Abstract

This study investigated the effects of residual H2O2 on hydrolysis-acidification and methanogenesis stages of anaerobic digestion after microwave-H2O2 (MW-H2O2) pretreatment of waste activated sludge (WAS). Results showed that high sludge solubilization at 35–45 % was achieved after pretreatment, while large amounts of residual H2O2 remained and refractory compounds were thus generated with high dosage of H2O2 (0.6 g H2O2/g total solids (TS), 1.0 g H2O2/g TS) pretreatment. The residual H2O2 not only inhibited hydrolysis-acidification stage mildly, such as hydrolase activity, but also had acute toxic effect on methanogens, resulting in long lag phase, low methane yield rate, and no increase of cumulative methane production during the 30-day BMP tests. When the low dosage of H2O2 at 0.2 g H2O2/g TS was used in MW-H2O2 pretreatment, sludge anaerobic digestion was significantly enhanced. The cumulative methane production increased by 29.02 %, but still with a lag phase of 1.0 day. With removing the residual H2O2 by catalase, the initial lag phase of hydrolysis-acidification stage decreased from 1.0 to 0.5 day.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the extensive operation of wastewater treatment facilities, huge amounts of sewage sludge are generated annually. In China, over 6.25 million tons of dry sludge was generated in 2013 and increases with the annual growth rate of 13 % (Yang et al. 2015). However, more than 80 % of dewatered sludge is not treated properly (Liu et al. 2013). According to the Action Plan for Water Pollution Prevention and Control (The State Council of the people’s Republic of China 2015) issued by the State Council of China in April 2015, the sewage sludge treatment rate will increase to 90 % by 2020 and the existing sludge disposal facilities should be upgraded to fulfill discharge standard by 2017. Sewage sludge treatment and disposal has become an extremely urgent challenge in China. On the other hand, sewage sludge is nutrient and energy-rich material, which can be used as fertilizer, as well as the source for energy recovery. Anaerobic digestion is a common technology for sewage sludge treatment. Biogas from the sewage sludge anaerobic digesters can be used in combined heat and power system for energy recovery. In the USA, about 48 % of total wastewater flow is treated with anaerobic digestion (Shen et al. 2015). In Europe, anaerobic digestion is the most commonly used regarding sludge stabilization in the countries such as Spain, UK, Italy, and Finland (Kelessidis and Stasinakis 2012). However, there are still some barriers for the application of sludge anaerobic digestion combined with biogas utilization in wastewater treatment plants (WWTPs). In China, for the little attention paid to sewage sludge treatment in the past decades, less than 3 % of WWTPs are equipped with sludge anaerobic digestion, and most of them do not operate properly (Jin et al. 2014). In addition, due to low organic matter and high inorganic content of sewage sludge in China (He et al. 2007), the methane yield of sludge anaerobic digestion is always low. In the USA, for the challenges such as slow biogas production rate, low energy content of the biogas, and the costs to upgrade biogas, less than 10 % of the WWTPs with anaerobic digestion utilize the biogas for energy recovery. To overcome these barriers, it has been widely accepted that sludge pretreatment technologies have the potential to improve sludge biodegradability and economics of sludge anaerobic digestion (Shen et al. 2015).

Sludge pretreatment was proved to be an effective method for enhancing sludge anaerobic digestion in various studies (Carrère et al. 2010; Tyagi and Lo 2011; Kim et al. 2003). The pretreatment technologies, including mechanical, chemical, thermal, and enzymatic methods, can disintegrate extracellular polymeric substances (EPS), disrupt microbial cells for releasing soluble organics, and improve sludge biodegradability. Thermal pretreatment is one of the few scaleup and commercially implemented technologies, e.g., CAMBI thermal hydrolysis process. This thermal hydrolysis process requires intense operational conditions, such as high temperature (150–180 °C) and high pressure (8–9 bars) (Pilli et al. 2014). Microwave irradiation is considered to be an alternative technology to conventional thermal pretreatment for the advantages of rapid heating and energy-efficient (Tyagi and Lo 2011; Mudhoo and Sharma 2011). Sludge anaerobic digestion has been proved to be significantly enhanced by microwave pretreatment both at the temperatures lower than boiling point (<100 °C) (Kuglarz et al. 2013) and higher temperatures between 110 and 175 °C (Toreci et al. 2009; Mehdizadeh et al. 2013). In previous studies (Eskicioglu et al. 2007a, b, c, 2008a; Sólyom et al. 2011; Kuglarz et al. 2013; Houtmeyers et al. 2014), the cumulative methane or biogas production could be improved by 15–50 % with microwave pretreatment at the temperatures lower than boiling point (<100 °C). Microwave pretreatment at higher temperatures between 110 and 175 °C was considered to be more efficient for sludge solubilization and enhancement of sludge anaerobic digestion. Eskicioglu et al. (2009) reported that an increase of 31 ± 6 % cumulative biogas production was observed by microwave pretreatment at temperature of 175 °C, which was much higher than the other pretreatment temperatures (50, 75, 120, 150 °C).

To further enhance sludge solubilization and anaerobic digestion, microwave irradiation combined with chemicals such as acid (Xiao et al. 2012a; Liu et al. 2015), alkali (Doğan and Sanin 2009; Chi et al. 2011; Jang and Ahn 2013), and H2O2 (Wong et al. 2006; Eskicioglu et al. 2008b; Wang et al. 2009; Xiao et al. 2012b; Bilgin Oncu and Akmehmet Balcioglu 2013) have been investigated. A better performance for sludge solubilization and anaerobic digestion can be achieved. Besides, the low temperature microwave irradiation combined with chemicals has the potential of enhancing sludge solubilization and anaerobic digestion under more acceptable conditions (Eskicioglu et al. 2008b; Liu et al. 2015). MW-H2O2 treatment was considered as a microwave-enhanced advanced oxidation process (MW-H2O2-AOP), which was an efficient and promising technology for sludge disintegration (Tyagi and Lo 2011), 20–37 % of total chemical oxygen demand (TCOD) could be solubilized at temperatures of 100–120 °C according to the previous studies (Eskicioglu et al. 2008b; Wang et al. 2009; Bilgin Oncu and Akmehmet Balcioglu 2013). Xiao et al. (2012a) reported that the soluble chemical oxygen demand (SCOD) was increased by 30.52 times after MW-H2O2 treatment, which was more efficient than MW, MW-acid and MW-alkali pretreatment methods.

Although the high solubilization performance was achieved by MW-H2O2 treatment, its impact on subsequent anaerobic digestion remains controversial. Liu et al. (2015) compared MW-H2O2 pretreatment with other methods (MW, MW-acid) in terms of sludge solubilization and anaerobic digestion, and the cumulative methane production was improved by 13.34 % with MW-H2O2 pretreatment at the conditions of 100 °C and 0.2 g H2O2/g TS. However, Eskicioglu et al. (2008b) reported that a 25 % reduction of methane yield occurred for the thickened WAS with H2O2 addition (1 g H2O2/g TS) at MW temperature of 100 °C. Shahriari et al. (2012) reported that anaerobic digestion was inhibited when municipal solid waste was pretreated by MW-H2O2 (0.66 g H2O2/g TS) at 85 °C and speculated that the inhibition of anaerobic digestion was possibly due to the residual H2O2 or the refractory compounds generated after MW-H2O2 pretreatment. Eskicioglu et al. (2008b) also pointed out that the formation of refractory organics led to the low biodegradability of sludge after MW-H2O2 pretreatment. However, these hypotheses were still not investigated clearly because the quantity of refractory compounds or residual H2O2 was never detected in these studies. To our knowledge, the residual H2O2 is an important factor for its toxic effect on cells (Jang and Imlay 2007). Especially, obligate anaerobes do not employ oxygen as a substrate, and their growth will quickly cease even small amounts of oxygen are introduced (Mishra and Imlay 2013). In addition, great amounts of residual H2O2 were detected in sludge pretreated by MW-H2O2 in our previous study (Xiao et al. 2012b). Therefore, although MW-H2O2 pretreatment of sludge for enhancing anaerobic digestion has been investigated in several studies, there are still many questions which need to be definitely answered, for instance: (1) What is the appropriate H2O2 dosage in pretreatment for enhancing sludge anaerobic digestion? (2) What is the mechanism of the inhibitory effect? (3) Is there a method to control the inhibitory effect and further improve the performance of sludge anaerobic digestion?

Based on the three-stage theory of anaerobic digestion, we speculated that the residual H2O2 possibly has inhibitory effect on hydrolysis-acidification or methanogenesis stages of sludge anaerobic digestion. Therefore, the purpose of this study was to investigate (1) the effects of H2O2 dosage on anaerobic digestion of sludge pretreated by MW-H2O2 pretreatment and (2) whether hydrolysis-acidification, methanogenesis, or both were inhibited by residual H2O2 during anaerobic digestion or not.

Materials and methods

Sludge pretreatment by MW-H2O2

Waste-activated sludge was collected from Qinghe municipal wastewater treatment plant with the sewage treatment capacity of 550,000 m3/day using A2/O activated sludge process in Beijing. After thickening, the sludge was stored at 4 °C and screened through 18-mesh sieve before pretreatment. The characteristics of WAS are listed in Table 1.

An industrial microwave oven operating at 2450 MHz, ambient pressure, with an adjustable power range from 0 to 1000 W was used in this study. Sludge pretreatment was conducted according to the strategy proposed by Wang et al. (2009). To improve the H2O2 oxidation efficiency and reduce the amounts of residual H2O2, NaOH solution at 5 mol/L was firstly added to adjust pH of the raw sludge to 10.0, and then the sludge was heated to 80 °C by microwave irradiation for inhibiting activity of catalase which is present in aerobic living cells. After that, H2O2 (A.R., 30 %, w/w) was added at different dosage of 0.2 g H2O2/g TS, 0.6 g H2O2/g TS, and 1.0 g H2O2/g TS, respectively. Finally, the sludge was continuously heated to 100 °C with microwave irradiation operating at 600 W, ambient pressure. Considering the energy consumption saving, easy maintenance, and safety of this MW-H2O2 pretreatment strategy in practice, temperature high than 100 °C was not preferred. The pretreatment process was carried out in 1 L beakers with plastic cap but was not sealed. Three hundred milliliters of sewage sludge in the beaker was heated at the rate of 20 °C/min to reach the target temperature, not holding at 80 or 100 °C. The characteristics of pretreated sludge are listed in Table 1. During MW heating, some water lost due to evaporation, therefore the TS and volatile solids (VS) concentration, increased by dosing 0.2 g H2O2/g TS. Additionally, about 5 mL NaOH solution was added to adjust pH of 300 mL sludge to 10.0, and about 4.39, 13.18, and 21.97 mL of H2O2 (A.R., 30 %, w/w) was added to 300 mL sludge to obtain the required H2O2 dosage of 0.2, 0.6, and 1.0 g H2O2/g TS, respectively. The more volume of H2O2 added in the pretreatment process led to the decrease of TS and VS concentration with 1.0 g H2O2/g TS dosage. Besides, it was found that the TCOD concentration was higher after pretreatment at all H2O2 dosages. This was probably caused by the residual H2O2 in pretreated sludge that was still not decomposed adequately by catalase during the analysis of chemical oxygen demand (COD) because the residual H2O2 can improve the measured COD value (Kang et al. 1999).

Anaerobic digestion

The biochemical methane potential (BMP) tests were conducted to analyze sludge biodegradability of anaerobic digestion. The BMP tests were performed by an AMPTS II instrument made by Bioprocess Control Company, Sweden. Four hundred milliliters of working volume bottles were fed with sludge samples and inoculum. Total 15 bottles including blanks, controls, and pretreatment groups with triplicate for each were kept in water bath at 37 ± 1 °C. The volume of different samples and inoculum in each bottle was calculated according to the inoculum to substrate ratio (ISR) based on VS content (Raposo et al. 2012), as listed in Table 2. Each bottle was equipped with a motor and rotating shaft for mixing at the speed of 112 rpm in an interval pattern. NaOH solution (3 mol/L) was used for absorption of CO2 in biogas. The volume of daily methane produced was automatically recorded and normalized (1.0 standard atmospheric pressure, 0 °C, and zero moisture content) by AMPTS II instrument.

The anaerobic inoculum was collected from the effluent of mesophilic anaerobic sludge digesters (sludge retention time (SRT) of 25–30 days) treating a mixture of WAS and primary sludge in Xiaohongmen municipal wastewater treatment plant with the sewage treatment capacity of 600,000 m3/day in Beijing. Before the BMP tests, no acclimation of the inoculum to MW pretreated or MW-H2O2 pretreated sludge was conducted.

Hydrolysis and acidification batch experiments

Batch experiments of hydrolysis-acidification were carried out with the same instrument as the BMP tests, while methane production was not recorded due to the frequent sampling. Only the sludge samples pretreated with H2O2 dosage of 0.2 g H2O2/g TS were tested in hydrolysis and acidification batch experiments. To confirm the inhibitory effect of residual H2O2, catalase was added into the pretreated sludge with concentration of 100 mg/L. The performance of hydrolysis-acidification was evaluated comparing with the control (without catalase addition). During the batch experiments, sampling was taken at the day of 0, 0.5, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, and 8.0 days respectively.

Analytical methods

All chemical analyses were carried out in duplicate. The β-glucosidase activities were measured according to Zhou et al. (2005) with p-nitrophenyl-β-d-glucopyranoside as the standards. Co-enzyme F420 was assayed by spectrophotometry (TU-1900, Purkinje General Instrument Co., Ltd, China); the extraction method was according to Qiang et al. (2014). Details for the other analytical methods such as TS, VS, residual H2O2, protein, carbohydrate, volatile fatty acids (VFAs), and COD were shown in the supporting information.

The degree of sludge organics solubilization was described according to the calculation of CODsolubilization, which details were shown in the supporting information. The anaerobic biodegradability was evaluated by fitting the cumulative methane production data with modified Gompertz equation (Eq. (1)) (Carvajal et al. 2013):

Where P is the methane production potential (mL/gVSadded), R m is the maximum methane yield rate (mL/day·gVSadded), and λ is the duration of lag phase (day). Gompertz equation fitting was carried out using the software SPSS version 18.0 for windows (SPSS, IBM, USA).

Results and discussion

Methane production

Although sludge solubilization reached 35–45 % at different H2O2 dosage pretreatment as shown in Fig. S1, a plenty of residual H2O2 remained in pretreated sludge (Table 1), nearly 8 times more residual H2O2 were detected in pretreated sludge with H2O2 dosage at 1.0 g H2O2/g TS compared with the H2O2 dosage at 0.2 g H2O2/g TS. The residual H2O2 in pretreated sludge would possibly damage the microbial cells or inhibit the microbial metabolism of anaerobic digestion. As shown in Fig. 1, the initial methane production could reveal the biodegradation rate and toxicity of tested samples relative to the control. The cumulative final methane production gave a valuable information on ultimate biodegradability. Compared with the control, MW-H2O2 pretreatment resulted in a lag phase (λ) in the initial days of BMP tests, especially for the sludge pretreated with high H2O2 dosage of 0.6 and 1.0 g H2O2/g TS (Table 3), which lasted up to 7.9 and 8.0 days, respectively. These results indicated the inhibitory effect of pretreated sludge on anaerobic digestion in initial days. This inhibitory effect was probably caused by the large amounts of residual H2O2 in pretreated sludge (Table 1). H2O2, known as one of the toxic forms of oxygen, could damage protein, lipids, and DNA components in organisms. For this reason, H2O2 was capable of inhibiting growth of pathogenic bacteria (Zhao et al. 1998). As a highly active biocide, H2O2 at concentration of 30 to 1000 mg/L can inhibit the bioactivity of microbial cells and has lethal effect on many bacteria (Jiang and Yuan 2013). The great amounts of residual H2O2 in pretreated sludge would damage microbial cells or inhibit microbial metabolism in anaerobic digestion of sludge. Due to the inhibitory effect with excessive H2O2 addition in pretreatment, low methane yield rate (R m ) was obtained at 0.6 and 1.0 g H2O2/g TS, respectively. The maximum methane yield rate was observed in the anaerobic digestion of pretreated sludge with the H2O2 dosage of 0.2 g H2O2/g TS, which was slightly higher than the control. After the 30-day BMP tests, the cumulative methane production (P) was significantly improved with MW-H2O2 pretreatment at low dosage of H2O2 (0.2 g H2O2/g TS), 29.02 % higher than the control. Although the similar concentration of soluble organics was released (Fig. S1), no enhancement of cumulative methane production was obtained with high H2O2 dosage (0.6 and 1.0 g H2O2/g TS) pretreatment. These results revealed that the refractory soluble organics were generated at high H2O2 dosage pretreatment. Increasing sludge solubilization does not always result in enhanced anaerobic digestion. Kim et al. (2013) observed that the soluble fraction obtained under mild pretreatment conditions (pH = 9 and ultrasonication 5 min) achieved 91 % methane yield of soluble fraction, while only 61 % methane yield of soluble fraction was obtained at conditions of pH = 13 and ultrasonication 60 min. The fraction of pretreated sludge, which was soluble but not convertible to methane, increased from 2.4 to 25.8 % in sludge under severe pretreatment conditions. The results of refractory soluble organics generated in thermal and chemical pretreatment processes were also discussed in several other studies. Slightly lower rate constants (k) of soluble organics degradation were observed due to MW or conventional heating pretreatment (at 96 °C) in Eskicioglu’s study (Eskicioglu et al. 2006). Bougrier et al. (2007) also reported that the soluble protein removal rate decreased from 75 % for the control to only 68 % due to thermal pretreatment at 190 °C. The formation of refractory compounds such as melanoidines from Maillard reactions was the most possible explanation to account for these results (Pilli et al. 2014; Wilson and Novak 2009).

Therefore, severe pretreatment conditions such as H2O2 dosage higher than 0.6 g H2O2/g TS in the MW-H2O2 pretreatment were not beneficial for enhancing sludge anaerobic digestion. On the one hand, the great amounts of residual H2O2 would cause inhibitory effect on sludge anaerobic digestion; on the other hand, soluble refractory compounds were generated which resulted in no enhancement of cumulative methane production. On the contrary, the H2O2 dosage at 0.2 g H2O2/g TS in this study was effective for enhancing sludge anaerobic digestion. Even though still a lag phase was observed in initial 1.0 day, the cumulative methane production was improved significantly.

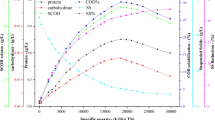

Degradation of organics

To investigate the negative effects of excessive H2O2 addition, degradation of key organics was analyzed during anaerobic digestion of sludge. Four times’ samplings were carried out during the BMP tests. As shown in Fig. 2a, with excessive addition of H2O2 (0.6 and 1.0 g H2O2/g TS) in MW-H2O2 pretreatment, the released soluble organics were less degraded in the initial 8.0 days. The SCOD removal rate was only 12.21 and 14.16 % for the H2O2 dosage of 0.6 and 1.0 g H2O2/g TS, respectively. On the contrary, the soluble organics were more degradable with pretreatment at low H2O2 dosage of 0.2 g H2O2/g TS, with 42.84 % of SCOD removal. This result was consistent with methane production in the initial 8.0 days, as shown in Fig. 1b, which demonstrated that the released soluble organics were not converted into methane with high H2O2 dosage pretreatment. After 30 days of thorough anaerobic digestion, almost no methane was produced any more. Overall, SCOD removal rate was up to 76.69, 72.64, and 73.28 % through anaerobic digestion with different H2O2 dosage pretreatment (0.2, 0.6, and 1.0 g H2O2/g TS, respectively). The remaining soluble organics were non-biodegradable in anaerobic digestion and increased with more H2O2 addition in pretreatment as shown in Fig. 2a.

As a microbiological process for converting biodegradable organics into methane, anaerobic digestion includes four steps, namely hydrolysis, acidogenesis, acetogenesis, and methanogenesis (Rajendran et al. 2014). Soluble protein, carbohydrate, VFAs, and methane are the key substances during anaerobic digestion. As shown in Fig. 2b, in the initial 8.0 days, soluble protein removal rates of pretreated sludge with different H2O2 dosage (0.2, 0.6, and 1.0 g H2O2/g TS) were 52.44, 53.44, and 47.37 %, respectively. After 30 days of anaerobic digestion, the overall soluble protein removal rates were 79.90, 81.04, and 80.46 %, respectively. Similarly, slightly lower removal rates of soluble carbohydrate with higher H2O2 addition in pretreatment were observed in the initial 8.0 days, e.g., 55.65, 46.18, and 38.83 %, respectively. These results indicated that the hydrolysis of protein and carbohydrate was mildly inhibited in the initial 8.0 days, but the process was still capable of hydrolyzing these substances. In addition, VFAs and acetic acid were generated, as shown in Fig. 3, which revealed that the acidogenesis and acetogenesis processes were also proceeding. However, it was found that the VFAs’ quantities and composition between high H2O2 dosage (0.6 and 1.0 g H2O2/g TS) and low H2O2 dosage (0.2 g H2O2/g TS) pretreatment in the initial 8.0 days were dramatically different. More VFAs especially acetic acid accumulated in the sludge pretreated with high H2O2 dosage. Acetic acid is the main substance used by methanogens for methanogenesis. Its accumulation combined with nearly no methane production in the initial 8.0 days revealed that the methanogenesis was seriously inhibited. However, with the low H2O2 dosage (0.2 g H2O2/g TS) in pretreatment, little negative effects on anaerobic digestion were observed.

Enzymatic activity

During the sludge anaerobic digestion, the conversion of macromolecular organics to methane depends on the enzymatic reactions. The pretreated sludge introduced into the anaerobic digestion system would result in the inhibitory effects on methane production as mentioned previously. The further research was thus carried out in this study in order to investigate the mechanism based on enzymatic activity.

β-Glucosidase is one of hydrolytic enzymes which is related to carbohydrate metabolism. Cellulose, as one of the carbohydrates, could be converted into glucose through synergetic action of endoglucanase, exoglucanase, and β-glucosidase enzymes (Sambusiti et al. 2014). Figure 4a shows that β-glucosidase activities of sludge during BMP tests with high H2O2 dosage (0.6 and 1.0 g H2O2/g TS) pretreatment were lower than that of the control and sludge with low H2O2 dosage (0.2 g H2O2/g TS) pretreatment. Therefore, lower soluble carbohydrate degradation rates were observed with high H2O2 dosage pretreatment in the initial 8.0 days, 55.65, 46.18, and 38.83 %, respectively. Besides, MW-H2O2 pretreatment with low H2O2 dosage (0.2 g H2O2/g TS) also resulted in the lower β-glucosidase activity compared with the control; this was due to the death of microorganisms in WAS after pretreatment. For these microorganisms in WAS are capable of hydrolyzing biodegradable organics. Along with the 30.0-day anaerobic digestion, the inhibitory effect of MW-H2O2 pretreatment on β-glucosidase activity weakened gradually. These results indicated that the high dosage of H2O2 (higher than 0.6 g H2O2/g TS) in the MW-H2O2 pretreatment had a negative effect on hydrolase activity in sludge anaerobic digestion, which would result in a slower hydrolysis rate of organics.

A further measurement of F420, which is a specific co-enzyme that only exists in methanogens and plays a key role in the metabolism of methanogenic bacteria, was used to quantify the methanogen biomass (Kubota et al. 2009). Figure 4b shows that the concentration of co-enzyme F420 in sludge with MW-H2O2 pretreatment decreased compared with the control in the initial 8.0 days. The higher H2O2 dosage led to a greater extent of methanogen biomass reduction. This result indicated that part of methanogens was killed due to the excessive H2O2 addition in pretreatment. Therefore, negative effect of residual H2O2 on methanogens was partially proved. Along with the 30.0-day anaerobic digestion, no significant change of methanogen biomass in each bottle was observed. This trend was not coincident with the changes of daily flow rate of methane production (Fig. 2b). Although great amounts of residual H2O2 resulted in the cease of converting acetic acid into methane, firstly, it gradually recovered after 8.0 days of anaerobic digestion. Therefore, the measurement of F420 concentration could not be used to explain the residual H2O2 inhibitory effect on methanogens adequately. From another point of view, this result revealed that the cease of methanogens metabolic activity would be the main reason that no acetic acid was converted into methane, but not the reduction of methanogen biomass. Actually, co-enzyme F420 concentration could not be adequate to reveal the potential methanogetic activity of methanogens. Although the concentration of co-enzyme F420 in several studies has been used to evaluate the ultrasonication pretreatment’s influence on anaerobic digestion (Mao and Show 2007), or the metabolic activity in the two-phase integrated sludge thickening and digestion reactor (Qiang et al. 2014), it is still not possible to estimate the potential methanogetic activity definitely (Dolfing and Mulder 1985). In this study, after 8.0 days of lag phase, the methanogen biomass did not increase obviously but methanogetic activity could recover even though large amounts of residual H2O2 introduced into sludge. Mishra and Imlay (2013) have reported that obligate anaerobes have the capacity of scavenging H2O2 through a consortium of enzymes. Obligate anaerobes do not employ oxygen as substrate, and their growth quickly ceases even if small amounts of oxygen are introduced. If an enzyme is damaged only, these obligate anaerobes could enter a period of stasis and ride out oxygen exposure until a more permissive hypoxic environment recovered.

Effect of residual H2O2 on hydrolysis and acidification

According to the results of BMP tests as mentioned previously, both hydrolysis-acidification and methanogenesis stages were inhibited. The inhibitory effect on metabolic activity of methanogens was much more serious, which resulted that acetic acid could not be converted into methane in initial days. However, it was still not confirmed that these inhibitory effects were derived from the residual H2O2 or the refractory compounds. For this purpose, the catalase was used to decompose the residual H2O2 in pretreated sludge. Catalase was more capable of decomposing H2O2 than MnO2 (Fig. S2). After 10 min, more than 2000 mg/L residual H2O2 in pretreated sludge was almost decomposed.

As shown in Fig. 5a, soluble organics released in the initial 2.0 days due to hydrolysis, and then were degraded because of methane production reversely. With the addition of catalase, more soluble organics were released compared with the control because the residual H2O2 was removed. Similar results were observed in the VFAs production (Fig. 5b), and more VFAs were produced after the residual H2O2 was removed with catalase. Additionally, the initial lag phase of hydrolysis-acidification stage decreased from 1.0 to 0.5 day. These results confirmed that the residual H2O2 surely had inhibitory effect on anaerobic digestion of sludge pretreated by MW-H2O2.

Therefore, it is worth noting that the high COD solubilization does not always result in enhanced anaerobic digestion of sludge. This negative effect of thermal-chemical pretreatment was caused by multiple reasons. Firstly, the formation of refractory compounds such as melanoidines has been suggested in many researches. Besides, the inhibitory effect on microbial metabolism was another key factor. Both Eskicioglu et al. (2007c) and Toreci et al. (2011) observed that inhibition of MW pretreatment on sludge anaerobic digestion occurred in the initial days of BMP tests, and this inhibition could be minimized by acclimation of anaerobic digestion inoculum. As shown in Fig. 6, this work confirmed that the residual H2O2 in the MW-H2O2 pretreatment process was another key factor, which not only resulted in the mild inhibition of hydrolysis-acidification stage, but also seriously inhibited metabolic activity of methanogens in anaerobic digestion. The way of removing residual H2O2 such as catalase addition after MW-H2O2 pretreatment could relieve the inhibitory effect.

Furthermore, the significant improvement of sludge biodegradability with low H2O2 dosage in pretreatment indicated that the MW-H2O2 pretreatment process could be a potential method for enhancing sludge anaerobic digestion in practice. Moreover, a continuous flow mode of sludge pretreatment can be achieved in MW-H2O2 pretreatment process (Yu et al. 2010). Wang et al. (2015) have reported a pilot scale study of sludge pretreatment by MW-H2O2. These researches indicated that MW-H2O2 pretreatment is suitable for treating sludge of full-scale WWTPs. However, for the enhanced anaerobic digestion, most studies so far have been conducted on laboratory scale with batch experiments. Scaling up the method is still difficult for the absent information such as the effect of MW-H2O2 pretreatment on anaerobic digestion in continuously fed digesters and the economic feasibility of this method.

Conclusions

The present work evaluated effects of residual H2O2 on hydrolysis-acidification and methanogenesis stages of anaerobic digestion after MW-H2O2 pretreatment of municipal sludge. A deeper understanding of this inhibition process has been provided. Great amounts of residual H2O2 in pretreated sludge after MW-H2O2 pretreatment resulted in inhibitory effect on sludge anaerobic digestion in the initial days of BMP tests. Besides, more refractory compounds were generated after pretreatment with high H2O2 dosage (0.6 and 1.0 g H2O2/g TS). These negative effects gave rise to a long lag phase, low methane production rate, and no enhancement of cumulative methane production, even though high COD solubilization was achieved after MW-H2O2 pretreatment. The residual H2O2 had seriously inhibitory effect on metabolic activity of methanogens and inhibited hydrolysis-acidification stage of anaerobic digestion mildly. Low dosage of H2O2 such as 0.2 g H2O2/g TS in MW-H2O2 pretreatment process was appropriate for enhancing anaerobic digestion. The cumulative methane production was increased by 29.02 % compared with the control. Moreover, decomposition of the residual H2O2 by catalase can relieve the inhibitory effect on enhanced anaerobic digestion.

References

Bilgin Oncu N, Akmehmet Balcioglu I (2013) Microwave-assisted chemical oxidation of biological waste sludge: simultaneous micropollutant degradation and sludge solubilization. Bioresour Technol 146:126–134. doi:10.1016/j.biortech.2013.07.043

Bougrier C, Delgenès JP, Carrère H (2007) Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge. Biochem Eng J 34:20–27. doi:10.1016/j.bej.2006.11.013

Carrère H, Dumas C, Battimelli A et al (2010) Pretreatment methods to improve sludge anaerobic degradability: a review. J Hazard Mater 183:1–15. doi:10.1016/j.jhazmat.2010.06.129

Carvajal A, Peña M, Pérez-Elvira S (2013) Autohydrolysis pretreatment of secondary sludge for anaerobic digestion. Biochem Eng J 75:21–31. doi:10.1016/j.bej.2013.03.002

Chi Y, Li Y, Fei X et al (2011) Enhancement of thermophilic anaerobic digestion of thickened waste activated sludge by combined microwave and alkaline pretreatment. J Environ Sci 23:1257–1265. doi:10.1016/S1001-0742(10)60561-X

Doğan I, Sanin FD (2009) Alkaline solubilization and microwave irradiation as a combined sludge disintegration and minimization method. Water Res 43:2139–2148. doi:10.1016/j.watres.2009.02.023

Dolfing J, Mulder JW (1985) Comparison of methane production rate and coenzyme F420 content of methanogenic consortia in anaerobic granular sludge. Appl Environ Microbiol 49:1142–1145

Eskicioglu C, Kennedy KJ, Droste RL (2006) Characterization of soluble organic matter of waste activated sludge before and after thermal pretreatment. Water Res 40:3725–3736. doi:10.1016/j.watres.2006.08.017

Eskicioglu C, Droste RL, Kennedy KJ (2007a) Performance of anaerobic waste activated sludge digesters after microwave pretreatment. Water Environ Res 79:2265–2273. doi:10.2175/106143007X176004

Eskicioglu C, Kennedy KJ, Droste RL (2007b) Enhancement of batch waste activated sludge digestion by microwave pretreatment. Water Environ Res 79:2304–2317. doi:10.2175/106143007X184069

Eskicioglu C, Terzian N, Kennedy KJ et al (2007c) Athermal microwave effects for enhancing digestibility of waste activated sludge. Water Res 41:2457–2466. doi:10.1016/j.watres.2007.03.008

Eskicioglu C, Kennedy KJ, Droste RL (2008a) Initial examination of microwave pretreatment on primary, secondary and mixed sludges before and after anaerobic digestion. Water Sci Technol 57:311–317. doi:10.2166/wst.2008.010

Eskicioglu C, Prorot A, Marin J et al (2008b) Synergetic pretreatment of sewage sludge by microwave irradiation in presence of H2O2 for enhanced anaerobic digestion. Water Res 42:4674–4682. doi:10.1016/j.watres.2008.08.010

Eskicioglu C, Kennedy KJ, Droste RL (2009) Enhanced disinfection and methane production from sewage sludge by microwave irradiation. Desalination 248:279–285. doi:10.1016/j.desal.2008.05.066

He P, Lü F, Zhang H et al (2007) Sewage sludge in China: challenges toward a sustainable future. Water Pract Technol 2:1–8. doi:10.2166/WPT.2007083

Houtmeyers S, Degrève J, Willems K et al (2014) Comparing the influence of low power ultrasonic and microwave pre-treatments on the solubilisation and semi-continuous anaerobic digestion of waste activated sludge. Bioresour Technol 171:44–49. doi:10.1016/j.biortech.2014.08.029

Jang J-H, Ahn J-H (2013) Effect of microwave pretreatment in presence of NaOH on mesophilic anaerobic digestion of thickened waste activated sludge. Bioresour Technol 131:437–442. doi:10.1016/j.biortech.2012.09.057

Jang S, Imlay JA (2007) Micromolar intracellular hydrogen peroxide disrupts metabolism by damaging iron-sulfur enzymes. J Biol Chem 282:929–937. doi:10.1074/jbc.M607646200

Jiang G, Yuan Z (2013) Synergistic inactivation of anaerobic wastewater biofilm by free nitrous acid and hydrogen peroxide. J Hazard Mater 250–251:91–98. doi:10.1016/j.jhazmat.2013.01.047

Jin L, Zhang G, Tian H (2014) Current state of sewage treatment in China. Water Res 66:85–98. doi:10.1016/j.watres.2014.08.014

Kang YW, Cho MJ, Hwang KY (1999) Correction of hydrogen peroxide interference on standard chemical oxygen demand test. Water Res 33:1247–1251. doi:10.1016/S0043-1354(98)00315-7

Kelessidis A, Stasinakis AS (2012) Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag (New York, NY) 32:1186–1195. doi:10.1016/j.wasman.2012.01.012

Kim J, Park C, Kim T-H et al (2003) Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge. J Biosci Bioeng 95:271–275. doi:10.1263/jbb.95.271

Kim D-H, Cho S-K, Lee M-K, Kim M-S (2013) Increased solubilization of excess sludge does not always result in enhanced anaerobic digestion efficiency. Bioresour Technol 143:660–664. doi:10.1016/j.biortech.2013.06.058

Kubota K, Ozaki Y, Matsumiya Y, Kubo M (2009) Analysis of relationship between microbial and methanogenic biomass in methane fermentation. Appl Biochem Biotechnol 158:493–501. doi:10.1007/s12010-008-8477-8

Kuglarz M, Karakashev D, Angelidaki I (2013) Microwave and thermal pretreatment as methods for increasing the biogas potential of secondary sludge from municipal wastewater treatment plants. Bioresour Technol 134:290–297. doi:10.1016/j.biortech.2013.02.001

Liu B, Wei Q, Zhang B, Bi J (2013) Life cycle GHG emissions of sewage sludge treatment and disposal options in Tai Lake Watershed, China. Sci Total Environ 447:361–369. doi:10.1016/j.scitotenv.2013.01.019

Liu J, Tong J, Wei Y, Wang Y (2015) Microwave and its combined processes: an effective way for enhancing anaerobic digestion and dewaterability of sewage sludge? Journal of Water Reuse and Desalination. doi:10.2166/wrd.2015.120

Mao T, Show K-Y (2007) Influence of ultrasonication on anaerobic bioconversion of sludge. Water Environ Res 79:436–441. doi:10.2175/106143006X123049

Mehdizadeh SN, Eskicioglu C, Bobowski J, Johnson T (2013) Conductive heating and microwave hydrolysis under identical heating profiles for advanced anaerobic digestion of municipal sludge. Water Res 47:5040–5051. doi:10.1016/j.watres.2013.05.055

Mishra S, Imlay JA (2013) An anaerobic bacterium, Bacteroides thetaiotaomicron, uses a consortium of enzymes to scavenge hydrogen peroxide. Mol Microbiol 90:1356–1371. doi:10.1111/mmi.12438

Mudhoo A, Sharma SK (2011) Microwave irradiation technology in waste sludge and wastewater treatment research. Crit Rev Environ Sci Technol 41:999–1066. doi:10.1080/10643380903392767

Pilli S, Yan S, Tyagi RD, Surampalli RY (2014) Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit Rev Environ Sci Technol 45:669–702. doi:10.1080/10643389.2013.876527

Qiang H, Xingfu S, Li G, Hainan A (2014) Two-phase integrated sludge thickening and digestion (TISTD) reactor microbial diversity and community structure succession rules. World J Microbiol Biotechnol 30:3137–3147. doi:10.1007/s11274-014-1741-x

Rajendran K, Kankanala HR, Lundin M, Taherzadeh MJ (2014) A novel process simulation model (PSM) for anaerobic digestion using Aspen Plus. Bioresour Technol 168:7–13. doi:10.1016/j.biortech.2014.01.051

Raposo F, De la Rubia MA, Fernández-Cegrí V, Borja R (2012) Anaerobic digestion of solid organic substrates in batch mode: an overview relating to methane yields and experimental procedures. Renew Sust Energ Rev 16:861–877. doi:10.1016/j.rser.2011.09.008

Sambusiti C, Rollini M, Ficara E et al (2014) Enzymatic and metabolic activities of four anaerobic sludges and their impact on methane production from ensiled sorghum forage. Bioresour Technol 155:122–128. doi:10.1016/j.biortech.2013.12.055

Shahriari H, Warith M, Hamoda M, Kennedy KJ (2012) Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag (New York, NY) 32:41–52. doi:10.1016/j.wasman.2011.08.012

Shen Y, Linville JL, Urgun-demirtas M et al (2015) An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States : challenges and opportunities towards energy-neutral WWTPs. Renew Sust Energ Rev 50:346–362

Sólyom K, Mato RB, Pérez-Elvira SI, Cocero MJ (2011) The influence of the energy absorbed from microwave pretreatment on biogas production from secondary wastewater sludge. Bioresour Technol 102:10849–10854. doi:10.1016/j.biortech.2011.09.052

The State Council of the people’s Republic of China (2015) Action Plan for Water Pollution Prevention and Control

Toreci I, Kennedy KJ, Droste RL (2009) Evaluation of continuous mesophilic anaerobic sludge digestion after high temperature microwave pretreatment. Water Res 43:1273–1284. doi:10.1016/j.watres.2008.12.022

Toreci I, Droste RL, Kennedy KJ (2011) Mesophilic anaerobic digestion with high-temperature microwave pretreatment and importance of inoculum acclimation. Water Environ Res 83:549–559. doi:10.2175/106143010X12780288628651

Tyagi VK, Lo S-L (2011) Application of physico-chemical pretreatment methods to enhance the sludge disintegration and subsequent anaerobic digestion: an up to date review. Rev Environ Sci Biotechnol 10:215–242. doi:10.1007/s11157-011-9244-9

Wang Y, Wei Y, Liu J (2009) Effect of H2O2 dosing strategy on sludge pretreatment by microwave-H2O2 advanced oxidation process. J Hazard Mater 169:680–684. doi:10.1016/j.jhazmat.2009.04.001

Wang Y, Xiao Q, Liu J et al (2015) Pilot-scale study of sludge pretreatment by microwave and sludge reduction based on lysis–cryptic growth. Bioresour Technol 190:140–147

Wilson CA, Novak JT (2009) Hydrolysis of macromolecular components of primary and secondary wastewater sludge by thermal hydrolytic pretreatment. Water Res 43:4489–4498. doi:10.1016/j.watres.2009.07.022

Wong WT, Chan WI, Liao PH, Lo KV (2006) A hydrogen peroxide/ microwave advanced oxidation process for sewage sludge treatment. J Environ Sci Health, Part A: Tox Hazard Subst Environ Eng 41:2623–2633. doi:10.1080/10934520600928086

Xiao Q, Wei Y, Wang Y, Zeng F (2012a) Comparison of sludge solubilization by microwave and its combined processes. China Water & Wastewater 28:61–64

Xiao Q, Yan H, Wei Y et al (2012b) Optimization of H2O2 dosage in microwave-H2O2 process for sludge pretreatment with uniform design method. J Environ Sci 24:2060–2067. doi:10.1016/S1001-0742(11)60998-4

Yang G, Zhang G, Wang H (2015) Current state of sludge production, management, treatment and disposal in China. Water Res 78:60–73. doi:10.1016/j.watres.2015.04.002

Yu Y, Chan WI, Lo IW et al (2010) Sewage sludge treatment by a continuous microwave enhanced advanced oxidation process. Can J Civ Eng 37:796–804. doi:10.1139/L10-044

Zhao Z-H, Sakagami Y, Osaka T (1998) Toxicity of hydrogen peroxide produced by electroplated coatings to pathogenic bacteria. Can J Microbiol 44:441–447. doi:10.1139/cjm-44-5-441

Zhou QH, Wu ZB, Cheng SP et al (2005) Enzymatic activities in constructed wetlands and di-n-butyl phthalate (DBP) biodegradation. Soil Biol Biochem 37:1454–1459. doi:10.1016/j.soilbio.2005.01.003

Acknowledgments

This work is supported by the National Water Pollution Control and Management Technology Major Project of China (2012ZX07202-005 and 2015ZX07203-005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 367 kb)

Rights and permissions

About this article

Cite this article

Liu, J., Jia, R., Wang, Y. et al. Does residual H2O2 result in inhibitory effect on enhanced anaerobic digestion of sludge pretreated by microwave-H2O2 pretreatment process?. Environ Sci Pollut Res 24, 9016–9025 (2017). https://doi.org/10.1007/s11356-015-5704-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5704-z

) and carbohydrate (

) and carbohydrate ( ) degradation)

) degradation)