is dependent on the value of solar radiation which suggests the net energy output based on the particular geographic location which can be further used to decide the installation location of the PV system. Generally, the PR value of a system ranges between 60 and 80% due to the different weather conditions. However, in cool conditions like winters, the PR value can exceed 0.9. During winter season of the first and second year, the PR is observed at 90.4% and 94.4%, respectively, which is higher than the other seasons. Generally, solar PV systems work at a comparatively higher temperature than STC temperature which can show ± 10% of large seasonal variation in PR [16].

4.3 Long-term solar irradiance, output, efficiency, and ambient temperature

Figure 8 represents the monthly solar irradiance received and generated output in kWh/(m2·day) for two consecutive years (Sep. 2015–Aug. 2017). From Fig. 8, a strong correlation between output generation and solar irradiance can be observed. In Jul., the solar irradiance and output generation showed a steep decline. According to the weather information gathered for Seoul during these periods in Jul. 2016 and 2017, there were 9–10 days with dense clouds [17]. Accordingly, the recorded solar irradiance for these days was less than 1500 Wh/(m2·day), and there were some days with an irradiance less than 600 Wh/(m2·day). In Nov. 2015, the maximum output power generation was just 308 kWh/day and the minimum value recorded was 18 kWh/day. There were 8 days which had irradiation less than 500 Wh/(m2·day). Figure 9 shows the average efficiency with respect to the average ambient temperature for 2 years (Sep 2015–Aug 2017). The maximum ambient temperature was 28.41ºC in Aug. The minimum efficiency was 15.31% in July. However, the efficiency increased in August. The rise in efficiency in August is due to the effect of the natural cleaning of the panel surface done by the rainfall during that period. From Sept. onwards, the efficiency showed an inverse pattern with the ambient temperature in winter due to lower temperature and the cool breeze flow around the PV panel. The highest efficiency was recorded in February. The efficiency in winter was 2.54% greater than the efficiency in summer. Accordingly, there was a difference of 3.57% between the maximum and minimum efficiency.

4.4 Long-term correlation between efficiency and ambient temperature

The long-term analysis of efficiency with ambient temperature shows the negative effect of ambient temperature on efficiency. At minimum temperature of −1.63℃, the efficiency was 18.31%, whereas at maximum temperature of 27.86℃, the efficiency became 15.31%. With R2 value of 0.7656, it shows a strong correlation that efficiency is inversely proportional to the ambient temperature. The long-term analysis of efficiency with ambient temperature (Sept. 2015–Aug. 2017) is shown in Fig. 10.

4.5 Prediction of module temperature

The module temperature was measured continuously and was recorded on hourly basis. The module temperature has been correlated using Eq. (8) [18].

Equation (8) is an empirical correlation of module temperature as a function of Tamb, Isolar, and Vair. Figures 11 and 12 show a predicted module temperature versus measured values for a period of Sept. 2015–Aug. 2016 and Sept. 2016–Aug. 2017, respectively. High R2 values for both periods indicate that Eq. (8) is reliable for the calculation of module temperature.

4.6 Predicted power output

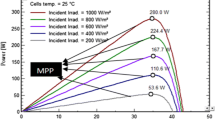

The correlation between monitored measured data and calculated power output is shown in Fig. 13 from Sept. 2015 to Aug. 2016. The measured output values were obtained from the monitored raw data which were converted to W/m2 units. The calculated power output Pcal is derived from Eq. (9) [19].

Pcal is the predicted output value, Pref is the reference output value, Cp is the power coefficient, Tmod is the module temperature, and Tref is the temperature at STC (25ºC), and Pref value is required and can be found using Eq. (10).

Pmax is the maximum generating capacity of the panel (327 W), Iref is the incident solar irradiance at STC (1000) W/m2), and Iinc is the monitored solar irradiance (W/m2). Figure 13 shows that calculated values are in good agreement with the measured data. This shows that Eq. (9) can predict the power output of the PV system with a little error. Figure 14 shows the correlation of measured output with the predicted output by using the predicted module temperature values. This graph shows a strong correlation between power output and calculated module temperature, and therefore, the calculated module temperature values can be used, in case the measured module temperatures are not available.

5 Conclusion

In this work, in situ operation data of a 98.1-kWp PV system installed on a rooftop of a university building located in Seoul, South Korea, were measured during Sep. 2015–Aug. 2017 and analyzed.

-

From monthly analysis, the highest efficiency was 18.97% and 19.87% in winters with a module temperatures at −2.10ºC and 1.74ºC and lowest in Jul. with an average annual efficiency of 15.49% and 15.13% at a module temperature of 29.80ºC and 30.12ºC for the 2 year’s time-period.

-

According to seasonal observation, the first year winters’ efficiency was 90.7% of the efficiency obtained at STC which increased to 94.8% in the second year. Summer and autumn seasons show the efficiency range between 16 and 17% with a minimum of 16.06% and a maximum of 16.88%. The annual efficiency of the 2nd year is 17.62% which shows an efficiency increment of 4.32% as compared to the 1st year.

-

Annual solar irradiance for the 1st year was measured at 3.50 kWh/(m2·day), which was reduced to 3.31 kWh/(m2·day) for the 2nd year with a maximum power output generation in spring and minimum in winter for both years due to high and low solar irradiance.

-

The average annual performance ratio of the PV system varies between 80 and 90% with a maximum of 87.4% in the 2nd year. The performance ratio shows the highest loss in Jul. 2017 due to a high temperature power loss and the highest number of rainy cloudy days. The system average annual final yield is observed at 2.93 kWh/(kWp·day) and 2.89 kWh/(kWp·day) for the 1st and 2nd years, respectively.

-

The predicted module temperature correlation with the measured values shows a strong correlation with R2 value of 0.98; therefore, calculated values can be used for the prediction of power output of PV modules and Pearson correlation value is 0. 95. MAE value is observed to be 3.571 ºC with a low standard deviation value of 5.33 ºC.

-

The minimum module temperature was recorded at −19.9 ºC with ambient temperature of −18 ºC, and the maximum module temperature was observed at 59.7 ºC with 43.1 ºC ambient temperature.

-

The power loss of 13.2% is observed when the module temperature reached to 59.7ºC which is 34.7ºC higher than the STC temperature of 25ºC, whereas with the correlated values the predicted power loss observed is 10.7%. During the 2nd year, the power loss was 12.2% when the module temperature was 57.1ºC with a temperature difference of 32.1ºC as compared to STC, whereas with the calculated module temperature, the power loss was 9.54%.

6 Nomenclature

R Pearson correlation coefficient

N Number of data

E Electrical energy output (kWh)

H Incident radiance (W/m2)

A Area of module (m2)

T Temperature (℃)

V Velocity (m/s)

P Power output (W)

I Solar irradiance (W/m2)

Iinc Solar irradiance at particular time (W/m2)

Iref Solar irradiance level at STC (1000 W/m2)

xi Measured data

yi Estimated value

Yf Final yield kWh/(kwp·day)

Po Peak capacity (kWp)

Yr Reference yield kWh/(kwp·day)

6.1 Greek letters

η Efficiency (%)

6.2 Subscript

max Maximum

mp Maximum power

oc Open circuit

sc Short circuit

avg,d Daily average

amb Ambient

mod Module

cal Calculated

ref Reference

t Total

Availability of data and materials

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- KEPCO:

-

Korea Electric Power Corporation

- PV:

-

Photovoltaic

- STC::

-

Standard Test Conditions

- PCS:

-

Power Conditioning System

- RTD:

-

Resistance temperature detector

- KMA:

-

Korea Meteorological Administration

- MAE:

-

Mean absolute error

- SD:

-

Standard deviation

- PR:

-

Performance ratio

References

Outlook, S.T.E. (2014). Independent statistics & analysis. US Energy Information Administration.

KESIS (Korea Energy Statistical Information System) Energy Info. Korea. (2017). No. 168, 2018-03-07. http://www.kesis.net/sub/sub_LastPubctList_eng.jsp. Accessed 6 Feb 2023.

Sharma, R., & Goel, S. (2017). Performance analysis of a 11.2 kWp roof top grid-connected PV system in Eastern India. Energy Reports, 3, 76–84.

Park, J.M., Piao, Z.G., Cho, Y.O.G.B., Baek, H.L. (2007). Performance evaluation and analysis of 50kw grid-connected pv system. In 2007 7th international conference on power electronics (pp. 528–530). IEEE.

Yadav, S. K., & Bajpai, U. (2018). Performance evaluation of a rooftop solar photovoltaic power plant in Northern India. Energy for Sustainable Development, 43, 130–138.

Falih, H., Hamed, A. J., & Khalifa, A. H. N. (2022). Techno-economic assessment of a hybrid connected PV solar system. International Journal of Air-Conditioning and Refrigeration, 30(1), 1–15.

Vasisht, M. S., Srinivasan, J., & Ramasesha, S. K. (2016). Performance of solar photovoltaic installations: Effect of seasonal variations. Solar Energy, 131, 39–46.

Ibrahim, A. (2011). Analysis of electrical characteristics of photovoltaic single crystal silicon solar cells at outdoor measurements. Smart Grid and Renewable Energy, 2(2), 169.

Ma, T., Yang, H., Zhang, Y., Lu, L., & Wang, X. (2015). Using phase change materials in photovoltaic systems for thermal regulation and electrical efficiency improvement: A review and outlook. Renewable and Sustainable Energy Reviews, 43, 1273–1284.

Seme, S., Požun, J., Štumberger, B., & Hadžiselimović, M. (2015). Energy production of different types and orientations of photovoltaic systems under outdoor conditions. Journal of Solar Energy Engineering, 137(2), 021021.

Nishioka, K., Hatayama, T., Uraoka, Y., Fuyuki, T., Hagihara, R., & Watanabe, M. (2003). Field-test analysis of PV system output characteristics focusing on module temperature. Solar Energy Materials and Solar Cells, 75(3–4), 665–671.

Bhattacharya, T., Chakraborty, A. K., Pal, K. (2014). Effects of ambient temperature and wind speed on performance of monocrystalline solar photovoltaic module in Tripura, India. Journal of Solar Energy, Vol. 2014, Article 817078, 5 pages.

Korea Meteorological Administration. http://web.kma.go.kr/eng/biz/climate_01.jsp. Accessed 5 Feb 2018.

Sharma, V., & Chandel, S. S. (2013). Performance analysis of a 190 kWp grid interactive solar photovoltaic power plant in India. Energy, 55, 476–485.

Dierauf, T., Growitz, A., Kurtz, S., Cruz, J. L. B., Riley, E., & Hansen, C. (2013). Weather-corrected performance ratio (no. NREL/TP-5200-57991). National Renewable Energy Lab. (NREL).

Kumar, S. S. (2016). Performance-economic and energy loss analysis of 80 KWp grid connected roof top transformer less photovoltaic power plant. Circuits and Systems, 7(06), 662.

Timeanddate.com. https://www.timeanddate.com/wea-ther/south-korea/historic. Accessed 15 Oct 2017.

Muzathik, A. M. (2014). Photovoltaic modules operating temperature estimation using a simple correlation. International Journal of Energy Engineering, 4(4), 151.

Chapter 5 Cells, modules and arrays (pp. 5–48). https://docplayer.net/22978212-Cells-modules-and-arrays.html. Accessed 6 Feb 2023.

Author information

Authors and Affiliations

Contributions

The authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Singh, R., Nam, A.Y., Park, J.J. et al. Analysis of in situ performance of rooftop PV system in Seoul, South Korea. Int. J. Air-Cond. Ref. 31, 10 (2023). https://doi.org/10.1007/s44189-023-00026-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44189-023-00026-8