Abstract

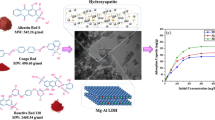

Dye removal from wastewater is of prominence due to its hostile effects on human health and the environment. The complex structure of the dye molecule is responsible for its difficulty in removal. Adsorption is found to be a promising technique to eliminate dye wastes due to its high removal capacity at low concentration. Among different adsorbents used, hydroxyapatite is a biocompatible adsorbent that is relatively efficient in both anionic and cationic dye removal. Recently, modification of hydroxyapatite by doping with other materials to increase its removal efficiency has gained much attention. This review summarizes compilation of recent literature on the removal of anionic and cationic dye by different hydroxyapatite nanocomposites, comparison of adsorption capacities of different hydroxyapatite nanocomposites, the possible adsorption mechanism of removal of dyes, the general isotherm, and kinetic and thermodynamic studies explaining the type of adsorption and the characteristics, advantages, and limitations of adsorbents.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rapid industrialization has resulted in a detrimental effect on the environment and human health. Inevitable use of chemicals which cannot be eliminated due to growth in the economy makes it essential to ensure its safe use and disposal. One such waste is dye which is commonly used in cosmetics, food, paper, pharmaceutical, plastic, textile, and tannery industries (Nguyen and Pho 2014). Dye molecules are hazardous to human health along with aquatic and floral environments (Manatunga et al. 2018). Dye molecule contains a complex chemical structure of chromogen-chromosphere which makes it difficult to biodegrade (Shertate and Thorat 2014). Of the dye produced, 80% is used by textile industries making them the largest consumers of dyes. India is the second-largest dye exporter after China (Bakre et al., 2005). As per the annual report of the Ministry of Textiles, 28.89 lakh kg of dye is produced in India which values around ₹ 27.02 crores (Ministry of Textile Govt of India 2018). Therefore, the treatment of wastewater containing dyestuff is very essential before discharge.

Various techniques are evolved for the treatment of dye wastes such as coagulation-flocculation (Dotto et al. 2019), biodegradation (Bharti et al. 2019), electrochemical oxidation (Shetti et al. 2019), ion exchange (Yan et al. 2019), Fenton oxidation (Sözen et al. 2019), reverse osmosis (Cinperi et al. 2019), ozonation (Venkatesh and Venkatesh 2019), electrocoagulation (Donneys-Victoria et al. 2019), and adsorption (Naushad, 2019). Researchers are under social pressure to produce eco-friendly and economic technique with relatively good efficiency. Adsorption is an efficient technique for dye removal which binds the particles on the surface of adsorbent by physical or chemical forces. India is one of the top 10 countries with documents on adsorption of dye as per Scopus as depicted in Fig. 1. Various metal oxides and waste products are used as adsorbents. Activated carbon is one of the widely used adsorbents (Jedynak et al., 2019). However, it is uneconomic; hence, we have focused our review on hydroxyapatite adsorbents.

Dyes

Due to high water solubility, it is difficult to remove dyes from wastewater by conventional methods (Yusuf 2019). Degradation of certain dye produces few products which are hazardous than the dye itself. Dye molecule adheres to the surface of the fiber by hydrogen bonding, van der Waals forces, or electrostatic interactions (dos Santos et al., 2007). Due to the improper coloring process, the excess dyestuffs mix with water and are released as effluent. When these dyestuffs are let-off to the environment, they may cause serious hazards as shown in Fig. 2.

Toxicity analysis of various dyes is investigated in many studies which concluded dyes to be highly genotoxic and carcinogenic (Ahmed et al., 2015; Fernandes et al., 2018). The dye may enter through skin pores, inhalation, or ingestion which causes diseases like dermatitis, kidney disorders, or even bladder cancer during long-term exposure (Akarslan and Demiralay 2015).

Dyes are classified as ionic dye and non-ionic dyes. Dyes that form positively charged ions in the aqueous solution are cationic dyes, and those which form negatively charged ions are anionic dyes. Acid dyes, reactive dyes, and direct dyes are few anionic dyes. Rhodamine B methylene blue and malachite green are few cationic dyes. Vat dyes and disperse dyes are non-ionic dyes (Naushad 2018). Production of dye can be from natural or synthetic sources. Figure 3 demonstrates the classification of dyes with their production source. Natural dyes are eco-friendly and are used principally in food sectors limiting their use in other sectors because of their high cost (Vankar 2000).

The removal of dyes by various adsorbents is given in Table 1.

Hydroxyapatite

Hydroxyapatite (HAP) consists of calcium and phosphate mineral confirming their association with the apatite family (Fig. 4). HAP can receive a significant number of anionic and cationic substituents. HAP can either be monoclinic or hexagonal (Piccirillo and Castro, 2017). It is used widely in medicine as its composition replicates that of human bone with a Ca/P molar ratio of 1.67 (Szcześ et al., 2017). HAP is white to off-white and a soft powder-like substance which has numerous applications such as fuel-cell materials, fluorescent lamps, adsorption of pollutants, and catalysis (Fihri et al. 2017). The physicochemical properties like stability, porosity, low water solubility, high sorption capacity, and modifiable surface groups enable strong interaction between HAP and pollutant molecules (A. K. Mishra 2016).

Synthesis of HAP

The techniques commonly used for the preparation of HAP include (i) dry method, (ii) wet method, (iii) high-temperature method, and (iv) green synthesis as mentioned in Table 2.

In the dry method, precisely weighed precursors are homogenously mixed without the addition of solvent, followed by sintering to produce the porous product. The requirement of high temperature is a major drawback of this method (Chaikina et al. 2019). In a study conducted by the researches (Pramanik et al. 2007), the precursors were mixed for 16 h with the binder in a mill. The resulting slurry was dried for 3 h at 80 °C to form a powder which was cold pressed in a steel dye to produce pellets. This was heated in a furnace at 500–1250 °C followed by cooling to avoid internal cracks. The product obtained was crushed again, compacted, and heated in a furnace for further characterization.

Wet methods involve chemical precipitation, hydrolysis, sol-gel, hydrothermal, and emulsion methods. In these processes, less agglomerated products are formed by simple procedures. Chemical precipitation is one of the widely used methods for the synthesis of HAP. In a method described by Wolff et al. (2018), calcium salt solution (pH 10) was stirred and heated with a dispersant to prevent agglomeration. On attaining a constant temperature, the phosphate salt solution was added dropwise and stirred for 1.5 h. After aging for 12 h, the product was filtered and washed many times with water and ethanol followed by calcination. This method produced HAP rapidly in a short time with poor crystallinity. The emulsion method involves the usage of precursors, specific solvent, and a surfactant at a controlled pH and temperature to obtain HAP. This method has been employed for obtaining high-purity HAP by adding CTAB, cyclohexane, and n-octyl alcohol to calcium and phosphate precursors under vigorous stirring and calcination for 4 h (Huang et al. 2019).

High-temperature processes involve the combustion of precursors at a high temperature for a specified period of time. The final products are powdered by milling to get homogeneous HAP particles (Canillas et al. 2017).

Green synthesis methods make use of waste materials as a substitution for calcium and phosphate precursors for the synthesis of HAP (Fihri et al. 2017). Limiting the use of toxic chemicals by using naturally available waste resources for the synthesis can be a solution to the arising problem of water pollution. Waste resources can be biowastes like eggshells, fishbone, and bovine bone; calcination of organic matters like a seashell, coral, starfish, and algae; and biomolecules from plants (Sadat-shojai et al. 2013). In a study conducted by researchers (Sathiskumar et al. 2019), fish scales were treated with dilute HCl to remove proteins followed by NaOH and heating to eliminate proteins. The white precipitate obtained is filtered and washed with distilled water. After drying in a hot air oven, the product is crushed and given NaOH treatment at 100 °C for 2 h with continuous stirring. The final product is obtained after drying at 100 °C after thorough washing to remove alkalinity from HAP.

Hydroxyapatite has calcium ions with a positive charge and phosphate ions with a negative charge. Therefore, it can remove pollutants by electrostatic interactions (Chahkandi 2017). However, it is difficult to obtain HAP in the required form due to its hardness and brittleness. Hence, modification of HAP by doping it with other compounds can solve this problem (Sreedhar et al. 2007). Research on the pollutants removal by adsorption has revealed that surface modification can advance adsorbent effectiveness (Darvishalipour et al. 2019). In a study conducted by researchers (Mohammad et al. 2017), adsorption capacity of chitosan doped HAP was found to be greater than that of HAP which indicated hydroxyapatite nanocomposite to be a better choice for the contaminant removal.

Hydroxyapatite nanocomposites

Enhancing the properties of HAP by doping it with other material is practiced recently by which adsorbent performance is increased. Synthesis of doped HAP can easily be obtained by mixing metal salts with calcium and phosphate salts during HAP production (Manatunga et al. 2018) or adding doping material after synthesis of HAP under controlled conditions (Hamzah and Salleh 2014). Figure 5 gives us a year-over-year increase in the number of publications in the area of HAP nanocomposites as per Scopus. Doping of HAP with magnesium (Khalil 2012), chitosan (Sadeghizadeh et al. 2019), bagasse biomass (Yan et al. 2019), zinc (El-Maghrabi et al. 2019), silver (Gottardo et al. 2019), and palladium (J. Mishra et al. 2019) for the adsorption of various pollutants is explored by various researchers.

Adsorption depends on many parameters like adsorbent dosage, contact time, agitation speed, initial concentration of adsorbate, and temperature. Recent research on HAP nanocomposite on dye removal is the focus of this review article. Adsorption of various dyes by metal/metal-oxide-based HAP nanocomposite, magnetic HAP nanocomposite, biochar-HAP nanocomposite, polymer-HAP nanocomposite, graphene-HAP is briefly discussed in the following sections.

Metal/metal-oxide-based HAP nanocomposite

The adsorption capacity of HAP increases when it is doped with metal or metal oxide. For example, doping HAP with titanium increased the adsorption of anionic reactive red dye by being positively charged at zeta potential, when compared with bare HAP which was negatively charged at zeta potential repulsing the dye molecules as shown by Asjadi, Salahi, and Mobasherpour (2016). Metal oxides in adsorbent increase the availability of hydroxyl groups which form hydrogen bonds with nitrogen atoms in dye molecules which increase the adsorption capacity. Oxygen species in metal oxides and positive charge in cationic dyes result in dipole ion interaction thereby increasing its adsorption capacity (Phasuk et al. 2018). Modification in properties of adsorbent which are prominent in enhancing adsorption capacity depends on the type of metal oxide doped (Manatunga et al. 2018).

Magnetic HAP nanocomposite

Magnetic hydroxyapatite (MHAP) is synthesized most commonly by a chemical precipitation method where the iron precursor is mixed with white precipitate formed by calcium and phosphate salt solution at high alkalinity (Sahoo et al. 2019). MHAP has a prominent advantage of easy removal by the application of external magnetic fields (Y. Wang et al. 2017). It is reported that electrostatic interactions and hydrogen bonding are the reasons for the increased adsorption capacity (Zhang et al. 2016).

Biochar-HAP nanocomposite

In general, HAP nanoparticles aggregate in aqueous solution thus reducing their dispersibility and adsorption capacity. To overcome these, few modifications can be done on the surface of HAP by doping them with biochar. Biochar produced from pyrolysis of reed straw biomass was blended with HAP which increased the adsorption of cationic dye (Y. Li et al. 2018).

Polymer/biopolymer-HAP nanocomposite

Hydrophobicity of polymer has restricted its use as a membrane for pollutant removal as it leads to membrane fouling (Lee et al. 2019). Modification of surface by doping it with nanoparticles containing hydrophilic groups can overcome this major drawback. Polymers are synthesized most commonly by the graft polymerization method where hydrogels are formed. When these polymers are soaked in calcium and phosphate salt solutions under controlled conditions, HAP/Polymer composite is produced (Hosseinzadeh and Ramin 2018). These composite membranes are efficient in the removal of dyes like Congo red (J. H. Li et al. 2019) and acid blue 113 (Varaprasad et al. 2018). The adsorption capacity depends on the quantity of HAP used in the preparation of the composite membrane (Varaprasad et al. 2018).

Graphene-hydroxyapatite nanocomposite

Carbon-rich materials possess a high surface area ensuing its high adsorption. Graphene has already been extensively used and is proven to be an excellent adsorbent. Doping HAP with graphene will further increase the adsorption capacity. HAP/graphene composite was successfully used as an adsorbent for the removal of methylene blue (M. A. Hassan et al. 2018). Similarly, Congo red and trypan blue dyes were removed by another HAP/graphene (Prabhu et al. 2018). These researchers have concluded that the adsorption efficiency of the HAP/graphene composite is higher than the individual components. Table 3 depicts the adsorption of different dyes by various HAP nanocomposites with their experimental conditions.

Dye removal by HAP nanocomposite

Dye removal by HAP nanocomposite is recently practiced. Adsorption takes place when adsorbate enters adsorbent through diffusion due to affinity between them. Adsorbate enters deep into adsorbent as time proceeds occupying all the available vacant sites (Trivedi and Mandavgane 2018).

Anionic dye removal

HAP/chitosan nanocomposite was used to remove the anionic reactive blue 19 dye in which adsorption capacity was higher at low pH as anionic dyes are negatively charged (Nguyen and Pho 2014). As pH increases, the adsorbent surface becomes negatively charged which decreases adsorption. Similar results were observed in a study where an acid yellow dye was adsorbed by four different HAP nanocomposites (Manatunga et al. 2018). Congo red dye was removed by HAP/chitosan composite wherein an increase in adsorption capacity was due to hydrogen bonding between amino groups of Congo red and hydroxyl ion of the adsorbent (Hou et al. 2012).

Three anionic dyes (methyl red, methyl orange and, and methyl yellow) were adsorbed on HAP/palladium/iron composite which revealed that the adsorption was affected due to change in the structure of adsorbent due to calcination and addition of palladium degraded dye by oxidation (Safavi and Momeni 2012). Removal of methyl orange by HAP micro composite film showed an increase in adsorption with the increase in adsorbent dosage (Azzaoui et al. 2019).

HAP/CeO2 composite was used to remove Erichrome black T. It was evident that with the decrease in pH adsorption increased as deprotonation of phosphate ions repulse adsorbent at high pH. An increase in adsorption was observed with an increase in the concentration of the dye and surface area (Chaudhary et al. 2016). Similar results were shown in the study on the removal of lead and acid yellow dye by HAP/chitosan and HAP/carboxymethyl cellulose (Manatunga et al. 2016).

Reactive red 141 was adsorbed on HAP and HAP/titanium to check which adsorbent was best suitable for adsorption (Asjadi et al., 2016). The effect of initial concentration and the adsorbent dosage was similar to the above studies. The addition of titanium modified the structure of bare HAP making it favorable for adsorption at higher pH. Hydrogen bonding between HAP and nitrogen in dye was prominently responsible for adsorption. Doped HAP had higher adsorption capacity than bare HAP due to higher surface area.

Cationic dye removal

Two basic dyes brilliant green and crystal violet were adsorbed on kaolinite (Sarma et al., 2019). The electrostatic attraction was the main adsorption mechanism. Crystal violet had higher adsorption efficiency than brilliant green due to the larger dimension and greater number of binding sites. Methylene blue was adsorbed on MHAP (Y. Wang et al. 2017). Adsorption was mainly due to electrostatic interactions and the functional groups –OH and –COOH of carbon nanotubes.

Adsorption of brilliant green on HAP chitosan composite showed optimum adsorption at pH 7 and other factors such as dosage, the concentration of dye, and contact time which were directly proportional to adsorption (Ragab et al., 2019). Rhodamine B was adsorbed on HAP/alginate composite in a study conducted by Oladipo and Gazi (2016) where both batch and continuous studies were conducted. In a continuous study, the depth of adsorbent and flow rate of dye affected the adsorption. Malachite green was adsorbed on a polysaccharide-based graphene HAP nanocomposite where electrostatic interactions were predominant in adsorption process (Hosseinzadeh and Ramin 2018).

Adsorption mechanism

It is well known that electrostatic interactions, hydrogen bonding, and ion exchange effects are the main possible mechanisms in the adsorption process. Hydrogen atom in HAP bonds to electronegative atom of dye to form strong hydrogen bond resulting in breaking of the complex structure of dye (Hou et al. 2012). Electrostatic interactions are principally triggered due to attraction and repulsion of counter and co-ions of HAP composites and dye molecules (Sarma et al., 2019). The description of the interactions of different functional groups in the process is surface complexation. Functional groups responsible for adsorption can be analyzed by FTIR of adsorbent before and after adsorption (Y. Wang et al. 2017). Phosphate ions in HAP composite are predominant in the ion exchange effect. Exchange of certain significant pollutant ion from the dye with this phosphate ion results in the removal of a considerable amount of contaminant from dye reducing its toxicity (You et al. 2019). Figure 6 depicts pictorial representations of mechanisms.

Adsorption isotherms, kinetics, and thermodynamic studies

The adsorption process is demonstrated by graphs showing the variation of adsorbed material with pressure at a constant temperature which is known as adsorption isotherm. Isotherms like Langmuir, Freundlich, and Temkin give the nature of adsorption. Monolayer or multilayer adsorption is depicted by isotherms. Adsorption kinetics are represented by pseudo first-order and second-order models. Determination of exothermic, endothermic, and spontaneous reaction is accomplished by adsorption thermodynamics.

Adsorption isotherms

Commonly used isotherms in the dye removal process are briefly discussed in this section. Langmuir, Freundlich, and Temkin are commonly used isotherms due to their simplicity and variable parameters. Langmuir and Freundlich isotherm equation can be altered into linear form and can be assessed effortlessly by graphical procedures (Oyekanmi et al. 2019).

Langmuir isotherm:

Freundlich isotherm:

Temkin isotherm:

where Qe is the amount of dye adsorbed per gram of the adsorbent at equilibrium (mg/g), Qo is the maximum monolayer coverage capacity (mg/g), b is the Langmuir isotherm constant (l/mg), Ce is the equilibrium concentration of adsorbate (mg/L) , Kf is the Freundlich isotherm constant (mg/g), R is universal gas constant (8.314 J/mol/K), T is the temperature at 298 K, AT is the Temkin isotherm equilibrium binding constant (l/g), and bT is the Temkin isotherm constant

Langmuir isotherm depends on the rate of adsorption and desorption which is assumed to be equal at equilibrium (Patiha et al. 2016).

Freundlich isotherm is used for heterogeneous surfaces. It describes multilayer adsorption, unlike Langmuir which demonstrates monolayer adsorption. It is based on the assumption in which vacant sites for adsorption are adsorbed first depending on their binding capacity till adsorption energy is decreased exponentially (Foo and Hameed 2010).

Temkin isotherm is based on assuming that there is a linear decrease in heat of adsorption with sorption coverage (Sampranpiboon 2014). This isotherm reveals that adsorption is exothermic or endothermic. Various isotherms used by different HAP nanocomposites are cited in Table 3.

Adsorption kinetics

The adsorption kinetics demonstrates the proportion of uptake dye molecules by the adsorbent (Lin 2015). Generally, used equations are pseudo first-order and pseudo second-order equations which describe physisorption and chemisorption respectively (Patiño-Ruiz et al. 2019).

Pseudo first-order:

Pseudo second-order:

where k and k1 are pseudo first-order and second-order rate constants. Various dye adsorption on HAP nanocomposite shows different kinetic model as mentioned in Table 3.

Thermodynamics study

Thermodynamics relates adsorption isotherms in equilibrium and reveals the spontaneity of the process (Myers 2002). There are three main parameters considered such as (i) Gibb’s free energy, indicating spontaneity of reaction, (ii) enthalpy, indicating exothermic and endothermic nature of the reaction, and entropy which is calculated by using equations given below.

where Kd is the distribution coefficient.

HAP/zein composite was used to adsorb Congo red in Nasab et al., 2018). Thermodynamic parameters were calculated by Vant Hoff’s equation indicating reaction being spontaneous and endothermic. Similar results were obtained in a study where methyl orange is adsorbed on HAP composite (Azzaoui et al. 2019), methylene blue was adsorbed on HAP composite (Y. Wang et al. 2017), and malachite green adsorption on HAP composite (Hosseinzadeh and Ramin 2018).

Methylene blue adsorption by HAP/alginate composite revealed that the adsorption process was spontaneous and exothermic, and ∆S being positive indicated nonaffinity of adsorbate extending the reaction process (Aslanov et al., 2017). Methylene blue adsorption by HAP/ polyacrylamide composite showed that the reaction is exothermic. Spontaneity reduced with an increase in the temperature, and ∆S being negative indicated a reduction in affinity of adsorbent and adsorbate at the interface (Mansri et al., 2019).

Regeneration of HAP nanocomposites

The overall waste management system is crucial in every aspect. Reduction in the amount of waste can be accomplished by three R’s “Reduce, Reuse, Recycle.” The adsorbent can be reused after desorption. Generally, a solvent is used against saturated adsorbent which causes it to release the adsorbed pollutant. In the case of MHAP, it is easy to remove adsorbent from the solution by using a neodymium magnet even though there is a slight reduction in adsorption capacity for each cycle after adsorption (Zhang et al. 2016). Practical application is directly dependent on good reusability.

HAP/biochar composite saturated with methylene blue dye was desorbed using weak acid as a solvent. A remarkable reduction in adsorption was found in the first cycle due to the solubility of HAP in weak HCl used as solvent (Y. Li et al. 2018). HAP/chitosan composite saturated with methylene blue and sunset yellow was desorbed by washing several times with deionized water followed by water-ethanol mixture at pH 12. No adsorbent loss or reduction in adsorption capacity of desorbed samples was found up to five cycles signifying stability of composite at a wide pH range (Chatterjee et al. 2018).

Conclusion and future scope

This review is summarized to give a brief idea about both anionic and cationic dye removal by various HAP nanocomposites and study their adsorption mechanism. Electrostatic interactions, hydrogen bonding, and ion exchange effects are the three main dye removal mechanisms that are concisely discussed. The review discloses that the greater adsorption capacity is a result of either modified or composite adsorbent with a high surface area. Besides, the constraints such as pH, initial dye concentration, temperature, and adsorbent dose are vital factors which illustrate substantial effects on dyes adsorption. Frequently used isotherms, kinetic models, and thermodynamic equations that describe the adsorption process with its type and nature are conversed in this review. Future studies can be done on the simultaneous removal of different constituents from dye effluents rather than focusing only on color removal. Being eco-friendly, synthesizing different adsorbents via green route is the area of interest that can be investigated. Cost analysis is an important factor that can be done in further studies.

References

Abd-Elhamid AI et al (2019) Evaluation of graphene oxide-activated carbon as effective composite adsorbent toward the removal of cationic dyes: composite preparation, characterization and adsorption parameters. J Mol Liq 279:530–539. https://doi.org/10.1016/j.molliq.2019.01.162

Ahmed YMZ, El-Sheikh SM, Zaki ZI (2015) Changes in hydroxyapatite powder properties via heat treatment. Bull Mater Sci 38(7):1807–1819

Akarslan F, Demiralay H (2015) Effects of textile materials harmful to human health. Acta Phys Pol A 128(2):407–408

Amirthalingam N, Deivarajan T, Paramasivam M (2019) Mechano chemical synthesis of hydroxyapatite using dolomite. Mater Lett 254:379–382. https://doi.org/10.1016/j.matlet.2019.07.118

Asjadi F, Salahi E, Mobasherpour I (2016) Removal of Reactive Red 141 Dye from aqueous solution by titanium hydroxyapatite pellets. J Dispers Sci Technol 37(1):14–22

Aslanov T, Uzunoğlu D, Özer A (2017) Synthesis of hydroxyapatite-alginate composite: methylene blue adsorption. Sinop Uni J Nat Sci 2(1) 2(1):37–47

Azzaoui K et al (2019) Preparation of hydroxyapatite biobased micro composite film for selective removal of toxic dyes from wastewater. Desalin Water Treat 149:194–208

Bakre N, Mathur N, Bhatnagar P (2005) Assessing mutagenicity of textile dyes from Pali (Rajasthan) using ames bioassay. Appl Ecol Environ Res 4(1):111–118

Bharti V, Vikrant K, Goswami M, Tiwari H, Sonwani RK, Lee J, Tsang DCW, Kim KH, Saeed M, Kumar S, Rai BN, Giri BS, Singh RS (2019) Biodegradation of methylene blue dye in a batch and continuous mode using biochar as packing media. Environ Res 171:356–364. https://doi.org/10.1016/j.envres.2019.01.051

Canillas M et al (2017) Processing of hydroxyapatite obtained by combustion synthesis. Boletin de la Sociedad Espanola de Ceramica y Vidrio 56(5):237–242. https://doi.org/10.1016/j.bsecv.2017.05.002

Chahkandi M (2017) Mechanism of Congo red adsorption on new sol-gel-derived hydroxyapatite nano-particle. Mater Chem Phys 202:340–351. https://doi.org/10.1016/j.matchemphys.2017.09.047

Chaikina MV et al (2019) Interaction of calcium phosphates with calcium oxide or calcium hydroxide during the ‘soft’ mechanochemical synthesis of hydroxyapatite. Ceram Int (May):1–7. https://doi.org/10.1016/j.ceramint.2019.05.239

Chatterjee S, Gupta A, Mohanta T, Mitra R, Samanta D, Mandal AB, Majumder M, Rawat R, Singha NR (2018) Scalable synthesis of hide substance-chitosan-hydroxyapatite: novel biocomposite from industrial wastes and its efficiency in dye removal. ACS Omega 3(9):11486–11496

Chaudhary S, Sharma P, Renu, Kumar R (2016) Hydroxyapatite doped CeO 2 nanoparticles: impact on biocompatibility and dye adsorption properties. RSC Adv 6(67):62797–62809

Chu TPM et al (2019) Synthesis, characterization, and modification of alumina nanoparticles for cationic dye removal. Materials 12(3):1–15

Cinperi NC, Ozturk E, Yigit NO, Kitis M (2019) Treatment of woolen textile wastewater using membrane bioreactor, nanofiltration and reverse osmosis for reuse in production processes. J Clean Prod 223:837–848

Darvishalipour F, Ghafouri Taleghani H, Ghorbani M, Salimi Kenari H (2019) Fabrication of nanoporous functionalized hydroxyapatite as high performance adsorbent for acid blue 25 dye removal. Int J Eng 32(2):193–200

Djilani C et al (2015) Adsorption of dyes on activated carbon prepared from apricot stones and commercial activated carbon. J Taiwan Inst Chem Eng 53:112–121

Donneys-Victoria D, Bermúdez-Rubio D, Torralba-Ramírez B, Marriaga-Cabrales N, Machuca-Martínez F (2019) Removal of indigo carmine dye by electrocoagulation using magnesium anodes with polarity change. Environ Sci Pollut Res 26(7):7164–7176

Dotto J et al (2019) Performance of different coagulants in the coagulation/flocculation process of textile wastewater. J Clean Prod 208:656–665

El-Maghrabi HH et al (2019) Preparation and characterization of novel magnetic ZnFe2O4–hydroxyapatite core–shell nanocomposite and its use as fixed bed column system for removal of oil residue in oily wastewater samples. Egypt J Pet 28(2):137–144. https://doi.org/10.1016/j.ejpe.2018.12.005

Fernandes FH, de Aragão Umbuzeiro G, Salvadori DMF (2018) Genotoxicity of textile dye C.I. disperse blue 291 in mouse bone marrow. Mutat Res Genet Toxicol Environ Mutagen 837(2019):48–51. https://doi.org/10.1016/j.mrgentox.2018.10.003

Fihri A, Len C, Varma RS, Solhy A (2017) Hydroxyapatite: a review of syntheses, structure and applications in heterogeneous catalysis. Coord Chem Rev 347:48–76. https://doi.org/10.1016/j.ccr.2017.06.009

Foo K, Hameed B (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J:2–10

Nasab SG et al (2018) Removal of Congo red from aqueous solution by hydroxyapatite nanoparticles loaded on zein as an efficient and green adsorbent: response surface methodology and artificial neural network-genetic algorithm. J Polym Environ 26(9):3677–3697. https://doi.org/10.1007/s10924-018-1246-z

Gottardo B et al (2019) One-pot synthesis and antifungal activity of nontoxic silver-loaded hydroxyapatite nanocomposites against Candida species. ACS Applied Nano Materials:1–36

Gouthaman A et al (2019) Enhanced dye removal using polymeric nanocomposite through incorporation of Ag doped ZnO nanoparticles: synthesis and characterization. J Hazard Mater 373(November 2018):493–503. https://doi.org/10.1016/j.jhazmat.2019.03.105

Guo X et al (2013) Effect of calcining temperature on particle size of hydroxyapatite synthesized by solid-state reaction at room temperature. Adv Powder Technol 24(6):1034–1038. https://doi.org/10.1016/j.apt.2013.03.002

Hamzah S, Salleh MFM (2014) Hydroxyapatite/chitosan biocomposite for Remazol blue dyes removal. Appl Mech Mater 695:106–109

Harrache Z, Abbas M, Aksil T, Trari M (2019) Thermodynamic and kinetics studies on adsorption of indigo carmine from aqueous solution by activated carbon. Microchem J 144:180–189. https://doi.org/10.1016/j.microc.2018.09.004

Hassan H, Salama A, El-ziaty AK, El-Sakhawy M (2019) New chitosan/silica/zinc oxide nanocomposite as adsorbent for dye removal. Int J Biol Macromol 131:520–526. https://doi.org/10.1016/j.ijbiomac.2019.03.087

Hassan MA, Mohammad AM, Salaheldin TA, El-Anadouli BE (2018) A promising hydroxyapatite/graphene hybrid nanocomposite for methylene blue dye’s removal in wastewater treatment. Int J Electrochem Sci 13(8):8222–8240

He K et al (2019) Graphene hybridized polydopamine-kaolin composite as effective adsorbent for methylene blue removal. Compos Part B 161(October 2018):141–149. https://doi.org/10.1016/j.compositesb.2018.10.063

Horta M et al (2019) Synthesis and characterization of green nanohydroxyapatite from hen eggshell by precipitation method. Materialstoday: Proceedings 14:716–721. https://doi.org/10.1016/j.matpr.2019.02.011

Hosseinzadeh H, Ramin S (2018) Fabrication of starch-graft-poly (acrylamide)/graphene oxide/hydroxyapatite nanocomposite hydrogel adsorbent for removal of malachite green dye from aqueous solution. Int J Biol Macromol 106:101–115. https://doi.org/10.1016/j.ijbiomac.2017.07.182

Hou H, Zhou R, Wu P, Lan W (2012) Removal of Congo red dye from aqueous solution with hydroxyapatite/chitosan composite. Chem Eng J 211–212:336–342. https://doi.org/10.1016/j.cej.2012.09.100

Huang A et al (2019) Synthesis and characterization of mesoporous hydroxyapatite powder by microemulsion technique. Journal of Materials Research and Technology 8(3):3158–3166. https://doi.org/10.1016/j.jmrt.2019.02.025

Inthapanya X, Wu S, Han Z, Zeng G, Wu M, Yang C (2019) Adsorptive removal of anionic dye using calcined oyster shells: isotherms, kinetics, and thermodynamics. Environ Sci Pollut Res 26(6):5944–5954

Zahra JH, Nasab SG, Teimouri A (2019) Synthesis and characterisation of magnetic activated carbon/diopside nanocomposite for removal of reactive dyes from aqueous solutions: experimental design and optimisation. Int J Environ Anal Chem 99(6):568–594. https://doi.org/10.1080/03067319.2019.1597867

Jedynak K, Wideł D, Rędzia N (2019) Removal of rhodamine B (a basic dye) and acid yellow 17 (an acidic dye) from aqueous solutions by ordered mesoporous carbon and commercial activated carbon. Colloids and Interfaces 3(1):30

Khalil KA (2012) A New-developed nanostructured Mg/HAp nanocomposite by high frequency induction heat sintering process. Int J Electrochem Sci 7(11):10698–10710

Khan S, Butt S (2019) Synthesis of nano-hydroxyapatite and nano–fluoroapatite particles by sol-gel method. Pakistan Journal of Medicine and Dentistry 8(2):40–44

Lee MR et al (2019) Biocompatibility of a PLA-based composite containing hydroxyapatite derived from waste bones of dolphin neophocaena asiaeorientalis. J Aust Ceram Soc 55(1):269–279

Li JH et al (2019) Preparation of three dimensional hydroxyapatite nanoparticles/poly (vinylidene fluoride) blend membranes with excellent dye removal efficiency and investigation of adsorption mechanism. Chinese Journal of Polymer Science (English Edition) 37:1234–1247

Li Y et al (2018) Reed biochar supported hydroxyapatite nanocomposite: characterization and reactivity for methylene blue removal from aqueous media. J Mol Liq 263:53–63. https://doi.org/10.1016/j.molliq.2018.04.132

Lin J (2015) Comparison between linear and non-linear forms of pseudofirst-order and pseudo-second-order adsorption kinetic models for the removal of methylene blue by activated carbon. Front Environ Sci Eng China 3(3):320–324

Manatunga DC, De Silva RM, Nalin De Silva KM, Ratnaweera R (2016) Natural polysaccharides leading to super adsorbent hydroxyapatite nanoparticles for the removal of heavy metals and dyes from aqueous solutions. RSC Adv 6(107):105618–105630

Manatunga DC et al (2018) Metal and polymer-mediated synthesis of porous crystalline hydroxyapatite nanocomposites for environmental remediation. R Soc Open Sci 171557(5):1–15. https://doi.org/10.6084/m9.%0Afigshare.c.3967896

Mansri A, Mahroug H, Dergal F (2019) In situ preparation of hydroxyapatite composites into hydrolyzed polyacrylamide solution and methylene blue dye retention. Turk J Chem 43(1):213–228

Ministry of Textile Govt of India. 2018. Annual Report 2017-18.

Mishra AK (2016) Sol-gel based nanoceramic materials: preparation, properties and applications Sol-Gel Based Nanoceramic Materials: Preparation. Applications, Properties and

Mishra J et al (2019) Enhanced photocatalytic degradation of cyanide employing Fe-porphyrin sensitizer with hydroxyapatite palladium doped TiO2nano-composite system. J Mol Liq 287(110821):1–22. https://doi.org/10.1016/j.molliq.2019.04.098

Mohammad AM, Salah Eldin TA, Hassan MA, El-Anadouli BE (2017) Efficient treatment of lead-containing wastewater by hydroxyapatite/chitosan nanostructures. Arab J Chem 10(5):683–690. https://doi.org/10.1016/j.arabjc.2014.12.016

Myers AL (2002) Thermodynamics of adsorption in porous materials. AICHE J 48(1):145–160

Naushad, Mu. 2018. A new generation material graphene: applications in water technology A New Generation Material Graphene: Applications in Water Technology.

Naushad M (2019) Adsorption kinetics, isotherm and reusability studies for the removal of cationic dye from aqueous medium using arginine modified activated carbon. J Mol Liq 293:111442. https://doi.org/10.1016/j.molliq.2019.111442

Nguyen VC, Pho QH (2014) Preparation of chitosan coated magnetic hydroxyapatite nanoparticles and application for adsorption of reactive blue 19 and Ni 2 + ions. Sci World J 2014:1–9

Oladipo AA, Gazi M (2016) Uptake of Ni2+ and rhodamine B by nano-hydroxyapatite/alginate composite beads: batch and continuous-flow systems. Toxicol Environ Chem 98(2):189–203

Oyekanmi AA, Ahmad A, Hossain K, Rafatullah M (2019) Adsorption of rhodamine B dye from aqueous solution onto acid treated banana peel: response surface methodology, kinetics and isotherm studies. PLoS One 14(5):1–20

Patiha E, Heraldy YH, Firdaus M (2016) The langmuir isotherm adsorption equation: the monolayer approach. IOP Conference Series: Materials Science and Engineering 107(1)

Patiño-Ruiz D, Bonfante H, De Ávila G, Herrera A (2019) Adsorption kinetics, isotherms and desorption studies of Hg(II) from aqueous solution at different temperatures on magnetic sodium alginate-thiourea microbeads. Environmental Nanotechnology, Monitoring & Management 12:100243 https://linkinghub.elsevier.com/retrieve/pii/S2215153219300455

Phasuk A, Srisantitham S, Tuntulani T, Anutrasakda W (2018) Facile synthesis of magnetic hydroxyapatite-supported nickel oxide nanocomposite and its dye adsorption characteristics. Adsorption 24(2):157–167. https://doi.org/10.1007/s10450-017-9931-0

Piccirillo C, Castro PML (2017) Calcium hydroxyapatite-based photocatalysts for environment remediation: characteristics, performances and future perspectives. J Environ Manag 193:79–91. https://doi.org/10.1016/j.jenvman.2017.01.071

Prabhu SM et al (2018) Synthesis and characterization of graphene oxide-doped nano-hydroxyapatite and its adsorption performance of toxic diazo dyes from aqueous solution. J Mol Liq 269:746–754. https://doi.org/10.1016/j.molliq.2018.08.044

Pramanik S, Avinash K, Rai KN, Garg A (2007) Development of high strength hydroxyapatite by solid-state-sintering process. Ceram Int 33(3):419–426

Qi C et al (2016) Sonochemical synthesis of hydroxyapatite nanoflowers using creatine phosphate disodium salt as an organic phosphorus source and their application in protein adsorption. RSC Adv 6(12):9686–9692. https://doi.org/10.1039/C5RA26231C

Ragab A, Ahmed I, Bader D (2019) The removal of brilliant green dye from aqueous solution using nano hydroxyapatite/chitosan composite as a sorbent. Molecules 24(5):847

Ruffini A, Sprio S, Preti L, Tampieri A (2019) Biomaterial-supported Tissue Reconstruction or Regeneration. In: Synthesis of nanostructured hydroxyapatite via controlled hydrothermal route

Sadat-shojai M, Khorasani M-t, Dinpanah-khoshdargi E, Jamshidi A (2013) Synthesis methods for nanosized hydroxyapatite with diverse structures. Acta Biomater 9(8):7591–7621. https://doi.org/10.1016/j.actbio.2013.04.012

Sadeghizadeh A et al (2019) Adsorptive removal of Pb(II) by means of hydroxyapatite/chitosan nanocomposite hybrid nanoadsorbent: ANFIS modeling and experimental study. J Environ Manag 232(November 2018):342–353. https://doi.org/10.1016/j.jenvman.2018.11.047

Safavi A, Momeni S (2012) Highly efficient degradation of azo dyes by palladium/hydroxyapatite/Fe 3O 4 nanocatalyst. J Hazard Mater 201–202:125–131

Sahoo JK et al (2019) Magnetic hydroxyapatite nanocomposite: impact on eriochrome black-T removal and antibacterial activity. J Mol Liq 294:111596. https://doi.org/10.1016/j.molliq.2019.111596

Sampranpiboon P (2014) Equilibrium isotherm models for adsorption of zinc (II) ion from aqueous solution on pulp waste faculty of engineering. WSEAS Trans Environ Dev 10:35–47

dos Santos AB, Cervantes FJ, van Lier JB (2007) Review paper on current technologies for decolourisation of textile wastewaters: perspectives for anaerobic biotechnology. Bioresour Technol 98(12):2369–2385

Sarker M, Shin S, Jeong JH, Jhung SH (2019) Mesoporous metal-organic framework PCN-222(Fe): promising adsorbent for removal of big anionic and cationic dyes from water. Chem Eng J 371(March):252–259. https://doi.org/10.1016/j.cej.2019.04.039

Sarma GK, Sen Gupta S, Bhattacharyya KG (2019) Removal of hazardous basic dyes from aqueous solution by adsorption onto kaolinite and acid-treated kaolinite: kinetics, isotherm and mechanistic study. SN Applied Sciences 1(3):1–15. https://doi.org/10.1007/s42452-019-0216-y

Sathiskumar S et al (2019) Green synthesis of biocompatible nanostructured hydroxyapatite from Cirrhinus mrigala fish scale – a biowaste to biomaterial. Ceram Int 45(6):7804–7810. https://doi.org/10.1016/j.ceramint.2019.01.086

Shertate RS, Thorat P (2014) Biotransformation of textile dyes: a bioremedial aspect of marine environment. Am J Environ Sci 10(5):489–499

Shetti NP et al (2019) Electrochemical detection and degradation of textile dye Congo red at graphene oxide modified electrode. Microchem J 146(2018):387–392. https://doi.org/10.1016/j.microc.2019.01.033

Singh NB, Rachna K, Agrawal A (2019) Methylene blue dye removal from water by nickel ferrite polyaniline nanocomposite. J Sci Ind Res 78:118–121

Sözen S, Olmez T, Masoomeh H, Derin H (2019) Fenton oxidation for effective removal of color and organic matter from denim cotton wastewater without biological treatment. Environ Chem Lett:1–7. https://doi.org/10.1007/s10311-019-00923-8

Sreedhar B, Aparna Y, Sairam M, Hebalkar N (2007) Preparation and characterization of HAP/carboxymethyl chitosan nanocomposites. J Appl Polym Sci 105(2):928–934

Szcześ A, Hołysz L, Chibowski E (2017) Synthesis of hydroxyapatite for biomedical applications. Adv Colloid Interf Sci 249:321–330

Tan, Tina Co Nnie, and Tushar Kanti Sen. 2019. Aqueous-phase methylene blue (MB) dye removal by mixture of eucalyptus bark (EB) biomass and kaolin clay (KC) adsorbents: kinetics, thermodynamics, and isotherm modeling. Separation Science and Technology (Philadelphia) : 1–15. https://doi.org/10.1080/01496395.2019.1580734.

Tanhaei B, Ayati A, Sillanpää M (2019) Magnetic xanthate modified chitosan as an emerging adsorbent for cationic azo dyes removal: kinetic, thermodynamic and isothermal studies. Int J Biol Macromol 121:1126–1134. https://doi.org/10.1016/j.ijbiomac.2018.10.137

Trivedi NS, Mandavgane SA (2018) Fundamentals of 2 , 4 dichlorophenoxyacetic acid removal from aqueous solutions. Sep Purif Rev:1–18. https://doi.org/10.1080/15422119.2018.1450765

Türk S et al (2019) Effect of solution and calcination time on sol-gel synthesis of hydroxyapatite. Journal of Bionic Engineering 16(2):311–318

Vankar PS (2000) Chemistry of natural dyes. Resonance 5(10):73–80

Varaprasad K, Nunez D, Yallapu MM, Jayaramudu T, Elgueta E, Oyarzun P (2018) Nano-hydroxyapatite polymeric hydrogels for dye removal. RSC Adv 8(32):18118–18127

Venkatesh K, Venkatesh S (2019) Ozonation for degradation of acid red 14: effect of buffer solution. Proceedings of the National Academy of Sciences, India Section A: Physical Sciences:2–5. https://doi.org/10.1007/s40010-018-0583-6

Wang MC et al (2015) Crystalline size, microstructure and biocompatibility of hydroxyapatite nanopowders by hydrolysis of calcium hydrogen phosphate dehydrate (DCPD). Ceram Int 41(2):2999–3008. https://doi.org/10.1016/j.ceramint.2014.10.135

Wang Y, Hu L, Zhang G, Yan T, Yan L, Wei Q, du B (2017) Removal of Pb(II) and methylene blue from aqueous solution by magnetic hydroxyapatite-immobilized oxidized multi-walled carbon nanotubes. J Colloid Interface Sci 494:380–388. https://doi.org/10.1016/j.jcis.2017.01.105

Wolff J et al (2018) Rapid wet chemical synthesis for 33 P-labelled hydroxyapatite – an approach for environmental research. Appl Geochem 97:181–186. https://doi.org/10.1016/j.apgeochem.2018.08.010

Yan L et al (2019) Dynamic adsorption of As(V) by hydroxyapatite/bagasse biomass carbon composite adsorbent. IOP Conference Series: Materials Science and Engineering 490(032037):1–7

Yelten-Yilmaz A, Yilmaz S (2018) Wet chemical precipitation synthesis of hydroxyapatite (HA) powders. Ceram Int 44(8):9703–9710. https://doi.org/10.1016/j.ceramint.2018.02.201

You Y, KeqiQu, Huang Z, Ma R, Shi C, Li X, Liu D, Dong M, Guo Z (2019) Sodium alginate templated hydroxyapatite/calcium silicate composite adsorbents for efficient dye removal from polluted water. Int J Biol Macromol 141:1035–1043. https://doi.org/10.1016/j.ijbiomac.2019.09.082

Yusuf M (2019) Synthetic dyes : a threat to the environment and water ecosystem. Textiles and Clothing:11–26

Zhang F, Ma B, Jiang X, Ji Y (2016) Dual function magnetic hydroxyapatite nanopowder for removal of malachite green and Congo red from aqueous solution. Powder Technol 302:207–214. https://doi.org/10.1016/j.powtec.2016.08.044

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible Editor: Tito Roberto Cadaval Jr

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pai, S., Kini, M.S. & Selvaraj, R. A review on adsorptive removal of dyes from wastewater by hydroxyapatite nanocomposites. Environ Sci Pollut Res 28, 11835–11849 (2021). https://doi.org/10.1007/s11356-019-07319-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07319-9