Abstract

In wastewater treatment plants (WWTPs), the portion of operating costs related to electric power consumption is increasing. If the electric power consumption decreased, however, it would be difficult to comply with the effluent water quality requirements. A protocol was proposed to minimize the environmental impacts as well as to optimize the electric power consumption under the conditions needed to meet the effluent water quality standards in this study. This protocol was comprised of six phases of procedure and was tested using operating data from S-WWTP to prove its applicability. The 11 major operating variables were categorized into three groups using principal component analysis and K-mean cluster analysis. Life cycle assessment (LCA) was conducted for each group to deduce the optimal operating conditions for each operating state. Then, employing mathematical modeling, six improvement plans to reduce electric power consumption were deduced. The electric power consumptions for suggested plans were estimated using an artificial neural network. This was followed by a second round of LCA conducted on the plans. As a result, a set of optimized improvement plans were derived for each group that were able to optimize the electric power consumption and life cycle environmental impact, at the same time. Based on these test results, the WWTP operating management protocol presented in this study is deemed able to suggest optimal operating conditions under which power consumption can be optimized with minimal life cycle environmental impact, while allowing the plant to meet water quality requirements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The electric power consumption of the wastewater treatment plants (WWTPs) in Korea account for approximately 20 % of total annual operating expenses of the plants, representing the second largest portion following the labor cost (about 24 %) (Korea Ministry of Environment 2013). The amount of wastewater treated in a year increased 1.08 times from 2006 to 2012, while the cost of the electric power consumed grew 1.84 times over the same period (Korea Statistics 2006–2012). Such a rise in electricity cost was mainly attributable to increases in the volume of wastewater treated due to population growth and improved living standards and to enhanced treatment capabilities to comply with more stringent effluent quality standards. In addition, because many wastewater treatment plants have placed top priority on stable wastewater treatment, they have often tended to neglect energy efficiency in their operation and management. The electric power consumption could be reduced substantially by analyzing the daily status of operation and by providing efficient and continuous operation and management skills.

The power consumption of a WWTP could be measured or estimated by summing up those of devices such as motors and pumps based on their specifications and operating times. However, the operating time of individual devices vary much depending on operating conditions such as influent flow rate, air supply rate, and many others. It is difficult to obtain the daily operating times of individual devices every day; instead, the power consumption could be calculated based on average operating times in a certain period, or on design values assuming continuous use. In addition, the power consumption of blower and pumps in the WWTP could be calculated by theoretical mathematical formulas (Yoon 2015), used for designing and evaluating the WWTPs. However, for calculating more accurate power consumption value, they should be tuned using on-site values such as air flow, inlet and outlet pressure, pump and motor efficiency, liquid flow rate, density, viscosity, and so on. It might be a time-consuming work to obtain these data in the target real-site WWTPs. In order to overcome these problems, prediction techniques involving artificial neural networks (ANN) can be used to estimate daily power consumption based on current operating data. ANN has been used for predicting electrical energy consumption in various industries, such as building with air conditioning systems (Neto and Fiorelli 2008; Escrivá-Escrivá et al. 2011), the solar steam generating plant, and other renewable energy systems (Kalogirou 2000).

In previous studies, water quality analysis for a WWTP was performed using averaged data by dividing them into groups based on month or season (Shrestha and Kazama 2007). However, results for power consumption from such analysis would show very limited results (e.g. highest power consumption in summer and the lowest in winter) due to the strong influence of the influent flow rate. By analyzing in this way, the impact on power consumption by many other operating conditions cannot be assessed. Therefore, to retain the characteristics of the effects of the many original variables, but using the minimum possible number of variables, a statistical method like principal component analysis (PCA) is recommended (Olsson 2012). PCA has been used to obtain essential information from the wastewater treatment process by reducing the dimensionality of the data (Lennox and Rosen 2002). In this way, a relatively small number of principal components can be used to classify all the operating data into groups, and to determine which groups have similar characteristics. This analysis can be done using a statistical method such as the K-mean cluster analysis (KMCA). These techniques have already been used for monitoring and diagnosing wastewater treatment processes (Kim et al. 2013) and providing the information on the operating state of WWTP (Moon et al. 2009). In addition, many studies have been applied these statistical techniques for extracting the meaningful and hidden information of natural water system (Singh et al. 2004; Saim et al. 2009; Bayo and Lopez-Castellanos 2016). These existing studies, however, did not attempt to evaluate the alternatives as combined with predictive models. Although the suggested approach in this research seems to be somewhat complicated, it can be applied as an appropriate solution for the complex problems such as to satisfy multiple objectives in the operation of wastewater treatment plants.

Recently, in response to heightened interest in energy and cost of electricity, research and development for optimization of energy efficiency have increased substantially. Kim et al. (2013) proposed control strategies for optimizing the dissolved oxygen (DO) concentrations and external carbon dose according to diagnosis of the process state in the A2/O process. Compared to the non-controlled case, not only the quality of wastewater effluent became more stable but also the electrical device load was reduced by minimizing the frequency of change of the process operating state. However, there was no assessment of how much the electric power was actually reduced or of how much the effluent quality was improved in relation to the reduction of electric power consumption. Panepinto et al. (2016) calculated the total electric power demand, made an energy balance for the whole plant, and proposed a solution to optimize the energy effectively. These control strategies suggested the possibility of reduced electric power consumption under stable operating conditions, mainly in the biological reactors. However, these strategies have failed to mention the life cycle environmental impacts, which might be increased as a result of the reduced electric power consumption. Eventually, one must be able to assess whether an alternative is energy efficient, and at the same time, if it could bring about positive outcomes for the environment over its entire life cycle. Therefore, the decision makers would be able to select more convincing alternatives when the results of analysis for the life cycle environmental impact was provided together with plans for reduction of electric power consumption. Meneses et al. (2015) proposed a process performance indicator that reflects both the quality of effluent and the operating cost, in addition to the outcomes of environmental impact evaluation based on life cycle assessment (LCA). However, these workers did not mention any alternative that considered the quality of the wastewater discharged in relation to the amount of electricity consumed.

Considering such research and the trends in development, this study was intended to propose a protocol that could identify appropriate operation and management conditions to optimize the electric power consumption, minimize the life cycle environmental impacts, and comply with regulations on the effluent quality for a wastewater treatment plant. This protocol would include such procedures as analysis of electric power consumption with multivariate statistical analysis, suggestion of improvement plans for optimizing electric power consumption through mathematical modeling and artificial neural network, and suggestion of an improvement plan determined using LCA, to minimize environmental impacts.

Materials and methods

Testing wastewater treatment plant

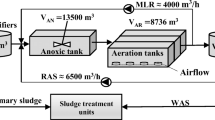

In order to achieve the purposes of this study, a protocol was developed and tested at the Sincheon wastewater treatment plant (S-WWTP), Daegu city, South Korea. The S-WWTP was designed to use the anaerobic/anoxic/oxic process (A2/O) process, with treatment capacity of 680,000 m3/day and an additional chemical treatment process for phosphorus removal. For this study, about 550 daily data sets were collected at the S-WWTP from June 2013 to December 2014. The average influent flow rate was 476,300 m3/day in this period. Total phosphorus was removed by adding poly-aluminum chloride (PAC) after the secondary settling tank. The primary and secondary sludge (along with food waste sludge) were transported to a landfill site after anaerobic digestion and dewatering. The solids retention time (SRT) and hydraulic retention time (HRT) of the aeration tanks were 22 days and 7 h, respectively, and the food to microorganism ratio (F/M) was 0.08 kg biochemical oxygen demand (BOD)/kg mixed liquor suspended solids (MLSS)/day. The ratios of return sludge and internal recycling sludge flows to the influent were 40 and 113 %, respectively. The digestion process (with 14-day SRT) produced about 16,000 m3/day of biogas and the CH4 portion was 66.7 %. The biogas was used to generate electricity and heat boilers to reduce the consumption of external power. About 80 % of the biogas was used for on-site generation of electricity and boiler heating, and 20 % was burned without energy recovery. The S-WWTP reactor volumes, which were used for mathematical modeling, are summarized in supplementary data 1. The schematic flow diagram of S-WWTP is shown in Fig. 1.

Methodologies for diagnosis of electric power consumption

Selection of major operating variables

The operating information about equipment specifications and their operating periods at the S-WWTP were collected. Next, the primary operating variables were selected, after complementing the direct investigation by consultation with the operators. Then, by analysis of the correlation of these variables with the electric power consumption, the variables with low (<0.4) correlation were excluded and the major operating variables were obtained. In overall, certain number of major operating variables were selected which influenced the electric power consumption and also could be useful for process control.

Principal component analysis

PCA is a method that is useful for compressing a large number of variables by analyzing the correlations among the original variables (Aguado and Rosen 2008). PCA is used for removing unnecessary dispersion as well as explaining the most important characteristics of the original variables. In our case, the derived principal components could explain the most important characteristics of electric power consumption. These compressed principal components were used as input data for the KMCA as follows.

K-mean cluster analysis

KMCA is able to classify a large number of data sets having various characteristics into a small number of groups based on the similarity among their principal components (Grieu et al. 2005). The differences in value between the principal components were converted into distances, and the shortest distances apart were considered a single group. Based on the KMCA results, it was possible to propose alternatives to optimize the operating conditions. In this study, based on the principal components and according to the characteristics of the major operating variables, the operations data were classified into three clusters of groups. Both the PCA and KMCA were run on IBM SPSS Statistics software (ver. 21).

The first LCA on operation of the S-WWTP using field data

The LCA is a method to evaluate the environmental impacts from energy and materials. To apply the LCA in phase III, first, the energy and materials were quantified that were produced and consumed within the system boundary, during their whole life cycle. LCA was conducted through four processes according to the evaluation standards guided by the ISO 14040 series. The processes include goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and life cycle interpretation (ISO 2006a, b).

Goal and scope definitions

The LCA was carried out in the three cluster groups that were obtained by PCA and KMCA analysis, in order to add the environmental perspectives to the power consumption analysis results. The system boundary for the LCA included the influent, A2/O process, anaerobic sludge digestion, production of sludge and biogas, and sludge landfill, as shown in Fig. 2. The inputs were influent, electricity, chemicals, and diesel and the outputs were effluent, gas emissions in wastewater treatment process, gas emission from biogas incineration, biogas energy generation, disposed sludge, and gas emission from landfill process. In sludge treatment process, the biogas from anaerobic digestion was used for boiler heating, electric power generation, and incineration (not energy reuse) with distribution ratios of 20, 40, and 40 %, respectively. The biogas for boiler heating was not considered as part of the treatment process so this portion of biogas was not included in the LCA result. The sludge produced by this WWPT was considered up to final disposal in a landfill. For the landfill process, methane gas emission via surface penetration (Kim et al. 2012) at the landfill site was considered; however, burning and recovery of methane gas was not considered. The functional unit (FU) for the LCA was unified based on 1 m3 of influent wastewater.

Inventory analysis

The inventory data of the three cluster groups derived from phase II, were collected from the qualities of influent and effluent, electric power consumption, chemical usage, biogas production, and sludge production. The detailed LCI data are summarized in Table 1. These inventories were collected and calculated based on real operating data from the S-WWTP. The detailed procedure was introduced by Piao et al. (2016). The on-site electric power generation from biogas was considered 750 kWh, using an average of 380 m3 biogas produced from sludge per hour, based on the Korean standards of 2012 (Korea Energy Corporation 2014). It was estimated based on 24 h of operation per day and 333 running days per year. The emissions of CH4 and N2O from biological reactors were cited from the report of the Korea Environment Corporation (2008). The emission of CO2 from biogas incineration was 3.2 kg CO2 eq/Nm3 (Korea Environment Corporation 2012). In addition, the back ground inventory data on the PAC and other polymer production processes were obtained from the LCI database of Korean Ministry of Environment (Korea National Cleaner Production Center 2015). The electricity grid mix, truck (22 t payload capacity), diesel mix at refinery, and landfill of municipal solid waste were derived from the GaBi 6 database (PE International 2015).

Impact assessment

Gabi Education software (ver. 6) and the Centre of Environmental Science (CML) method (Guinée 2002) were used to evaluate the environmental impact of operation and electric power consumption at the S-WWTP. The CML is one of the most common LCIA methods and has already been applied in the majority of WWTP LCA studies (Hospido et al. 2008; Pasqualino et al. 2009; Piao et al. 2016). In this study, four environmental impact categories were considered. The categories of eutrophication potential (EP) and global warming potential (GWP) were considered to assess the effects on rivers by the effluent and greenhouse gas emissions, which varied according to effluent quality and electric power consumption. Then, the categories of acidification potential (AP) and human toxicity potential (HTP) were considered due to the large amounts of heavy metal, NOx, and SOx discharged from the energy and chemical production processes, landfill, and transport processes.

Uncertainty analysis and sensitivity analysis

Uncertainty analysis is very important for assessing the final LCA results according to the variability of the inventory data (Corominas et al. 2013). In this study, which was based on the standard deviations of all inventory data, a 1000-run Monte Carlo analysis (Maurice et al. 2000) was conducted. These inventory data were assumed to have a normal distribution and the standard deviations obtained from the uncertainty analysis were presented. Sensitivity analysis is a systematic procedure for estimating the effects of the chosen data on the outcome of a study (ISO 2006b). In this case, it was conducted to determine the impact of significant inventory components in the LCA results. According to the highest uncertainty standard deviation (18 %), a 20 % increment was defined by this sensitivity analysis. The rates of change in the LCA results were calculated and the ratios of changes were defined as sensitivity. Both uncertainty and sensitivity analysis were conducted in Gabi software (PE International 2015).

Mathematical modeling and prediction of electric power consumption

Mathematical modeling

The improvement plans for inefficient groups according to the diagnosis and LCA results were deduced by using the mathematical models. The simulations were carried out by changing the variables that affected the electric power consumption significantly, such as airflow in the aeration tank, waste sludge flow in the secondary settling tank, and internal recycling sludge flow as a certain percentage. Then, several kinds of improvement plans were derived that could reduce the electric power consumption, as well as maintain stable effluent quality. To carry out these simulations, a commercial simulation tool known as Massflow™ (v. 2.8) was used. Massflow™ was developed based on an activated sludge model (ASM) no. 1 (Henze 2000) from the International Water Association (IWA) (UnU soft co., Ltd. 2016a). It can provide static and dynamic simulation of various activated sludge systems and physical and chemical treatment processes. This software has been used for modeling the wastewater treatment processes in South Korea (Yoo et al. 2014).

Artificial neural network

The ANN has ability to learn complicated relationships from imprecise data. It can be used to extract patterns and detect trends that are too complex to be noticed by either human beings or other computing techniques (Du et al. 1999; Simsir and Ertugrul 2009). In this study, no daily information was available from the S-WWTP about the operating times of each device. Moreover, when new alternatives were proposed about modeling technique, the water quality data for the effluent could be provided but information about the operating time of devices and their operating status, was not available. Therefore, the ANN was used to estimate the electric power consumption based on the current operating data.

To develop the ANN model, 550 datasets were collected and among them, 70 % were used for training and 30 % for validation after random selection. The electric power consumption for the improvement plans were estimated using these data and based on the major operating variables used for energy analysis. Through a process of trial and error, the optimal ANN model was derived by selecting one hidden layer and five nodes. The ANN results proved reliable as the R 2 was more than 90 % in the training and validation processes. In addition, the RMSE obtained during train and validation was 5366 and 5550, respectively. These were relatively small compared with the power consumption in the range of 80,000–100,316 kWh/day. The Dataflow™ was used for the ANN analysis (UnU soft co., Ltd. 2016b).

The second LCA for the proposed improvement plans

In phase VI, the second LCA was carried out based on the improvement plans developed in phase IV. The final improvement plans were derived, which could optimize the electric power consumption and life cycle environmental impacts at the same time. The LCA system boundary and functional units were exactly the same as those in the section “The first LCA on operation of the S-WWTP using field data.” For the proposed improvement plans, the effluent BOD, total nitrogen (TN), and total phosphorus (TP were obtained by mathematical modeling of the S-WWTP (as explained for phase IV) and the values of electric power consumption were estimated using the ANN, as described for phase V. The LCI data of six improvement plans are shown in Table 2. The effluent concentrations of TP (cases 1–4) and BOD (cases 5–6), were higher than previously measured values (see Table 1). However, those values were much lower than the effluent quality standards in Korea (TP and BOD <0.2 and <10 mg/L, respectively) (Korea Ministry of Environment 2014). The environmental impacts on AP, EP, GWP, and HTP were evaluated using LCIA as described in the “Impact assessment” section. The uncertainty analysis was performed by the procedure in the “Uncertainty analysis and sensitivity analysis” section.

Development of a protocol to optimize WWTP operations

Using the above methodologies, we proposed a “protocol to optimize electric power consumption and life cycle environmental impacts” that consisted of the six phases shown in Fig. 3.

In phase I, following above procedure explained in the “Selection of major operating variables” section, the major operating variables that most affected the power consumption were derived. In phase II, PCA was carried out on the major operating variables to reduce unnecessary dispersion. Then, KMCA was conducted on the principal component results to classify them based on electric power consumption and operating characteristics. All 550 operating data were classified into three cluster groups according to the consumption of electric power. Moreover, the impacts of the major operating variables within each clustered group were determined at three levels. By analyzing these results, it was possible to evaluate the electric power consumption of each cluster group and to provide some advice for improvements. In phase III, the first LCA was carried out based on the operational data of the three cluster groups obtained in phase II. To analyze the result, each of the environmental impact indicators obtained in this step were considered in relation to the electric power consumption derived from phase II. Based on the results of the LCA and energy consumption analysis, the most efficient group was identified. For the less efficient groups, corresponding operational alternatives were suggested. Then, uncertainty and sensitivity analysis were carried out to determine the degree of effect of the inventory item on each of the environmental impact indicator. In phase IV, mathematical modeling was applied to derive improvement plans that would ensure stable effluent qualities while reducing electric power consumption. For the high-power consumption group, improvement plans were derived that could reduce the electric power consumption by adjusting the Air and Qsec by increments of 10 %. In the low-power consumption group, improvement plans were derived to improve the environmental impacts by adjusting the Qrasin and Qsec, as before. Then, these improvement plans were evaluated by considering their impact on the effluent quality. In phase V, the electric power consumption was estimated using ANN when applying the improvement plans derived from phase IV. Then, the results were compared to the electric power consumption of groups 2 and 3, which represented the previous operation status. Finally, in phase VI, the second LCA was carried out for the proposed improvement plans using the data obtained by mathematical modeling in phase IV and the electric power consumption of phase V. By comparing these LCA results, sustainable improvement plans were selected that could simultaneously optimize electric power consumption and life cycle environmental impacts.

Results and discussions

Deduction of major operating variables affecting electric power consumption (phase I)

The major operating variables were obtained and summarized in Supplementary data 2. Overall, the variables of influent flow (Qin), air flow (Air), return sludge flow (Qras), inner return sludge flow (Qrasin), waste sludge flow in primary settling tank (Qfir), waste sludge flow in secondary settling tank (Qsec), waste sludge flow in thickener (Qthic), sludge flow in digestion tank (Qdi), waste sludge flow in dewatering equipment (Qdw), dewatered sludge (Cake), and Electric power consumption (Elec) were obtained. The Air and Qin showed high correlations with the electric power consumption.

Deduction of principal components and K-mean cluster analysis (phase II)

Deduction of principal components highly affecting electric power consumption

The 11 major operating variables were reduced to four principal components and their component score coefficients are shown in Table 3. The coefficients could be used to specify how much each principal component was affected by a certain operating variable (Moon et al. 2009). Principal component 1 (PC1) was affected very much by the electric power related operating variables such as the Air and Qrasin; while PC2 was highly affected by the sludge treatment line variables such as the Qdi, Qdw, and the Cake. PC3 was affected by the Qin and the Qras variables, and PC4 was affected by Qfir and Qsec.

Classification of operation status by K-mean cluster analysis based on electric power consumption

The K-mean cluster analysis identified three cluster groups from depending on the level of electric power consumption and the results are summarized in Table 4. Also, it was found how much each major operating variable could contribute to electric power consumption comparing among three groups. Group 1 included about 51 % of data sets which was medium level in terms of the electric power consumption. Group 2 contained 15 % of the data sets as high level of the electric power consumption and group 3 was low level in electric power consumption occupying 34 % of datasets. The high electric power consumption (Group 2) occurred during April, May, and July. The low power consumption (group 3) occurred during November, December, January, February, and March. The medium-level cases (group 1) occurred in most months, except for February, July, and November. These results showed that the electric power consumption was somewhat related to seasons, but not directly dependent.

The influence of each major operating variable (among the three cluster groups) was classified as high (H), medium (M), or low (L). The operating conditions of the data sets belonging to group 1 showed the highest Qin, and the values of Qras, Qfir, and Cake were also high. Therefore, it could be expected that the related pumps were run at a high rate of energy consumption. However, Air and Qsec were maintained at medium level and the overall electric power consumption was at medium level. Therefore, group 1 would be considered a relatively efficient operation status. Group 2 had medium level Qin but the values of Air and Qsec showed highest among the three cluster groups. Thus, it could be estimated that the oxygen supply would be higher than expected and therefore, the electric power consumption was high. From this, it might be possible to reduce the electric power consumption by reducing the oxygen supply. Group 3 had low Qin but very high BOD concentration, as shown in Table 1. Even though it had highest BOD load, it showed the lowest Air and Qsec, corresponding to the lowest Qin. Therefore, the electric power consumption was lowest among three groups. Therefore, group 3 could be considered to present the most efficient power consumption conditions. In addition to this analysis, a life cycle impact analysis should follow to provide appropriate information for proper operation of WWTPs.

Environmental impact assessments by LCA on cluster groups under field operating conditions (phase III)

Comparison of environmental impact assessments

The results of environmental impact assessments of the three cluster groups are shown in Fig. 4. The impacts on AP, EP, GWP, and HTP were analyzed in the wastewater and sludge treatment processes, energy and chemical production processes, and the transport and landfill processes. More detailed LCA results were presented in Supplementary data 3. As shown in Fig. 4a, d, for the effects on AP and HTP Group 2 had relatively large impacts among the three groups. Therefore, detailed analysis on group 2 is followed. High effects on AP and HTP were due to high electric power and chemical consumption. Most of the effects on AP were related to electric power and chemical consumption, which were up to 38 and 50 %, respectively. The main substances that contributed to the AP were nitrogen oxides and sulfur dioxide (12 and 24 %, respectively) from the electric power production process, and ammonia and SOx (20 and 24 %, respectively) from the chemical production process. More than 80 % of the effects on the HTP occurred in relation to the electric power production process. This was because heavy metals, inorganics such as hydrogen fluoride, and organics such as polycyclic aromatic hydrocarbons were released into the air (33, 15, and 15 %, respectively). The main contributors of the effects on the EP were TN, TP, nitrate, and phosphorus in the effluent and ammonia and phosphorus which were discharged into the soil during the landfill process. The main contributors of the effects on the GWP were methane and nitrous oxide which were emitted from the primary settling tank and the anaerobic tank with 18 and 28 %, respectively. The methane gas from the landfill process also contributed about 24 % of the effects.

Group 1 showed the lowest impacts on EP and GWP, and low impacts on AP and GWP, similar to those in group 3. The group 2 conditions resulted in the highest impacts on AP and HTP; and slightly lower impact on GWP. Group 3 showed the lowest impacts on AP and HTP but highest impacts on EP and GWP. Overall, group 1 would be considered the most appropriate operating condition because it showed the least impacts in terms of LCA. However, group 3 was selected beforehand as the most energy efficient based on its electric power consumption. The reasons for the highest impacts on the EP and GWP in Group 3 were probably due to the highest BOD and TN loading, as shown in Table 1. These conditions might indicate that the oxygen supply was insufficient, resulting in poorer effluent quality than for conditions of the other groups. Therefore, group 1 was considered the most efficient when the comparison was made by integrating electric power consumption analysis and LCA as results. For more efficient operation, group 2 required an alternative to reduce the electric power consumption and group 3 required an alternative to improve effluent quality.

Uncertainty analysis for cluster groups

As shown in Fig. 4, the uncertainty analysis provided the distribution and confidence intervals of the results of each impact category in the three groups. The error bars represent that 10–90 % of the LCA results were within the range and the standard deviations (SD) were 8–16 % in all four environmental categories, in all groups. Table 5 showed that the EP and GWP had low uncertainty; whereas AP and HTP showed the highest SD. More detailed sensitivity results were presented in Supplementary data 4. The main contribution to the AP and HTP were nitrogen oxides and sulfur dioxide emissions from electric power production processes, and ammonia and SOx emissions from chemical production processes. These uncertainty results were directly related to the statistical distribution of the electric power and chemical consumption. Overall, the uncertainty was not significantly different among the three groups; it was considered that such uncertainty would not affect the final LCA results.

Sensitivity analysis for inventory data

Among all input inventory data used for the LCA, the ones of relatively high sensitivity were summarized in Table 6 and more detailed sensitivity results were presented in Supplementary data 6. For example, in group 1, the most sensitive variable of the GWP was the N2O emissions from the bioreactor, and that of the EP was the TN in the effluent. The most sensitive variable of the AP and HTP was the electric power consumption. Therefore, these variables should get the most attention when improvement alternatives were proposed. Groups 2 and 3 showed similar sensitivity results on these variables.

Derivation of improvements plans for reducing electric power consumption by mathematical modeling (phase IV)

Application of mathematical modeling for S-WWTP

To apply mathematical modeling on the S-WWTP, a schematic diagram (process flow sheet) was developed and is shown in Fig. 5. The mathematical model was calibrated using the average data of group 1, which was the medium level operating status in terms of electric power consumption. For carrying out the calibration, the calculated effluent qualities were matched with the measured data by adjusting the removal rates of the primary and secondary settling tanks and the phosphorus concentrations of the bioreactor. The average data of groups 2 and 3 were used to verify the calibrated mathematical model. As shown in Fig. 6, the verification results of the calculated BOD, TN, and MLSS were in good agreement with the measured values. However the T-P was not well matched because the T-P removal by chemical treatment was not included in this mathematical model.

Procedures for derivation of improvement plans based on mathematical modeling

In the results of phase III, group 2 showed the highest impacts on AP and HTP in the LCA because of the high electric power consumption of this group. Optimized operating conditions were derived to reduce the electric power consumption. A simulation was carried out within the range of the effluent quality standard of WWTPs, by increasing or decreasing the dissolved oxygen concentration in the aeration tank (DO) and waste sludge flow in the secondary settling tank (Qsec) by 10 % increments. Manipulation of DO meant adjusting aeration rate and therefore, the aeration cost would be directly affected. When the waste sludge flow was manipulated, the SRT and therefore the sludge production rate would be affected. This also would affect the operating cost as well as the performance.

Eventually, the following four improvement plans were derived. Here, the DO was an adjustable variable and the airflow was derived from the result of simulation. The MLSS in the bioreactor was increased according to reduction of Qsec by 10 to 30 %. Therefore, the air flows obtained were decreased by 6–8 % when both DO and Qsec were reduced.

-

Case 1.

DO falls to 20 %;

-

Case 2.

DO falls to 20 % at the same time Qsec falls to 10 %;

-

Case 3.

DO falls to 20 % at the same time Qsec falls to 20 %;

-

Case 4.

DO falls to 20 % at the same time Qsec falls to 30 %.

In group 3, the electric power consumption was low, but the impacts on EP and GWP were relatively high. According to the sensitivity analysis, the effluent TN and N2O emissions of the bioreactor had their strongest effects on EP and GWP. Therefore, to improve the effluent TN the Qrasin should be increased to induce more denitrification. Based on this analysis, it was attempted also to reduce Qsec to promote additional savings of electric power. As a result, the following two improvement plans were derived.

-

Case 5.

Increase Qrasin 10 %

-

Case 6.

Increase Qrasin 10 %, at the same time Qsec falls to 20 %

The simulation results in these improvement plans (cases 1–6) were compared with the results obtained under the previous field operating conditions expressed as groups 2 and 3 (shown in Table 7). Even though the effluent quality was slightly higher in the improvement plans than produced under the previous field conditions, this should be no problem because they were within the legally mandated effluent standards. In addition, during the simulation process, a safety factor was considered. It was defined as a ratio of 120 %, between the highest effluent values derived by modeling, and the effluent legal standard. Therefore, these improvement plans would not make the effluent water quality worse.

Evaluation of electric power consumption based on the improvement plans (phase V)

The electric power consumption of cases 1–6 of the improvement plans were predicted using the ANN program optimized in this study, and the results are shown in Table 8. In group 2, cases 1–3 improvement plans could reduce electric power consumption by 5.4, 5.5, and 5.8 %, respectively, under the condition that effluent quality was not changed, except for TP. Usually, in A2O WWTPs, about 30 % of the electric power used, is consumed by the air blower in the biological reactor. When an air flow reduction was in a range from 5 to 9 % was done in cases 1–4, the electric power reduction would be 1.5–3 %. However, group 2 used excessive air so it was possible to reduce it by 5.4–5.8 % by controlling the airflow and Qsec. In case 4, there was a rising trend in effluent quality and electric power consumption, compared to case 3; although the electric power consumption was reduced more than that of group 2. Therefore, in case 4, decreasing the DO or Qsec did not seem appropriate. For group 3, the case 5 improvement plan could reduce electric power consumption by 1.2 % and decrease effluent TN and TP by 3 and 8 %, respectively. In case 6, when reducing the Qsec by 10 % below that of case 5, the effluent quality was not improved but electric power consumption was increased about 4 % over than that of the standard condition of group 3. This was attributed to increase in the MLSS and SRT of the bioreactor due to excessive Qsec. For this reason, case 6 was not a recommendable alternative.

The ANN results were derived from a black-box model; therefore, it might be difficult to determine the superiority of certain cases using only simple predictions of electric power consumption. Moreover, the environmental impacts of these improvement plans need to be considered further because the effluent quality has a great influence on EP even though they were below the effluent water quality standards. Therefore, the environmental impacts of the proposed improvement plans were analyzed further using LCA.

LCA evaluation of environmental impacts from proposed plans for reduction of electric power consumption (phase VI)

Environmental impact assessment for high electric power consumption conditions

When the improvement plans of cases 1–4 were implemented to reduce the electric power consumption of the group 2 standard condition, the environmental impacts on AP, GWP, and HTP were reduced by 1–5 %, as shown in Fig. 7. However, the impact on EP was increased in cases 3 and 4, as shown in Fig. 7b. This occurred because the effluent quality, particularly the TP concentration, increased while the electric power consumption decreased. Considering the electric power consumption and environmental impacts together, the best choice for improvement among the group 2 plans would be case 2. In this plan, 20 % reduction of air flow, and 10 % reduction of waste sludge flow in the secondary settling tank, was recommended.

Environment impact assessment for low electric power consumption conditions

Cases 5–6 improvement plans were implemented for improving effluent quality based on the group 3 standard condition. As shown in Fig. 8, the environmental impacts on AP, EP, and HTP were reduced to 1, 2, and 1 %, respectively, in case 5. The impact on GWP was not changed much. In case 6, however, all environmental impact indicators became slightly higher than that of the group 3 standard. Therefore, case 5 would increase Qrasin by 10 %, could improve effluent quality, and also has no significant influence on the electric power consumption. Finally, case 5 was considered the most efficient operating condition for group 3.

Uncertainty analysis for alternatives to optimize electric power consumption

As shown in Figs. 7 and 8, the error bars showed the minimal and maximal values (within the range of 10 to 90 %) from the uncertainty analysis. Previous Table 5 showed that the standard deviations (SDs) were 8–18 % in all four environmental categories in those cases, and case 6 showed the highest uncertainty in the AP and HTP among them. However, the uncertainty was also not significantly different from that in cases 1–6 and it was considered that such uncertainty would not affect the final LCA results.

Conclusion

In this study, we proposed a protocol designed to identify the operation and management conditions that comply with regulations on effluent water quality for a WWTP and to optimize electric power consumption while also minimizing the life cycle environmental impacts. It comprised six phases of procedures, and the major function of each phase is as follows. The major functions include drawing the major operating variables influencing electric power consumption (I), classifying three cluster groups using PCA and KMCA (II), carrying out LCA for three cluster groups and deriving the optimal operating conditions (III), deriving the electric power-saving improvement plans capable of securing the proper level of effluent water quality by mathematical modeling (IV), estimating the power consumption of the improvement plans by ANN (V), and deriving the optimized improvement plans as operation alternatives enabling simultaneous optimization of power consumption and life cycle environmental impacts (VI).

This protocol was tested and applied using actual operation management data from the S-WWTP in order to prove its applicability. In the S-WWTP, 11 major operating variables were selected including influent flow and others. They were classified into three cluster groups according to the results of the electric power consumption analysis. The LCA, with four environmental impact indicators, was conducted on these groups. It was found that improvement plans were needed in two groups from the results of the LCA, considering the electric power consumption condition. Six improvement plans were derived by mathematical modeling; and for them, the electric power consumption was calculated using ANN. A second round of LCAs was conducted on these six improvement plans. Comprehensively considering the results of the LCA and electric power consumption, while meeting the effluent quality standard, the case 2 improvement plan for group 2 (Air flow decreased by 8 %, Qwas decreased by 10 %) and the case 5 plan for group 3 (Qrasin increased by 10 %) were determined to be the most efficient operating conditions. The sensitivity and uncertainty analyses of LCA confirmed the stability of the application.

The proposed protocol may look complicated but it is configured logically with several proven scientific methods. And for practical application, the operator requires only regular operating data for input and then he or she can obtain recommendations for appropriate operating conditions without any detail knowledge about the protocol. The protocol could suggest the optimal operating conditions under optimized power consumption with more desirable environmental impact, while allowing the plant to meet effluent quality standards. This approach showed meaningful scientific value that could satisfy several objective functions with a set of algorithm, which was limited beforehand. Also, for wastewater treatment field, the application of technique combining appropriate statistical methods, artificial intelligence, and modeling together would contribute for advancing its operation and management technologies.

Abbreviations

- A2/O:

-

Anaerobic/anoxic/oxic process

- PAC:

-

Poly-aluminum chloride (kg/day)

- SRT:

-

Solids retention time (day)

- HRT:

-

Hydraulic retention time (day)

- F/M ratio:

-

Food to microorganism ratio

- MLSS:

-

Mixed liquor suspended solids (mg/l)

- BOD:

-

Biochemical oxygen demand (mg/l)

- TN:

-

Total nitrogen (mg/l)

- TP:

-

Total phosphorus (mg/l)

- PCA:

-

Principal component analysis

- KMCA:

-

k-mean clustering analysis

- ANN:

-

Artificial neural network

- Air:

-

Air flow rate (m3/day)

- Qin:

-

Influent flow rate (m3/day)

- Qras:

-

Return sludge flow rate (m3/day)

- Qrasin:

-

Inner return sludge flow rate (m3/day)

- Qfir:

-

Waste sludge flow rate in primary settling tank (m3/day)

- Qsec:

-

Waste sludge flow rate in secondary settling tank (m3/day)

- Cake:

-

Dewatered sludge cake production (t/day)

- Qdi:

-

Influent flow rate of digester (m3/day)

- Qdw:

-

Influent flow rate of dewatering facility (m3/day)

- Qthic:

-

Influent flow rate of centrifugal thickener (m3/day)

- Elec:

-

Electric power (kWh/day)

References

Aguado D, Rosen C (2008) Multivariate statistical monitoring of continuous wastewater treatment plants. Eng Appl Artif Intell 21(7):1080–1091

Bayo J, Lopez-Castellanos J (2016) Principal factor and hierarchical cluster analyses for the performance assessment of an urban wastewater treatment plant in the southeast of Spain. Chemosphere 155:152–162

Corominas L, Foley J, Guest JS, Hospido A, Larsen HF, Morera S, Shaw A (2013) Life cycle assessment applied to wastewater treatment: state of the art. Water Res 47(15):5480–5492

Du YG, Tyagi RD, Bhamidimarri R (1999) Use of fuzzy neural-net model for rule generation of activated sludge process. Process Biochem 35:77–83

Escrivá-Escrivá G, Álvarez-Bel C, Roldán-Blay C, Alcázar-Ortega M (2011) New artificial neural network prediction method for electrical consumption forecasting based on building end-uses. Energy Build 43:3112–3119

Grieu S, Traoré A, Polit M, Colprim J (2005) Prediction of parameters characterizing the state of a pollution removal biologic process. Eng Appl Artif Intell 18:559–573

Guinée JB (2002) Handbook on life cycle assessment operational guide to the ISO standards. Int J LCA, 7(5):311–313

Henze, M. (2000) Activated sludge models ASM1, ASM2, ASM2d and ASM3 (Vol. 9). IWA publishing

Hospido A, Moreira MT, Feijoo G (2008) A comparison of municipal wastewater treatment plants for big centres of population in Galicia (Spain. Int J Life Cycle Assess 13:57–64

ISO (2006a) Environmental management-life cycle assessment-principles and framework. International Organization for Standardization (ISO), Geneve

ISO (2006b) Environmental management-life cycle assessment-requirements and guidelines. International Organization for Standardization (ISO), Geneve

Kalogirou SA (2000) Applications of artificial neural-networks for energy systems. Appl Energy 67:17–35

Kim K, Kang J, Jeon A, Rhee S, Kim K, Oh G (2012) A study on management and utilization of landfill gas, national institute of environmental research, Nier-rp2012–32 (in Korean)

Kim HS, Moon TS, Kim YJ, Kim MS, Piao WH, Kim SJ, Kim CW (2013) Evaluation of rule-based control strategies according to process state diagnosis in A2/O process. Chem Eng J 222:391–400

Korea Energy Corporation (2014) New and renewable energy white paper. http://www.knrec.or.kr/knrec/dfile/ Accessed 26 April 2016 (in Korean)

Korea Environment Corporation (2008) Report of development of greenhouse gas inventory and emission factors in environment sector. Korea Environment Corporation Accessed 5 September 2015 (in Korean)

Korea Environment Corporation (2012) User manual for GHG emissions in waste sector. Available at: http://www.keco.or.kr/kr/main/index.do. Accessed January 2015 (in Korean)

Korea Ministry of Environment (2013) Public sewage facilities operations management analysis. Korea Environment Corporation Web. http://www.keco.or.kr/kr/business/water/communityid/191/view.do?idx=521. Accessed 19 September 2015 (in Korean)

Korea Ministry of Environment (2014) Water resources management information system, http://www.wamis.go.kr/wke/wke_wqbase_lst.aspx Accessed 26 April 2016 (in Korean)

Korea National Cleaner Production Center (2015) Korea life cycle inventory database Web. http://www.kncpc.or.kr/ resource/lci_pass_db.asp. Accessed 15 July 2015 (in Korean)

Korea Statistics (2006–2012) Statistics of sewerage in Korea. Korea Statistics Web. http://www.me.go.kr/home/web/index.do?menuId=130 Accessed 10 September 2015 (in Korean)

Lennox J, Rosen C (2002) Adaptive multiscale principal components analysis for online monitoring of wastewater treatment. Wat Sci Tech 45(4–5):227–235

Maurice B, Frischknecht R, Coelho-Schwirtz V, Hungerbühler K (2000) Uncertainty analysis in life cycle inventory. Application to the production of electricity with French coal power plants. J Clean Prod 8:95–108

Meneses M, Concepción H, Vrecko D, Vilanova R (2015) Life cycle assessment as an environmental evaluation tool for control strategies in wastewater treatment plants. J Clean Prod 30:1–9

Moon T, Kim Y, Kim J, Cha J, Kim D, Kim C (2009) Identification of process operating state with operational map in municipal wastewater treatment plant. J Environ Manag 90:772–778

Neto AH, Fiorelli FAS (2008) Comparison between detailed model simulation and artificial neural network for forecasting building energy consumption. Energy Build 40:2169–2176

Olsson G (2012) ICA and me—a subjective review. Water Res 46:1585–1624

Panepinto D, Fiore S, Zappone M, Genon G, Meucci L (2016) Evaluation of the energy efficiency of a large wastewater treatment plant in Italy. Appl Energy 161:404–411

Pasqualino JC, Meneses M, Abella M, Castells F (2009) LCA as a decision support tool for the environmental improvement of the operation of a municipal wastewater treatment plant. Environ Sci Technol 43:3300–3307

PE International (2015) GaBi 6 Software Web. http://www.Gabi-software.com. Accessed 10 September 2015.

Piao W, Kim Y, Kim H, Kim M, Kim C (2016) Life cycle assessment and economic efficiency analysis of integrated management of wastewater treatment plants. J Clean Prod 113:325–337

Saim N, Osman R, DR SAS, et al. (2009) Chemometric approach to validating faecal sterols as source tracer for faecal contamination in water. Water Res 43:5023–5030

Shrestha S, Kazama F (2007) Assessment of surface water quality using multivariate statistical techniques: a case study of the Fuji river basin, Japan. Environ Model Softw 22:464–475

Simsir U, Ertugrul S (2009) Prediction of manually controlled vessels’ position and course navigating in narrow waterways using artificial neural networks. Appl Soft Comput 9:1217–1224

Singh KP, Malik A, Mohan D, Sinha S (2004) Multivariate statistical techniques for the evaluation of spatial and temporal variations in water quality of Gomti River (India)—a case study. Water Res 38:3980–3992

UnU soft co., LTD. (2016a) MassFlow Web. http://www.massflow.kr/main.aspx Accessed 26 April 2016

UnU soft co., LTD. (2016b) DataFlow Web. http://unusoft.kr/WebPagesEn/Solution.aspx Accessed 26 April 2016

Yoo K, Kim J, Yun Z, Hwang H, Lee H, Kim S (2014) A study on performance estimation and operation strategy of biological aerated filter using semi-empirical biofilm model, journal of Korean society on water. Environment 30(3):269–282 in Korean

Yoon Seong-Hoon (2015) Membrane bioreactor processes: principles and applications. CRC Press. Available at: http://onlinembr.info/cost/pump-power-calculation/

Acknowledgments

This research was supported by the Korean Ministry of Environment and the Korean Environmental Industry and Technology Institute (KEITI) through the “The Eco-Innovation Project”. This work was also supported by the Brain Korea 21 Plus Project in the Division of Creative Low Impact Development and Management for Ocean Port City Infrastructures.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Philippe Garrigues

Electronic supplementary material

ESM 1

(XLSX 37 kb)

Rights and permissions

About this article

Cite this article

Piao, W., Kim, C., Cho, S. et al. Development of a protocol to optimize electric power consumption and life cycle environmental impacts for operation of wastewater treatment plant. Environ Sci Pollut Res 23, 25451–25466 (2016). https://doi.org/10.1007/s11356-016-7771-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7771-1