Abstract

Phosphorus (P) recovery from sewage sludge (SS) have been regarded as an effective method of P recycling. The effects of incineration temperature, incineration time, and chlorine additives on the distribution of P speciation during sludge incineration were studied. Moreover, the reactions between model compounds AlPO4 and additives (MgCl2 and CaCl2) were investigated by thermogravimetric differential thermal analysis and X-ray diffraction measurements. The results demonstrated that the increase in temperature and time stimulated the volatilization of non-apatite inorganic phosphorus (NAIP) instead of apatite phosphorus (AP). MgCl2 and CaCl2 can greatly promote the conversion of NAIP to AP. Additionally, AlPO4 reacted with MgCl2 are incinerated at 500–600 °C to form Mg3(PO4)2, which is mainly due to the reaction of the intermediate product MgO and AlPO4. Reactions between AlPO4 and CaCl2 occurred at 700–750 °C and produced Ca2PO4Cl, which can be directly used with high bioavailability. These findings suggested that chlorine additives in the SS incineration process can obtain phosphorus-containing minerals with higher bioavailability to realize the resource utilization of P in sludge.

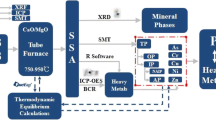

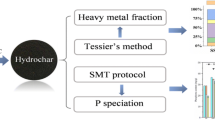

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phosphorus (P) is a kind of non-renewable and irreplaceable natural resource, which is widely used in chemical industry and agricultural production and plays a vital role in modern society (Cieślik and Konieczka 2016). In order to feed the growing population, the demand for phosphate rock will continue to increase. It is predicted that global production of economically exploitable phosphate rock will peak in 2033 or earlier (Cordell et al. 2009; Sorensen et al. 2015), and then global P demand will exceed P supply. At present, the most promising way of sustainable utilization of P resources is to replace phosphate ore with phosphorus-rich materials. Sewage sludge (SS) is a by-product produced in the wastewater treatment process rich in P, and nearly 98% of P is discharged into wastewater and eventually enriched in SS, indicating that the sludge is an important source for P recycling (Franz 2007; Liang et al. 2019). However, the presence of contaminants prevents the SS from being directly used in agriculture (Chen and Yan 2012; Nowak et al. 2012b). Sewage sludge ash (SSA) is the product of SS incineration which is rich in high concentration of P; the P2O5-content of SSA typically ranges from 10 to 25.7% (Adam et al. 2009, Fang et al. 2018, Lee and Kim 2017). Therefore, SSA has significant potential as a source of P fertilizer production.

SS contains various forms of P due to the different P removal processes in the wastewater treatment plant (Donatello and Cheeseman 2013). P in SS can usually be divided into organic P (OP) and inorganic P (IP). Most of the P in the sewage is finally present in the sludge in the form of IP after chemical treatment. Studies have shown that it accounts for 70–90% of total phosphorus (TP) (Desmidt et al. 2014; Zhang et al. 2016). In addition, some P exists in the form of OP after biological action (Huang and Yuan 2015, Zhang et al. 2017). However, the above P forms are not ideal in terms of bioavailability, and in order to realize the resource utilization of phosphorus in the sludge, it is necessary to convert its morphology to achieve better bioavailability. There are several different additives that can be used in the thermochemical treatment method, including chloride additives (MgCl2, CaCl2, Fe Cl2, KCl, HCl), sodium-based additives (Na2CO3, Na2SO4), Mg-based additives (MgCO3, MgO), and Ca-based additives (CaO) to react with sludge (Cai et al. 2012, Havukainen et al. 2016, Nowak et al. 2012a, Steckenmesser et al. 2017, Vogel and Adam 2011, Vogel et al. 2014). It mainly reacts with heavy metals (HMs) and then removes them at a temperature of about 1000 °C (Gorazda et al. 2017). At the same time, it can change the forms of P in ash and generally can improve its bioavailability. The temperature during the incineration of sludge will significantly affect the species of P and the removal of HMs (Qian and Jiang 2014). High temperature promoted the formation of IP, and the P forms will be converted from non-apatite inorganic phosphorus (NAIP) to apatite phosphorus (AP) (Wang et al. 2013). Additionally, the addition of chlorinating agents (PVC, NaCl, MgCl2, CaCl2) during the heat treatment of sludge can largely remove HMs to a large extent, and the formation of Mg3(PO4)2 leads to a significant increase in the bioavailability of P (Xia et al. 2020). The additives of MgO and CaO in the process of sludge incineration also had a positive effect on the conversion of NAIP to AP, and the main phosphorus minerals in the SSA were Ca5(PO4)3OH, Ca4P2O5, Mg3(PO4)2, Mg3Ca3(PO4)4, and CaHPO4 (Li et al. 2017; Li et al. 2019).

The mechanism of different P species chemical conversion by adding chlorinating agents during the sludge incineration is still unclear. Therefore, this study focused on the regulation of the P content and morphology of sludge in the process of incineration and the related mechanism. The chlorinating agents MgCl2 and CaCl2 were used to enhance the formation of Mg-P and Ca-P, which has higher bioavailability than Fe/Al-P. The simulation experiment was used to qualitatively analyze the transformation process of P forms during incineration.

Materials and methods

Materials

The SS used in the experiments was dewatered waste activated sludge obtained from a municipal wastewater treatment plant located in Shanghai, China. After 3 days of outdoor ventilation, the SS was dried in an oven at 105 °C. Then the dried SS was ground with a grinder and passed through a 100 mesh sieve to obtain a fine particle sludge powder sample with a particle size of less than 150 μm. The samples were stored in closed plastic containers in a freezer at 4 °C until the experiments were carried out. The characteristics of raw sewage sludge have been described in previous studies (Yang et al. 2019).

Incineration experiments

In the incineration experiments, 10 g of pretreated sludge was incinerated in a muffle furnace, and the SSA samples were prepared by setting the parameters of the muffle furnace to control the sludge incineration conditions. The dried raw SS was incinerated at different incineration temperatures (800, 850, 900, 950, and 1000 °C) for 2 h or at 800 °C for different incineration time (0.5, 1, 2, 3, and 4 h). After being naturally cooled to room temperature in the furnace, the incineration products were ground and passed through a 100 mesh sieve and then placed in a vacuum dryer for storage. The P speciation and content in incineration products were explored.

The dried 10 g SS sample was mixed uniformly with the required amounts of chlorinating agents MgCl2 (1, 1.6, 2.5, and 3.0 wt% Mg) and CaCl2 (1, 3, 5, and 10 wt% Ca) and then burned in a muffle furnace at 800 °C for 2 h. In order to further explore the mechanism of adding MgCl2 and CaCl2 to the transformation of P species in sludge, model compound incineration experiments were carried out. AlPO4 was selected as model material of sludge and then mixed with MgCl2 or CaCl2 for incineration experiments. The molar ratio of Al to Mg (n(Al):n(Mg)) in the mixed sample was set to 1:1, and the molar ratio of Al to Ca (n(Al):n(Ca)) was set to 1:3. Then the homogenized sample was incinerated at 800 °C for 2 h. The P speciation and content in the pure substance incineration products were analyzed.

Analysis methods

X-ray diffraction

The crystalline compounds in the samples obtained from the incineration of AlPO4 and chlorine additives at different temperatures were identified by an X-ray diffractometer (XRD) (DX2700, Haoyuan, China). The XRD test was performed by using Cu Kα radiation at 40 kV and 40 mA, scanning in the range of 15° to 75° with a scan rate of 4°/min. In addition, the samples obtained after incineration were milled and sieved before XRD analysis.

Phosphorus speciation analysis

The determination of the P speciation in the samples before and after the sludge incineration was analyzed using the standards, measurements, and testing (SMT) program extraction protocol (Medeiros and Cid 2005; Xu et al. 2015). According to the SMT protocol, the TP was defined as the sum of OP and IP content, and the IP was divided into AP (calcium-bound P) and NAIP (P bound to aluminum, iron, and manganese oxides and hydroxides). Since OP was almost converted to IP during high-temperature incineration, its content can be ignored. The molybdenum blue method was used to determine the various P speciations by spectrophotometer at the wavelength of 700 nm.

Thermal characteristics

To determine the temperature range of transformation from NAIP to AP, a simultaneous thermal analyzer (STA-449F5, Germany) equipped with thermogravimetry (TG) and differential thermal analysis (DTA) was used to analyze the weight changes and physical and chemical processes of pure chemical substances and model compounds. The sample was dried and mixed thoroughly before testing, and approximately 10 mg of sample was used for each test. The test was carried out in an atmosphere where the gas environment was air, the test temperature range was 30–800 °C, and the ramping rate was 10 °C/min.

Results and discussion

Effect of incineration time on the distribution of phosphorus speciation

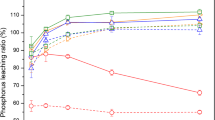

The changes in the content of various P forms, NAIP/IP and AP/IP, in the products obtained by sludge at 800 °C for different incineration time are shown in Fig. 1.

As can be seen from Fig. 1, the IP content in the SSA after incineration at 800 °C was significantly increased compared with the untreated raw sludge, which was 1.7–2.1 times than that of the raw sludge. As the incineration time increases, the IP content increased slowly, but the whole trend was not obvious, which indicated that the time had little effect on the IP content. In order to ensure that most of the organic matter in the sludge is destroyed (Chen and Yan 2012), the incineration time of 2 h is more suitable.

In addition, with the increase of incineration time, the NAIP content in sludge incineration ash decreased first and then stabilized. When the time was 0.5–3 h, the NAIP content decreased from 23.41 to 7.78 mg/g. The AP content increased at first and then remained stable, increasing from 17.02 to 44.93 mg/g. Meanwhile, with the increase of time, NAIP/IP decreased continuously, from 51.4 to 14.6%, while AP/IP gradually increased from 37.4 to 84.5%. The above phenomenon indicated that the increase of incineration time promoted the morphological transformation of NAIP into AP in the SS.

Effect of incineration temperature on the distribution of phosphorus speciation

Figure 2 shows the changes in phosphorus content, NAIP/IP and AP/IP, in the product obtained by incineration of sludge at different temperatures for 2 h.

According to Fig. 2, the IP content of the sludge product after incineration is significantly increased compared with the untreated raw sludge, which was 2.1–2.9 times than that of the raw sludge. As the incineration temperature increases, the IP content increased first and then decreased.

When the temperature was 800–950 °C, the IP content increased from 57.27 to 77.73 mg/g, which is mainly due to the decomposition of organic matter at 800–950 °C. The degree gradually increased with increasing temperature. Most of the P remains in the solid phase due to its low volatility, which increased the relative content of IP in the sludge. However, at a temperature of 1000 °C, the IP content begins to decrease, possibly because some of the P begins to volatilize at temperatures above 950 °C (Li et al. 2015), causing a drop in IP content in the SSA.

Additionally, compared with the original sludge, the P in the sludge product after incineration mainly exists in the form of AP, and NAIP accounts for a small amount. As the temperature increases, both IP and NAIP content increased at first and then decreased, while AP content increased slowly. At the same time, NAIP/IP increased slightly and then decreased, while AP/IP is exactly the opposite. Combined with the study by Li et al. (Li et al. 2015), it is speculated that during the incineration process, due to the gradual conversion of NAIP to AP, partially unstable NAIP began to volatilize at temperatures above 950 °C, resulting in a decrease in IP and NAIP content and an increase in AP.

Effect of MgCl2 on the distribution of phosphorus speciation

The content of various P forms, NAIP/IP and AP/IP, in the product obtained by incineration of sludge with different proportions of MgCl2 at 800 °C for 2 h are displayed in Fig. 3.

From Fig. 3, with the amount of MgCl2 increased, the content of IP first increased and then decreased slightly in the sludge. A 3% addition of MgCl2 resulted in a slight decrease in IP, which is related to the increase of product quantity after MgCl2 addition. With the increase of MgCl2, the NAIP content decreased at first and then increased. The NAIP decreased from 11.75 mg/g without addition of MgCl2 to 9.06 mg/g when the Mg added was 1.6%. When the MgCl2 added was continuously increased, the NAIP content began to increase and reached the maximum of 19.17 mg/g when the addition of Mg in the mixture was 3.0%. However, the AP content increased first and then decreased. Meanwhile, the trend of NAIP/IP and AP/IP is consistent with NAIP and AP, respectively. This result indicated that the addition of MgCl2 could change the distribution of P speciation during sludge incineration. Studies has pointed out that Mg-P belongs to the NAIP (He et al. 2016). In addition, the bioavailability of Mg-P is slightly higher than that of Ca-P and significantly higher than that of Fe-P and Al-P (Vogel and Adam 2011). Based on the SMT protocol, it is speculated that the following P transformation process may occur: When a small amount of MgCl2 is present, some Fe/Al-P (NAIP) in the sludge is converted into Ca-Mg-P, which leads to a decrease in NAIP/IP and an increase in AP/IP. When the content of MgCl2 is high, AP may react with MgCl2 to form Mg-P (NAIP), which causes an increase in NAIP/IP and a decrease in AP/IP.

Since the sludge product without any additives contains more AlPO4, the pure material MgCl2·6H2O and the mixture of AlPO4 and MgCl2·6H2O are subjected to TG analysis to further analyze the reaction process of MgCl2 with phosphorus-containing substances in the sludge and determine the temperature range in which MgCl2 and AlPO4 react.

Figure 4 shows the TG analysis results of pure MgCl2·6H2O (a) and the mixture of AlPO4 and MgCl2·6H2O (n(Al):n(Mg) = 1:1) (b).

According to Fig. 4, the trends of the TG and DTA curves of the pure MgCl2·6H2O and AlPO4+ MgCl2·6H2O mixtures are almost identical at temperatures between 29 and 600 °C, and there is a significant quality degradation. Similar peaks were observed on the DTA curve at 150–350 and 500 °C. It can be inferred that AlPO4 will not react with MgCl2 in this temperature range. According to previous studies, the pure material MgCl2·6H2O undergoes dehydration and hydrolysis reactions between 29 and 500 °C, wherein the hydrolysis reaction produces intermediates products Mg(OH)Cl and HCl, which coincide with the trend of the TG and DTA curves in Fig. 4. When the temperature was 500 °C, Fig. 4a, b both show mass reduction, and there is an obvious endothermic peak on the DTA curve. According to the relevant literatures, this is mainly caused by the decomposition of Mg(OH)Cl to produce MgO and HCl (Xiang et al. 2016).

When the temperature was between 600 and 650 °C, there is no significant change in the TG and DTA curves of MgCl2·6H2O, while the TG curve of MgCl2·6H2O +AlPO4 shows almost no mass loss, and a small endothermic peak appears on the DTA curve. It can be inferred that MgO and AlPO4 have undergone a solid-phase endothermic reaction within this temperature range. Studies have also shown that the addition of MgO was beneficial for the transformation of NAIP to AP (Li et al. 2019).

In order to further verify the above speculation, the pure MgCl2·6H2O and AlPO4 were incinerated at 500, 600, and 700 °C, respectively. The XRD detection results are shown in Fig. 5. By comparing the P forms in the incineration products at different temperatures, the exact temperature at which MgCl2·6H2O reacts with AlPO4, and the P form before and after the reaction can be determined.

As shown in Fig. 5a, no peak of MgCl2 was detected in the incineration products of pure MgCl2 and AlPO4 at 500 °C, and signals of MgO and Al(PO3)3 appeared. This indicated that when MgCl2 is added, it will react with AlPO4 to generate some intermediate products and eventually lead to the formation of Mg-P, resulting in the formation of Mg-P, thus improving the bioavailability of P. When the temperature was raised to 600 °C, the new phosphate mineral phases of Mg3(PO4)2 were observed; this implied that AlPO4 reacted with MgCl2 to produced Mg-P at 500–600 °C. At 700 °C, no new phosphate mineral phase were formed, and Mg3(PO4)2 was still the main phosphate mineral produced by the reaction of AlPO4 and MgCl2. The XRD analysis of the reaction between AlPO4 and MgCl2·6H2O in the temperature range of 500–700 °C indicated that MgCl2 could effectively promote AlPO4 transformation to Mg-P, which can be considered as the conversion of NAIP to AP, and the AP can be produced in the range of 500–600 °C with higher bioavailability.

To further examine the mechanism of the reaction between MgCl2 and AlPO4, MgO and AlPO4 were incinerated at 500, 600, and 700 °C, respectively. XRD analysis was performed to explore the changes in the form of P before and after the reaction at different incineration temperatures, and the results are shown in Fig. 5b.

Figure 5b shows that there were no new peaks in the incineration of MgO and AlPO4 at 500 °C, indicating that the two substances have not react. When incinerated at 600 °C, a new peak of phosphorus-containing mineral phase Mg3(PO4)2 appeared, and the main mineral phase was also Mg3(PO4)2 at 700 °C. This result proves that the reaction between MgCl2 and AlPO4 was mainly through the formation of the intermediate product MgO, which reacts with AlPO4 to form Mg-P.

Effect of CaCl2 on the distribution of phosphorus speciation

Figure 6 shows the changes of the content of various P, NAIP/IP and AP/IP, in the product obtained by adding different CaCl2 incineration for 2 h at 800 °C.

It can be seen from Fig. 6 that with the increase of CaCl2, the IP content increased and then decreased slightly in the sludge. The dilution effect of excessive CaCl2 addition leads to a decrease in IP content when the CaCl2 was 10%. When the addition of CaCl2 increased from 0% Ca to 10.0% Ca, the NAIP content decreased from 11.75 to 0.09 mg/g, and the AP content increased first and then decreased. However, AP/IP continues to increase with the addition of CaCl2, while NAIP/IP was the opposite. When the Ca content reaches 5%, the IP is almost entire in the form of AP. The results showed that the addition of CaCl2 changed the distribution of P forms during sludge incineration. The possible reason was that CaCl2 reacted with Fe/Al-P in the sludge to form Ca-P during sludge incineration, which resulted in the continuous decrease of NAIP and the increase of AP.

In order to further analyze and determine the reaction process of CaCl2 and AlPO4, thermal analysis of the mixture of AlPO4 and CaCl2 was carried out.

Figure 7 shows the TG analysis results of pure CaCl2 (a) and the mixture of AlPO4 and CaCl2 (n(Al):n(Ca) = 1:3) (b).

According to Fig. 7 and the previous researches, when the temperature was between 29 and 300 °C, the TG curves of pure CaCl2 and the mixture of CaCl2 and AlPO4 showed significant mass loss, and two endothermic peaks appeared in the DTA curve, which was speculated to be caused by the removal of crystal water.

When the temperature was between 740 and 750 °C, there is no mass loss in the TG analysis of the pure CaCl2 and no endothermic or exothermic peak appears in the DTA curve, which indicated that no reaction occurred within this temperature range. However, the thermogravimetric analysis of CaCl2+AlPO4 showed that the mass began to decrease between 740 and 750 °C, and a small endothermic peak appeared in the DTA curve. This may be due to the endothermic reaction of CaCl2 and AlPO4 that occurs within this temperature range, which produces gas and leads to mass loss (Fraissler et al. 2009).

The TG analysis of pure CaCl2 showed no mass loss, and a strong endothermic peak appeared in the DTA curve between the temperatures of 770 and 800 °C. Since the melting point of CaCl2 is about 782 °C, it is presumed that this phenomenon is caused by the melting of CaCl2. However, the TG analysis of CaCl2+AlPO4 showed that the quality still showed a downward trend, and a strong endothermic peak also appeared in the DTA curve. It is speculated that this is mainly caused by the melting of CaCl2, and the loss of mass may be caused by an endothermic reaction at 740–750 °C.

In order to further verify the above speculation, the pure CaCl2 and AlPO4 were incinerated at 700, 750, and 800 °C, respectively, and subjected to XRD test. By comparing the P forms in the incineration product at different temperatures, the temperature range of the reaction between CaCl2 and AlPO4 and the form of P before and after the reaction can be determined.

Figure 8 shows the results of XRD detection of CaCl2 and AlPO4 compounds incinerated at 700, 750, and 800 °C.

As shown in Fig. 8, peaks of AlPO4, Al2O3, and Al(PO3)3 appeared at 700 °C, but no peaks of CaCl2 appeared. It is speculated that CaCl2 may react with AlPO4 to form phosphorus-containing minerals. As the temperature increased to 750 °C, the peak of AlPO4 and Al2O3 disappeared, and the new mineral phases of Ca2PO4Cl were observed, indicating that the reaction between AlPO4 and CaCl2 produced Ca-P in the temperature range of 700–750 °C. The peak of Al(PO3)3 disappeared, and only the peak of Ca2PO4Cl exists at 800 °C, indicating that no new phosphorus-containing mineral phase were formed as the temperature rises. The main phosphorus-containing mineral formed by the reaction of AlPO4 and CaCl2 was Ca2PO4Cl, which has higher bioavailability and can be directly used as fertilizer.

Conclusions

This study focused on the conversion mechanism between various P speciations when chlorine additives were added during SS incineration. The SS was incinerated at various temperatures and time, and the results showed that as the incineration temperature and time increased, the content of IP in the SSA increased, and the conversion of NAIP to AP in SS was promoted. Additionally, SS was incinerated at 800 °C with the addition of MgCl2 and CaCl2, and the reaction between AlPO4 and MgCl2 or CaCl2 promoted the formation of AP with higher P bioavailability. The temperature and the minerals produced of the reaction between the model compound of NAIP in the sludge and the chloride additives were analyzed by TG-DTA and XRD detection. AlPO4 reacted with MgCl2 at 500–600 °C to produced Mg3(PO4)2 were determined. And the reaction between AlPO4 and MgCl2 is mainly due to the reaction of the intermediate product MgO and AlPO4 to produce phosphorus-containing minerals. When AlPO4 and CaCl2 compounds were incinerated, Ca2PO4Cl was formed at 700–750 °C, which has higher P bioavailability and can be used in agriculture to alleviate the shortage of phosphorus resources. As proposed by this paper, it was expected to provide a basis for obtaining products with more agricultural use value in the process of sludge incineration.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Adam C, Peplinski B, Michaelis M, Kley G, Simon FG (2009) Thermochemical treatment of sewage sludge ashes for phosphorus recovery. Waste Manag 29:1122–1128

Cai QY, Mo CH, Lü H, Zeng QY, Wu QT, Li YW (2012) Effect of composting on the removal of semivolatile organic chemicals (SVOCs) from sewage sludge. Bioresour Technol 126:453–457

Chen T, Yan B (2012) Fixation and partitioning of heavy metals in slag after incineration of sewage sludge. Waste Manag 32:957–964

Cieślik B, Konieczka P (2016) A review of phosphorus recovery methods at various steps of wastewater treatment and sewage sludge management. The concept of “no solid waste generation” and analytical methods. J Clean Prod 142:1728–1740

Cordell D, Drangert J-O, White S (2009) The story of phosphorus: global food security and food for thought. Glob Environ Chang 19:292–305

Desmidt E, Ghyselbrecht K, Zhang Y, Pinoy L, Van der Bruggen B, Verstraete W, Rabaey K, Meesschaert B (2014) Global phosphorus scarcity and full-scale p-recovery techniques: a review. Crit Rev Environ Sci Technol 45:336–384

Donatello S, Cheeseman CR (2013) Recycling and recovery routes for incinerated sewage sludge ash (ISSA): a review. Waste Manage 33:2328–2340

Fang L, Jiang-shan G, Zhi M, Cheeseman CR, Tsang DCW, Donatello (2018) Phosphorus recovery and leaching of trace elements from incinerated sewage sludge ash (ISSA). Environmental toxicology and risk assessment, Chemosphere

Fraissler G, Jöller M, Brunner T, Obernberger I (2009) Influence of dry and humid gaseous atmosphere on the thermal decomposition of calcium chloride and its impact on the remove of heavy metals by chlorination. Chem Eng Process Process Intensif 48:380–388

Franz M (2007) Phosphate fertilizer from sewage sludge ash (SSA). Waste Manag 28:1809–1818

Gorazda K, Tarko B, Werle S, Wzorek Z (2017) Sewage sludge as a fuel and raw material for phosphorus recovery: combined process of gasification and P extraction. Waste Manag 73:404

Havukainen J, Nguyen MT, Hermann L, Horttanainen M, Mikkilae M, Deviatkin I, Linnanen L (2016) Potential of phosphorus recovery from sewage sludge and manure ash by thermochemical treatment. Waste Manag 49:221–229

He ZW, Liu WZ, Wang L, Tang CC, Guo ZC, Yang CX, Wang AJ (2016) Clarification of phosphorus fractions and phosphorus release enhancement mechanism related to pH during waste activated sludge treatment. Bioresour Technol 222:217–225

Huang HJ, Yuan XZ (2015) The migration and transformation behaviors of heavy metals during the hydrothermal treatment of sewage sludge. Bioresour Technol 200:991–998

Lee M, Kim DJ (2017) Identification of phosphorus forms in sewage sludge ash during acid pre-treatment for phosphorus recovery by chemical fractionation and spectroscopy. J Ind Eng Chem 51:64–70

Li R, Zhang Z, Li Y, Teng W, Wang W, Yang T (2015) Transformation of apatite phosphorus and non-apatite inorganic phosphorus during incineration of sewage sludge. Chemosphere 141:57–61

Li R, Teng W, Li Y, Wang W, Cui R, Yang T (2017) Potential recovery of phosphorus during the fluidized bed incineration of sewage sludge. J Clean Prod 140:964–970

Li R, Teng W, Li Y, Yin J, Zhang Z (2019) Transformation of phosphorus and stabilization of heavy metals during sewage sludge incineration: the effect of suitable additives and temperatures. Environ Sci Pollut Res 26:29917–29929

Liang S, Chen H, Zeng X, Li Z, Yu W, Xiao K, Hu J, Hou H, Liu B, Tao S (2019) A comparison between sulfuric acid and oxalic acid leaching with subsequent purification and precipitation for phosphorus recovery from sewage sludge incineration ash. Water Res 159:242–251

Medeiros JJG, Cid BP, Gómez EF (2005) Analytical phosphorus fractionation in sewage sludge and sediment samples. Anal Bioanal Chem 381:873–878

Nowak B, Rocha SF, Aschenbrenner P, Rechberger H, Winter F (2012) Heavy metal removal from MSW fly ash by means of chlorination and thermal treatment: influence of the chloride type. Chem Eng J 179:178–185

Nowak B, Wegerer H, Aschenbrenner P, Rechberger H, Winter F (2012b) Sewage sludge ash to phosphate fertilizer by chlorination and thermal treatment: residence time requirements for heavy metal removal. Environ Technol 33:2375–2381

Qian TT, Jiang H (2014) Migration of phosphorus in sewage sludge during different thermal treatment processes. ACS Sustain Chem Eng 2:1411–1419

Sorensen BL, Dall OL, Habib K (2015) Environmental and resource implications of phosphorus recovery from waste activated sludge. Waste Manag 45:391–399

Steckenmesser D, Vogel C, Adam C, Steffens D (2017) Effect of various types of thermochemical processing of sewage sludges on phosphorus speciation, solubility, and fertilization performance. Waste Manag 62:194–203

Vogel C, Adam C (2011) Heavy metal removal from sewage sludge ash by thermochemical treatment with gaseous hydrochloric acid. Environ Sci Technol 45:7445–7450

Vogel C, Adam C, Kappen P, Schiller T, Lipiec E, McNaughton D (2014) Chemical state of chromium in sewage sludge ash based phosphorus-fertilisers. Chemosphere 103:250–255

Wang L, Wang Z, Ning P, Jiang M, Qin Y (2013) Phosphorus-fixation by hydrated lime in fluidized bed combustion of yellow phosphorus tail gas. Journal of Central South University of Science and Technology 44:835–842

Xia Y, Tang Y, Shih K, Li B (2020) Enhanced phosphorus availability and heavy metal removal by chlorination during sewage sludge pyrolysis. J Hazard Mater 382:121110.1–121110.8

Xiang Jun Yu, Qiao Jie, Hong Yao, Chuan Ma, Sun, (2016) Mechanism on heavy metals vaporization from municipal solid waste fly ash by MgCl2 center dot 6H(2)O. Waste Manage 49:124–130

Xu Y, Hu H, Liu J, Luo J, Qian G, Wang A (2015) pH dependent phosphorus release from waste activated sludge: contributions of phosphorus speciation. Chem Eng J 267:260–265

Yang F, Chen J, Yang M, Wang X, Sun Y, Xu Y, Qian G (2019) Phosphorus recovery from sewage sludge via incineration with chlorine-based additives. Waste Manag 95:644–651

Zhang MY, Hao AM, Kuba T (2016) The crystallization of struvite by recycling poly-phosphate released from sewage sludge after thermal treatment. Adv Mater Res 781-784:1963–1967

Zhang J, Tian Y, Zhang J (2017) Release of phosphorus from sewage sludge during ozonation and removal by magnesium ammonium phosphate. Environ Sci Pollut Res 24:1–9

Funding

This work was supported by the Program for Science and Technology Innovative Research (CTKY-ZDXM-2019-018), National Natural Science Foundation of China (No. 41472312), and Program for Innovative Research Team in University (No. IRT13078).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Jingyan Chen, Fei Yang, and Yangfan Fang. The first draft of the manuscript was written by Yunfeng Xu, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Kitae Baek

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Y., Chen, J., Yang, F. et al. Transformation of phosphorus by MgCl2 and CaCl2 during sewage sludge incineration. Environ Sci Pollut Res 28, 60268–60275 (2021). https://doi.org/10.1007/s11356-021-13859-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13859-w