Abstract

Azo dyes are extensively used in different industries areas, such as Allura Red (R-40). Previous studies have proven its carcinogenic and mutagenic properties. For the removal of this type of emerging pollutant from effluents, tertiary treatment techniques such as activated charcoal are used. Alternatively, the use of bacteria is preferred because of its quick discoloration processes. The aim of the present investigation is to compare the efficiency removal of R-40 from aqueous media by a physicochemical process and a biological one. The sorption kinetics of 10 ppm of R-40 was carried out with the use of activated charcoal based on walnut shells in water. Moreover, Pseudomonas aeruginosa and Bacillus subtilis stains were used separately to decolorize nutrient broth media supplemented with 50 ppm of R-40. The activated carbon was capable to remove 99.87% of R-40 at 264 h, while the bacterial strains decolorized 92.13% (P. aeruginosa) and 88.21% (B. subtilis), respectively, under microaerophilic conditions after 168 h. Therefore, both process strategies, physicochemical and biological rapprochements, were able to remove the dye from aqueous media. R-40 was not cytotoxic to used strains, besides gram-positive either negative bacteria could be applied to turn over this azo dye in short term. Combination of both approaches may be implemented in tandem architecture.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Azo dyes are the main industrially synthesized organic colored compounds and they have the particularity to contain one or more azo groups (N=N). These dyes are used as coloring agents in the cosmetic, textile, plastic, paint, paper, food, and pharmaceutical areas (Hsueh and Chen 2007; Khalid et al. 2008; Saratale et al. 2011; Meng et al. 2014; Kelm et al. 2019). Also, the disposal of azo dyes in aquatic bodies causes a diminution of water transparency and oxygen content, causing a negative impact on the different species that inhabit the aquatic environment, which impairs the balance of the ecological function, being emerging pollutants; therefore, the elimination of azo dyes from polluted effluents is of great importance (Govindwar et al. 2014; Khattab et al. 2020). One of the dyes mostly used in the industries is Allura Red, which is an azoic type colorant, and has been proven in previous studies that it is carcinogenic and mutagenic (Honma 2015).

Tertiary treatment techniques are used for the removal of this type of contaminant, but they have the drawback of being expensive; therefore, the application of adsorbent materials such as activated carbon for the removal of dyes in aqueous media is an alternative, and although its commercial production is highly expensive, a special emphasis has been placed on its preparation using lignocellulosic agricultural by-products through application of physical activation with water vapor, which makes the material low cost for use in the treatment of contaminated water (Hameed et al. 2007). Activated carbon is a carbonaceous, microcrystalline, and non-graphite material; it is prepared by means of the carbonization of organic materials, especially of vegetal origin. The activation process increases its porosity and develops its internal surface, conferring a high adsorbent and versatile capacity because the size and distribution of the pores can be controlled by the choice of the precursor, the method of activation, and the control of the preparation conditions (Martínez de Yuso 2012). Activated carbon has the ability to retain organic and inorganic chemical compounds through Van der Waals forces, and the presence of surface polar groups that contain oxygen causes an increase in the hydrophilicity of the carbon, since water molecules can form bridges of hydrogen with the oxygen atoms of the carbon surface. Some compounds generally retained by active carbons are as follows: dyes and colored compounds, aromatic compounds (benzene derivatives, phenols, nitrated aromatic compounds, among others) (Maeda et al. 2019), pesticides, various organic macromolecules, hypochlorous acid and chlorine, ammonia, mercury chloride (II), cyanides, dichromate, iodine, molybdate, and permanganates (Torres-Pérez et al. 2015; Mendonça et al. 2019).

Otherwise, compared with physicochemical methods, biodegradation has been considered as very efficient and environmentally sustainable method (Bent and Forney 2008; Chen et al. 2019). The use of bacteria is preferred for the decolorization activity due to its relatively short life cycle and the completion of the decolorization process more effectively (Mishra and Maiti 2018). Moreover, the isolation of bacterial with azoreductase genes can be performed from soils and the same effluents (Hussain et al. 2013). A large number genera including Pseudomonas, Shewanella, Rhodopseudomonas, Psychrobacter, Comamonas, Enterococcus, Staphylococcus, Providencia, and Bacillus have been reported in the degradation of azo dyes under aerobic and anaerobic environments, as well as in presence of different carbon and nitrogen sources, pH, temperature, salt concentration (Hussain et al. 2013), and dye chemical structure or concentration. It is proven that the efficiency of dye elimination is linked to the type of microorganism and the conditions that are applied in the decolorization process (Zabłocka-Godlewska et al. 2014).

The use of physicochemical and biological processes, for the removal of dyes in water systems, could contribute to the remediation of aquatic bodies contaminated with R-40 dye, in addition to generating economic well-being in the treatment plants by the use of low-cost methods, taking into account that they are advanced treatments. The aim of the present study was to compare between both methods to eliminate Allura Red azo dye (R-40) from aqueous media, using agricultural wastes such as precursors and bacteria strains with azo reductase activity.

Materials and methods

Preparation of alternative activated carbon

For the preparation of the raw material, 25 g of pecan nutshell dried were carbonized in the oven with a rotary reactor (Carbolite®, HTR 11/75), and with nitrogen (99.9%) for inert atmosphere. The program oven was 850 °C for 80 min, and 0.5 mL of distilled water was injected every minute in order to exert a physical activation to the carbon. Subsequently, nut activated carbon (NAC) was screened to obtain a particle size between 0.5 and 1.0 mm, and weighed before and after screening—until obtaining 25 g of NAC.

The activated carbon was washed with 100 mL of distilled water. The water volume was replaced every 24 h, until there were no changes in the pH measurement.

Adsorption and kinetic studies

Standard solution (10 mg/L) of the Allura Red azo dye (R-40) were prepared in deionized water, and 5.0 pH adjusted to ensure that the sorption process will be optimal since azoic dyes have been shown better removal rates when the aqueous media is acid (Torres-Pérez et al. 2015). A 0.25 g sample of activated carbon from pecan nutshell was added to 250 mL Allura Red standard solution. 2.0 mL aliquots were taken the first 8 h, then every 24 h. The concentration was measured by UV/Visible spectrophotometry (Jenway® Model 7315) at 502 nm (Torres-Pérez et al. 2015).

Batch adsorption kinetics models

To know the possible mechanism that governs the sorption process of R-40 onto the NAC and the potential rate controlling steps that includes the diffusion control, chemical reaction, and mass transport, three kinetic models were tested to describe the experimental data. The sorption kinetic models could be organized in two different models: pseudo-kinetic chemical reaction controlled and mass transfer controlled. In the present research, the selected kinetic models to describe the adsorption process were pseudo-first order and pseudo-second order (Eqs. 1 and 2).

Pseudo-first-order kinetic model (Lagergren 1898)

Pseudo-second-order kinetic model (Ho and Fellow 1998; Ho and Mckay 1999)

Integrating and rearranging (1) provides Eq. (2):

For the pseudo-second-order model, the plot of t/qt versus t Eq. (2) leads to a linear relationship when this model describes properly the experimental data. This Eq. (2) provides information about the sorption capacity (qe) and it can be obtained from the slope of the linear plot. This model has been widely used to describe the kinetic data for various systems where the solute passes from aqueous media to a solid phase (Ho and Mckay 1999; Ho and McKay 2000) (Table 1).

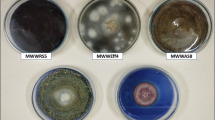

Screening of dye decolorizing microorganism

Strains of different clinical and environmental origins (Pseudomonas, Bacillus, and Escherichia genus) were tested for R-40 (50 ppm) removal on Nutrient Agar at 37 °C for 24 h.

Cells culture and decolorization conditions

Two strains were selected because of its ability to remove 50 ppm of R-40 in Nutrient Agar (NA) petri dishes, after 48 h of incubation at 37 °C. Pseudomonas aeruginosa strain C (Dinesh et al. 2003) and Bacillus subtilis 168 (ATCC®27370TM) were separately inoculated in a flask with 10 mL of Nutrient Broth (Bioxon®) at 200 rpm, 37 °C for 18–22 h (overnight culture, ON). For decolorization experiment, 10 mL of Nutrient Broth supplemented with R-40 50 ppm was adjusted, independently, at 0.1 OD600 (≈ 1 × 108 cell/mL) using ON of each strain. The flasks were incubated at 25° and 37 °C in static condition for 168 h. Rubber plugs were used to generate microaerophilic conditions.

One milliliter of each culture was centrifuged at 13,000 rpm for 5 min (Hettich, MIKRO 185). The supernatant absorbance was read at OD505, and the values were interpolated in R-40 calibration curve to calculate the residual concentration. Separately, the cell growth (1 mL directly form cultures) was measured at OD600.

Results and discussion

Preparation of alternative activated carbon

The pecan nut shells used as precursor material showed good properties for alternative activated carbon preparation. The properties of the agricultural waste lead to obtain an important average yield (25.79%) of activated carbon from pecan nut shells (nut activated carbon, NAC) by means of dehydrated pecan nutshell. The yield value obtained in this work was higher compared with other investigations, where the nut shell was also subjected to 850 °C and activated with water; in that case, the achieved yield was 22.10% (Soria-Serna et al. 2018). However, a chemical activation of another different precursor such as the pumpkin fruit peel by using 1% zinc chloride as an activating agent for 45 min obtained a yield of 25.50% (Reátegui 2017); this result is quite similar to the physical activation employed in this study but also is more sustainable and cheap because a non-toxic compound (steam water) was used as an activating agent for NAC preparation.

pH equilibria determination

The decay of the pH value of the NAC was observed across the time, where at 216 h a start of equilibrium of the granular carbon with a pH of 10.99 is observed (Fig. 1), which can be related to the functional groups present on the surface of the adsorbent; these groups could be formed by the reactions between the precursor (pecan nutshell) and the activating agent (steam water) (Moreno-Piraján et al. 2007). The pH of an activated carbon favors the adsorption of substances according to their polarity, where the acidic pH promotes the adsorption of heavy metals and, on the other hand, the basic pH favors the adsorption of anions and organic molecules such as azo dyes (Moreno-Piraján et al. 2007; Fernandez et al. 2014). So, it could be spectated that the NAC obtained by physical activation will be suitable for adsorption of the R-40 dye.

Adsorption and kinetic studies

After sorption experiments of R-40 onto NAC, the dye concentration was measured by UV/Visible spectrophotometry (Jenway® Model 7315) at 502 nm using a calibration curve (Fig. 2). The contact effect for dye removal showed rapid adsorption in the first 8 h (Fig. 3), from the first hour of interaction of NAC with the R-40 in the aqueous solution (10 ppm) showed a decrease in the concentration in the medium (9.64 ppm). After 24 h, a reduction in the initial concentration was observed up to 5.43 ppm; meanwhile at 72 h, the solution only presented 2.62 ppm of R-40. On the eighth day of contact, the aqueous solution did not show any coloration, and the final concentration of the R-40 dye in the medium was only 0.013 ppm, leading to a 99.87% removal of R-40 in the aqueous medium (Fig. 3). Other materials such as coconut shell and rice husk were used for the removal of R-40 at 10 ppm and 0.2 g of the carbonaceous material, where the removal percentage was 85 and 57%, respectively (Ensuncho et al. 2015); these values were even lower than that obtained in this investigation. It was observed that the use of NAC for the removal of R-40 from an aqueous medium is more efficient.

Figures 4 and 5 show the adjustments to kinetic models of the R-40 onto NAC. Retained dye milligrams per mass in grams of activated carbon (qe) and adsorption time in hours (t) were plotted, thus obtaining the correlation coefficient (R). The pseudo-first-order and pseudo-second-order model were used to describe the kinetics of the adsorption of R-40 on the NAC, where the first-order model best described the kinetic data with a value of R = 0.9949 (Fig. 4), compared with the pseudo-second-order model (R = 0.9443) (Fig. 5). This indicated that the carbon material used for R-40 removal corresponds to a diffusion-controlled process since Lagergren’s equation is applied for the explanation of intra-particle diffusion (Simonin 2016). Also, the pseudo-first-order kinetic model allowed to determine the maximum sorption capacity of the prepared material (NAC) at C0 = 10 mg/L, being 9.99 mg/g. The sorption rate constants and the correlation coefficients for NAC, indicating the level of adjustment of the experimental data to the theoretical model, are shown in Table 1. The pseudo-first-order kinetic model presented good R value (0.9948) for R-40 sorption onto NAC, which suggests that the sorption process occurs on a homogeneous surface in terms of the sorption sites (Vadivelan and Vasanth Kumar 2005).

In reactions involving chemical adsorption on a solid surface without desorption of the products, the sorption rate decreases over time due to an increase in the surface coverage of the carbonaceous material (Aharoni and Tompkins 1970). One of the most useful models to describe such activated chemical adsorption is the Elovich equation (Juang and Chen 1997), that adequately described the kinetics of a heterogeneous chemisorption of R-40 on the nut-based activated carbon. Elovich parameters were highly correlated with experimental data (R = 0.9977) (Fig. 6); the sorption constant (a = 0.9778) was higher than desorption constant (b = 0.1520), meaning that the sorption process was favorable (Table 1). The kinetic parameters obtained from the application of the models allowed to determine the maximum sorption capacity (9.9 mg/L), the sorption rate constants (0.0209 h−1 and 93.35 g/mgh for pseudo-first and pseudo-second order, respectively), and the correlation coefficients for each material, indicating the level of adjustment of the experimental data to the theoretical model (Table 1). The adjustment of the sorption process of the materials to the kinetic model of the pseudo-second order was lower, assuming that the speed limiting step is a chemical sorption or chemisorption, that involves valence forces when sharing or exchanging electrons between NAC material and R-40 dye (Ho and McKay 2000). Moreover, the best fitting to the Elovich kinetic model of the experimental data suggests that the adsorption process was given by chemisorption. Elovich model represents the chemical adsorption between the functional groups of the NAC material and R-40 azo dye (Qiu et al. 2009).

Bacteria discoloration potential

The bleaching ability of six different strains, C strain, SG17M, PAO1, PA14 (P. aeruginosa), 168 (B. subtilis), and TOP10 (E. coli) were observed on NA plates with 50 ppm of R-40. The strains C and 168 do not present any radical colony morphology changes at 48 h of incubation, indicating stress-free growth or cytotoxicity.

Bacteria bleaching optimal conditions

The bleaching efficiency results of both strains are shown in Table 2, in relation to temperature and oxygen availability. All the experiments were stopped at the same time, when one of the triplicates cultures media appeared colorless. There was any sign of cytotoxicity associated with the R-40 presence, because all the cultures were saturated at the end of experiments (data not shown).

After 168 h of incubation, B. subtilis 168 showed its highest efficiency; the bacteria could remove 88% of R-40 from culture media, at 25 °C under microaerophilic conditions. On the other hand, at 37 ºC and non-oxygen availability, the R-40 residual concentration was 15.65 ppm (74 % of discoloration). Being temperature an important parameter in discoloration, it has been shown that Bacillus sp. CH12 increases the decolorization (96%) of red 239 (50 ppm) at 96 h and 25 °C, but at 35 °C, the decolorization ability decreases in the middle (Guadie et al. 2017). Those could be due to the loss of viable cells or the deactivation of the bleaching enzymes. Regarding discoloration within Bacillus genus, B. stratosphericus SCA1007 can decolorate 100% of 50 ppm of methyl orange azo dye at 35 °C, 48 h of incubation. However, as the dye concentration increases, the decolorization percentage declines, which can be caused by the dye cytotoxicity (Akansha et al. 2019).

Similarly, P. aeruginosa strain C decolorized the aqueous medium in greater quantity under microaerophilic conditions at 37 °C, showing a residual concentration of 3.93 ppm, which corresponds to 92% discoloration of the medium (Table 1), comparing with studies where strains Sz6 and SDz3 of P. fluorescens, under static conditions at 26 °C, removed 95% and 87% of the Evans blue diazo dye, respectively (Zablocka-Godlewska et al. 2012). Likewise, P. aeruginosa has removed 52% of Reactive Red (50 ppm) in 120 h (Arshi and Pandey 2014), showing strain C even more efficient in bleaching of R-40 media.

P. aeruginosa strain C is a gram-negative bacterium and presented the highest bleaching capability of R-40, due to the fact this type of bacteria has a higher adsorption capacity than gram-positive bacteria, such as B. subtilis 168 (Zablocka-Godlewska et al. 2012). Both strains showed more efficient bleaching activity under microaerophilic condition, in accordance to strains of Bacillus, Pseudomonas, Proteus, and Aeromonas genera that are more effective in anaerobic degradation of a large number of azo dyes (Saratale et al. 2011) under static and semi-static cultures, because the stirring samples are promoting oxygenation of the medium, which reduces the activity of the azoreductases activity.

Conclusions

NAC preparation responds to green chemistry approaches.

The removal of Allura Red azo dye from an aqueous medium was equally efficient by a physical method of adsorption based on nut activated carbon and by a biological process with azoreductive characteristic, where the removal of the first process was 99.9% of the dye, while biological process presented 92% of dye removal.

The physical activation with water steam allowed the NAC to remove R-40 dye from the aqueous medium, and also it provided a homogeneous structure and a chemisorption mechanism between R-40 and the carbonaceous material.

Either gram-positive or gram-negative bacteria were not intoxicated by R-40; they were able to remove it in different conditions. B. subtilis 168 and P. aeruginosa strain C showed growth in liquid and solid media with the presence of R-40 dye, however, low oxygen availability at 37 °C in liquid medium proved the best condition for dye removal of P. aeruginosa strain C. Both strains could remove R-40 under same conditions. Synergistic cultures or tandem architectures in combination with NAC could be performed.

References

Aharoni C, Tompkins FC (1970) Kinetics of adsorption and desorption and the Elovich equation. Adv Catal 21:1–49. https://doi.org/10.1016/S0360-0564(08)60563-5

Akansha K, Chakraborty D, Sachan SG (2019) Decolorization and degradation of methyl orange by Bacillus stratosphericus SCA1007. Biocatal Agric Biotechnol 18:101044. https://doi.org/10.1016/j.bcab.2019.101044

Arshi H, Pandey V (2014) Decolourisation of textile effluent by Pseudomonas aeruginosa in low nutrient medium. Int J Plant Sci 9:449–453

Bent SJ, Forney LJ (2008) The tragedy of the uncommon: understanding limitations in the analysis of microbial diversity. ISME J 2:689–695. https://doi.org/10.1038/ismej.2008.44

Chen Y, Zhang L, Feng L, Chen G, Wang Y, Zhai Z, Zhang Q (2019) Exploration of the key functional strains from an azo dye degradation microbial community by DGGE and high-throughput sequencing technology. Environ Sci Pollut Res 26:24658–24671. https://doi.org/10.1007/s11356-019-05781-z

Dinesh SD, Grundmann H, Pitt TL, Römling U (2003) European-wide distribution of Pseudomonas aeruginosa clone C. Clin Microbiol Infect 9:1228–1233. https://doi.org/10.1111/j.1469-0691.2003.00793.x

Ensuncho AE, Milanés N, Robles JR (2015) Remoción del colorante rojo allura en solución acuosa utilizando carbones activados obtenidos de desechos agrícolas. Inf Tecnol 26:69–78. https://doi.org/10.4067/S0718-07642015000200009

Fernandez ME, Nunell GV, Bonelli PR, Cukierman AL (2014) Activated carbon developed from orange peels: batch and dynamic competitive adsorption of basic dyes. Ind Crop Prod 62:437–445. https://doi.org/10.1016/j.indcrop.2014.09.015

Govindwar SP, Kurade MB, Tamboli DP, Kabra AN, Kim PJ, Waghmode TR (2014) Decolorization and degradation of xenobiotic azo dye Reactive Yellow-84A and textile effluent by Galactomyces geotrichum. Chemosphere 109:234–238. https://doi.org/10.1016/j.chemosphere.2014.02.009

Guadie A, Tizazu S, Melese M, Guo W, Ngo HH, Xia S (2017) Biodecolorization of textile azo dye using Bacillus sp. strain CH12 isolated from alkaline lake. Biotechnol Reports 15:92–100. https://doi.org/10.1016/j.btre.2017.06.007

Hameed BH, Din ATM, Ahmad AL (2007) Adsorption of methylene blue onto bamboo-based activated carbon: kinetics and equilibrium studies. J Hazard Mater 141:819–825. https://doi.org/10.1016/j.jhazmat.2006.07.049

Ho YS, Fellow GM (1998) Kinetic models for the sorption of dye from aqueous solution by wood. Process Saf Environ Prot 76:183–191

Ho YS, Mckay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Ho YS, McKay G (2000) The kinetics of sorption of divalent metal ions onto sphagnum moss peat. Water Res 34:735–742. https://doi.org/10.1016/S0043-1354(99)00232-8

Honma M (2015) Evaluation of the in vivo genotoxicity of Allura Red AC (Food Red No. 40). Food Chem Toxicol 84:270–275. https://doi.org/10.1016/j.fct.2015.09.007

Hsueh CC, Chen BY (2007) Comparative study on reaction selectivity of azo dye decolorization by Pseudomonas luteola. J Hazard Mater 141:842–849. https://doi.org/10.1016/j.jhazmat.2006.07.056

Hussain S, Maqbool Z, Ali S, Yasmeen T, Imran M, Mahmood F, Abbas F (2013) Biodecolorization of reactive black-5 by a metal and salt tolerant bacterial strain Pseudomonas sp. RA20 isolated from Paharang drain effluents in Pakistan. Ecotoxicol Environ Saf 98:331–338. https://doi.org/10.1016/j.ecoenv.2013.09.018

Juang RS, Chen ML (1997) Application of the Elovich equation to the kinetics of metal sorption with solvent-impregnated resins. Ind Eng Chem Res 36:813–820. https://doi.org/10.1021/ie960351f

Kelm MAP, da Silva Júnior MJ, de Barros Holanda SH, de Araujo CMB, de Assis Filho RB, Freitas EJ, dos Santos DR, da Motta Sobrinho MA (2019) Removal of azo dye from water via adsorption on biochar produced by the gasification of wood wastes. Environ Sci Pollut Res 26:28558–28573. https://doi.org/10.1007/s11356-018-3833-x

Khalid A, Arshad M, Crowley DE (2008) Accelerated decolorization of structurally different azo dyes by newly isolated bacterial strains. Appl Microbiol Biotechnol 78:361–369. https://doi.org/10.1007/s00253-007-1302-4

Khattab TA, Abdelrahman MS, Rehan M (2020) Textile dyeing industry: environmental impacts and remediation. Environ Sci Pollut Res 27:3803–3818. https://doi.org/10.1007/s11356-019-07137-z

Lagergren S (1898) Zur theorie der sogenannten adsorption geloster stoffee. K Sven Vetenskapsakademiens, Handl 24:1–39

Maeda CH, Araki CA, Moretti AL, de Barros MASD, Arroyo PA (2019) Adsorption and desorption cycles of reactive blue BF-5G dye in a bone char fixed-bed column. Environ Sci Pollut Res 26:28500–28509. https://doi.org/10.1007/s11356-018-3644-0

Martínez de Yuso A (2012) Desarrollo De Carbones Activados a Partir De Residuos Lignocelulósicos Para La Adsorción Y Recuperación De Tolueno Y N-Hexano

Mendonça ARV, Zanardi GB, Brum SS, de Campos TA, Cardoso CMM, Zavarize DG (2019) RR2 dye adsorption to Hymenaea courbaril L. bark activated carbon associated with biofilm. Environ Sci Pollut Res 26:28524–28532. https://doi.org/10.1007/s11356-018-3786-0

Meng X, Liu G, Zhou J, Fu QS (2014) Effects of redox mediators on azo dye decolorization by Shewanella algae under saline conditions. Bioresour Technol 151:63–68. https://doi.org/10.1016/j.biortech.2013.09.131

Mishra S, Maiti A (2018) The efficacy of bacterial species to decolourise reactive azo, anthroquinone and triphenylmethane dyes from wastewater: a review. Environ Sci Pollut Res 25:8286–8314. https://doi.org/10.1007/s11356-018-1273-2

Moreno-Piraján JC, Navarrete LF, Giraldo L, García V (2007) Adsorción de fenol y 3-cloro fenol sobre carbones activados mediante calorimetría de inmersión. Inf Tecnol 18:71–80. https://doi.org/10.4067/s0718-07642007000300009

Qiu H, Lv L, Pan BC, Zhang QJ, Zhang WM, Zhang QX (2009) Critical review in adsorption kinetic models. J Zhejiang Univ Sci A 10:716–724. https://doi.org/10.1631/jzus.A0820524

Reátegui K (2017) Obtención de carbón activado a partir de la cáscara del fruto de la calabaza (Cucurbita ficifolia Bouchë). Univ Nac Agrar La Molina 91

Saratale RG, Saratale GD, Chang JS, Govindwar SP (2011) Bacterial decolorization and degradation of azo dyes: a review. J Taiwan Inst Chem Eng 42:138–157. https://doi.org/10.1016/j.jtice.2010.06.006

Simonin JP (2016) On the comparison of pseudo-first order and pseudo-second order rate laws in the modeling of adsorption kinetics. Chem Eng J 300:254–263. https://doi.org/10.1016/j.cej.2016.04.079

Soria-Serna LA, Torres-Pérez J, Reyes-López SY (2018) Tetracycline adsorption on steam alternative activated carbon: kinetic and thermodynamic parameters. Desalin Water Treat 114:307–312. https://doi.org/10.5004/dwt.2018.22313

Torres-Pérez J, Soria-Serna LA, Solache-Ríos M, McKay G (2015) One step carbonization/activation process for carbonaceous material preparation from pecan shells for tartrazine removal and regeneration after saturation. Adsorpt Sci Technol 33:1–22

Vadivelan V, Vasanth Kumar K (2005) Equilibrium, kinetics, mechanism, and process design for the sorption of methylene blue onto rice husk. J Colloid Interface Sci 286:90–100. https://doi.org/10.1016/j.jcis.2005.01.007

Zabłocka-Godlewska E, Przystaå W, Grabińska-Sota E (2014) Decolourisation of different dyes by two pseudomonas strains under various growth conditions. Water Air Soil Pollut 225:1846. https://doi.org/10.1007/s11270-013-1846-0

Zablocka-Godlewska E, Przystas W, Grabinska-Sota E (2012) Decolourization of diazo evans blue by two strains of pseudomonas fluorescens isolated from different wastewater treatment plants. Water Air Soil Pollut 223:5259–5266. https://doi.org/10.1007/s11270-012-1276-4

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Zhihong Xu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Herrera-García, S., Aguirre-Ramírez, M. & Torres-Pérez, J. Comparison between Allura Red dye discoloration by activated carbon and azo bacteria strain. Environ Sci Pollut Res 27, 29688–29696 (2020). https://doi.org/10.1007/s11356-020-09584-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09584-5