Abstract

In this study, in-house isolated laccase isoforms, i.e., Lac-I and Lac-II of the basidiomycete Pycnoporus sanguineus (CS43), were evaluated in relation to their Remazol Brilliant Blue R (RBBR) dye degradation capacity. A modified Dhouib medium additionally supplemented with 3% ethanol as a secondary inducer was used to propagate P. sanguineus CS43 for enhanced production of laccase under liquid state fermentation. The crude laccase extract was purified by passing through ion exchange diethylaminoethanol (DEAE)-Sepharose and gel filtration-based Sephadex G-200 column chromatography. The purified laccase fractions were subjected to the electrophoresis, and sodium dodecyl sulfate-polyacrylamide gel electrophoresis analysis revealed two laccase isoforms Lac-I and Lac-II with 66 and 68 kDa, respectively. To explore the industrial applicability, for RBBR dye, degradation efficiencies ranged from 82 to 88% after 3 h of incubation for both; Lac-I and Lac-II at both concentrations were recorded. However, with 8 U/mL, the degradation ranged between 70 to 80% during the first 5 min of incubation. Enhanced degradation of RBBR dye was obtained in the presence of violuric acid and N-hydroxypthalamide as laccase mediators. Finally, using RBBR as a substrate kinetic characterization of both Lac-I and Lac-II isoforms was performed that revealed K m (0.243 and 0.117 mM for Lac-I and Lac-II) and V max (1.233 and 1.012 mM/Sec for Lac-I and Lac-II) values, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Dyes and colorants are widely used in a variety of industrial activities, including the production of paper, cosmetics, food, plastics, textiles, pharmaceuticals, and personal care products along with many others (Ahmed et al. 2017). The most obvious effect of dyes and colorants in the liquid effluents is esthetic, although there are other adverse effects such as high chemical and biological oxygen demand levels and reduction in photosynthetic activity due to the decrease in light penetration (Yesilada et al. 2003; Aksu 2005; Nilsson et al. 2006; Teerapatsakul et al. 2008; Asgher et al. 2016), that are toxic, carcinogenic, mutagenic, and posing serious health hazards to the entire living ecosystem (Asgher et al. 2014). Most of the industries discharged their routine waste, dyes, and dye-based effluents into the main water streams with or without some partial treatments. An eco-friendly treatment of such wastes, removal of dyes, and colorants from wastewaters is not simple and thus still a major environmental concern of the modern world (Agathos et al. 2010; Asgher and Iqbal 2013, Teerapatsakul et al. 2017).

In spite of the existing physical/chemical technologies which are usually expensive and commercially unattractive, biological processes provide an alternative cost-effective and eco-friendly approach that can be applied to wide range of dye-containing industrial effluents (Teerapatsakul et al. 2008; Asgher et al. 2012a, b; Asgher and Iqbal 2013). Thus, the use of other microorganisms, primarily fungi, has been explored as an alternative to degrade aromatic and recalcitrant compounds such as dyes (Lucas et al. 2006). The basidiomycetes group, in particular white rot fungi, has been reported as capable of degrading these types of contaminants by virtue of its extracellular ligninolytic enzyme system that includes laccases, lignin peroxidases, and manganese peroxidases (Eichlerova et al. 2007; Teerapatsakul et al. 2008; Asgher et al. 2012a, 2013; Asgher and Iqbal 2013).

Laccases (benzenediol: oxygen oxidoreductases, EC 1.10.3.2) can degrade a wide variety of substrates phenolic and aromatic pollutants. These enzymes belonging to the group of blue oxidases and possess a low redox potential which offers it the ability to be a good oxidizing agent (Shraddha et al. 2011). Laccases have much environmental application in bioremediation of herbicides, pesticides, and insecticides and biodegradation of different contaminants such as endocrine disruptors (Shraddha et al. 2011; Garcia-Morales et al. 2015; Rodríguez-Delgado et al. 2016; Gonzalez-Coronel et al. 2017; Barrios-Estrada et al. 2018).

Because laccases can catalyze the oxidation of aromatic compounds and lignin units, three applications of these enzymes for dyes degradation from wastewater has been studied. This paper reports the results of a study focused on the use of purified laccase isoforms, i.e.,, Lac-I and Lac-II produced from P. sanguineus (CS43) for the degradation of industrially relevant synthetic Remazol Brilliant Blue R (RBBR) dye(Ramírez-Cavazos et al. 2014). During the past many years, we have established substantial development in many processes related to the indigenous culture isolates and triggered in-depth studies of ligninolytic-secreting strains, their complex enzyme systems, and the use of those enzymes as a biological catalyst. In this context, the present study was aimed to evaluate the biological degradation potential of in-house isolated two laccase isoforms in the presence or absence of violuric acid (VA) and N-hydroxypthalamide (N-HPT) as a mediator to assess their efficiency in favoring the degradation of RBBR dye. Moreover, the kinetic and catalytic parameters were also calculated using different models including the Lineweaver-Burk, Eadie-Hofstee, Scatchard, and Hanes-Woolf.

2 Materials and Methods

2.1 Chemicals/Reagents and Textile Dyestuff

The anthraquinone-based dye Remazol Brilliant Blue R “RBBR” (CAS 2580-78-1), 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonate) diammonium salt (ABTS), diethylaminoethanol (DEAE)-Sepharose, Sephadex G-200, violuric acid (VA), and N-hydroxyphthalimide (N-HPT) were mainly purchased from Sigma-Aldrich (St. Louis, MO, USA). All culture medium components were purchased from Difco (BD Diagnostics, Sparks, USA). All other reagents used in the present study were of analytical laboratory grade and used as received without further purification. Figure 1 represents the chemical structure of RBBR textile dye and the two compounds were used as mediators, VA and N-HPT.

2.2 Microbial Culture Maintenance and Fermentation Protocol

In the present study, a previously isolated native strain of P. sanguineus (CS43) obtained from the local culture collection of the Universidad Autónoma de Nuevo León, Mexico, was initially maintained on yeast-malt-glucose agar medium (YMGA). Three mycelial plugs (5 mm) were taken from the fully grown culture and transferred to a modified Dhouib medium additionally supplemented with copper sulfate (0.35 mM) as a primary inducer. The main constituents of the fermentation medium were (g/L): glucose, 10; peptone, 5; yeast extract, 1; ammonium tartrate, 2; potassium phosphate, 1; potassium chloride, 0.5; magnesium sulfate, 0.5; and trace elements solution (ethylenediaminetetraacetic acid (EDTA), FeSO4, ZnSO4, MnCl2, H3BO4, CoCl2, CuCl2, and NaMoO4) in aqueous solution (1 mL). The medium was sterilized at 121 °C for 15 min. All of the sterilized culture flasks were incubated at 25 °C on a rotary shaker at 150 rpm. Three days after initial inoculation, ethanol (3%) was added as a secondary inducer.

2.3 Extraction Protocol and Laccase Activity

After the stipulated period, the fermented liquid broth was centrifuged at 14,000g for 10 min (Eppendorf Centrifuge Model 5415c) to remove the cell debris with maximal clearance. Following that, a 100-μL sample aliquot was taken from the previously centrifuged culture extract and the laccase activity was determined spectrophotometrically at 405 nm by monitoring the oxidation of ABTS. Blanks contained 100 μL of distilled water instead of culture supernatants. Laccase activity was expressed in units (U/mL). Laccase activity was measured using the formula as shown in Eq. 1:

where M is the slope of the reaction kinetics (absorbance/s), ε = 36,000 M−1 cm−1, Df is the sample dilution factor, and B is the cell path length (1 cm).

2.4 Laccase Purification

The crude laccase produced by the basidiomycete P. sanguineus (CS43) was purified by ammonium sulfate precipitation technique, followed by ion exchange DEAE-Sepharose and Sephadex G-200 column gel filtration chromatography. The desalted laccase extract was first ultra-filtered and then loaded on a DEAE-Sepharose column (2.5 × 17 cm) equilibrated with 20 mM sodium phosphate buffer of pH 6.0. The enzyme fractions were eluted with a linear concentration gradient from 20 to 150 mM potassium phosphate. Fractions containing laccase activity were collected and further concentrated in an Amicon cell. Ion exchange chromatography showed two distinct laccase activity peaks that were labeled as Lac-I and Lac-II according to the elution time. Concentrated samples of Lac-I and Lac-II were then applied and eluted independently on a Sephadex G-200 column (1.5 × 71 cm) equilibrated with 100 mM sodium phosphate buffer of pH 6.0. Fractions containing laccase activity were collected and concentrated. In both cases, an apparently homogeneous single peak was detected. The purified laccase fractions were subjected to the electrophoresis and sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis.

2.5 RBBR Dye Degradation Analysis

For RBBR degradation assays, each laccase isoform was assessed at 1 and 8 U/mL in the presence of VA and N-HPT as laccase mediators. RBBR dye was evaluated at two different concentrations, i.e., 50 and 100 mg/L. The analyses were performed at the maximum absorbance spectra (λmax) of the dye tested (595 nm) using a microplate reader (FLUOstar Omega, BMG Labtech, Germany).

The degradation efficiency was calculated in percent according to the equation:

where A 0 = initial absorbance and A f = final absorbance. The final absorbance for the dye RBBR was reported after 3 h incubation and for RB-5 after 15 h. The statistical analyses were performed using the statistical software Minitab 15.1. Treatment effects were declared statistically significant if P < 0.001 unless otherwise noted.

2.6 Kinetic Parameters Calculation

The kinetic constants, i.e., K m and V max of Lac-I and Lac-II for RBBR, were determined using different kinetic models: the Michaelis-Menten and Lineweaver-Burk, Eadie-Hofstee, Scatchard, and Hanes-Woolf models. The conditions of the experiment were at 25 °C. Equation 3 was used to calculate the kinetic parameters:

where v 1 is the rate of the enzyme-catalyzed reaction, [S] the concentration of substrate, K m the Michaelis-Menten constant, and V max is the maximum reaction rate. Table 1 shows additional methods for the calculation of the kinetic parameters used in this work.

3 Results and Discussion

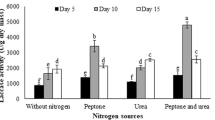

In-house isolated basidiomycete P. sanguineus (CS43) strain was used to produce its laccase isoforms Lac-I and Lac-II under some previously optimized liquid state fermentation parameters (Ramírez-Cavazos et al. 2014). After the stipulated fermentation period, the maximal Lac-1 and Lac-II activities of 2713 ± 41 and 2443 ± 113 U/L were recorded when the fermentation medium was additionally supplemented with 3% ethanol as a secondary inducer. Ligninolytic enzymes production is strongly affected by the nature and amount of the nutrients and physical elements of the growth substrate. A wider spectrum of various fungal species has particular responses to various nutrients and show different growth and enzyme activity patterns with different fermentation substrates (Vanhulle et al. 2007; Teerapatsakul et al. 2007; Junghanns et al. 2008; Iqbal et al. 2011; Iqbal and Asgher 2013). Moreover, the above mentioned both laccase isoforms, i.e., Lac-I and Lac-II were purified by passing through ion exchange DEAE-Sepharose and gel filtration-based Sephadex G-200 column chromatographic techniques accordingly. The purified laccase fractions were subjected to SDS-PAGE analysis and revealed two laccase isoforms Lac-I and Lac-II with 66 and 68 kDa, respectively (Fig. 2).

Dye degradation capability of the newly purified laccase isoforms produced by P. sanguineus was assayed on RBBR at 50 and 100 mg/L. Dye degradation was evaluated with 1 U/mL and 8 of the enzyme without redox mediators (Fig. 3). Both laccase isoforms, i.e., Lac-I and Lac-II, showed higher degradation behaviors against RBBR. At 50 mg/L RBBR concentration and after 3 h incubation, Lac-I at both 1 and 8 U/mL degraded about 84% of the dye, whereas Lac-II achieved 82 and 88% of degradation using 1 and 8 U/mL, respectively. For RBBR at 100 mg/L, both laccase isoforms showed a similar degradation pattern showing efficiencies above 80% at 1 and 8 U/mL. Degradation efficiency at the first 5 min by both laccase isoforms showed interesting results, where 8 U/mL of enzyme degraded 70 to 80% of initial dye concentration (50 and 100 mg/L). In order to make evident the initial velocities (V o) relevant to the Michaelis and Menten model, Fig. 4 shows a close-up of the fast kinetics occurring in the first 5 min of degradation with 8 U/mL of Lac-I and Lac-II; during this time, a significant degradation between 70 to 80% was reached for both isoforms. Other studies have tested RBBR degradation by laccases produced by Lentinula edodes (Nagai et al. 2002), Trametes SQ01 (Yang et al. 2009), Ganoderma lucidum (Murugesan et al. 2007), and P. sanguineus (Wang et al. 2010; Sarnthima and Khammuang 2013). Soares et al. (2001) reported no degradation of RBBR by a commercial laccase in the absence of redox mediators. In contrast, a laccase from P. sanguineus was able to degrade about 90% of this dye in 10 min with an activity of 5 U/mL.

Based on the factorial statistical analysis, the most significant factor in the dye degradation was the enzyme concentration, followed by the interaction between the enzyme isoform and enzyme concentration (Table 2), which explains the difference in degradation efficiency between 1 and 8 U/mL of the enzyme. The main effects were significant at P < 0.001 up to 10 min of degradation progress. The statistical analysis for the RBBR degradation at 3 h showed that the most significant factor in the dye degradation was an interaction between the enzyme isoform and enzyme concentration (Table 2). The two-way interaction was significant at P < 0.001, opposite to what was observed in the short incubation times.

The dye degradation efficiency for RBBR was very low for both laccase isoforms, i.e., Lac-I and Lac-II, owing to this issue two mediators, i.e., VA and N-HPT, were tested to enhance the overall degradation yield and were also added to reduce the degradation time. Each mediator was tested at 1 and 5 mM for colorant concentrations of 50 and 100 mg/L; the enzyme concentration selected was 1 U/mL (Figs. 5 and 6). The mediators are substrates that can be oxidized by laccase first forming highly active cation radicals capable of oxidizing non-phenolic compounds that laccase alone cannot oxidize (Asgher et al. 2014). The fastest degradation was achieved with Lac-I in the presence of VA at 5 mM and 50 mg/L of dye concentration, showing that higher degradation yields might be obtained at lower mediator concentrations. Meanwhile, slow degradation process was observed for Lac-II in the presence of VA (1 mM of mediator concentration) at 100 mg/L of dye concentration. After 5 min, degradation reached the stabilization phase with efficiencies around 80–90% at the end of 3 h. With an N-HPM mediator, Lac-I after 15 h of incubation showed efficiencies of 71 and 67% at 50 and 100 mg/L of dye, respectively. For Lac-II, the maximum degradation efficiencies were obtained after 15 h, reaching 67 and 37% for 50 and 100 mg/L of dye concentration.

The factorial statistical analysis showed that main effects, two- and three-way interactions were statistically significant at P < 0.001 at 25 min and 15 h of incubation time. Based on the factorial statistical analysis, a model was built with all the significant factors and interactions with a fit data of R adj 2 = 99.99%. The most significant factor in the dye degradation analysis was the mediator type, followed by mediator concentration. In initial speeds, VA caused the higher degradation percentage compared to N-HPM. This can be attributed to the difference in chemical structure that, although the VA does not have an aromatic ring, as most mediators, the presence of conjugated carbonyl groups can provide resonance in the cycle such as an aromatic ring. Thus, VA has a simpler structure compared to N-HPM and more like a phenolic ring. The model equation was based on the statistical parameters obtained in the experimental design at 25 min of incubation:

The kinetic parameters of the enzymatic reaction catalyzed by Lac-I and Lac-II were calculated using four different approaches: the Michaelis-Menten and Lineweaver-Burk model, Eadie-Hofstee model, Scatchard model, and Hanes-Woolf model. The enzyme concentration selected was 0.6 U/mL, and RBBR was used as the substrate. Lineweaver-Burk model best fitted the data (data not shown) with a correlation coefficient of 0.998. Model plots gave an apparent K m of 0.243 and 0.117 mM and V max 1.233 and 1.012 mM/s for Lac-I and Lac-II, respectively. From the K m can be concluded that Lac-II is a more efficient catalyst for RBBR substrate. Table 3 summarizes the enzyme kinetic fit with different methods for Lac-I and Lac-II, respectively. For Lac-II, concentrations of 30 and 50 mg/L of colorant were taken away from the calculation due to an error in the laccase concentration. Lac-II has two times higher K m than Lac-I which means that it will reach 50% of V max in half of the time although in larger concentrations, both isoforms will reach the same V max . It was demonstrated that the molecular weight difference (11%) of both enzymes has a degradation difference in the kinetic properties which is the starting point for new research on protein engineering.

4 Conclusion

In conclusion, both newly isolated laccase isoforms demonstrated the high capability to degrade reactive dyes. These new enzymes offer an opportunity to treat wastewater effluents that contain dyes with local technology. The use of synthetic mediators improved the overall dye degradation at the low mediator and isoform concentration. It is recommended further studies of these enzyme isoforms for other recalcitrant pollutants such as hormones and organic pesticides which are closely related at themolecular level to the tested dyes. Because of the great potential for degradation, it is interesting to study the scale-up process for industrial exploitation. Further studies are required in the medium design, bioreactor optimization, and the downstream process.

References

Agathos, S. N., Junghanns, C., Nair, R., Parra, R., Jaouani, A., & Demarche, P. (2010). Harnessing the power of enzymes for environmental stewardship. Journal of Biotechnology, 150, 57.

Ahmed, I., Iqbal, H. M. N., & Dhama, K. (2017). Enzyme-based biodegradation of hazardous pollutants—an overview. Journal of Experimental Biology and Agricultural Sciences, 5(4), 402–411.

Aksu, Z. (2005). Application of biosorption for the removal of organic pollutants: a review. Process Biochemistry, 40(3), 997–1026.

Asgher, M., & Iqbal, H. M. N. (2013). Enhanced catalytic features of sol–gel immobilized MnP isolated from solid state culture of Pleurotus ostreatus IBL-02. Chinese Chemical Letters, 24(4), 344–346.

Asgher, M., Iqbal, H. M. N., & Irshad, M. (2012a). Characterization of purified and xerogel immobilized novel lignin peroxidase produced from Trametes versicolor IBL-04 using solid state medium of corncobs. BMC Biotechnology, 12(1), 1–8.

Asgher, M., Kamal, S., & Iqbal, H. M. N. (2012b). Improvement of catalytic efficiency, thermo-stability and dye decolorization capability of Pleurotus ostreatus IBL-02 laccase by hydrophobic sol gel entrapment. Chem Cent, J6(1), 1–10.

Asgher, M., Shah, S. A. H., & Iqbal, H. M. N. (2016). Statistical correlation between Ligninolytic enzymes secretion and Remazol brilliant yellow-3GL dye degradation potential of Trametes versicolor IBL-04. Water Environment Research, 88(4), 338–345.

Asgher, M., Yasmeen, Q., & Iqbal, H. M. N. (2013). Enhanced decolorization of solar brilliant red 80 textile dye by an indigenous white rot fungus Schizophyllum commune IBL-06. Saudi Journal of Biological Sciences, 20(4), 347–352.

Asgher, M., Yasmeen, Q., & Iqbal, H. M. N. (2014). Development of novel enzymatic bioremediation process for textile industry effluents through response surface methodology. Ecological Engineering, 63, 1–11.

Barrios-Estrada, C., Rostro-Alanis, M. J., Muñoz-Gutiérrez, B. D., Iqbal, H. M. N., Kannan, S., & Parra-Saldívar, R. (2018). Emergent contaminants: endocrine disruptors and their laccase-assisted degradation-a review. Science of the Total Environment, 612, 1516–1531.

Eichlerova, I., Homolka, L., & Nerud, F. (2007). Decolorization of high concentrations of synthetic dyes by the white rot fungus Bjerkandera adusta strain CCBAS 232. Dyes and Pigments, 75(1), 38–44.

Garcia-Morales, R., Gomez-Mariscal, K. K., Orona-Navar, C., Hernandez-Luna, C. E., García-Arrazola, R., Torres, E., Cardenas-Chavez, D., Mahlknecht, J., Parra, R., & Ornelas-Soto, N. (2015). Biotransformation of endocrine-disrupting compounds: bisphenol A, nonylphenol, ethynylestradiol and triclosan by a Laccase cocktail from Pycnoporus sanguineus CS43. Water Air Soil Pollution, 226(251), 1–14.

Gonzalez-Coronel, L. A., Cobas, M., Rostro-Alanis, M., Parra, R., Hernandez-Luna, C., Pozos, M., & Sanromán, M. A. (2017). Immobilization of laccase of Pyconporus sanguineus CS43. New Biotechnology, 39(Part A), 141–149.

Iqbal, H. M. N., Asgher, M., & Bhatti, H. N. (2011). Optimization of physical and nutritional factors for synthesis of lignin degrading enzymes by a novel strain of Trametes versicolor. BioResources, 6(2), 1273–1287.

Iqbal, H. M. N., & Asgher, M. (2013). Characterization and decolorization applicability of xerogel matrix immobilized manganese peroxidase produced from Trametes versicolor IBL-04. Protein and Peptide Letters, 20(5), 591–600.

Junghanns, C., Parra, R., Keshavarz, T., & Schlosser, D. (2008). Towards higher laccase activities produced by aquatic ascomycetous fungi through combination of elicitors and an alternative substrate. Engineering Life Science, 8(3), 277–285.

Lucas, M. S., Amaral, C., Sampaio, A., Peres, J. A., & Dias, A. A. (2006). Biodegradation of the diazo dye reactive black 5 by a wild isolate of Candida oleophila. Enzyme and Microbial Technology, 39(1), 51–55.

Murugesan, K., Nam, I. H., Kim, Y. M., & Chang, Y. S. (2007). Decolorization of reactive dyes by a thermostable laccase produced by Ganoderma lucidum in solid state culture. Enzyme and Microbial Technology, 40(7), 1662–1672.

Nagai, M., Sato, T., Watanabe, H., Saito, K., Kawata, M., & Enei, H. (2002). Purification and characterization of an extracellular laccase from the edible mushroom Lentinula edodes, and decolorization of chemically different dyes. Applied Microbiology and Biotechnology, 60(3), 327–335.

Nilsson, I., Möller, A., Mattiasson, B., Rubindamayugi, M. S. T., & Welander, U. (2006). Decolorization of synthetic and real textile wastewater by the use of white-rot fungi. Enzyme and Microbial Technology, 38(1), 94–100.

Ramírez-Cavazos, L. I., Junghanns, C., Nair, R., Cárdenas-Chávez, D. L., Hernández-Luna, C. E., Agathos, S., & Parra, R. (2014). Enhanced production of thermostable laccases from a native strain of Pycnoporus sanguineus by optimization using central composite design. J Zhejiang Univ-Sci B (Biomed & Biotechnol), 15(4), 343–352.

Rodríguez-Delgado, M., Orona-Navar, C., García-Morales, R., Hernandez-Luna, C., Parra, R., Mahlknecht, J., & Ornelas-Soto, N. (2016). Biotransformation kinetics of pharmaceutical and industrial micropollutants in groundwaters by a laccase cocktail from Pycnoporus sanguineus CS43 fungi. International Biodeterioration & Biodegradation, 108, 34–41.

Sarnthima, R., Khammuang, S. (2013). Laccase production by Pycnoporus sanguineus grown under liquid state culture and its potential in remazol brilliant blue R decolorization. International Journal of Agriculture & Biology, 15(2).

Soares, G. M., de Amorim, M. P., & Costa-Ferreira, M. (2001). Use of laccase together with redox mediators to decolourize remazol brilliant blue R. Journal of Biotechnology, 89(2), 123–129.

Teerapatsakul, C., Parra, R., Bucke, C., & Chitradon, L. (2007). Improvement of laccase production from Ganoderma sp. KU-Alk4 by medium engineering. World Journal of Microbiology and Biotechnology, 23, 1519–1527.

Teerapatsakul, C., Bucke, C., Parra, R., Keshavarz, T., & Chitradon, L. (2008). Dye decolorisation by laccase entrapped in copper alginate. World Journal of Microbiology and Biotechnology, 24(8), 1367–1374.

Teerapatsakul, C., Parra, R., Keshavarz, T., & Chitradon, L. (2017). Repeated batch for dye degradation in an airlift bioreactor by laccase entrapped in copper alginate. International Biodeterioration & Biodegradation, 120, 52–57.

Vanhulle, S., Radman, R., Parra, R., Cui, T., Bols, C.-M., Tron, T., Sannia, G., & Keshavarz, T. (2007). Effect of mannan oligosaccharide elicitor and ferulic acid on enhancement of laccases production in liquid cultures of bacidiomycetes. Enzyme and Microbial Technology, 40, 1712–1718.

Wang, Z. X., Cai, Y. J., Liao, X. R., Tao, G. J., Li, Y. Y., Zhang, F., & Zhang, D. B. (2010). Purification and characterization of two thermostable laccases with high cold adapted characteristics from Pycnoporus sp. SYBC-L1. Process Biochemistry, 45(10), 1720–1729.

Yang, X. Q., Zhao, X. X., Liu, C. Y., Zheng, Y., & Qian, S. J. (2009). Decolorization of azo, triphenylmethane and anthraquinone dyes by a newly isolated Trametes sp. SQ01 and its laccase. Process Biochemistry, 44(10), 1185–1189.

Yesilada, O., Asma, D., & Cing, S. (2003). Decolorization of textile dyes by fungal pellets. Process Biochemistry, 38(6), 933–938.

Acknowledgements

The financial support by the FINNOVA project “Caracterización génica de nuevas isoenzimas lacasas de P. sanguineuspara la biorremediación de efluentes y suelos” contract no. 192118 is greatly appreciated.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Salazar-López, M., Rostro-Alanis, M.d.J., Castillo-Zacarías, C. et al. Induced Degradation of Anthraquinone-Based Dye by Laccase Produced from Pycnoporus sanguineus (CS43). Water Air Soil Pollut 228, 469 (2017). https://doi.org/10.1007/s11270-017-3644-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-017-3644-6