Abstract

Chiral mesoporous silica (SiO2) with helical structure was synthesized by using anionic surfactants as template. Pre-prepared graphene oxide (GO) was then loaded onto SiO2 to synthesize composite carrier chial-meso-SiO2@GO for the immobilization of laccase. The enzyme activity, thermostability, acid stability, and repeatability of the immobilized enzyme were significantly improved after immobilization. The chial-meso-SiO2@GO-immobilized laccase was then used for the degradation of MXC in aqueous phase. The degradation conditions, including temperature, time, pH, MXC concentration, and the dose of immobilized enzyme for cellulosic hydrolysis, were optimized. The optimum conditions for degradation of methoxychlor were selected as pH 4.5, MXC concentration 30 mg/L, immobilized enzyme dose 0.1 g, the maximum MXC removal of over 85% and the maximum degradation rate of 50.75% were achieved after degradation time of six h at temperature of 45 °C. In addition, the immobilized cellulase was added into the immobilized laccase system to form chial-meso-SiO2@GO-immobilized compound enzyme with the maximum MXC degradation rate of 59.58%, higher than that of 50.75% by immobilized laccase. An assessment was made for the effect of chial-meso-SiO2@GO-immobilized compound enzyme on the degradation of MXC in soil phase. For three contaminated soils with MXC concentration of 25 mg/kg, 50 mg/kg, and 100 mg/kg, the MXC removals were 93.0%, 85.8%, and 65.1%, respectively. According to the GC-MS analyses, it was inferred that chial-meso-SiO2@GO-immobilized compound enzyme had a different degradation route with that of chial-meso-SiO2@GO-immobilized laccase. The hydrolysis by immobilized cellulase might attack at a weak location of the MXC molecule with its free radical OH and ultimately removed three chlorine atoms from MXC molecule, leading to generating small molecular amount of degradation product.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Dichlorodiphenyltrichloroethane (DDT) has been used broadly in China’s past, even though the use of technical DDT has been banned in China since 1983; the concentrations of DDT derivatives, such as p,p′-DDT, p,p′-DDE, and o,p′-DDT, are all very high in the air (Qiu et al. 2004), due to its strong persistence and toxicities. Methoxychlor (MXC, 1,1′,1″-trichloro-2, 2-bis(p-methoxyphenyl)-ethane), with lower toxicity and better insecticidal effect, is a popular substitute for DDT and has been applied in agriculture, forest, sanitation etc. all over the world (Wu et al. 2015). However, a large-scale application of MXC may cause contamination accumulation in the hydrological and environmental systems, affecting the abiding organisms (Ullah et al. 2018). Recently, MXC has been demonstrated as one of endocrine disrupters that would inhibit growth and induce atresia of primate follicles (Gupta et al. 2007). Substantial mortalities of fish have been reported worldwide due to different toxicant accumulation (Ullah and Zorriehzahra 2015), which would seriously threaten human via consumption of the aquatic organisms with chemical bioaccumulation (Ullah et al. 2018; Gavelle et al. 2016). Therefore, effective methods of MXC removal or degradation in water and soil environment are urgently needed.

In practice, physical and chemical procedures present several serious constraints such as low efficiency, high costs, insufficient purification, and application to narrow concentration range for the mineralization of organic compounds (Bilal et al. 2019a; Rasheed et al. 2019; Lin et al. 2018). Currently, enzyme-assisted method is recognized as one of the most efficient and environmentally friendly approaches for biodegradation of hazardous compounds including MXC (Chatha et al. 2017). The use of enzymes separated from their cells shows several advantages such as nontoxicity, high catalytic efficiency, high substrate specificity and mild reaction conditions (Sharma et al. 2018). Furthermore, immobilization of enzymes is a suitable technique that can increase the stability, facilitate the efficient recovery, and reuse of enzymes, enabling their cost-effective use in continuous processes (Gasser et al. 2014; Bilal et al. 2019b; Barrios-Estrada et al. 2018a).

Laccases (benzenediol: oxygen oxidoreductases, EC 1.10.3.2), belonging to the group of blue oxidases, can degrade a wide variety of substrate phenolic and aromatic pollutants (Salazar-López et al. 2017). Laccases have been documented to have much environmental application in bioremediation of herbicides, pesticides, and insecticides and biodegradation of different contaminants such as endocrine disruptors (Barrios-Estrada et al. 2018b; Gonzalez-Coronel et al. 2017; Rodríguez-Delgado et al. 2016; Garcia-Morales et al. 2015). Previous studies have primarily focused on single enzyme immobilization. However, there are many situations where a single enzyme cannot completely catalyze reactions and multiple enzymes working together in a cascade are needed (Jia et al. 2014). In nature, many cascaded reactions are catalyzed by multi enzyme complexes that are constituted of highly ordered assemblies of enzymes. It has been reported that the use of multi-enzyme complexes can significantly promote the overall degradation efficiency of substrates (Cohn et al. 2009; Jones et al. 2012).

Cellulase is a group of hydrolytic enzymes produced and secreted by soil microbes to decompose cellulose into oligosaccharides, cellobiose, and glucose (Akanbi et al. 2018). As reported by Zhai, cellulase is capable of catalyzing the degradation of dicofol efficiently without any other substrate (Zhai et al. 2015). The removal efficiency by free cellulase increased continuously and reached equilibrium. The mechanism of reaction might involve an attack by the OH free radical of cellulase at a weak location of the dicofol molecule, resulting in the removal of three chlorine atoms from dicofol (Zhang et al. 2011). The Silvia Fragoeiro study on the degradation of the mixture of pesticides (dieldrin and trifluralin) showed good capacity by both laccase and cellulase produced by Phanerochaete chrysosporium and T. versicolor, respectively, especially T. versicolor exhibited significantly higher activities of cellulase in the pesticide treatments (Fragoeiro and Magan 2005). The findings suggest the multiple enzymes could significantly enhance degradation efficiency of organochlorine pesticide.

As a low-cost, biocompatible, and good environmentally friendly material (Bilal et al. 2018; Zdarta et al. 2018), mesoporous silica materials have been widely utilized as an ideal carrier due to its large pore volume, high specific surface area, narrow pore size distribution, and continuously adjustable pore size, this stable and active enzyme system is expected to make a broad impact in various enzyme applications such as bioremediation, biosensors, and bioconversion (Ispas et al. 2009; Chang et al. 2011; Chen et al. 2017; Lin et al. 2014). Hierarchical mesocellular mesoporous silica (HMMS) synthesized by Jinwoo Lee was used as a host for enzyme immobilization, showing an impressive stability with extremely high enzyme loadings, and prevents enzyme leaching (Lee et al. 2005). The formation of nanometer scale cross-linked enzyme aggregates entrapped in the mesocellular pores of HMMS (37 nm), which did not leach out of HMMS (Kim et al. 2007). The immobilized enzyme on mesoporous silica sheets also showed extremely high relative activity (Nakanishi et al. 2014). It is generally accepted, the immobilization of enzyme onto the chiral surfaces presents high chiral preference, leading to keeping most of the catalytic activity of the immobilized enzymes based on the chiral effect (Ding et al. 2017). But chiral mesoporous silica (SiO2) with helical structure employed as carrier of immobilized enzyme has been seldom reported.

Besides, grapheme oxide (GO), a novel nanostructured material, has been illustrated as an ideal enzyme immobilization substrate due to its unique chemical and structural properties (Wu et al. 2019; Zhang et al. 2010). Due to a large number of hydroxyl groups, epoxy groups, and carbonyl and carboxyl groups, GO are beneficial to co-immobilization of compound enzymes (Zhao et al. 2014), which exhibited significantly higher enzymatic activity. The multipoint attachment of enzyme molecules is well-known to stabilize the enzyme activity by effectively preventing enzyme denaturation (Lee et al. 2005). The GO-immobilized enzyme showed improved thermal stability and a wide active pH range, attractive for practical applications. There is reason to believe that the attachment techniques used in single enzyme immobilization are also effective in multiple enzyme colocalization (Jia et al. 2014), which has a direct impact on the overall enzyme orientation and activity.

In this work, chiral mesoporous silica (SiO2) and graphene oxide (GO) were incorporated to construct the carrier for the immobilization of enzyme. The enzyme activity, thermostability, acid stability, and repeatability of the immobilized enzyme were investigated. Chial-meso-SiO2@GO-immobilized laccase was further utilized to degradate MXC in aqueous and soil phase. The degradation conditions, including temperature, time, pH, MXC concentration, and the dose of immobilized enzyme for cellulosic hydrolysis, were optimized. Increased degradation rate of MXC in aqueous phase by chial-meso-SiO2@GO-immobilized laccase was realized. In addition, the immobilized cellulase was added into the immobilized laccase system to form chial-meso-SiO2@GO-immobilized compound enzyme. An assessment was made for the effect of chial-meso-SiO2@GO-immobilized compound enzyme on the degradation of MXC in soil phase. The degradation kinetics constant and the possible degradation mechanism were discussed.

Experiment

Materials

The following materials were purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd. (Shanghai, China): myristoyl chloride (C14H27OCl); (3-aminopropyl) triethoxysilane (C9H23NO3Si, APTES); N-hydroxysuccinimide (C4H5NO3, NHS); d-alanine (C3H7NO2); 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (C8H17N3·HCl, EDC·HCl); graphite powder (C); dioctyl sulfosuccinate sodium (C20H37NaO7S, AOT); tetraethoxysilcane (Si (OC2H5)4, TEOS); calcium chloride (CaCl2·2H2O); ammonia (NH3·H2O); oleylamine (C18H37N); diphenyl ether (C12H10O); anhydrous acetic acid (C2H4O2, HAc); anhydrous sodium acetate (CH3COONa, NaAc), n-hexane (n-C6H14); absolute ethyl alcohol (C2H5OH); 1,2-hexadecane glycol (C16H34O2); 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid (C18H24N6O6S4, ABTS); carboxymethylcellulose sodium (C8H16NaO8, CMC–Na); dicyclohexylcarbodiimide (C13H22N2, DCC) (all of analytical grade). Methoxychlor (C16H15Cl3O2, MXC) was supplied by Shanghai TCI Development Co., Ltd. Laccase (≧ 0.5 U/mg, from Trametes versicolor) was purchased from Sigma–Aldrich Co. Cellulase (18 U/mg, extracted from Trichoderma longibrachiatum) was purchased from Heshibi Biological Technology Co., Ltd., Shanghai, China. They were used directly in experiments without additional modifications.

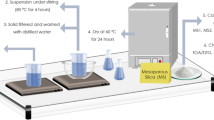

Preparation of GO−PEI functionalized chiral mesoporous SiO2

The chiral SiO2 was synthesized via the co-structure directing agent with amination to form SiO2–NH2 (Che et al. 2004). The graphene oxide (GO) was prepared by modified Hummers method (Xu et al. 2011). Detailed method for the preparation of SiO2@GO is included in the supplementary material.

To prepare GO−PEI functionalized chiral mesoporous SiO2, a mixture of 100 mg of SiO2@GO, 100 mL of deionized water, 25 mg of EDC, 20 mg of NHS, and 25 mL (0.1 mg/mL) of PEI were subjected to a 24-h shaken reaction to generate the SiO2@GO−PEI.

Enzyme immobilization

The enzyme was coupled to the chial-meso-SiO2@GO−PEI with the help of glutaraldehyde as a cross-linker as follows: 0.1 g chial-meso-SiO2@GO−PEI was treated with five mL of 0.1 wt% glutaraldehyde aqueous solution in the vessel. It is then placed in a temperature-controlled shaking incubator (model, TQZ-312) with a speed of 150 rpm and kept at 80 °C for 2 h. After the treatment, it was washed with the buffer followed by an incubation with the 10 mL HAc–NaAc buffer solution containing 0.8 mg/mL laccase or 1.0 mg/mL cellulase (pH 4.5) under shaking condition for 4 h at 10 °C. The chial-meso-SiO2@GO-immobilized enzyme was then washed thoroughly with chilled HAc–NaAc buffer and kept in refrigerator at 4 °C until use. The optimal immobilization conditions resulted from the Fig. S1 in a typical process, which were selected as pH 4.5, laccase concentration 1.0 mg/mL, GO concentration 0.2mg/mL, immobilization temperature 10 oC hours and immobilization time four hours.

The determination of laccase activity was based on the method reported by Hu et al. (2007). A unit of laccase activity (U) is defined as the quantity of laccase needed to increase the absorbency of 0.001 per mmol substrate per minute under the specified condition of 30 °C. Guaiacol aqueous solution (4 mmol/L) is used as the substrate at a pH of 5.0 adjusted by HAc–NaAc buffer solution, and the laccase activity is determined at 465 nm. The specific activity of the immobilized laccase (U/g) = the total activity of immobilized enzyme/mass of the dry immobilized laccase.

A unit of cellulase activity (U) is defined as the quantity of reducing sugar in equivalent to 1 mg of glucose produced in hydrolysis of sodium carboxymethylcellulose per minute under the specified condition of 50 °C. Accurately weighed adequate quantity of cellulase, 1.0 mL of deionized water, and 1.0 mL of CMC–Na solution in a graduated tube react for 30 min in a water bath of 50 °C. 1.5 mL DNS reagent is added in the tube that is then placed in boiling water coloring for 5 min. After cooling, the volume was kept to 20 mL and the OD wavelength value at 540 nm was determined to get the standard curve and calculate the amount of reducing sugar and enzyme activity. (Cellulase standard curve is shown in the supplementary material). Cellulase activity (U/g) = amount of glucose (mg)/time (min) × mass of the dry cellulase

Thermal and operating stability

The thermal stability of free and immobilized laccase was conducted by treating laccase in five mL of 4.0 mmol/L guaiacol merging with five mL HAc–NaAc buffer solution (pH 5) for 30 min at different temperatures. After reaction, the solution was separated using a high-speed centrifuge operating at RCF of 1504×g for one min, and five mL of the supernatant liquid was taken for immediate measurement of the activity. The operating stability of the immobilized laccase was assessed by performing several consecutive operating cycles with five mL of 4.0 mmol/L guaiacol as substrate at 30 °C, respectively. At the end of each cycle, the immobilized laccase was separated by centrifugation, washed three times with HAc–NaAc buffer solution (pH 5), and repeated with a fresh liquid of substrate.

Degradation of MXC by chial-meso-SiO2@GO-immobilized enzyme

(1) Degradation in polluted aqueous solution

In a typical degradation of MXC by immobilized laccase, 0.1 g chial-meso-SiO2@GO-immobilized laccase was added into the reaction vessel containing 10 mL pH 4.5 HAc–NaAc buffer solution of 30 mg/L MXC aqueous solution containing AOT 2‰. The reaction vessel was then placed in the model TQZ-312 platform temperature-controlled shaking incubator for adequate amount of time at an adequate temperature for the degradation of methoxychlor. After degradation, the reaction mixture was centrifuged to separate the immobilized laccase. Following the collection of upper liquid, MXC was extracted from upper liquid by 10 mL n-hexane thrice. The obtained organic phase was dried by anhydrous sodium sulfate and concentrated by vacuum rotary evaporator. The concentrated residue and 40 μL of 3.0 g/L octacosane (internal standard)/hexane were then dissolved in hexane to volume to five mL.

(2) Degradation in polluted soil

Ten grams of simulated MXC-contaminated soil was placed in a small flowerpot. 0.15 g of chial-meso-SiO2@GO-immobilized compound enzyme and four mL buffer solution with pH 4.5 were mixed to form a homogeneous compound enzyme solution, which was then sprayed evenly in the contaminated soil (water content of 30%) fully stirred evenly. Pots were then placed in an incubator at 25 °C for incubation. Four milliliters of buffer solution was added daily to ensure the reactor maintaining sufficient water and oxygen. A degraded soil sample was transferred into a 50-mL centrifuge tube with 20 mL of analytical hexane. The sample was ultrasonic at 25 °C for 10 min and shaken for 5 min at thermostat oscillator before centrifugation at RCF of 3008×g for five min, followed by collecting the supernatant and extracting the solid material repeatedly for five times. The supernatant was then dried by adding a small amount of anhydrous sodium sulfate, and the mixture was then evaporated on a rotary evaporator. The residual MXC was transferred to a five-mL volumetric flask with three to four mL of chromatographic pure hexane. The internal standard solution was added, and the volume was volumed to five mL with n-hexane. The content of MXC was determined by gas chromatography.

Sets of three soil samples of different weight percent of MXC as 25 mg/kg (C1), 50 mg/kg (C2), and 100 mg/kg (C3) were prepared to monitor the remediation of different contaminated soil samples by immobilized enzyme. In addition, the effect of various factors on the degradation were evaluated by changing the pH, degradation time, degradation temperature and so on. For comparison, degradation experiment with SiO2@GO free of enzyme was also carried out under exactly the same condition.

Evaluation of MXC degradation efficiency

The determination of MXC was referenced in our previous work (Huang et al. 2018; Yang et al. 2016; Yang et al. 2015) by subjecting one μL obtained sample solution to GC analysis. The MXC concentration can be obtained according to CMXC = 66.9 (AMXC/As) + 0.46 originated from standard curve (Fig. S2), where AMXC/As was the peak–area ratio of MXC to standard sample of octacosane. Each set of experiments was carried out in triplicate, and the arithmetic average values were calculated with a standard deviations around 3%.

In the degradation process of MXC by SiO2@GO-immobilized enzyme, the SiO2@GO used as carriers could directly adsorb MXC. Thus, in order to calculate degradation efficiency, the adsorption amount of MXC on the SiO2@GO must be determined. The MXC removal efficiency, the adsorption efficiency, and the degradation efficiency were calculated by the following equations:

MXC adsorption efficiency (%) = ((C0 – Ca)/C0) × 100%

MXC removal efficiency (%) = ((C0– Cd)/C0) × 100%

MXC degradation efficiency (%) = ((Ca– Cd)/C0) × 100%

The degradation efficiency of MXC is the difference between MXC removal efficiency and adsorption efficiency, where C0 was the initial MXC concentration, Ca was the MXC concentration in the supernatant after adsorption of blank carrier, and Cd was the MXC concentration after degradation.

Analysis and discussion

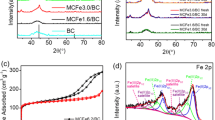

Characterization of SiO2@GO-immobilized laccase

Small angle X-ray diffraction (SXRD) pattern of chiral mesoporous silica (C-SiO2) was previously reported (Sasidharan et al. 2013), demonstrating that C-SiO2 has a 2D hexagonal mesoporous structure. Nitrogen adsorption/desorption experiments (Fig. 1b) showed that the measured Brunauer–Emmett–Teller (BET) surface area was 531.03 m2/g while the Barrett–Joyner–Halenda (BJH) pore volume was 0.7221 cm3/g. The most probable pore diameter of this structure was 3.56 nm, with about 90% of C-SiO2 having this pore size.

From the SEM and TEM characterizations of the chiral mesoporous silica (Fig. 1c, d), it can be clearly seen that the synthesized SiO2 exhibits a helical rod-like morphology with nanorods of 40–50 nm in diameter and 300–500 nm in length. There are a small amount of spherical particles with smaller particle size observed on the surface of the rod-like SiO2. These smaller particles might be due to the lack of uniform agitation during the deposition of the silicon source, so small amount of silicate agglomerates to form some small irregularly globular-shaped SiO2. Figure 1d is the TEM of the unmodified chiral mesoporous SiO2. It could be seen that there are ordered helical micelle structures in the nanorods formed by the self-assembly of chiral anionic surfactant molecules. The micelle template was removed by calcination or extraction, leaving a helical chiral pore structure with helical orientation consistent with the helical orientation of the nanorods. TEM image indicates the chiral channels of the obtained nanorods have hexagonal order, similar to the 2D hexagonal p6mm phase and consistent with the XRD analysis.

In order to load the GO layer onto the surface of SiO2, we need to aminate SiO2 first, and the SiO2@GO was prepared via amide condensation between the –COOH of GO and –NH2 of SiO2 under the catalysis of DCC. The results of elemental analysis showed that the percentage of N was increased from 0.3 to 2.02%, percentage of H was increased from 0.33 to 1.73%, and percentage of C had no obvious change, indicating that the amino group was successfully grafted onto the surface of SiO2. The carbon content of SiO2@GO increases from < 0.3 to 5.86% as shown in Table S1, indicating that the GO layer was loaded onto the SiO2 surface successfully. Raman spectroscopy shows that there are two absorption peaks of SiO2@GO at 1358 cm−1 and 1601 cm−1 in Fig. S3, respectively, both being the characteristic peaks of graphene oxide and confirming the successful loading of GO onto SiO2–NH2 surface.

The preparation process of SiO2@GO composite is shown in Fig. 2. The graphene oxide sheet obtained by ultrasonication has a large number of oxygen-containing groups on its surface. Its –COOH can be condensed with –NH2 on the surface of SiO2 after amination, so that the GO sheet can be loaded onto the surface of SiO2.

Effect of GO modification on immobilized enzyme

As shown in Figure S1, the effect of GO concentration on immobilized enzyme is significant. The activity of the immobilized enzyme is about 251 U/g when mesoporous silica alone is used as the carrier. When the concentration of GO in the composite is 0.2 mg/mL, the immobilized enzyme activity reaches a maximum value of 618.82 U/g. The activity of immobilized enzyme decreases significantly as the GO content increases. This is because the mesoporous materials immobilize the enzyme only by physical adsorption and then the enzyme molecules are apt to fall off during the washing process. The GO has a large specific surface area and abundant functional groups so that a strong electrostatic interaction may occur with the amino group of the enzyme molecules. There is concentration window in which GO increases the effectiveness of laccase molecules via more attachments so that the enzyme activity increases accordingly. However, when the GO content is higher, too many oxygen-containing functional groups such as carboxyl binding with laccase molecules will wrap the laccase protein and the active sites, thereby resulting in the decrease of enzyme activity. The optimum concentration of GO is found to be 0.2 mg/mL for the immobilization of enzyme on the composite.

Loading amount and thermal and operating stability of immobilized laccase

The stability measurement of immobilized enzyme and free enzyme is shown in Fig. 3. It is clear that the acid stability and thermal stability of enzyme are improved after immobilization. Free enzyme is particularly sensitive to the acidity of the system. When the pH is 4.0, the free enzyme activity reaches the optimum value, but a small increase or decrease of acidity leads to rapid inactivation of free enzyme. By contrast, the immobilized enzyme remains active in a relatively wider range of acidity. When the pH is in the range of 3.0 to 4.5, the immobilized enzyme can maintain high activity (Fig. S1). Meanwhile, immobilized enzyme also extends the high activity temperature range compared with free enzyme. The optimum temperature for free enzyme is 30 °C. When the temperature is over 40 °C, the activity of free enzyme decreases dramatically. When the temperature reaches 55 °C, the free enzyme activity is only 35% of that at the optimum condition. However, the optimal temperature of immobilized enzyme is 40 °C and the enzyme activity remains stable in the range of 30–45 °C. When the temperature reaches 55 °C, 70% of the optimum condition activity is maintained (Fig. 3a).

As shown in Fig. 3b, the activity of SiO2@GO-immobilized laccase decreases with the increase of repetition times in the repeated use experiment. The maximum decrease occurs in the second round, indicating detachment of some enzymes from the carrier during the wash process, a common phenomenon of the macromolecule immobilization by electrostatic force. The activity of immobilized enzyme continues to decrease in the next few rounds of repeated use, and after repeated for seven times, the immobilized enzyme activity still remains 74% of the initial activity, indicating strong stability and good repeatability of the SiO2@GO-immobilized laccase.

Optimum condition of the MXC degradation by SiO2@GO-immobilized laccase in polluted aqueous solution

As shown in Fig. 4a, the removal rate and adsorption rate of MXC decreases with the increase of MXC concentration, while the degradation rate of MXC increases first and then decreases with the increase of MXC concentration. When the MXC concentration is 30 mg/L, the degradation rate reaches a maximum of 50.75% and the adsorption rate is 31%. The experimental data are consistent with the fact that the composite carrier has a large specific surface area and the adsorption reaction is strong. When the MXC concentration is relatively low, most of the MXC can be adsorbed on the carrier and some of the MXC molecules are degraded. However, other MXC molecules would diffuse into the mesopores of the chiral SiO2 or would be adsorbed in the blind zones of GO where the interaction with the enzyme is weak. As a result, the total removal rate is relatively high while the degradation rate is relatively low. With the increase of MXC concentration, the carrier adsorption comes to a saturation and more MXC molecules would be degraded by enzymatic oxidation, leading to increased degradation rate accordingly. However, since the maximum amount of immobilized enzyme on the carrier is constant, a relatively smaller fraction of MXC can be degraded when the MXC concentration is too high. In addition, large amount of MXC molecules accumulating on the carrier would cause steric hindrance, hindering the diffusion of substrate and slowing the contact reaction with the immobilized enzyme, which would lead to decreased degradation rate. The optimal degradation concentration of MXC in aqueous phase is found to be 30 mg/L.

From Fig. 4b, it is shown that the degradation rate and the adsorption rate both increase with the dosage of immobilized enzyme. When the immobilized enzyme dosage is 0.1 g, the removal rate reaches 84.23%, the adsorption rate is 32.78%, and the degradation rate is 53.45%. As the immobilized enzyme dosage increases by 0.05 g, the degradation rate increases only about 5%. Therefore, considering the cost-effectiveness, the optimal amount of immobilized enzyme is 0.1 g,

In Fig. 4c, it is suggested that pH value has a great impact on MXC degradation by immobilized enzyme. When the pH value is below 4.5, the degradation rate increases with the increase of pH, and the degradation rate of MXC reaches a maximum of 51.43% at pH 4.5. As the pH value continues to increase, the degradation rate declines rapidly. The high degradation sensitivity to pH is consistent with the effect of pH on immobilized enzyme activity in Fig. S1. The adsorption rate of MXC by blank carrier has no obvious change with the pH value because the MXC adsorption onto SiO2@GO carrier is mainly dependent on the π-π reaction between GO and the benzene ring of MXC. The pH mainly affects the charge properties of surface groups on the carrier and then has little influence to the MXC adsorption.

When the pH exceeds 5.5, the degradation of MXC by immobilized enzyme becomes weak and the removal of MXC mainly depends on the adsorption of complex carrier. When the pH is too high or too low, the conformation of enzyme activity center changes and the activity space structure of laccase may change as well, resulting in the loss of enzyme activity. In this experiment, laccase is extracted from white rot fungi and the optimum pH range is determined to be between 4 and 5. Therefore, pH 4.5 is chosen as the optimal pH.

From Fig. 4d, it can be seen that the removal rate and degradation rate gradually increase with the reaction time, and reaches the peak at 6-h reaction time with the degradation rate of 53.48%. When the reaction time continues to increase, the degradation rate changes slightly. However, the adsorption rate of MXC on the blank carrier decreases after 4-h reaction time, which might be due to the equilibrium between adsorption and desorption of MXC on the composite carrier. With the increase of the reaction time, the adsorption capacity of the composite carrier reaches maximum and the desorption would play a main role, leading to the decrease of adsorption rate.

The effect of the temperature on the adsorption rate of MXC by the composite carrier is shown in Fig. 4e. The adsorption reaction of MXC by SiO2@GO is mainly dependent on the π-π effect of the GO surface and the benzene ring of MXC, so the adsorption rate fluctuates around 28% in the temperature range of 25–60 °C. However, the removal rate and degradation rate of MXC have significant correlation with the reaction temperature. According to the curve, the degradation rate maintains above 50% in the temperature range of 40–50 °C. Because the temperature affects the speed of molecular thermal motion, the appropriate temperature rise makes the adsorption rate of polyelectrolyte faster, the enzyme activity promoted, and the diffusion rate of the substrate and product increased, leading to the rise of degradation rate.

When the temperature exceeds 50 °C, the degradation rate significantly reduces. This is because the enzyme is essentially a protein molecule and higher temperature deactivates the enzyme and causes a drastic decline in degradation rate. So, the optimum temperature for the degradation of MXC by immobilized enzyme is 45 °C.

Effect of the ratio of compound enzyme on the degradation rate

Laccase belongs to oxidoreductase, and cellulase belongs to hydrolase. In order to explore whether the mixture of different enzymes can promote the degradation of MXC, laccase and cellulase are immobilized in the composite carrier SiO2@GO, respectively. The effect of the ratio of laccase and cellulase on the biodegradation of MXC can be tested by the degradation experiment with the two immobilized enzymes.

From Fig. 4f, it can be shown that the degradation of MXC can indeed be promoted by the compound enzymes with synergistic mechanisms. When the immobilized cellulase is added into the immobilized laccase system, the degradation rate of MXC is increased to some extent. When the mass ratio of immobilized cellulase and immobilized laccase is 1:4, the degradation rate reaches a maximum of 59.58%, 17% higher than that of a single immobilized laccase. This might be because the molecular chain of macromolecules would be broken by the cellulase, which would accelerate the degradation efficiency of the substrate and promote the degradation rate of laccase. Based on Fig. S5, the Michaelis–Menten constants of MXC degraded by free laccase, immobilized laccase, and immobilized compound enzyme are calculated to be 4.31 × 10−4 mol/L, 1.76 × 10−4 mol/L, and 3.81 × 10−5 mol/L, respectively. MXC is degraded by the immobilized laccases at a smaller Michaelis–Menten constant than that of free laccase, indicating that the immobilized enzyme has higher affinity for MXC than the free enzyme. This may be due to better adsorption performance of immobilized carrier and the substrate adsorbed on the carrier would help enzyme molecules and substrate achieve full contact. Secondly, the smaller Michaelis–Menten constant of the compound enzyme than that of the single immobilized laccase indicates that the compound enzyme has better affinity to the substrate and can reach the maximum reaction speed under the condition of relatively low substrate concentration.

On the other hand, when the proportion of immobilized cellulase continues to increase, the degradation rate decreases significantly. This is because the activity of immobilized cellulase is significantly lower than that of immobilized laccase. The larger the proportion of immobilized cellulase, the lower the total activity of the compound enzyme, and therefore, the weaker the catalytic oxidative capacity, resulting in significantly decreased degradation.

Effect of ABTS on MXC degradation

The catalytic oxidation of laccase to substrate mainly includes the following three aspects: (1) electron transfer process in enzyme molecules, (2) oxidation of substrate and reaction of products by enzymes, and (3) reduction process of enzyme by oxygen molecules (Solomon et al. 1996). The electron transfer in the enzyme molecule is one of the major factors that affect the reaction, and speeding up the electron transfer rate can improve the immobilized enzyme degradation rate. In recent years, studies have been shown that during the process of laccase catalytic oxidation, some small molecules, such as ABTS (2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) and HBT (2.2 1-hydroxy benzo three azole), can be used as mediators to promote electron transfer rate, further improving the oxidation of laccase (Cañas and Camarero 2010; Bourbonnais et al. 1998).

To evaluate the effect of ABTS on degradation, experiments were designed and performed as follows:

pH of acetic acid-sodium acetate buffer solution = 4.5,

pH of the fixed system = 4.5,

the concentration of MXC = 30 mg/L,

immobilized enzyme dosage = 0.10 g,

degradation temperature = 40 °C,

degradation time = 4 h,

concentration of added ABTS = 0, 0.11, 0.22, 0.33, 0.44, 0.55, 0.66, 0.77 g/L, respectively.

As shown in Fig. 5, the addition of ABTS to the system has little effect on the adsorption rate of the carrier, but the degradation rate of MXC by the immobilized enzyme increases almost linearly. Without ABTS, the removal rate is 83.5% and the degradation rate is 54.2%. When the concentration of ABTS is 0.33 g/L, the removal rate reaches above 97% and the degradation rate also reaches 65%, an increase of nearly 20% compared with that without ABTS. When the concentration of ABTS continues to increase, the growth of the degradation rate slows down. The degradation effect with ABTS concentration of 0.44 g/L is almost the same as that with ABTS concentration of 0.33 g/L. Therefore, considering the cost-effectiveness, ABTS concentration of 0.33 g/L appears to be an optimal concentration.

ABTS is a small molecular medium effective for the mediation of electron transfer to increase the electron transfer speed and the reaction rate of the system. The existence of small molecular mediators makes up the defect of low REDOX potential during the laccase degradation, and the large space steric hindrance formed during the degradation of pollutants by protein macromolecular is alleviated so that the degradation efficiency is promoted (Sasidharan et al. 2013; Solomon et al. 1996). The MXC degradation effect of laccase/ABTS mesosystem is significantly better than that of single immobilized laccase. However, as shown in Fig. 5, there is a downward trend of the degradation when the ABTS concentration is 0.66 g/L, indicating an inhabitation of higher media concentration. When the mediators’ oxidation potential is beyond the oxidation potential of laccase, the mediators’ oxidation rate by laccase decreases (Cañas and Camarero 2010; Bourbonnais et al. 1998), leading to the decreased degradation rate.

The reaction mechanism of laccase/ABTS mediator system is proposed as follows (Cañas and Camarero 2010; Bourbonnais et al. 1998): under the catalytic oxidation of the enzyme, the mediator is oxidized to a more active oxidation state with adequate stability. The oxidation state mediator could obtain electrons from oxygen molecules and transfer the electrons to the substrate, degrading the substrate as the oxidant. This is essentially an indirect oxidation reaction between the substrate and the enzyme. During the degradation of MXC by immobilized laccase, the mediator ABTS reacts with laccase immediately to lead to ABTS+ and ABTS++ that then react with the substrate MXC and reduce ABTS+ and ABTS++ to ABTS.

Effect of MXC concentration, degradation time, and immobilization on the degradation rate of MXC by immobilized compound enzyme in contaminated soil

Figure 6 shows the curve of the MXC removal rate by free enzyme and immobilized compound enzyme over time for three soil samples with different MXC concentrations. In Fig. 6, the removal rate of MXC by free enzyme is higher than that of immobilized enzyme in the range of one–four days in the initial stage. After four days, however, the removal rate of free enzyme shows the slower growth trend with the degradation time than that of immobilized enzyme because the free enzyme is easy to be hydrolyzed after five~six days. The higher the weight percent content of MXC, the lower the degradation rate of MXC by free enzyme.

The degradation of MXC by immobilized enzyme is weak at the initial mass ratio of 25 mg/kg, 50 mg/kg, and 100 mg/kg, and the removal is not obvious. But there is an adaptation or incubation stage for the degradation of MXC by immobilized enzyme, and the higher the initial weight percent content of MXC, the longer the adaptation time. After the adaptation, the MXC removal rate increases rapidly with the time. The total removal of MXC in the first 8 days is 85.8%, 76.5%, and 69.8% for the MXC mass ratio of 25 mg/kg, 50 mg/kg, and 100 mg/kg, respectively, which are significantly higher than those of free enzyme. At the end of the degradation reaction, the removal of the three MXC mass ratios were 93.0%, 85.8%, and 65.1%, respectively. The removal rate of MXC is higher in the middle stage and lower in the early and later stages. The average removal rate is 193.75, 357.50, and 542.51 mg/(kg day), respectively. The immobilized enzyme is much more stable than the free enzyme and could be used in the soil environment for a long time. The removal of MXC in low concentration in soil could reach above 85%, a remarkable potential for future applications in a variety of environmental conditions.

Acidity and temperature also have an influence for the pollutant removal by immobilized laccase. In Figs. S6 and 7, when the acidity is at 4.0–5.0 and temperature at 30–40 °C, the removal of MXC by the immobilized enzyme (cellulase to laccase ratio at 1:4) reaches above 85%.

Mechanism of MXC degradation by immobilized laccase and immobilized compound enzymes of laccase and cellulase

In order to study the reaction mechanism of co-immobilization of compound enzymes on chial-meso-SiO2@GO carrier in the degradation of MXC in polluted aqueous solution, the degradation products were tested by GC/MS.

The analysis of the mass spectrum (Fig. S8) shows that the degradation product by immobilized single enzyme of laccase appears to be 1,1-diphenylethylene (Fig. S9). The strong peak at m/z = 182 should be the molecular ion peak of benzophenone, the strong peak at m/z = 105 corresponds to the fragment of C8H7 + 2H+, the peak at m/z = 77 is the fragment ions of benzene ring C6H5, and m/z = 51 corresponds to the fragment ions for the C4H4- H+. So degradation route of MXC by immobilized laccase can be explained as follows:

The removal of a chlorine atom occurs in the first step, and the first intermediate product of 1,1′-dichloro-2, 2-bis(p-methoxyphenyl)-ethane is generated; then, the second and third chlorine are continuously removed, 1,1′-dihydro-2, 2-bis(p-methoxyphenyl)-ethylene can be obtained. The occurrence of demethoxylation leads to the production of the final product of 1,1′-dihydro-2, 2-bis(phenyl)-ethylene. The degradation products of MXC by immobilized compound enzymes of laccase and cellulase could be analyzed from the mass spectrum (Fig. S10), the final degradation product is benzoic acid (Fig. 7). The peak at m/z = 122 is attributed to the molecular ion of benzoic acid. The peak at m/z = 105 is the fragment of C6H5CO, and the peak at m/z = 77 is the benzene ring fragment of C6H5. Therefore, the specific reaction route is proposed as shown in Fig. 7.

It has been reported that cellulase could attack at a weak location of the dicofol molecule with its free radical OH and ultimately removes three chlorine atoms from dicofol, thus oxygenizing dicofol and producing 4,4′-dichloro-dibenzophenone (Zhang et al. 2011). Based on this fact, the degradation route of MXC by immobilized compound enzymes of laccase and cellulase could be deduced as follows. The weak position of CCl3 at molecule of MXC is first attacked by the OH free radical of cellulase, generating 1-hydroxyl-2, 2-bis(p-methoxyphenyl)-ethane and then second oxidized to the intermediate product of 4,40-methoxy-dibenzophenone by laccase. In the next third step, the ketone group of second intermediate product is attacked by the OH free radical of cellulase again, and the second intermediate cleavages into p-methoxy benzoic acid CH3OC6H5COOH and other molecular fragments. Last, the methoxy group would be removed under the action of laccase to obtain the degradation terminal product benzoic acid C6H5COOH.

From the above analysis, it is shown that the degradation products of immobilized laccase and immobilized compound enzyme are different. The compound enzyme degradation products have smaller molecular weights and simple structures, which may be related to the different function mechanism of laccase and cellulase. The first step by immobilized laccase is only to remove one chlorine atom in the degradation of MXC. In contrast with catalytic oxidation by immobilized laccase, the hydrolysis by immobilized compound enzymes of laccase and cellulase first remove carbon trichloride; this is due to the fact that the OH free radical of cellulase might play a role on attacking weak location of CCl3.

Conclusion

The composite material chial-meso-SiO2@GO was constructed as a support to immobilize compound enzymes of laccase and cellulase. Due to unique chemical and structural properties of GO, the co-immobilization improves thermostability, acid stability, and repeatability of the immobilized enzyme significantly. The enzyme activity was maintained at 74% of the initial activity after 7 times of repeated use. The chial-meso-SiO2@GO-immobilized compound enzyme was used for the degradation of MXC in aqueous phase. The optimum conditions for degradation of methoxychlor were screened out as follows: pH 4.5, MXC concentration 30 mg/L, immobilized enzyme dose 0.1 g, the maximum MXC removal of over 85%, and the maximum degradation rate of 59.58% by immobilized compound enzyme is higher than that of 50.75% by immobilized laccase when degradation time was 6 h at temperature of 45 °C. 0.33 g/L of ABTS can enhance both MXC removal rate and degradation rate above 97% and 65%, respectively. The chial-meso-SiO2@GO immobilized compound enzyme was also employed to treat three contaminated soils with MXC weight percent of 25, 50, and 100 mg/kg, and the MXC removal rate was observed as 93.0%, 85.8%, and 65.1%, respectively.

The GC-MS analyses showed the degradation product by chial-meso-SiO2@GO-immobilized laccase was 1,1-diphenylethylene, while the degradation product by chial-meso-SiO2@GO-immobilized compound enzyme was benzoic acid. The findings showed that they have different degradation route. The hydrolysis by immobilized cellulase may attack at a weak location of the MXC molecule with its free radical OH and ultimately removes three chlorine atoms from MXC molecule, leading to generating small molecular amount of degradation product.

References

Akanbi MO, Hernandez LM, Mobarok MH, Veinot JGC, Tufenkji N (2018) QCM–D and NanoTweezer measurements to characterize the effect of soil cellulase on the deposition of PEG-coated TiO2 nanoparticles in model subsurface environments. Environ Sci–Nano 5:2172–2183

Barrios-Estrada C, Rostro-Alanis MJ, Parra AL, Belleville MP, Sanchez-Marcano J, Iqbal HMN, Parra-Saldívar R (2018a) Potentialities of active membranes with immobilized laccase for bisphenol A degradation. Int J Biol Macromol 108:837–844

Barrios-Estrada C, Rostro-Alanis MJ, Muñoz-Gutiérrez BD, Iqbal HMN, Kannan S, Parra-Saldívar R (2018b) Emergent contaminants: endocrine disruptors and their laccase-assisted degradation-a review. Sci Total Environ 612:1516–1531

Bilal M, Rasheed T, Iqbal HM, Yan Y (2018) Peroxidases-assisted removal of environmentally-related hazardous pollutants with reference to the reaction mechanisms of industrial dyes. Sci Total Environ 644:1–13

Bilal M, Rasheedb T, Nabeelb F, Iqbalc HMN, Zhao YP (2019a) Hazardous contaminants in the environment and their laccase-assisted degradation-a review. J Environ Manag 234:253–264

Bilal M, Rasheed T, Zhao YP, Iqbal HMN (2019b) Agarose-chitosan hydrogel-immobilized horseradish peroxidase with sustainable bio-catalytic and dye degradation properties. Int J Biol Macromol 124:742–749

Bourbonnais R, Leech D, Paice MG (1998) Electrochemical analysis of the interactions of laccase mediators with lignin model compounds. BBA–Gen Subj 1379:381–390

Cañas AI, Camarero S (2010) Laccases and their natural mediators: biotechnological tools for sustainable eco-friendly processes. Biotechnol Adv 28:694–705

Chang RHY, Jang J, Wu KCW (2011) Cellulase immobilized mesoporous silica nanocatalysts for efficient cellulose-to-glucose conversion. Green Chem 13:2844

Chatha SAS, Asgher M, Iqbal HMN (2017) Enzyme-based solutions for textile processing and dye contaminant biodegradation—a review. Environ Sci Pollut Res 24:14005–14018

Che SA, Liu Z, Ohsuna T, Sakamoto K, Terasaki O, Tatsumi T (2004) Synthesis and characterization of mesoporous silica with chiral structure. Nature 429:281–284

Chen BY, Qiu JH, Mo HD, Yu YL, Ito K, Sakai E, Feng HX (2017) Synthesis of mesoporous silica with different pore sizes for cellulase immobilization: pure physical adsorption. New J Chem 41:9338–9345

Cohn MA, Kee Y, Haas W, Gygi SP, D’Andrea AD (2009) UAF1 is a subunit of multiple deubiquitinating enzyme complexes. J Biol Chem 284:5343–5351

Ding C, Sun HJ, Ren JS, Qu XG (2017) Immobilization of enzyme on chiral polyelectrolyte surface. Anal Chim Acta 952:88–95

Fragoeiro S, Magan N (2005) Enzymatic activity, osmotic stress and degradation of pesticide mixtures in soil extract liquid broth inoculated with Phanerochaete chrysosporium and Trametes versicolor. Environ Microbiol 7:348–355

Garcia-Morales R, Gomez-Mariscal KK, Orona-Navar C, Hernandez-Luna CE, García-Arrazola R, Torres E, Cardenas-Chavez D, Mahlknecht J, Parra R, Ornelas-Soto N (2015) Biotransformation of endocrine-disrupting compounds: bisphenol A, nonylphenol, ethynylestradiol and triclosan by a laccase cocktail from Pycnoporus sanguineus CS43. Water Air Soil Pollut 226:1–14

Gasser CA, Ammann EM, Shahgaldian P, Corvini PFX (2014) Laccases to take on the challenge of emerging organic contaminants in wastewater. Appl Microbiol Biotechnol 98:9931–9952

Gavelle EDe, de Lauzon-Guillain B, Charles MA, Chevrier C, Hulin M, Sirot V, Nougadere A (2016) Chronic dietary exposure to pesticide residues and associated risk in the French ELFE cohort of pregnant women. Environ Int 92:533-542.

Gonzalez-Coronel LA, Cobas M, Rostro–Alanis M, Parra R, Hernandez–Luna C, Pozos M, Sanromán MA (2017) Immobilization of laccase of Pyconporus sanguineus CS43. New Biotechnol 39:141–149

Gupta RK, Aberdeen G, Babus JK, Albrecht ED, Flaws JA (2007) Methoxychlor and its metabolites inhibit growth and induce atresia of baboon antral follicles. Toxicol Pathol 35:649–656

Hu X, Zhao X, Wang HM (2007) Comparative study of immobilized Trametes versicolor laccase on nanoparticles and kaolinite. Chemosphere 66:1618–1626

Huang Y, Yang YX, Wang XX, Yuan X, Pi N, Yuan HM, Liu XN, Ni CY (2018) Heterogeneous Fenton-like degradation of methoxychlor in water using two different FeS@hydrotalcites (LHDs) and Fe3O4@LHDs catalysts prepared via an in situ growth method. Chem Eng J 342:142–154

Ispas C, Sokolov I, Andreescu S (2009) Enzyme-functionalized mesoporous silica for bioanalytical applications. Anal Bioanal Chem 393:543–554

Jia F, Narasimhan B, Mallapragada S (2014) Materials-based strategies for multi-enzyme immobilization and co-localization: a review. Biotechnol Bioeng 111:209–222

Jones SM, van Dyk JS, Pletschke BI (2012) Bacillus subtilis SJ01 produces hemicellulose degrading multi-enzyme complexes. BioRes 7:1294–1309

Kim MI, Kim J, Lee J, Jia HF, Na HB, Youn JK, Kwak JH, Dohnalkova A, Grate JW, Wang P, Hyeon T, Park HG, Chang HN (2007) Crosslinked enzyme aggregates in hierarchically-ordered mesoporous silica: a simple and effective method for enzyme stabilization. Biotechnol Bioeng 96:210–218

Lee J, Kim J, Jia HF, MIl K, Kwak JH, Jin S, Dohnalkova A, Park HG, Chang HN, Wang P, Grate JW, Hyeon T (2005) Simple synthesis of hierarchically ordered mesocellular mesoporous silica materials hosting crosslinked enzyme aggregates. Small 1:744–753

Lin DR, Zhao Q, Hua LJ, Xing BS (2014) Synthesis and characterization of cubic mesoporous bridged polysilsesquioxane for removing organic pollutants from water. Chemosphere 103:188–196

Lin DR, Huang YC, Liu YQ, Luo TT, Xing BS, Yang YM, Yang ZF, Wu ZJ, Chen H, Zhang Q, Qin W (2018) Physico-mechanical and structural characteristics of starch/polyvinyl alcohol/nano-titania photocatalytic antimicrobial composite films. LWT Food Sci Technol 96:704–712

Nakanishi K, Tomita M, Kato K (2014) Improvement in the catalytic activity of cytochrome c by immobilisation on a novel mesoporous silica sheet. RSC Adv 4:4732–4735

Qiu XH, Zhu T, Li J, Pan HS, Li QL, Miao GF, Gong JC (2004) Organochlorine pesticides in the air around the Taihu Lake, China. Environ Sci Technol 38:1368–1374

Rasheed T, Bilal M, Nabeel F, Adeel M, Iqbal HMN (2019) Environmentally-related contaminants of high concern: potential sources and analytical modalities for detection, quantification, and treatment. Environ Int 122:52–66

Rodríguez-Delgado M, Orona-Navar C, García-Morales R, Hernandez-Luna C, Parra R, Mahlknecht J, Ornelas-Soto N (2016) Biotransformation kinetics of pharmaceutical and industrial micropollutants in groundwaters by a laccase cocktail from Pycnoporus sanguineus CS43 fungi. Int Biodeterior Biodegradation 108:34–41

Salazar-López M, Rostro-Alanis MJ, Castillo-Zacarías C, Parra-Guardado AL, Hernández-Luna C, Iqbal HMN, Parra-Saldivar R (2017) Induced degradation of anthraquinone-based dye by laccase produced from Pycnoporus sanguineus (CS43). Water Air Soil Pollut 228:469

Sasidharan M, Zenibana H, Nandi M, Bhaumik A (2013) Synthesis of mesoporous hollow silica nanospheres using polymeric micelles as template and their application as a drug-delivery carrier. Dalton Trans 42:13381–13389

Sharma B, Dangi AK, Shukla P (2018) Contemporary enzyme based technologies for bioremediation: a review. J Environ Manag 210:10–22

Solomon EI, Sundaram UM, Machonkin TE (1996) Multicopper oxidases and oxygenases. Chem Rev 96:2563–2606

Ullah S, Zorriehzahra MJ (2015) Ecotoxicology: a review of pesticides induced toxicity in fish. Adv Anim Vet Sci 3:40–57

Ullah S, Zuberi A, Alagawany M, Farag MR, Dadar M, Karthik K, Tiwari R, Dhama K, Iqba HMN (2018) Cypermethrin induced toxicities in fish and adverse health outcomes: Its prevention and control measure adaptation. J Environ Manag 206:863–871

Wu QH, Leung JYS, Yuan X, Huang XX, Li HY, Huang ZY, Li Y (2015) Biologicrisk, source and pollution history of organochlorine pesticides (OCPs) in the sediment in Nansha mangrove, South China. Mar Pollut Bull 96:57–64

Wu ZJ, Huang YC, Xiao LJ, Lin DR, Yang YM, Wang HW, Yang YQ, Wu DT, Chen H, Zhang Q, Qin W, Pu SY (2019) Physical properties and structural characterization of starch/polyvinyl alcohol/graphene oxide composite films. Int J Biol Macromol 123:569–575

Xu YX, Sheng KX, Li C, Shi GQ (2011) Highly conductive chemically converted graphene prepared from mildly oxidized graphene oxide. J Mater Chem 21:7376–7380

Yang YX, Wei QM, Zhang JB (2015) Degradation of MXC by host/guest-type immobilized laccase on magnetic tubular mesoporous silica. Biochem Eng J 97:111–118

Yang YX, Pi N, Zhang JB, Huang Y, Yao PP, Xi YJ, Yuan HM (2016) USPIO assisting degradation of MXC by host/guest-type immobilized laccase in AOT reverse micelle system. Environ Sci Pollut Res 23:13342–13354

Zdarta J, Antecka K, Frankowski R, Zgoła-Grześkowiak A, Ehrlich H, Jesionowski T (2018) The effect of operational parameters on the biodegradation of bisphenols by Trametes versicolor laccase immobilized on Hippospongia communis spongin scaffolds. Sci Total Environ 615:784–795

Zhai Z, Yang T, Zhang B, Zhang J (2015) Effects of metal ions on the catalytic degradation of dicofol by cellulase. J Environ Sci 33:163–168

Zhang F, Zheng B, Zhang J, Huang X (2010) Horseradish peroxidase immobilized on graphene oxide: Physical Properties and Applications in Phenolic Compound Removal. J Phys Chem C 114:8469–8473

Zhang JB, Yan HH, Yang T, Zong YE (2011) Removal of dicofol from water by immobilized cellulase and its reaction kinetics. J Environ Manag 92:53–58

Zhao F, Li H, Jiang Y, Wang X, Mu X (2014) Co-immobilization of multi-enzyme on control-reduced graphene oxide by non-covalent bonds: an artificial biocatalytic system for the one-pot production of gluconic acid from starch. Green Chem 16:2558–2565

Funding

This work was supported by the National Natural Science Foundation of China (20577010, 20971043), the Fundamental Research Funds for the Central Universities, and the Open Project Program of State Key Laboratory of Inorganic Synthesis and Preparative Chemistry, Jilin University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Diane Purchase

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 272 kb)

Rights and permissions

About this article

Cite this article

Huang, Y., Li, J., Yang, Y. et al. Characterization of enzyme-immobilized catalytic support and its exploitation for the degradation of methoxychlor in simulated polluted soils. Environ Sci Pollut Res 26, 28328–28340 (2019). https://doi.org/10.1007/s11356-019-05937-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-05937-x