Abstract

The unique geographical location of waterworks and wastewater treatment plant (WWTP) in Graulhet (France) profited the environmental resource integration and “Circular Economy.” Alum sludge from a local waterworks was introduced to co-conditioning and dewatering with waste-activated sludge from a nearby WWTP to examine the role of the alum sludge in improving the dewaterability of the mixed sludge. Experiments demonstrated that the optimal mixing ratio was 1:1 (waste-activated sludge/alum sludge, v/v). Alum sludge has been shown to beneficially enhance mixed sludge dewaterability, by decreasing both the specific resistance to filtration (SRF) and the capillary suction time (CST). Moreover, the optimal polymer (Sueprfloc-492HMW) dose for the mixed sludge (mix ratio 1:1) was 200 mg/L, highlighting a huge savings (14 times) in polymer addition without alum sludge involvement. In addition, cost-effective analysis of its potential full-scale application has demonstrated that the initial investment could be returned in 11 years. The co-conditioning and dewatering strategy can be viewed as a “win-win” strategy for the Graulhet, France, water and wastewater industry.

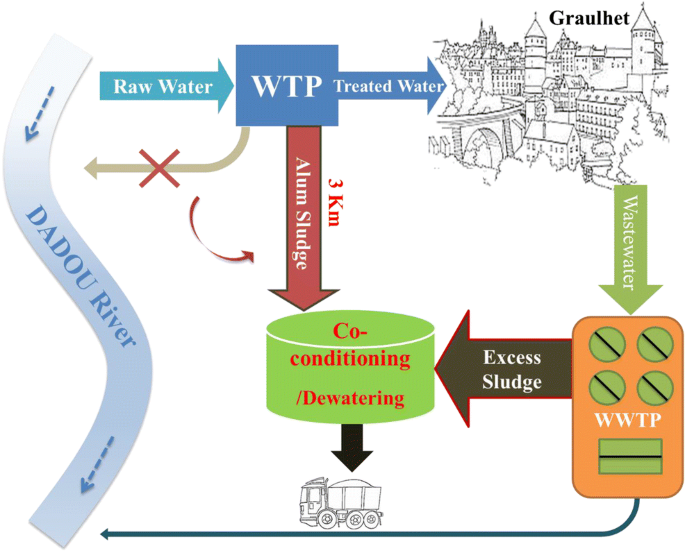

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Global expansion of urban areas and industrial development are often associated with substantial water demand that require intensive treatment of both water and wastewater. Large amount of sludges as inevitable by-product along with the water/wastewater purification process is generated worldwide (Zhao et al. 2018). In particular, the sewerage sludge’s hydrophilic nature of extracellular polymeric substances (EPSs) binds water molecules to the solid surface and traps the water within sludge flocs, forming a high compressibility sludge matrix (Zhu et al. 2018). Water increases transportation and disposal costs. Thus, sludge dewatering is a vital step for reducing the sludge volume, being regarded as the most expensive and least understood process (Chang et al. 2001; Xiong et al. 2018). Accordingly, efficient sludge conditioning prior to mechanical dewatering is required. Various studies have been performed to enhance sludge dewatering recently, such as (1) the magnetic field pretreatment combined with cationic polyacrylamide additive (Bi et al. 2015), (2) polyaluminum chloride (PACl) co-conditioning with two linear polyelectrolytes (Pambou et al. 2016), (3) the combination of ultrasound-cationic polyacrylamide–rice husk to sludge conditioning (Zhu et al. 2018), and (4) a combined coagulation−flocculation process using PACl and a biopolymer harvested from anaerobically digested swine wastewater (Guo et al. 2018). Additionally, Wei et al. (2018) have reviewed the updated process of coagulation/flocculation using different coagulants/flocculants and their combinations with other pretreatments with massive information on this area. Practical operations indicate that dewatering performance for waste-activated sludge is still relatively poor (Qi et al. 2011a). In particular, extra energy requirements as well as the highly complicated and multilevel structural features among these aforementioned approaches seem to hinder their performance in waterworks and wastewater treatment plants’ (WWTPs) sludge dewatering.

Alum sludge, a kind of waterworks residues when aluminum sulfate was used for the raw water purification, can be easily obtained from local waterworks either in liquid phase or in solid phase (after dewatering) (Wang et al. 2018). Historically, the waterworks residues were discharged directly to nearby natural water bodies without any further treatment or reuse. However, regulations implemented in many places have now made these disposal methods forbidden due to the negative environmental impacts, such as the heavy metal contained in the waterworks residues (Mazari et al. 2018). Therefore, the prevalence of mechanically dewatering of waterworks residues to sludge cakes in most places worldwide could significantly reduce its volume for final disposal. Unfortunately, landfilling of waterworks residues has indeed been the most famous applied method over the world, as the valuable elements/materials contained in the waterworks residues did not have any kind of recycle or reuse (Yang et al. 2018). Nowadays, transforming the waterworks residues as a useful material, rather than a waste for landfill, has drawn universal attention while the beneficial reuse of alum sludge becomes an overwhelming superiority in researchers and engineers for the last decade, as alum sludge accounts for the majority of the waterworks residues over the world (Ren et al. 2019).

Four major routes which include eleven possible ways of reusing alum sludge, such as the use in wastewater treatment process, use as building/construction materials, the use in land-based application, and the recovery of the coagulant (Ahmad et al. 2016), had been developed and recognized in the last decades. In fact, only few studies investigated alum sludge co-conditioning and dewatering with sewage sludge to improve the sewage sludge dewaterability. For example, Lai and Liu (2004) indicated that alum sludge may act as a skeleton builder in mixed sludge and thus has a beneficial dewatering process effect. Yang et al. (2007, 2009) examined the role of alum sludge in improving sewerage sludge dewaterability. Their results demonstrated that an optimal mixed ratio of 2:1 (anaerobic digested sludge:alum sludge, in the on volume basis) could improve the resultant sludge dewaterability and could cause about 99% reduction in phosphorus loading in the reject water. Moreover, the optimal polymer (Superfloc C2260) dosage required for conditioning was also reduced to 15 mg/L (in the mixed sludge) from 120 mg/L (blank), thus providing cost savings in polymer addition. However, considering the co-conditioning practice, alum sludge transport, and haul distance (50 km away) between treatment facilities in Dublin, Ireland, these made the benefits of co-conditioning and dewatering and related economics unrealistic.

In contrast, the WWTP of Graulhet, France, is uniquely located 3 km away from the waterworks. Co-conditioning of the sludges generated from these two plants seems realistic. The Graulhet WWTP employs a conventional biological treatment process with the capacity of 11,000 m3/day, while the waterworks produces 2200 m3 drinking water per day. Currently, the liquid alum sludge was directly drained into the Dadou river. Significantly, these two plants are operated by the same company (Régie Municipale de l’Eaux et de l’Assainissement de Graulhet). This provides an opportunity of co-conditioning the sewerage sludge with alum sludge in order to achieve sustainable development and reuse regarding sludge management of using “waste,” i.e., alum sludge, for sewage sludge treatment, i.e., used as “conditioner.” Therefore, a scientific investigation was needed to promote its application by examining the feasibility of co-conditioning sewerage sludge with liquid alum sludge in Graulhet, France. It is expected that this study forms the main technical issues of the co-conditioning and thus forms the basis of further investigation towards co-conditioning and dewatering of sewage sludge with alum sludge practice in Graulhet, France.

Materials and methods

Materials

Liquid alum sludge with moisture content of 99.43% was obtained from the settling tank of the treatment plant, located upstream of Graulhet right bank, where aluminum sulfate is used as coagulant for treating river water. The sewerage sludge (or excess/waste-activated sludge) with an average water content of 96.46% was obtained from the bottom of a secondary clarifier at the Graulhet WWTP. Currently, the Graulhet WWTP used the cationic polymer Sueprfloc-492HMW (Kemira, Finland), which was granular powder and off-white in appearance with a molecular weight of 10,000,000, bulk density of 0.75 kg/L, and pH of 3–5 for 0.5% solution (25 °C), for sludge conditioning before mechanical dewatering using a belt press filter. Polymer Sueprfloc-492HMW was also collected from the Graulhet WWTP.

Co-conditioning procedure

The conditioning tests were performed at room temperature using a four-paddle standard jar-stirring apparatus, where blended sludge samples of 600 mL in 1000-mL beakers were used in the experiments. Alum sludge and waste-activated sludge were mixed at different volume ratios (2:1, 1:1, 1:2, 1:3, and 1:4). The optimized mixing ratio (alum sludge:waste-activated sludge, v/v) was determined by considering the daily quantity of alum sludge generated from Graulhet WWTP as well as the mixed sludge dewaterability.

Thereafter, the dosage range based on the literature (Yang et al. 2007, 2009) (from 10 to 400 mg/L, 10, 50 to 400 mg/L, at increments of 50 mg/L) of the polymer Sueprfloc-492HMW was added as chemical conditioner to the optimized mixing ratio to achieve the optimal polymer dosage. This procedure was also performed using the jar-stirring apparatus, where the sludge and various polymer doses were fast mixing at 200 rpm (a mean velocity gradient (G) value of 330 s−1) for 30 s, and then slowly mixing at 60 rpm (at a G value of 34 s−1) for 300 s. This provides a GT value of 10,000, which is considered as the most critical determinant factor to ensure the shear conditions. In the end, the dewaterability of the resultant sludge was evaluated using capillary suction time (CST) and specific resistance to filtration (SRF) following the standard procedure. All those processes (e.g., co-conditioning, polymer dosage, and measuring CST and SRF) have been repeated by three parallel experiments. The standard deviation was also calculated.

CST (s) is a measure of the readiness with which a sludge sample “releases” its water. The sample is placed in a reservoir above a sheet of chromatography paper, and the time taken for the liquid to be drawn to a certain radial distance by capillary action is measured. Much of the appeal of the method lies in its speed, simplicity, and need for only small volumes (Lai and Liu 2004).

SRF (m/kg) is a kinetic parameter of a unit mass of sludge per unit area of filter, which could be obtained from the following equations:

where, ΔP is the applied pressure, ф0 is the bulk or initial porosity, ρs is the density of sludge, v is the specific filtrate volume (volume per unit superficial cross-sectional flow area), and ηL is the liquid viscosity (Yang et al. 2007).

Further, the adjustment to the SRF measurement with the intention of removing of filter-pore blocking occurs at high excess polymer doses (Chang et al. 2001; Zhu et al. 2018). The methods can be described as the following equations:

where, C is the mass of dry solids per volume of filtrate, rm is a resistance due to the membrane (and drainage system), and αm is the cake specific resistance, based upon mass of solids in cake (per unit area).

Characterization and analyses

To examine the elements in the solid phase and supernatant of the sludge, a laboratory-model centrifuge (Sigma 2K15, Germany) was operated at 8000 r/min to separate the sludge. The solids were then washed with distilled water three times. Next, the solids were dried at 105 °C for 24 h. The solid element content was tested by inductively coupled plasma-atomic emission spectroscopy (ICP-AES) and by CHNS analysis using a Thermoquest NA2100. Scanning electron microscopy (SEM) (Philips XL30 ESEM apparatus; FEI Company), coupled with an energy-dispersive X-ray spectroscopy (EDX analysis), was used to observe the sludge samples before and after dewatering.

The sludge dewaterability before and after co-conditioning was evaluated using the CST apparatus and SRF facility. A Triton CST apparatus (Triton WPRL, Type 130) with a CST paper size 7 × 9 cm was used for the CST measurement, while the Buchner funnel with the Whatman No. 1 qualitative filter paper (11-μm particle retention, 10 cm diameter) and equipped with a 70-mbar vacuum suction was used for the SRF test and measurement.

Results and discussion

Characterization of the two kinds of sludges

Table 1 presents the element composition in the solid and supernatant of two kinds of sludges, i.e., alum sludge and sewerage sludge. It shows that Al was the dominant element in solid phase of the alum sludge apart from silicon; Ca and Fe were also presented in the solid phase of alum sludge. It can be concluded that the majority of elements (such as Al and Fe) were in the solid phase of alum sludge, compared with the alum sludge supernatant. In sewerage sludge, Fe was the most abundant element observed in the solid phase of sewerage sludge; Al, Ca, S, and Si were also presented. It can be seen that Na, Ca, Fe, K Mg, P, and S were distributed within the supernatant of sewerage sludge. Moreover, the presence of P both in solids and in supernatant of sewerage sludge is because the phosphorus can be released when bacteria-containing stored phosphorus (i.e., phosphate-accumulating organisms, PAOs) were subjected to anaerobic conditions, which include thickening and/or anaerobic digestion, leading to a phosphorus-enriched supernatant and filtrate obtained from mechanical dewatering of the sludge; this result was in agreement with Yang et al. (2007).

The element percentage of CHNS of the two kinds of sludges is shown in Table 2. Regarding the alum sludge, carbon, nitrogen, sulfur, and hydrogen only account very little percentage (less than 10%). However, in the sewerage sludge, carbon is the overwhelming element compared with the other three elements, even there is very little percentage of sulfur in the sewerage sludge, which agreed with Gutiérrez Ortiz et al. (2014a, b)

The SEM-EDX data is shown in Fig. 1; the solid phase texture of alum sludge and sewerage sludge as well as the elements on the surface of the two kinds of sludges was presented. Alum sludge presented a more porous surface compared with the flat surface of sewerage sludge. Regarding the result obtained from the EDX analysis, Si was the most abundant element observed on points 1 and 2 of alum sludge; point 1 of alum sludge contains more elements such as Fe, Mg, and P compared with point 2. It indicated that the elements were not distributed uniformly on the surface of the alum sludge. From the sewerage sludge (in Fig. 1b), elements such as Na, Cl, and Cr were identified in addition to the ones reported in Table 1. Furthermore, this morphology also indicated that alum sludge could be used as a physical conditioner or skeleton builder during the conditioning process (Qi et al. 2011a, b).

Optimal mixing ratio of the sludges

The CST and SRF of the two kinds of sludges as well as the mixed sludge are jointly presented in Fig. 2. It can be seen that the sewerage sludge CST and SRF were 59 s and 5.5 × 1012 m/kg, respectively; compared with the alum sludge CST and SRF (3 s and 2.6 × 1012 m/kg), the dewaterability of the sewerage sludge can be characterized as poor, as the CST and SRF of sewerage sludge were about 23 times and 18 times higher than those of alum sludge, respectively.

To examine the effect of the introduction of alum sludge on both the sewerage sludge dewaterability and the element variation in the mixed sludge, different ratios, i.e., 2:1, 1:1, 1:2, 1:3, and 1:4 (alum sludge/sewerage sludge, v/v), of the two sludges were mixed, and the CST and SRF of mixed sludge and the element composition of the mixed sludge were measured. The results are jointly shown in Fig. 2 and Table 3.

As illustrated in Fig. 2 (plot in blue columns), by adding the liquid alum sludge into the sewerage sludge, the CST and SRF were decreasing. It indicated that the dewaterability of the sewerage sludge improved. Moreover, the improved sewerage sludge dewaterability can be enhanced with an increasing amount of the alum sludge addition from the ratio of 1:4 to 2:1 (alum sludge:sewerage sludge, v/v), since the SRF (4.2 × 1012 m/kg) and CST (50s) of the mixed ratio 1:4 were both decreased to a SRF of 2.0 × 1012 m/kg and a CST of 4 s of the mixed ratio 2:1. The mechanisms were likely driven by a large portion of insoluble aluminum hydroxides in the liquid and/or solid phase of alum sludge acting as a coagulant in coagulation/flocculation by particle-particle bridging and surface charge neutralization processes (Chu 2001). Additionally, the solid phase of alum sludge could act as the skeleton builders as well during the conditioning process (Basibuyuk and Kalat 2004). Many researchers reported similar results about using alum sludge as a chemical coagulant. Nair and Ahammed (2015) examined alum sludge usage as a coagulant for the post-treatment of up-flow anaerobic sludge blanket (UASB) reactors treating urban wastewater. Foroughi et al. (2018) reported turbidity removal in drinking water treatment using alum sludge as a coagulant agent. Mazari et al. (2018) investigated the potential reuse of alum sludge as primary coagulant in terms of membrane fouling reduction. Alum sludge can also act as a skeleton builder or filter aid (Li et al. 2016), which can effectively reduce sludge compressibility. This helps the sludge cake form a permeable and rigid structure while maintaining porosity, even under a high compression pressure. This is because its physical morphology is rigid which could act as a skeleton.

Table 3 shows the different elemental concentrations in supernatant of the different sludge mixing ratios. Overall, increasing the sewerage sludge ratio could result in the relevant elements rising in mixed sludge, such as Al, Fe, and Na. This is likely because the sewerage sludge could bring various metal elements into the mixed sludge. As in Table 1, the various metal elements in the supernatant of sewerage sludge are greater than those of alum sludge. Significantly, it has been proved by Yang et al. (2009) that Al has a very strong affinity with P, due to the ligand exchange adsorption mechanisms. Therefore, the P concentration was decreasing from 1.8 to 0 mg/L, by mixing the liquid alum sludge with sewerage from 1:4 to 2:1 (alum sludge:sewerage sludge, v/v). However, the initial P concentration in the supernatant of the sewerage sludge is 6 mg/L (see Table 1). The co-conditioning process could partially remove the P in the supernatant, which could benefit for the biological P removal process of Graulhet WWTP. In fact, by adding the liquid, alum sludge could potentially increase the overall treatment volume of the mixed sludge, which will increase the hydraulic load as well as the treatment capacity on the dewatering unit in the WWTP of Graulhet (France). Currently, the volume of sludge thickening tank is 400 m3, which was over-designed. Thus, by considering the P concentration in the supernatant as well as the sludge treatment capacity of WWTP in Graulhet, the optimal mix ratio was chosen as 1:1 for the following sludge conditioning tests by adding the polymer as a conditioner.

Polymer conditioning of the mixed sludge

As above, the optimal 1:1 mix ratio was determined that ensures the lowest mixed sludge CST and SRF as well as the phosphate concentration in the supernatant with the least amount of alum sludge addition. However, as a chemical conditioner, organic polymer has been widely used in sludge treatment practice to significantly improve the sludge dewaterability. It is believed that the addition of polymer in optimal mixed sludge could further improve the sludge dewaterability but with an obviously reduced dosage (compared with the sewerage sludge conditioning). The dewatering ability (evaluated by CST and SRF) of the optimal mixed ratio (1:1) by adding a cationic polyacrylamide Superfloc-492HMW (dosage range from 10 to 400 mg/L) is jointly presented in Fig. 3. It can be seen that SRF and CST decreased from 2.9 × 1012 to 1.4 × 1012 m/kg and from 5 to 2 s, respectively, when the polymer dosage increased from 10 to 200 mg/L. Thereafter, the SRF and CST were continuously rising by increasing the polymer dosage. It indicated that a further increase of polymer dosage did not bring about any further decrease of SRF and/or CST. Thus, the optimal polymer dosage for the mixed sludge was determined to be 200 mg/L (the turning point).

In summary, adding the liquid alum sludge into sewerage sludge could result in an easily dewatering mixed sludge, as the lower SRF and CST were achieved. Moreover, it has been proved that a continuous reduction of SRF and CST can be achieved by adding a very little amount of polymer (200 mg/L) into the mixed sludge. Significantly, the polymer (Superfloc-492HMW) dosage under the current treatment capacity of Graulhet WWTP is 2.8 g/L (CST and SRF are 12 s and 3.6 × 1012 m/kg, respectively), while the mixed sludge only needs a 200-mg/L polymer dosage. In fact, this result also agrees with Lai and Liu (2004); they have shown a decrease in the cationic polyelectrolyte when alum sludge was co-conditioned with an activated sludge. Additionally, it has been investigated by Yang et al. (2009) that the alum sludge could act as a skeleton builder, making the mixed sludge more incompressible and making the dewatering process more effective.

Case analysis

The process illustrated in Fig. 4 details the proposed integration of the alum sludge in co-conditioning and dewatering with waste-activated sludge. Specifically, the waterworks of Graulhet is just located 3 km from the Graulhet WWTP and operated by the same company; thus, it may be practical to build a drain pipe from the waterworks to the Graulhet WWTP. Considering the sludge production balance in these two sources, the maximum liquid alum sludge generation rate of the waterworks is 66 m3/day (3% of the raw water volume) while the design compacity of sewerage sludge thickening tank in Graulhet WWTP is 400 m3. Thus, a steel tank is needed to store the alum sludge. Table 4 summarizes the main pipe materials and estimated costs with the pipe manufacturing, tank construction, and electricity needed. The unit prices are based on Herstein and Filion (2011). The flow velocity of liquid alum sludge in the cement-mortar-lined ductile iron pipe was estimated at 1.0 m/s; thus, the diameter of 100-mm pipe could fulfill the requirement. The prices of commercially available steel tank was based on a French steel supplier. The horizontal multistage centrifugal pump was estimated with a 70-m pump head, while the price is from “2016 price list of Salmson Warehouse, Laval, France.” It can be seen that 418,577 Euro should be invested for the co-conditioning strategy.

Regarding the co-conditioning process, currently, Graulhet WWTP could consume 25 kg polymer per day. However, if the strategy of co-conditioning with liquid alum sludge was applied, the annual polymer saving could be 8473 kg. Currently, the price of polymer (from a local supplier in France) is 5.24 Euro/kg (including tax); the polymer saving could equal 44,399 Euro per year, accounting for 93% of the current annual polymer costs. On the other hand, the potential increases of sludge cakes will be from 25,000 to 25,321 kg/day when liquid alum sludge is introduced. Accordingly, the relevant sludge disposal cost will be rising to approximately 7100 Euro per year (considering the average sludge disposal fee of 65 Euro/ton (Zhao et al. 2016)).

Although extra capital investment and construction cost are estimated at 418,577 Euro, as well as the extra sludge disposal fee of approximately 7100 Euro/year, the polymer saving benefits of 44,399 Euro/year can be achieved, which means the initial investment and operational expenses could be returned by polymer saving in 11 years. It seems a long time. But compared with the long-term effect for the local “circular economy,” it is a relatively short period. Significantly, the sustainable sludge management route should be prioritized since the legislation is not allowed in the liquid alum sludge from the waterworks drainage to the river anymore. In addition, in spite of the increased quantity of the reject water from dewatering unit, the significant reduction of P in reject water could benefit the wastewater treatment process regarding P loading. Overall, from a technical point-of-view, the co-conditioning and dewatering strategy is practicable, and the cost-effective analysis also demonstrated that the initial investment fee could be returned.

Conclusions

The liquid alum sludge obtained from Graulhet (France) WWTP can be used to co-conditioning and dewatering with the sewerage sludge from WWTP, since the addition of liquid alum sludge to the waste-activated sludge could improve its dewaterability. By considering the P concentration in the supernatant as well as the treatment capacity of Graulhet WWTP, the optimal mixing ratio is 1:1 (sewerage sludge:alum sludge, v/v). Moreover, the optimal polymer (Superfloc-492HMW) dosage for the mixed sludge ratio (1:1) was 200 mg/L, while the current dosage for the waste-activated sludge in Graulhet WWTP is 2.8 g/L. An integrated cost-effective evaluation of process capabilities, sludge transport, and increased cake disposal, additional administration, etc. suggests that the co-conditioning and dewatering strategy for Graulhet water industry is practicable; theoretically, the initial investment could be returned in 11 years. Therefore, a scientific investigation but also a “Circular Economy” approach was provided for Graulhet (France) water industry.

References

Ahmad T, Ahmad K, Alam M (2016) Sustainable management of water treatment sludge through 3‘R’ concept. J Clean Prod 124(Supplement C):1–13

Basibuyuk M, Kalat DG (2004) The use of waterworks sludge for the treatment of vegetable oil refinery industry wastewater. Environ Technol 25(3):373–380

Bi DS, Guo XP, Cai ZH, Yu Z, Wang DM, Wang YQ (2015) Enhanced dewaterability of waste-activated sludge by combined cationic polyacrylamide and magnetic field pretreatment. Environ Technol 36(4):455–462

Chang GR, Liu JC, Lee DJ (2001) Co-conditioning and dewatering of chemical sludge and waste activated sludge. Water Res 35(3):786–794

Chu W (2001) Dye removal from textile dye wastewater using recycled alum sludge. Water Res 35(13):3147–3152

Foroughi M, Chavoshi S, Bagheri M, Yetilmezsoy K, Samadi MT (2018) Alum-based sludge (AbS) recycling for turbidity removal in drinking water treatment: an insight into statistical, technical, and health-related standpoints. J Mater Cycles Waste Manage 20(4):1999–2017

Guo J, Chen C, Jiang S, Zhou Y (2018) Feasibility and mechanism of combined conditioning with coagulant and flocculant to enhance sludge dewatering. ACS Sustain Chem Eng 6(8):10758–10765

Gutiérrez Ortiz FJ, Aguilera PG, Ollero P (2014a) Biogas desulfurization by adsorption on thermally treated sewage-sludge. Sep Purif Technol 123:200–213

Gutiérrez Ortiz FJ, Aguilera PG, Ollero P (2014b) Modeling and simulation of the adsorption of biogas hydrogen sulfide on treated sewage–sludge. Chem Eng J 253:305–315

Herstein LM, Filion YR (2011) Life-cycle assessment of common water main materials in water distribution networks. J Hydroinf 13(3):346–357

Lai JY, Liu JC (2004) Co-conditioning and dewatering of alum sludge and waste activated sludge. Water Sci Technol 50(9):41–48

Li J, Liu L, Liu J, Ma T, Yan A, Ni Y (2016) Effect of adding alum sludge from water treatment plant on sewage sludge dewatering. J Environ Chem Eng 4(1):746–752

Mazari L, Abdessemed D, Szymczyk A (2018) Evaluating reuse of alum sludge as coagulant for tertiary wastewater treatment. J Environ Eng 144(12):04018119

Nair AT, Ahammed MM (2015) The reuse of water treatment sludge as a coagulant for post-treatment of UASB reactor treating urban wastewater. J Clean Prod 96:272–281

Pambou YB, Fraikin L, Salmon T, Crine M, Leonard A (2016) Enhanced sludge dewatering and drying comparison of two linear polyelectrolytes co-conditioning with polyaluminum chloride. Desalin Water Treat 57(58):27989–28006

Qi Y, Thapa KB, Hoadley AFA (2011a) Application of filtration aids for improving sludge dewatering properties – a review. Chem Eng J 171(2):373–384

Qi Y, Thapa KB, Hoadley AFA (2011b) Benefit of lignite as a filter aid for dewatering of digested sewage sludge demonstrated in pilot scale trials. Chem Eng J 166(2):504–510

Ren B, Zhao Y, Lyczko N, Nzihou A (2019) Current status and outlook of odor removal technologies in wastewater treatment plant. Waste Biomass Valoriz 10(6):1443–1458

Wang Y, Ren BM, Zhao YQ, English A, Cannon M (2018) A comparison of alum sludge with peat for aqueous glyphosate removal for maximizing their value for practical use. Water Sci Technol 2017(2):450–456

Wei H, Gao B, Ren J, Li A, Yang H (2018) Coagulation/flocculation in dewatering of sludge: a review. Water Res 143:608–631

Xiong Q, Zhou M, Yang H, Liu M, Wang T, Dong Y, Hou H (2018) Improving the dewaterability of sewage sludge using rice husk and Fe2+-sodium persulfate oxidation. ACS Sustain Chem Eng 6(1):872–881

Yang Y, Zhao YQ, Babatunde AO, Kearney P (2007) Co-conditioning of the anaerobic digested sludge of a municipal wastewater treatment plant with alum sludge: benefit of phosphorus reduction in reject water. Water Environ Res 79(13):2468–2476

Yang Y, Zhao YQ, Babatunde AO, Kearney P (2009) Two strategies for phosphorus removal from reject water of municipal wastewater treatment plant using alum sludge. Water Sci Technol 60(12):3181–3188

Yang Y, Zhao YQ, Liu RB, Morgan D (2018) Global development of various emerged substrates utilized in constructed wetlands. Bioresour Technol 261:441–452

Zhao Y, Liu R, Awe OW, Yang Y, Shen C (2018) Acceptability of land application of alum-based water treatment residuals – an explicit and comprehensive review. Chem Eng J 353:717–726

Zhao Y, Ren B, O’Brien A, O’Toole S (2016) Using alum sludge for clay brick: an Irish investigation. Int J Environ Stud 73(5):719–730

Zhu C, Zhang P, Wang H, Ye J (2018) Conditioning of sewage sludge via combined ultrasonication-flocculation-skeleton building to improve sludge dewaterability. Ultrason Sonochem 40:353–360

Acknowledgments

The first author greatly acknowledges the Ph.D. scholarship received jointly from the University College Dublin, Ireland, and China Scholarship Council (CSC). The RAPSODEE Research Centre (CNRS UMR 5302), France, and the staff in Régie Municipale de l’Eaux et de l’Assainissement de Graulhet were also gratefully acknowledged for the technological support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, B., Lyczko, N., Zhao, Y. et al. Integrating alum sludge with waste-activated sludge in co-conditioning and dewatering: a case study of a city in south France. Environ Sci Pollut Res 27, 14863–14871 (2020). https://doi.org/10.1007/s11356-020-08056-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-08056-0