Abstract

A new approach for easy synthesis of Bacillus pseudomycoides immobilized polyvinyl alcohol (PVA)/glutaraldehyde (GA) hydrogel for application in a wastewater treatment system is reported. Optimization studies revealed that GA/PVA mass ratio of 0.03 and acidic pH of 2 were required for hydrogel synthesis and eventually for bacterial cell immobilization. The synthesized crosslinked matrix possessed a pore size suitable for microbial cell entrapment while maintaining cell accessibility to external environment for bioremediation. Possible crosslinking and bacterial cell immobilization in the hydrogel were evidenced by FTIR, XRD, and SEM studies, respectively. Further, the extent of crosslinking of GA with PVA was investigated and confirmed by transmittance and permeability experiments. The viability and proliferation of hydrogel embedded cells (after 25 days) was confirmed by confocal fluorescence microscopy which also indicated that acidic pH of polymer solution did not affect the immobilized live cells. B. pseudomycoides immobilized hydrogel were demonstrated to be effective for treatment of municipal wastewater and reduced biochemical oxygen demand (BOD), chemical oxygen demand (COD), and protein content below the recommended levels. Overall, the results from this bench-scale work show that employing bacteria-embedded PVA/GA hydrogel for the treatment of municipal wastewater yield promising results which should be further explored in pilot/field-scale studies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Technology involving microorganisms immobilized in a polymeric matrix has been efficiently used in wastewater treatment (Halma et al. 2015; Jianlong et al. 2002; Paula et al. 2015; Xu et al. 2015; Zhang et al. 2016). Immobilized microbial cells in a polymeric gel have significant advantages for wastewater treatment over free cells. First, immobilization provides high cell density at any particular time for their long-term and effective action in the treatment process. Second, the cells entrapped are protected from adverse environmental stresses (Cho et al. 2006; Hsia et al. 2008; Lee and Cho 2010). Third, it provides an easy way of separating treated water and solid sludge, i.e. liquid-solid separation (Lee and Cho 2010; Zhang et al. 2016). Immobilizing single bacterium (pure culture) is easier and more beneficial for a specific application than the whole microbial community isolated from a complex polluted system which may comprise of myriad microorganisms like bacteria, algae, viruses, fungi, etc. In a multi-species microbial community, the synergistic/antagonistic effects of microbial consortia, interdependent community growth patterns, and wide-ranging metabolic activities are complicated with high degree of variability making it difficult to achieve a defined or specific application. Several natural and synthetic polymers have been evaluated for their potential to serve as a suitable support matrix material for immobilization of viable microbial cells in wastewater applications (Leenen et al. 1996).

Microbial cells are typically able to survive the immobilization process and grow well in the matrix of natural polymers like alginate and carrageenan (Lozinsky and Plieva 1998). Immobilized cells, however, have less practical applications in wastewater treatment owing to several limitations including uninhibited hydration rate, high contamination rate, and loss of adhesiveness over long-term (approximately 20–25 days) storage (Labus et al. 2015; Suhag et al. 2015). Thus, the characteristics of the supporting material/carrier are important for effective immobilization of microbes and their use in wastewater treatment.

Polyvinyl alcohol, i.e. PVA, with chemical formula [CH2CH(OH)]n, colorless, synthetic, biocompatible, semi-crystalline white material, is a promising candidate for the hydrogel support matrix due to its high mechanical strength, hydrophilicity, high hydraulic shock resistance (in the wastewater treatment chamber), non-toxicity, biocompatibility, and low cost (Lee and Cho 2010). Moreover, the PVA hydrogel has high permeability, which is essential to allow the contaminants in wastewater to be exposed to and degraded by the immobilized microbes in the gel. Unaltered PVA hydrogel has low stability when placed in water or any biological fluid, which reduces its efficiency (Figueiredo et al. 2009). Upon crosslinking, however, the hydrophilic polymer forms an insoluble compressed material under the influence of pressure (Bolto et al. 2009). Crosslinking provides the requisite hydrophobicity to PVA hydrogel and increases its stability and ability to entrap biomolecules including live microorganisms—making the PVA hydrogel favorable for various applications. Various physical and chemical methods have been employed to synthesize crosslinked, insoluble PVA hydrogel. These methods, however, are associated with several disadvantages. For example, physical methods like irradiation-based crosslinking that employ gamma and electron beam radiations can degrade some polymers/microbes, if immobilized in hydrogel, during the hydrogel preparation (Shakeel et al. 2017; van de Wetering et al. 2005; Wu et al. 2011). Various crosslinkers have been reported in the literature to crosslink PVA, including sulphosuccinic acid (Tsai et al. 2010), poly styrene sulfonic acid-co-maleic acid (PSSA-MA) with glutaraldehyde (Kang et al. 2005), sulfophthalic acid with sulfoacetic acid (Chanthad and Wootthikanokkhan 2006; Seeponkai and Wootthikanokkhan 2007), maleic acid (Gohil et al. 2006), and glutaraldehyde (Varshosaz and Koopaie 2002). Glutaraldehyde, a bifunctional crosslinker molecule, has two aldehyde groups one of which may react with the hydroxyl group of polyvinyl alcohol, forming a hemiacetal (in the polymeric network) while the other does not react due to a kinetic or conformational limitation (Mansur et al. 2008). Other than being a crosslinker, glutaraldehyde also acts as a preservative, by preventing any cross-contamination to the available bacterial growth. Furthermore, glutaraldehyde helps to preserve microbial enzyme activity which helps in their growth and metabolism, and results in a higher shelf life (or longer period of viability) for the entrapped microbes (Figueiredo et al. 2009; Russell and Hopwood 1976).

Hydrogel beads/films made from PVA crosslinked by glutaraldehyde have been previously used for drug delivery (Figueiredo et al. 2009; Varshosaz and Koopaie 2002), for controlled drug release (More et al. 2010), for microbial fuel cells (Rudra et al. 2015), and for the study of water-proofing properties (Marin et al. 2014). In most of these studies, however, the formation of the 3-dimensional network of the polymeric gel as well as cell immobilization procedure is arduous, cumbersome, and time consuming. Preparation time of ~ 6 h has been reported by Rudra et al. (2015) and 72 h by Mansur et al. (2008). Also, the survival of the cells in these supports was reportedly poor. Unfortunately, there is lack of a systematic study to characterize and improve PVA/GA hydrogel properties under varying physical-chemical and environmental factors, e.g. polymer concentration, pH, and salinity for specific applications, especially wastewater treatment. Swelling characteristic of hydrogel is an important aspect because swelling behavior relates to the pore size which is important for bacterial cell immobilization. Hydrogel swelling is also important for the transport of various biomolecules/drugs through hydrogels as the transportation primarily depends on the amount of water present in the hydrogel system (Kodavaty and Deshpande 2014).

In the current study, we investigated a range of PVA/GA mass ratios under varying pH, temperature, and salinity conditions to systematically assess and optimize the hydrogel formation and functionality. We also report the kinetics of hydrogel swelling and describe an expedited, single-step method for the formation of PVA/GA hydrogel (Fig. 1) and immobilization of viable microbial cells within the hydrogel. Not only was the viability of cells in the hydrogel maintained for more than 3 weeks, the concentration of viable cells increased during that time period. Further, results from a test application of the developed hydrogels to treat local municipal wastewater demonstrated effective removal of organics and proteins upon exposure to the PVA/GA hydrogels immobilized with bacteria isolated from the wastewater. Overall, this work reports results from a systematic study investigating the development and characterization of robust PVA/GA hydrogels with specific applications for wastewater treatment, which could also have potential implications for wider use of PVA/GA hydrogel.

Materials and methods

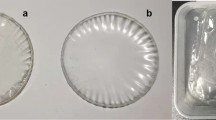

PVA/GA hydrogel synthesis

An aqueous homogenized 100 mL solution of 5 wt% PVA (molecular weight 44.05 g.mol−1; degree of hydrolysis 85–89%; Thermo Fisher Scientific Pvt. Ltd., India) was prepared under continuous magnetic stirring at temperature 70 ± 5 °C. The solution was allowed to cool to room temperature and the pH was maintained at 2 ± 0.05 with 1 M HCl. PVA/GA hydrogels were synthesized by mixing 20 mL of 5 wt% aqueous PVA solution with 6.25 % aqueous GA solution (molecular weight 100.12 g.mol−1; Central Drug House Pvt. Ltd., India). Different GA volumes of 0.5, 1, 2, 3, 4, and 5 mL were used to provide varying PVA/GA mass ratios. These solutions were mixed well and poured into a plastic mold and allowed to solidify at room temperature, producing disc-shaped optically transparent PVA/GA hydrogels of ~ 2 ± 0.03 g in approximately 2 h. Double distilled deionized water was used to prepare all the solutions.

Swelling behavior of PVA/GA hydrogel

The swelling capacity and swelling kinetics of the hydrogel is an indicator of its permeability and structural integrity, which are important parameters for the hydrogel performance. As the prepared hydrogels are introduced in a water solution, they absorb water and increase in weight and size. The weight of the hydrogel before and after swelling was measured. The swelling behavior of the PVA/GA hydrogels was thus evaluated under varying GA/PVA mass ratios, as mentioned above. For the hydrogel with the optimal mass ratio, further tests were done to determine the effect of varying temperature and chemical characteristics (like ionic strength and pH) of the solution into which the hydrogels were introduced.

Ionic strength variation

Swelling capacity of the selected hydrogels was assessed in 0.15 M solutions of NaCl, CaCl2, and AlCl3 such that their ionic strength values were 0.15, 0.45, and 0.9 M, respectively. The ionic strength was calculated as 0.5 × \( \Sigma {C}_i{Z}_i^2 \), where Ci is the concentration of the ionic species “i”, and Zi is the ionic charge on species “i”. Deionized water was used as control. For evaluating the effect of pH, the hydrogels were submerged in 50 mL of phosphate buffer solution at pH 3, 6, and 9, and the swelling capacity was assessed for each of the samples after every 5 min until they attained equilibrium. For temperature tests, deionized water was used at temperature ranging from 50 to 100 °C.

The swelling capacity (or ratio) at time t, Qt, was calculated according to Eq. (1) below.

where Wt is the weight of the hydrogel in swollen state at time t, and W0 is the initial weight of the dry hydrogel (Li et al. 2011).

Swelling kinetics of PVA/GA hydrogel

The swelling behavior of hydrogel with time for different GA/PVA mass ratio was estimated assuming that swelling process followed the first order kinetics, according to the equation:

Where t is the swelling time, Qt denotes swelling capacity at time t, Qe is the equilibrium swelling capacity, Q0 is the swelling capacity at initial time t0, dQt/dt is the rate of swelling, and k denotes the swelling rate constant.

By integrating Eq. (2), we get:

This can also be written as:

For measuring the swelling capacity at a particular time t, prepared PVA/GA hydrogels were submerged in deionized double distilled water for that particular time interval and then their swelling ratio % was calculated using Eq. (1) (Li et al. 2011; Zhang and Ye 2014).

Permeability of PVA/GA hydrogel

Hydrogels of different GA/PVA mass ratios were fully swollen in deionized double distilled water to equilibrium and their permeability was determined by immersing the hydrogels in diluted (1:1 of 50 ppm) Acid Black 24 dye (purchased from Control Textile Ltd., Ghaziabad, India) and leaving undisturbed for 4 h at room temperature. The UV transmission of the dye solution was also measured at wavelengths ranging from 400 to 800 nm.

Isolation of bacterial isolates from wastewater

Municipal wastewater samples were collected in 2000 mL sterile plastic bottles from the wastewater treatment plant located at Noida, Uttar Pradesh, India (28.535°N, 77.391°E). Samples were transported to the laboratory within 2 h and stored in the refrigerator at 4 °C until further use. Ten millilitres of wastewater sample was serially diluted till 10 dilutions using nutrient broth and plated repeatedly for approximately 15 to 20 times to select 40 different bacterial strains based on colony morphological characteristics.

The isolated bacterial strains were cultivated in nutrient broth or NB medium (peptone 5 g.L−1, NaCl 5 g.L−1, meat extract 1.5 g.L−1, and yeast extract 1.5 g.L−1) at final pH of 7.4 ± 0.2, and at 25 °C temperature (Aneja 2005). The isolates were characterized using several standard biochemical tests like amylase production test, cellulase production test, hydrogen sulphide (H2S) production test, urease test, gelatin hydrolysis test, casein hydrolysis test, citrate utilization test, catalase test, methyl-red test, Voges-Proskauer test, indole test, carbohydrate catabolism, and triple sugar iron (TSI) test as per standard protocols (Aneja 2005). In addition, isolated bacteria were also tested for their growth in wastewater and for their potential to treat/remediate wastewater parameters such as biochemical oxygen demand or BOD, chemical oxygen demand or COD, and protein content. BOD and COD were determined according to the standard protocols described in APHA (APHA/AWWA/WEF 2012), and Lowry’s method was employed for protein content estimation (Lowry et al. 1951). Glycerol stocks of isolated pure strains were prepared and stored at − 80 °C until further use.

The bacterial strain that showed maximum positive results in the biochemical tests, highest growth rate, and was the most efficient in wastewater treatment (demonstrated by reduction of BOD, COD, and protein content of the wastewater effluent) was selected for immobilization in the hydrogels.

Identification and phylogenetic analysis of the selected bacterium

Bacterial strain was identified using 16S rRNA sequencing analysis using single-pass sequencing method. The sequencing was carried out at Yaazh Xenomics, Coimbatore, Tamil Nadu, India. Centrifuged 2 mL of bacterial culture (OD600 = 0.5) was used to extract genomic DNA using Pure Link Genomic DNA Mini Kit (Invitrogen, California). Extracted DNA was then amplified by polymerase chain reaction (PCR) in a thermocycler. Sequencing reactions were performed using ABI PRISM® BigDyeTM Terminator Cycle Sequencing kits with AmpliTaq® DNA polymerase (FS enzyme) (Applied Biosystems, CA). The samples after PCR were subjected to electrophoresis in an ABI 3730xl sequencer (Applied Biosystems, CA). FastQC program was employed for quality control of genomic information (Andrews 2010a, 2010b). The 16S rRNA sequence was queried through BLAST, the NCBI similarity search tool. The phylogeny analysis of query sequence with the closely related sequence of BLAST results was performed followed by multiple sequence alignments. The program MUSCLE 3.7 was used for multiple alignments of sequences (Edgar 2004). To remove alignment noise, the resulting aligned sequences were cured using the program Gblocks 0.91b, which eliminates poorly aligned positions and divergent regions (Talavera and Castresana 2007). Finally, the program PhyML 3.0 aLRT was used for phylogenetic tree construction and analysis, and HKY85 as substitution model. The program Tree Dyn 198.3 was used for tree rendering (Dereeper et al. 2008).

Preparation of bacteria immobilized PVA/GA hydrogel

PVA was homogenized and prepared as described in the section “PVA/GA hydrogel synthesis.” After the maintenance of pH, 0.5 mL of the selected bacterial culture (OD600 = 0.5; 1.31 × 109 CFU/mL) was added to the PVA solution, under sterilized conditions. Finally, 6.25% GA was added, with adequate mixing, to this PVA/bacteria solution to obtain bacteria immobilized PVA/GA hydrogel (henceforth referred to as BI PVA/GA hydrogel). The solution was finally poured into a plastic mold and allowed to solidify at room temperature for 2 h. A disc-shaped BI PVA/GA hydrogel weighing ~ 2.5 ± 0.04 g was obtained.

Attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR)

ATR-FTIR was conducted on pure PVA hydrogel, PVA/GA hydrogel, and bacteria immobilized PVA/GA hydrogel. Samples were prepared as 1–2 mm thick films and analysed using a Frontier Perkin Elmer ATR-FTIR (Massachusetts, USA) in the range of 4000 to 650 cm−1, using transmittance mode.

X-Ray diffraction (XRD)

XRD studies of raw polymer, PVA, and PVA/GA hydrogels of the chosen ratio, with and without bacteria, were conducted using Bruker D-8 powder X-ray diffractometer at room temperature. Powdered samples were filled in a sample holder and the surface was smoothened using a glass slide. The X-ray scanning was done over a range of 2θ values from 10° to 80°, using Cu Kα radiation source at wavelength = 1.54 Å (Minhas et al. 2013).

Scanning electron microscopy (SEM)

The microstructure morphologies of the 3 and 5 wt% PVA/GA hydrogel, with and without immobilized bacteria, were imaged using an SEM (ZEISS EVO 50 Model. Carl Zeiss, Bangalore, India). SEM images and pore size distribution were acquired using SmartSEM V-05.04.05.00 software. For sample preparation, the hydrogels were cut into a thin film of approximately 60 nm, fixed on an aluminium stub with a double-sided adhesive, conductive carbon tape. The samples were then sputter-coated with gold for 2–3 min and SEM images were taken at magnification ranging ×2000 to ×10,000.

Confocal fluorescence microscopy

The viability and growth of immobilized microbial cells in 3 and 5 wt% PVA/GA hydrogels were examined by confocal fluorescence microscopy at different time intervals, with a radiance 2100 (BioRad) laser scanning system on a ZEISS Axiovert 200 Microscope (Carl Zeiss, Bangalore, India). The hydrogel was cut into a 1-mm thick film, stained with acridine orange and ethidium bromide (1 mg.mL−1 of acridine orange, 1 mg.mL−1 of ethidium bromide, and phosphate-buffered saline at pH 7.4) in the dark for 20 min and observed under the microscope. The acridine orange penetrates through both living and dead cells of immobilized bacteria and stains all the nucleated cells to generate green fluorescence. Whereas, ethidium bromide enters only the dead cells with compromised membranes and stains them red to generate red fluorescence.

Hydrogel application for wastewater treatment

PVA/GA hydrogel, with and without immobilized bacteria, were evaluated for treatment of wastewater effluent. In addition, free living bacterial cells of the selected culture were also evaluated to compare the metabolic activity of the bacteria within and without the hydrogel. Around 20 discs of PVA/GA hydrogels, BI PVA/GA hydrogels, and 20 mL of bacterial culture (OD600 = 0.5) were added separately to 2000 mL conical glass flasks containing 1000 mL of untreated municipal wastewater effluent. BOD, COD, and protein content were tested as per the standard methods at the beginning and after 5 days (APHA/AWWA/WEF 2012; Lowry et al. 1951).

Statistical analyses

All experiments were conducted in triplicates and data is presented as mean ± standard deviation (S.D.). Statistical analyses were done using t-tests, by one-way analysis of variance (ANOVA) with Tukey’s test, using statistical software tool Origin 8 (Northampton, MA, USA) and GraphPad Prism 5 (San Diego, CA). Differences were considered significant for P < 0.05.

Results and discussion

Swelling behavior of PVA/GA hydrogels

Optimization studies of the PVA/GA hydrogel swelling were performed to investigate the hydrogel swelling kinetics as well as conditions required for maximum swelling capacity of hydrogels against a range of factors, like PVA concentration, GA/PVA mass ratio, solution matrix temperature, pH, and ionic strength (Fig. 2). Results from each are discussed below.

a Effect of PVA concentration on the swelling capacity (ratio) of hydrogel. b Effect of GA/PVA mass ratio on swelling capacity of hydrogel ([PVA] = 5%). c Effect of temperature on PVA/GA hydrogel swelling ratio (GA/PVA mass ratio 0.03). d Effect of salt solution on swelling behavior of hydrogel (GA/PVA mass ratio 0.03; ionic strength values are shown in parentheses). Error bars denote standard deviation of triplicate measurements. For each dataset shown here, the mean values were significantly different at P < 0.0001 (one-way ANOVA with Tukey’s test)

Effect of PVA concentration on hydrogel swelling

The trend of swelling capacity of hydrogel with PVA concentration is depicted in Fig. 2a. Maximum swelling capacity was observed at 5 wt% PVA, while other factors were held constant. The effect of PVA concentration on swelling followed the same trend as reported in a previous study (Hosseinzadeh 2013). Swelling of hydrogel substantially increased with increase in PVA concentration from 4 to 5 wt%. This increasing trend is attributed to more sites being available for crosslinking with glutaraldehyde with increasing PVA. Beyond 5 wt% PVA, however, the swelling capacity starts to reduce, which might be due to increased viscosity of the medium with increasing PVA concentration, thereby restricting the PVA chain movements and hence decreasing the water absorbing capacity.

Effect of GA/PVA mass ratio on hydrogel swelling

The effect of GA concentration as a crosslinking agent was evaluated in terms of the impact of GA/PVA mass ratio on the swelling capacity of the hydrogel, shown in Fig. 2b. Compared to the impact of PVA wt% on swelling ratio (Fig. 2a), the impact of GA/PVA mass ratio on the swelling ratio was much lower; increasing GA/PVA ratio resulted in only a slight decrease in swelling capacity (Fig. 2b). This observed decrease in swelling of the hydrogel with increasing GA concentration may be attributed to increasing di-aldehyde in higher GA content hydrogels, which helps in building a denser crosslinked network that prevents PVA dissolution, but also results in lower swelling capacity (Hosseinzadeh 2013). In our experiments, 0.03 GA/PVA minimum mass ratio was needed to prepare stable PVA/GA hydrogel. GA/PVA ratio was increased up to 0.31, which exhibited the lowest swelling ability, presumably due to a higher degree of crosslinking. Hydrogels with GA/PVA mass ratio 0.03, showing stable hydrogel formation and high swelling capacity, were thus selected for further studies with immobilized microbial cells.

Effect of solution temperature on hydrogel swelling

The impact of temperature on PVA/GA hydrogel was investigated by varying the temperature from 50 to 120 °C, as depicted in Fig. 2c. The results showed that by temperature variation, the swelling capacity of hydrogels ranged between ~ 1.1 and 1.3%, and thus there was no significant impact of temperature on the swelling ratio within the temperature range tested. With increasing temperature, the swelling capacity first increased till 100 °C, but a slight decrease was noted as the temperature increased beyond 100 °C. A possible explanation for this behavior could be increasing diffusivity of GA into the PVA backbones with increasing temperature from 50 to 100 °C. But, “thermal crosslinking” of the PVA backbones at higher temperatures, i.e. above 100 °C, caused a slight decrease in swelling capacity. This was also because of maximum extent of crosslinking achieved between GA and PVA, via the completion of di-acetal formation. These findings and temperature behavior are in agreement with prior reports (Hosseinzadeh 2013).

Effect of solution ionic strength on hydrogel swelling

Swelling capacity of PVA/GA hydrogel in different ionic strength solutions can shed light onto hydrogel behavior for several practical applications. Effect of salt solutions (NaCl, CaCl2, and AlCl3) with varying ionic strengths on the swelling behavior of the hydrogel is shown in Fig. 2d. As the ionic concentration of the medium increased from NaCl to AlCl3, the swelling capacity decreased. This could be due to the higher osmotic pressure in the hydrogels arising from unequal distribution of ions in the gel-salt aqueous medium. The ions remain static in the polymeric network, separating them from the external medium through a semi-permeable membrane. With increasing ionic concentration in the medium, the difference in the counter ions in the polymeric network and surrounding medium increased, causing a higher outward osmotic pressure for the water in the hydrogel and thus a reduction in the water uptake of the hydrogel at equilibrium, thereby reduced the swelling capacity. On the other hand, when hydrogels were placed in distilled water, maximum swelling was achieved due to minimum osmotic pressure of the water in the hydrogel allowing uninhibited permeation of water into the gel (Hosseinzadeh 2013).

Swelling kinetics of hydrogels

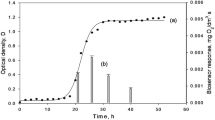

Swelling kinetic behavior was investigated to examine the rate of diffusion of water into the hydrogel, the consequent swelling, and the time it takes to come to an equilibrium state. The swelling kinetics of the hydrogel for various GA/PVA mass ratios is depicted as a function of time in Fig. 3a. For all concentrations, it was observed that initially the hydrogel absorbed water at a high rate, almost instantly, leading to a rapid increase in swelling capacity with time, and attained equilibrium in ~ 30 min.

a Swelling behavior of PVA/GA hydrogel at different time intervals for different GA/PVA mass ratio. b Swelling kinetics of PVA/GA hydrogel with time. The mean values are significantly different with P < 0.0001 and P = 0.0032, respectively (one-way ANOVA followed by repeated measures ANOVA with Tukey’s test)

Water absorption rate and equilibrium swelling % were also affected by the addition of glutaraldehyde. The plots of log(Qe–Qt) vs. time, as shown in Fig. 3b, were used to determine the swelling rate constant k from the slope of each line by using Eq. (4). Table 1 lists the calculated values of swelling rate constants k as deduced from the plots in Fig. 3b and equilibrium swelling % of each GA/PVA mass ratio. Though the k values did not show a clear trend (Fig. S5, R2 = 0.33), they were significantly different (P < 0.0001). Highest k value (k = 0.22 min−1) was for lowest GA/PVA ratio of 0.03, and lowest k value was for the highest GA/PVA ratio of 0.31 (k = 0.17 min−1); the data thus indicated slower swelling kinetics with higher GA/PVA mass ratio. The equilibrium swelling capacity, however, clearly decreased with increasing GA/PVA ratio. Increasing GA/PVA ratio and higher crosslinking presumably leads to increased resistance to gel swelling and decrease in the voids for water uptake, ultimately resulting in decreased equilibrium swelling (Li et al. 2011).

Effect of pH on swelling behavior of hydrogels

A comparative analysis of the swelling behavior of PVA/GA hydrogels over time, without and with bacterial cells, at varying pH levels is shown in Fig. 4a and Fig. 4b, respectively. The swelling of hydrogel increased slightly with increase in pH from 3 to 6, and then decreased significantly as the pH rose to 9. When the pH is raised from 3 to 6, the PVA chains become highly ionic, leading to repulsion of the like charges, thereby increasing the swelling ratio. However, further increase in pH from 6 to 9 resulted in decrease in swelling ratio, which can be explained by increase in ionic strength that possibly neutralized the negative charges of the acetates (Mansur et al. 2008). PVA (with the degree of hydrolysis 85–89%) seemed to possibly act as an amphiphilic polymer, where the balance between hydrophilic groups (OH− ions) and hydrophobic groups (acetate groups) in the aqueous solution provided the pH sensitivity. The presence of large and bulky acetate groups in partially hydrolysed PVA weakens both inter-molecular and intra-molecular hydrogen bonding between the hydroxyl groups present around, thereby affecting the balance between the hydroxyls and acetates. Thus, the swelling capacity of a pH-responsive hydrogel is influenced by hydrogen bonds and attractive/repulsive electrostatic interactions among the functional groups. Both PVA/GA hydrogel and BI PVA/GA hydrogel exhibited a similar swelling trend and pattern with varying pH of the media. The swelling capacity in BI PVA/GA hydrogel, however, was almost double as compared to that for the PVA/GA hydrogel. This could be because of the immobilized viable bacterial cells providing extra water retention capacity within the hydrogels. The bacterial cell membrane acts as a permeability barrier for most molecules, except solvents. The results thus clearly indicated that PVA-derived hydrogels were indeed vulnerable to pH changes in the evaluated pH range, exhibiting highest swelling capacity at near-neutral pH values.

a Effect of pH on the swelling behavior of PVA/GA hydrogel with time (GA/PVA mass ratio 0.03). b Effect of pH on the swelling behavior of BI PVA/GA hydrogel with time (GA/PVA mass ratio 0.03). The mean values were significantly different with P = 0.0177 and P = 0.0001, respectively (one-way ANOVA with Tukey’s test)

Isolation and phylogenetic analyses for identification of bacteria from wastewater

Out of the 40 isolated bacterial strains (named as IB1 to IB40), IB15 was selected, based on its maximum strong positive results in the biochemical assays namely amylase, urease, citrate, Voges-Proskauer, gelatin, indole, TSI, catalase, and casein tests. It also exhibited best growth rate when grown in the wastewater and maximum reduction in pollutant parameters, namely BOD, COD, and protein content. Microbial analyses identified the selected IB15 strain as Bacillus pseudomycoides, as shown in Fig. S1. The 16S rRNA sequence of the isolate was submitted to GenBank (NCBI) under the accession number MH229766. Bacillus pseudomycoides has similarity with bacterium Bacillus mycoides. Bacillus pseudomycoides has been reported in several previous research reports such as the enhanced potassium uptake in tea plants by increasing potassium availability in mica waste-treated soil in north-east India by Pramanik et al. (2019), in the production and characterization of extracellular polymeric substance by Solmaz et al. (2018), and in the production and characterization of biosurfactant utilizing soyabean oil waste by Li et al. (2016). Even Bacillus mycoides has been identified/used in several studies such as its high nematocidal activity as demonstrated by Luo et al. (2018), transcriptional response to potato root exudates as shown by Yi et al. (2018), antibacterial activity and characterization of bacteriocin from B. mycoides as reported by Sharma and Gautam (2008), development of an efficient electroporation method for rhizobacterial Bacillus mycoides strains as reported by Yi and Kuipers (2017), and aerobic and anaerobic biodegradation of TNT by B. mycoides reported by Lin et al. (2013). As per our knowledge, however, there are no extant reports of either Bacillus pseudomycoides or Bacillus mycoides being used for wastewater treatment.

Structural and chemical characterization of PVA/GA hydrogels

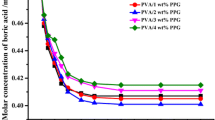

Effect of GA on permeability

The assessment of pore size of hydrogel on the basis of concentration of GA is an important criterion required for microbial immobilization. The results of the effect of addition of different amount of GA on the transmittance showed that the hydrogel became less transparent (Fig. S2), and the % light transmittance reduced (Fig. S3) (Ma and Xiong 2008). The hydrogel with GA/PVA mass ratio of 0.03 had the best visible light transmittance at wavelength 600 nm. Moreover, with increasing GA/PVA mass ratio from 0.03 to 0.31, UV transmission of Acid Black 24 dye solution at wavelength range 400–800 nm significantly decreased, indicating a reduction in the hydrogel permeability towards the dye (Fig. S3) (Li et al. 2011); the same was also illustrated by the hydrogel images when exposed to 1:1 dilution of 50 ppm of Acid Black 24 dye for 4 h (Fig. S4).

ATR-FTIR analyses

ATR-FTIR absorption spectra of pure PVA hydrogel, PVA/GA hydrogel, and BI PVA/GA hydrogel are shown in Fig. 5. The pure PVA hydrogel spectrum in Fig. 5a has a characteristic wide peak at 3311 cm−1 indicative of O-H stretching from inter-molecular and intra-molecular hydrogen bonding. The vibrational band at 2954 and 1434 cm−1 can be attributed to asymmetrical stretching vibration and the symmetrical bending vibration of –CH from alkyl groups, respectively (Rudra et al. 2015). Also, the appearance of peaks at 1735, 1278, and 1434 cm−1 in the PVA spectrum is due to C=O stretching, C-O stretching, and O-H bonding, respectively, of the acetate groups remaining in partially hydrolysed PVA (85–89% hydrolysed). The absorption bands at 1110 and 3311 cm−1 may be attributed to C-O stretching and O-H stretching from alcoholic group of PVA, respectively (Rudra et al. 2015). Figure 5b is the ATR-FTIR spectrum of PVA crosslinked with GA, i.e. PVA/GA hydrogel. Interestingly, the reduction in peak at 1735 cm−1 indicates that the aldehyde group of GA has reacted with –OH group of PVA to a great extent. In addition, the sharp C-O stretching band at approximately 1110 cm−1 in pure PVA is shifted to 1090 cm−1, which could be attributed to the ether (C-O-) and the acetal (C-O-C) bonds formed due to the crosslinking of GA with PVA. The considerable reduction of peak at 1735 cm−1 could be presumably due to the CHO groups of GA (present at both ends) being almost completely utilized in crosslinking with OH group of PVA chain as shown in Fig. 1. Also, the reduction in peak at 1110 cm−1 and shifting of 3311 cm−1 peak towards a slightly higher frequency in PVA/GA spectrum supports the hypothesis regarding crosslinking of alcoholic group of PVA with CHO group of GA resulting into the formation of ether (C-O-) and acetal ring (C-O-C) (Zhang and Ye 2014). For the BI PVA/GA hydrogel, Bacillus pseudomycoides, a Gram-positive bacterium, was immobilized in the hydrogel as discussed above. Teichoic acids in the cell walls of Gram-positive bacteria impart an overall negative charge to the cell wall, which impacts the bacterial adhesion properties (Rudra et al. 2015). The FTIR analyses for BI hydrogels, shown in Fig. 5c, revealed that the absorbance peaks associated with C-O stretching/bending vibrations of alcoholic/acetate group were reduced significantly after immobilization and consequently shifted towards higher energy. This could be because of interaction between negatively charged bacterial surface and slightly positively charged carbon linked with oxygen atom in the hydrogel structure. The significant decrease in peak intensity at 2943 cm−1 also supports the entrapment as well as the involvement of weaker interactions between the cell surface and the PVA/GA hydrogel.

XRD analyses

Figure 6 shows the XRD spectra of (a) PVA, (b) PVA/GA hydrogel, and (c) BI PVA/GA hydrogel. As seen in spectrum (a), PVA has sharp peaks at 2θ = 19.52°, 22.51°, and 41.02°—indicating a high level of crystallinity. Spectrum (b) of PVA/GA hydrogel showed a different XRD pattern, with just one peak observed at 2θ = 20.31°, indicating low crystallinity level as compared to the pure PVA. This was attributed to the presence of crosslinking between PVA and GA. Further, increased crosslinking density due to addition of bacterial cells leads to a more amorphous BI PVA/GA hydrogel. This was evident from one weak broad peak at 2θ = 19.88° (spectrum (c)), on account of possible interactions between PVA and GA; and PVA, GA, and bacteria (Minhas et al. 2013; Rudra et al. 2015).

SEM analyses

Based on swelling tests discussed above, both 3 and 5 wt% PVA/GA hydrogels were selected for immobilization of bacterial cells, as both showed appreciable swelling capacity, clearly illustrated in Fig. 2a. However, after immobilization in 3 wt% hydrogel, its stability and robustness was lost; which was not in the case of 5 wt% PVA/GA hydrogel, wherein the stability and mechanical strength were maintained before as well as after immobilization of bacterial cells. The unique microstructure morphologies of cross-section of 3 and 5 wt% PVA/GA hydrogels, with and without bacterial cells, are illustrated in Fig. 7a–e. The average pore size distribution ranging from 1.5 to 3.4 μm and 1.3–2.6 μm in 3 and 5 wt% PVA/GA hydrogels, respectively, was observed all around. A large number of rod-shaped Bacillus sp. (see Fig. S6) were found adhered in 5 wt% PVA/GA hydrogel (Fig. 7d, e in comparison to 3 wt% PVA/GA hydrogel (Fig. 7c). This might be attributed to the presence of comparatively larger pore size in 3 wt% PVA/GA hydrogel which could not effectively hold the bacterial cells. However, the pore size in 5 wt% PVA/GA hydrogel was small enough to immobilize Bacillus sp., and retain the immobilized cells through various electrostatic interactions between the hydrogel surfaces and negatively charged microbial cell wall.

Fluorescence microscopy

The ATR-FTIR spectra and SEM images confirmed the immobilization of Bacillus sp. within the hydrogel. Additionally, confocal fluorescence microscopy was undertaken to evaluate the PVA/GA hydrogels for maximum cell immobilization in viable state and extent of their proliferation with time. Fluorescence images of 3 wt% BI PVA/GA and 5 wt% BI PVA/GA hydrogel after 2 and 25 days are shown in Fig. 8. The stains acridine orange and ethidium bromide were used to differentiate between live (green) and dead (red) bacterial cells immobilized in the hydrogel. The appearance of larger number of green cells (viable cells) with a few red cells (dead cells) on day 2 in 5 wt% BI PVA/GA (Fig. 8c) as compared to 3 wt% BI PVA/GA hydrogel (Fig. 8a) demonstrated the suitability of 5 wt% PVA/GA hydrogel as a supporting matrix with significant pore size to retain immobilized cells in a viable state. Further, the increase in the number of living cells in comparison to the dead cells of bacteria on day 25 (Fig. 8d) with respect to day 2 (Fig. 8c) in 5 wt% BI PVA/GA hydrogel revealed that the immobilization did not affect the growth and metabolic activities of microbial cells and a high percentage of cells remained viable for almost 3–4 weeks.

Fluorescence images of a BI in 3 wt% of PVA/GA hydrogel at day 2, b BI in 3 wt% of PVA/GA hydrogel at day 25, c BI in 5 wt% of PVA/GA hydrogel at day 2, d BI in 5 wt% of PVA/GA hydrogel at day 25. All images include an intensity plot below them with x-axis in micrometre and y-axis in intensity units

PVA/GA hydrogel application for wastewater treatment

The BOD, COD, and protein content of the untreated municipal wastewater effluent and treated effluent after the Bacillus pseudomycoides application as free cells or immobilized in hydrogel were measured and compared with the permissible limit given by WHO (Sayre 1988), and the results are shown in Table 2. Reduction in BOD was noted to be 32 and 86% by PVA/GA hydrogel and BI PVA/GA hydrogel, respectively. Free bacterial cells were also able to reduce BOD by 87%, much similar to BI PVA/GA application. Further, COD and protein content also reduced significantly. COD was reduced by 71 and 73% by BI PVA/GA hydrogel and free bacterial cells, respectively. Additionally, protein parameter was noted to have reduced by 60% by BI PVA/GA hydrogel much like by free cells, i.e. 63%. Metabolic activity of the free bacterial cells was evidently at par with the immobilized cells and both the forms were successfully able to reduce the pollutant parameters effectively. These results indicate that Bacillus pseudomycoides holds a great promise for use in wastewater treatment. The abatement in pollution parameters confirmed the suitability of pore size of gel matrix for easy diffusion of organic substances and N/P from wastewater into the gel carrier to be metabolized by the immobilized microbial cells in the hydrogel. Moreover, in course of effluent treatment, no degradation of support matrix occurred due to the presence of an abundant microbial population in the wastewater, even after 2–3 months of continuous use. Also, there was no significant difference in Bacillus sp. activity, whether in free or immobilized forms, during the treatment of municipal wastewater effluent.

Conclusions

A simple, expedited, single-step preparation of PVA/GA hydrogel (with and without immobilized bacterial cells) was effectively demonstrated with a rapid method that takes 2 h, which is significantly faster than preparation times (6–72 h) reported in prior studies (Mansur et al. 2008; Rudra et al. 2015). The porosity of developed hydrogel favored the growth and proliferation of immobilized bacteria and also diffusion of nutrients to the cells (within the hydrogel) from the surrounding environment. Temperature independent preparation of the present hydrogel achieved its equilibrium swelling capacity in 30 min and showed maximum swelling at a slightly acidic pH of 6, posing no harsh effect on the cell growth and activity. Bacteria immobilized PVA/GA hydrogel had favorable kinetics without any leaching complications of the supporting matrix. Moreover, metabolic activity of the immobilized cells was investigated in terms of reduction in BOD, COD, and protein—suggesting the potential of immobilized microbial cells in a mechanically stable matrix for successful wastewater treatment. Finally, viability of the immobilized bacteria in the hydrogel for more than 2 months bodes well for the future use of this technology on an applied scale, in municipal wastewater treatment plants or in the industry.

References

Andrews S (2010a) FASTQC package. Available online at: http://www.bioinformatics.babraham.ac.uk/projects/fastqc/ (last accessed: 21 September 2019)

Andrews S (2010b) Fastq-screen package. Available online at: http://www.bioinformatics.babraham.ac.uk/projects/fastq_screen/ (last accessed: 21 September 2019)

Aneja KR (2005) Experiments in microbiology, plant pathology and biotechnology. New Age International.

APHA/AWWA/WEF (2012) Standard methods for the examination of water and wastewater.

Bolto B, Tran T, Hoang M, Xie Z (2009) Crosslinked poly(vinyl alcohol) membranes. Prog Polym Sci 34:969–981. https://doi.org/10.1016/J.PROGPOLYMSCI.2009.05.003

Chanthad C, Wootthikanokkhan J (2006) Effects of crosslinking time and amount of sulfophthalic acid on properties of the sulfonated poly(vinyl alcohol) membrane. J Appl Polym Sci 101:1931–1936. https://doi.org/10.1002/app.23660

Cho KS, Park KJ, Jeong HD, Nam SW, Lee SJ, Park TJ, Kim JK (2006) Characteristics of immobilized PVA beads in nitrate removal. J Microbiol Biotechnol 16:414–422

Dereeper A, Guignon V, Blanc G, Audic S, Buffet S, Chevenet F, Dufayard J-F, Guindon S, Lefort V, Lescot M, Claverie J-M, Gascuel O (2008) Phylogeny.fr: robust phylogenetic analysis for the non-specialist. Nucleic Acids Res. 36:W465–W469. https://doi.org/10.1093/nar/gkn180

Edgar RC (2004) MUSCLE: multiple sequence alignment with high accuracy and high throughput. Nucleic Acids Res. 32:1792–1797. https://doi.org/10.1093/nar/gkh340

Figueiredo KCS, Alves TLM, Borges CP (2009) Poly(vinyl alcohol) films crosslinked by glutaraldehyde under mild conditions. J Appl Polym Sci. 111:3074–3080. https://doi.org/10.1002/app.29263

Gohil JM, Bhattacharya A, Ray P (2006) Studies on the crosslinking of poly (vinyl alcohol). J Polym Res. 13:161–169. https://doi.org/10.1007/s10965-005-9023-9

Halma M, Mousty C, Forano C, Sancelme M, Besse-Hoggan P, Prevot V (2015) Bacteria encapsulated in layered double hydroxides: towards an efficient bionanohybrid for pollutant degradation. Colloids Surf B Biointerfaces 126:344–350. https://doi.org/10.1016/j.colsurfb.2014.11.029

Hosseinzadeh H (2013) Synthesis and swelling properties of a poly(vinyl alcohol)-based superabsorbing hydrogel. Curr Chem Lett 2:153–158. https://doi.org/10.5267/j.ccl.2013.05.001

Hsia TH, Feng YJ, Ho CM, Chou WP, Tseng SK (2008) PVA-alginate immobilized cells for anaerobic ammonium oxidation (anammox) process. J Ind Microbiol Biotechnol. 35:721–727. https://doi.org/10.1007/s10295-008-0336-7

Jianlong W, Xiangchun Q, Liping H, Yi Q, Hegemann W (2002) Microbial degradation of quinoline by immobilized cells of Burkholderia pickettii. Water Res. 36:2288–2296

Kang MS, Kim JH, Won J, Moon SH, Kang YS (2005) Highly charged proton exchange membranes prepared by using water soluble polymer blends for fuel cells. J Memb Sci. 247:127–135. https://doi.org/10.1016/J.MEMSCI.2004.09.017

Kodavaty J, Deshpande AP (2014) Mechanical and swelling properties of poly (vinyl alcohol) and hyaluronic acid gels used in biomaterial systems—a comparative study. Def Sci J 64:222–129

Labus K, Drozd A, Trusek-Holownia A (2015) Preparation and characterisation of gelatine hydrogels predisposed to use as matrices for effective immobilisation of biocatalysts. Chem Pap 70:523–530. https://doi.org/10.1515/chempap-2015-0235

Lee J, Cho MH (2010) Removal of nitrogen in wastewater by polyvinyl alcohol (PVA)—immobilization of effective microorganisms. Korean J Chem Eng. 27:193–197. https://doi.org/10.1007/s11814-009-0330-4

Leenen EJTM, Dos Santos VAP, Grolle KCF, Tramper J, Wijffels R (1996) Characteristics of and selection criteria for support materials for cell immobilization in wastewater treatment. Water Res. 30:2985–2996. https://doi.org/10.1016/S0043-1354(96)00209-6

Li X, Hu A, Ye L (2011) Structure and property of porous polyvinylalcohol hydrogels for microorganism immobilization. J Polym Environ. 19:398–404. https://doi.org/10.1007/s10924-011-0289-1

Li J, Deng M, Wang Y, Chen W (2016) Production and characteristics of biosurfactant produced by Bacillus pseudomycoides BS6 utilizing soybean oil waste. Int Biodeterior Biodegradation 112:72–79. https://doi.org/10.1016/J.IBIOD.2016.05.002

Lin H, Yu C-P, Chen Z (2013) Aerobic and anaerobic biodegradation of TNT by newly isolated Bacillus mycoides. Ecol Eng 52:270–277. https://doi.org/10.1016/J.ECOLENG.2012.11.004

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Lozinsky VI, Plieva FM (1998) Poly(vinyl alcohol) cryogels employed as matrices for cell immobilization. 3. Overview of recent research and developments. Enzyme Microb. Technol 23:227–242. https://doi.org/10.1016/S0141-0229(98)00036-2

Luo T, Hou S, Yang L, Qi G, Zhao X (2018) Nematodes avoid and are killed by Bacillus mycoides-produced styrene. J Invertebr Pathol 159:129–136. https://doi.org/10.1016/j.jip.2018.09.006

Ma R, Xiong D (2008) Synthesis and properties of physically crosslinked poly (vinyl alcohol) hydrogels. J China Univ Min Technol 18:271–274. https://doi.org/10.1016/S1006-1266(08)60057-7

Mansur HS, Sadahira CM, Souza AN, Mansur AAP (2008) FTIR spectroscopy characterization of poly (vinyl alcohol) hydrogel with different hydrolysis degree and chemically crosslinked with glutaraldehyde. Mater Sci Eng C 28:539–548. https://doi.org/10.1016/J.MSEC.2007.10.088

Marin E, Rojas J, Ciro Y (2014) A review of polyvinyl alcohol derivatives: promising materials for pharmaceutical and biomedical applications. African J Pharm Pharmacol 8:674–684. https://doi.org/10.5897/ajpp2013.3906

Minhas M, Ahmad M, Ali L, Sohail M (2013) Synthesis of chemically cross-linked polyvinyl alcohol-co-poly (methacrylic acid) hydrogels by copolymerization; a potential graft-polymeric carrier for oral delivery of 5-fluorouracil. DARU J Pharm Sci 21:44. https://doi.org/10.1186/2008-2231-21-44

More SM, Kulkarni RV, Sa B, Kayane NV (2010) Glutaraldehyde-crosslinked poly(vinyl alcohol) hydrogel discs for the controlled release of antidiabetic drug. J Appl Polym Sci. 116:1732–1738. https://doi.org/10.1002/app.31627

Paula AV, Nunes GFM, de Castro HF, Santos JC (2015) Synthesis of structured lipids by enzymatic interesterification of milkfat and soybean oil in a basket-type stirred tank reactor. Ind Eng Chem Res 54:1731–1737. https://doi.org/10.1021/ie503189e

Pramanik P, Goswami AJ, Ghosh S, Kalita C (2019) An indigenous strain of potassium-solubilizing bacteria Bacillus pseudomycoides enhanced potassium uptake in tea plants by increasing potassium availability in the mica waste-treated soil of north-east India. J Appl Microbiol 126:215–222. https://doi.org/10.1111/jam.14130

Rudra R, Kumar V, Kundu PP (2015) Acid catalysed cross-linking of poly vinyl alcohol (PVA) by glutaraldehyde: effect of crosslink density on the characteristics of PVA membranes used in single chambered microbial fuel cells. RSC Adv 5:83436–83447. https://doi.org/10.1039/C5RA16068E

Russell AD, Hopwood D (1976) 4 The biological uses and importance of glutaraldehyde. Prog Med Chem 13:271–301. https://doi.org/10.1016/S0079-6468(08)70140-1

Sayre IM (1988) International standards for drinking water. J Am Water Works Assoc 80:53–60. https://doi.org/10.1002/j.1551-8833.1988.tb02980.x

Seeponkai N, Wootthikanokkhan J (2007) Proton conductivity and methanol permeability of sulfonated poly(vinyl alcohol) membranes modified by using sulfoacetic acid and poly(acrylic acid). J Appl Polym0 Sci 105:838–845. https://doi.org/10.1002/app.26116

Shakeel A, Singh A, Das S, Suhag D, Sharma AK, Rajput SK, Mukherjee M (2017) Synthesis and morphological insight of new biocompatible smart hydrogels. J Polym Res 24:113–110. https://doi.org/10.1007/s10965-017-1267-7

Sharma N, Gautam N (2008) Antibacterial activity and characterization of bacteriocin of Bacillus mycoides isolated from whey. Indian J Biotechnol 7:117–121

Solmaz KB, Ozcan Y, Dogan NM, Bozkaya O, Ide S (2018) Characterization and production of extracellular polysaccharides (EPS) by Bacillus pseudomycoides U10. Environments 5:63. https://doi.org/10.3390/environments5060063

Suhag D, Bhatia R, Das S, Shakeel A, Ghosh A, Singh A, Sinha OP, Chakrabarti S, Mukherjee M (2015) Physically cross-linked pH-responsive hydrogels with tunable formulations for controlled drug delivery. RSC Adv. 5:53963–53972. https://doi.org/10.1039/C5RA07424J

Talavera G, Castresana J (2007) Improvement of phylogenies after removing divergent and ambiguously aligned blocks from protein sequence alignments. Syst Biol 56:564–577. https://doi.org/10.1080/10635150701472164

Tsai CE, Lin CW, Hwang BJ (2010) A novel crosslinking strategy for preparing poly(vinyl alcohol)-based proton-conducting membranes with high sulfonation. J. Power Sources 195:2166–2173. https://doi.org/10.1016/J.JPOWSOUR.2009.10.055

van de Wetering P, Metters AT, Schoenmakers RG, Hubbell JA (2005) Poly(ethylene glycol) hydrogels formed by conjugate addition with controllable swelling, degradation, and release of pharmaceutically active proteins. J Control Release 102:619–627. https://doi.org/10.1016/j.jconrel.2004.10.029

Varshosaz J, Koopaie N (2002) Cross-linked poly (vinyl alcohol) hydrogel: study of swelling and drug release behaviour. Iranian Polymer J. 11:123–131

Wu J, Gong X, Fan Y, Xia H (2011) Physically crosslinked poly(vinyl alcohol) hydrogels with magnetic field controlled modulus. Soft Matter 7:6205. https://doi.org/10.1039/c1sm05386h

Xu X, Cai Y, Song Z, Qiu X, Zhou J, Liu Y, Mu T, Wu D, Guan Y, Xing J (2015) Desulfurization of immobilized sulfur-oxidizing bacteria, Thialkalivibrio versutus, by magnetic nanaoparticles under haloalkaliphilic conditions. Biotechnol Lett 37:1631–1635. https://doi.org/10.1007/s10529-015-1845-x

Yi Y, Kuipers OP (2017) Development of an efficient electroporation method for rhizobacterial Bacillus mycoides strains. J Microbiol Methods 133:82–86. https://doi.org/10.1016/j.mimet.2016.12.022

Yi Y, Li Z, Kuipers OP (2018) Plant-microbe interaction: transcriptional response of Bacillus mycoides to potato root exudates. J Vis Exp 137:e57606. https://doi.org/10.3791/57606

Zhang Y, Ye L (2014) Structure and property of polyvinyl alcohol/precipitated silica composite hydrogels for microorganism immobilization. Compos Part B Eng 56:749–755. https://doi.org/10.1016/J.COMPOSITESB.2013.09.015

Zhang Y, Hui B, Ye L (2016) Preparation and structure of poly(vinyl alcohol)/polyacrylate elastomer composite hydrogels and their application in wastewater treatment by immobilizing with microorganisms. Ind Eng Chem Res 55:9934–9943. https://doi.org/10.1021/acs.iecr.6b02313

Acknowledgements

The authors are grateful to Amity Institute of Biotechnology, Amity University Uttar Pradesh, India for providing the laboratory facilities. We would like to thank Mr. Tufail Ahmad, CIRBSc (CIF), Jamia Millia Islamia, New Delhi for FTIR and XRD analyses. The authors would also like to acknowledge Dr. Saras Jyoti, Research Associate, Amity Institute of Molecular Medicine & Stem Cell Research, Amity University Uttar Pradesh for confocal fluorescence microscopy. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Funding

Author S. Aggarwal acknowledges support from an early-career research fellowship from the Gulf Research Program of the National Academies of Sciences, Engineering, and Medicine (USA). The content is solely the responsibility of the authors and does not necessarily represent the official views of the Gulf Research Program of the National Academies of Sciences, Engineering, and Medicine.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 734 kb)

Rights and permissions

About this article

Cite this article

Mehrotra, T., Zaman, M.N., Prasad, B.B. et al. Rapid immobilization of viable Bacillus pseudomycoides in polyvinyl alcohol/glutaraldehyde hydrogel for biological treatment of municipal wastewater. Environ Sci Pollut Res 27, 9167–9180 (2020). https://doi.org/10.1007/s11356-019-07296-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07296-z