Abstract

In the paper, a modified method for elemental sulfur (S8) determining using gas chromatography coupled with mass spectrometry (GC-MS) is proposed with estimation of selected validation parameters. The aim of this work was a review of problems associated with the determination of S8 and selection of the most optimal conditions for S8 analysis with GC-MS. The presented studies have shown that the temperature of the injector and the chromatographic column during S8 determination should not exceed 180 °C. At temperatures over 180 °C, the sulfur S8 is decomposed to the other sulfur species such as S2, S3, S4, S5, and S6. During decreasing injector and column temperature below 180 °C the chromatographic peak eluted as S8 is badly extended and asymmetric. To minimize the problems of S8 decomposition to other sulfur species during chromatographic process also other parameters of the GC-MS have been selected. In order to apply the proposed method for real sediments samples, determination of sulfur S8 in bottom sediments, collected in the Gulf of Gdansk (southern Baltic Sea), has been performed. The concentration of S8 fell in the range from below the limit of detection to 0.1432 ± 0.0095 mg/g d.w. The research has also shown that addition of approx. 200 mg of activated copper is effective for removing sulfur from bottom sediment extracts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sulfur compounds are ubiquitous in the water environment; they can be found in marine and ocean waters, as well as in fresh, surface, and ground waters and in the sediments. The sources of sulfur compounds in the environment are both natural (such as rock weathering, organic matter decay) and anthropogenic processes. The main anthropogenic sources of sulfur compounds are burning of traditional fossil fuels such as coal or oil, leakages from landfills for sulfur containing industrial wastes or disposal of sewage with high sulfur inputs.

In the sulfur cycle, sulfates are generally well accessible in aquatic ecosystems, but they mainly occur near the upper layers of water (Giordano et al. 2005). In water bodies, they can undergo various types of transformation. The sulfates can be used for amino acid synthesis by plankton, or they can be dispersed in the atmosphere. The sulfates slowly diffuse to the lower layers of water, where due to decreasing amount of oxygen, they can be converted to the hydrogen sulfide and other sulfides. In anaerobic zone, organic matter can undergo decomposition with production of hydrogen sulfide. Under reductive conditions, the sulfur can be precipitated as water insoluble heavy metals sulfides and it can settle in the benthic zone. Due to those processes, sulfur can be excluded from the cycle and not transformed hydrogen can slowly diffuse into the oxygen-rich layers. As a result of partial oxidation/oxidation of sulfide, elemental sulfur (S8) is formed (Van Stempvoort and Kwong 2010). In addition, the presence of S8 in sediments may be a product of bacterial reduction of sulfate in anaerobic respiration or a product of organic matter mineralization carried out by some types of cyanobacteria (e.g., Oscillatoria, Desulfurella) (Cetkauskaite et al. 2004; Madigan et al. 1997). Due to its importance in geochemical cycle and environmental studies, it is necessary to acquire knowledge on the circulation of sulfur in nature.

Sulfur is one of the critical elements in living matter, as it participates in several structural, metabolic and catalytic activities, but it can also have negative impacts on terrestrial and aquatic ecosystems (Jasińska et al. 2012; Norici et al. 2005). Sulfur compounds are considered to elicit toxic action. For instance such compounds sulfur dioxide and hydrogen sulfide are highly toxic so they are well examined regarding its toxicity. Elemental sulfur is highly hydrophobic hence non-bioavailable and therefore it is believed to be virtually non-toxic in the environment and non-accumulative in the food chain (Kuklińska et al. 2013). The chemical properties of elemental sulfur cause negligible toxicity to animals, insects, and plants. (Svenson et al. 1998; Pardos et al. 1999). However, several studies have shown that elemental sulfur was toxic to the indicator organisms (Cetkauskaite et al. 2004; Svenson et al. 1998; Ricking et al. 2004). This means that the presence of S8 in the samples (or extracts) can affect on the toxicity level and may complicate interpretation of the ecotoxicological results.

The presence of sulfur in sediment samples also interferes with the determination of certain compounds such as polycyclic aromatic hydrocarbons (PAHs) or polychlorinated biphenyls (PCBs) due to similar retention parameters in chromatographic system (under chromatographic conditions). The result may be impaired and it sometimes can preclude proper interpretation of chromatograms. Consequently, it is necessary to effectively control the method of sulfur removal from the solvent extracts. Accordingly, there is a necessity for studies of elemental sulfur concentration in the aqueous environment, particularly in the sediments.

Studies on the determination of sulfur in the environment have been conducted for many years. Elemental sulfur in sediments has been determined using various techniques such as high pressure liquid chromatography in reverse phase (RP-HPLC), electrochemical methods (linear sweep voltammetry, polarography), iodo-azidic methods, spectroscopy methods (colorimetry, turbidimetry) (Welz et al. 2009; Ranzan et al. 2015), or ion chromatography (Kuklińska et al. 2013; Fabbri et al. 2001). One of the most preferred technique of the final determination of S8 in sediments is gas chromatography, due to its unexcelled separation potential and simplicity of compounds determination. Moreover, procedures based on gas chromatography for S8 analysis are characterized by good recovery and repeatability and have the advantage of relative simplicity (Fabbri et al. 2001). To allow detection of trace levels of analytes, often, a selective derivatization with triphenylphosphine to form triphenylphosphine sulfide has been reported (Pauls 2010; Al-Zahrani et al. 2015). For the determination of mentioned analytes with gas chromatography-mass spectrometry, detectors are commonly used and less frequently other specific detectors such as SCD (sulfur chemiluminescence detector) (Hua et al. 2003), FPD (flame photometric detector) (Yin et al. 2014), FID (flame ionization detector), or AED (atomic emission detector) (Wardencki 1998).

However, some problems related to the GC-MS determination of S8 appear and most frequently involved:

-

The sorption and loss of sulfur species in the chromatographic system

-

Problems with sensitive and selective S8 detection in complex matrices (Wardencki 1998)

-

Problems with separation of S8 from other sulfur species

The literature review has revealed that in many cases S8 analysis may lead to analytical errors, as the final applied temperature of chromatographic analysis is set at as high as 310 °C (Pardos et al. 1999; Ricking et al. 2004; Chen et al. 1997). In our research, we noticed that at higher temperatures of chromatographic process the elemental sulfur can undergo decomposition. Therefore, in the paper, we have investigated problems with elemental sulfur determination in sediments using gas chromatography-mass spectrometry (GC-MS) and necessity of its removal before PCBs and PAHs determination in environmental samples. The aim of this study was to (1) optimize conditions for determining of S8, (2) define the basic parameters of validation, (3) S8 determine in the bottom sediments samples, and (4) evaluate the effectiveness of elemental sulfur removal from bottom sediment samples using an activated copper.

Materials and methods

Analysis of the S8 solution

Preparation of solutions

Stock solution used in the research model has been prepared by dissolving 12.5 mg S (Sulfur Sigma-Aldrich, Germany) in 50 ml acetone (corresponding to 250 mg/l) (Acetone Suprasolv, Merck, Germany) in ultrasonic bath (30 min, InterSonic IS-5.5, Poland). Standard solution has been prepared with 40 μl of stock solution and 460 μl hexane (n-Hexane SupraSolv, Merck, Germany. Injection volume for the chromatography column was 2 μl of sulfur solution.

GC-MS conditions

Sulfur compounds have been analyzed by GC-MS (Shimadzu QP2010 Ultra). The GC-MS has been equipped with a ZB-5MS capillary column and helium has been used as the carrier gas. The determination of sulfur has been performed under conditions of GC-MS listed in Table 1. The following mass to ion ratios have been monitored (m/z): 64, 96, 128, 160, 192, 256, 257, 258, and 259, which correspond to S2, S3, S4, S5, S6, and S8 respectively.

Quality control/quality assurance

Ensuring the quality of the measurement results was carried out by:

-

Calibration of the GC-MS system

-

Determination of the basic validation parameters based on parameters obtained from calibration curves

The calibration step involves the preparation of calibration curves. The relationship between the area of the chromatographic peak for the analyte and its concentration in the sample of suitable reference solutions dosed into analytical system (GC-MS) has been determined.

The stock solution used for calibration has been prepared with 12.5 mg S and 50 ml of acetone as the diluting solvent. In the next step, a series of calibration solutions in hexane have been prepared by serial dilution method. The nine calibration solutions with concentration in the range from 1 to 20 mg S/l have been prepared. The injection volume for the chromatography column was 2 μl of sulfur reference solutions. Table 2 gives information on the GC-MS operating conditions.

Analysis of the real sediment samples

Sample collection

Sediment samples have been taken at various locations in the area of Gulf of Gdansk (southern Baltic Sea). The Gulf of Gdansk is particularly susceptible to human pressure due to high level of urbanization and industrialization. In this study, the following samples have been selected: at the mouth of the Vistula River (samples V1–V6), at the site of wreckage s/s “Stuttgart” from World War II (samples C1–C6), from the harbor basin (samples D1–D5), and at the area of treated wastewater outlet from sewage treatment plants (STP) “East” into the waters of the Gulf of Gdansk (samples W1–W5). Samples of surface sediments have been collected with the van-Veen-gripper, next transported to the laboratory and frozen (−18 °C).

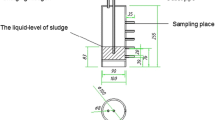

Sample extraction and clean-up method

Sediment samples have been lyophilized and prepared according to a modified procedure proposed by Pardos et al. 1999. Approx. 2 g of dry sediments have been weighed. All samples have been extracted with 40 ml of acetone to hexane (1:2, v/v) (Acetone Suprasolv, n-hexane Suprasolv, Merck, Germany) in ultrasonic bath (30 min, InterSonic IS-5.5, Poland). Next, they have been centrifuged for 15 min at 1000g (Eppendorf Cenrtifuge 5804, Germany) and the supernatants have been collected. The residual solids have been re-extracted using the same procedure. The final extracts have been combined and evaporated by rotary evaporation to dryness (40 °C) (Heidolph, Germany). The residues have been dissoluted in 10 ml of hexane.

Sulfur removal

For sulfur removal, approximately 200 mg of acid-activated copper has been added to a 3-ml aliquot of the extract and incubated at room temperature for 120 h. The copper powder (Copper fine powder <63 μm, Merck, Germany) has been activated with the use of HCL to water solution (1:1, v/v) (HCL 32 %, Merck, Germany), neutralization with demineralized water and acetone dried.

GC-MS determination of elemental sulfur

Solvent extracts, obtained before and after sulfur removal, have been analyzed using a GC-MS with split/splitless injector. Conditions of the GC-MS system are presented in Table 2. Identification of elemental sulfur in real samples has been carried out based on a comparison of retention times of characteristic fragment ions in real samples and standard solutions.

Results and discussion

Chromatographic analysis of standard solutions has been performed under different chromatographic conditions (see Table 1) and then the optimal conditions for analysis have been selected. Under the optimal chromatographic conditions, calibration curves have been prepared and basic validation parameters have been estimated. Subsequently, the real sample extracts have been analyzed before and after sulfur treatment with activated copper.

Analysis of the S8 solution

The results of sulfur determination in standard solution under different GC-MS condition are presented in the Fig. 1.

Chromatogram obtained from analysis carried out in accordance to method SI indicates that the S8 disintegrates in the injector heated to a temperature of 280 °C. The result is generation of peaks corresponding to decomposition products S8. The most intense peak in the chromatogram is derived from ion S2 [m/z = 64]. For chromatograms SIV and SV, we have observed that the chromatographic peaks are tailing and signal to noise ratio decreased. This is connected with too low temperature of the sample injection (injector temperature and the process chromatography was <180 °C). Furthermore, in the case of the methods SVI and SVII, extending of analysis time and the deterioration of peaks symmetry has been observed.

Obtained chromatograms indicate that for the S8 determination the GC oven and the injector temperature should not exceed 180 °C. Above this temperature, S8 decomposes to other sulfur species: S2, S3, S4, S5, and S6, what can be seen from the chromatograms SVI-SVIII and SI, where appropriate ions mass ratios (m/z) have been monitored. Verification of chromatograms SI–SVIII allowed the indication of the optimal S8 separation methods, the SII method, in which the most symmetric and thin peaks generated from S8 have been observed and S8 decomposition does not occur.

The structures and properties of elemental sulfur have been well established (Meyer 1976). S8 occurs in the three allotropes with the boiling temperature 444.7 °C. Above 150 °C substantial ring scission can be observed (Meyer 1976). In our experiment, the decomposition of sulfur occurs at 180 °C. How this difference (30 °C) in the observed data can be explained?

The several things can be identified as parameters which can affect on it:

-

During injections, in injector and chromatographic column higher than normal pressure can be observe and the temperature increases at which the decomposition of S8 occurs.

-

The moment of the extract injecting is related to the rapid evaporation of the solvent, what can cause decrease of the temperature in the injecting area.

-

A column separation process is a dynamic process with a constantly occurring sorption process in stationary phase and desorption process to mobile phase.

The above-described problem of elemental sulfur decomposition in the case of very high temperatures during the chromatographic process has been observed in previous studies presented by Pardos et al. 1999, Ricking et al. 2004, Chen et al. 1997 and Nair et al. 2014, despite the fact that in the methodology proposed by the authors the final temperature of chromatographic process ranged from 260 to 310 °C, and temperature of injection was between 250 and 300 °C.

Quality control/quality assurance

Analysis of standard solutions has been performed for selecting a suitable temperature program (Table 1, SII). Based on these results (each of which was the average of four parallel determinations), calibration curves have been prepared, and regression coefficients and basic parameters of validation have been calculated (Table 3). High regression coefficient (0.996) shows the linearity of the method in a concentration range of elemental sulfur (1–20 mg/l).

Limit of determination has been calculated from the parameters of a calibration curve constructed on the basis of the three lowest concentrations of standard solutions. The limit of determination has been calculated according to the formula:

where:

- a :

-

slope of the calibration curve

- s :

-

the standard deviation

In the calculation, we have taken into account residual standard deviation (s xy) and standard deviation of the intercept (s a ). The calculated values are as follows: LOD(s xy) = 0.42 mg/l, LOD(s a ) = 0.38 mg/l, and the mean value LOD = 0.4 mg/l. The established detection limit of this method is close to the detection limit obtained by Pardos et al. 1999 (0.1 mg/l).

Analysis of real samples

In view of the fact that S8 in sediments are not only of natural origin but also may be a result of anthropogenic processes, levels of concentrations can be varied. Close to harbors and area of industrial activities, the concentrations in sediments have been found to be higher, while lower amounts have been measured in samples from the deep sea bottom and in sediments with low organic contents (Svenson et al. 1998). Amounts of S8 in sediments vary widely depends upon the sampling place and its contamination, but they can be range from about 0.016–0.960 mg/g (Yücel et al. 2010) to even 6.4–9.6 mg/g (Burton et al. 2006a, b).

The analysis of real samples carried out according to the proposed method showed that the sulfur occurs at concentrations in the range of 0.0011 ± 0.000075 up to 0.1432 ± 0.0095 mg/g d.w. (dry weight). The highest concentration levels of sulfur have been found in samples collected in the area of the wreck of the ship s/s “Stuttgart” deposition. In most of the samples taken at the mouth of the Vistula River, the mouth of the sewage collector from STP “East” into the waters of the Gulf of Gdansk, and the harbor basin, the sulfur concentration was below the level of quantification (Table 4).

The source of high sulfur content in sediments samples taken in the area of the wreck of s/s “Stuttgart” deposition may be connected with fuel released from ship, which still remain at sea bottom. There is no clear/confirmed information on the type of fuel which contaminates this area. It is very likely that the remaining fuel was not crude oil. Earlier studies may indicate that fuel could be obtained in the processing of coal (synthetic gasoline) (Rogowska et al. 2010; Kudłak et al. 2012). Sulfur compounds are both in the crude oil and coal. The sulfur content in coals varies considerably, but is most commonly within the range of 0.5 to 5 % of total sulfur (Chou 2012), while, gasoline contains 0.001 to 0.010 mg/g of elemental sulfur (Pauls 2010).

The next stage of the study was to evaluate the effectiveness of the removal of elemental sulfur from solvent extracts with activated copper from solvent extracts to determine micropollutants. The presence of sulfur in the solvent extracts may hinder the development of further stages determinations and affect the interpretation of results. Removal of sulfur from the solvent extracts is required for chromatographic determinations of compounds such as PCBs and PAHs (Rogowska et al. 2013). This is due to the fact that the elemental sulfur S8 has a molecular mass of 256 Da such as PCB 28 (2,4,4′-trichlorobiphenyl) and a retention time similar to PAH and, as a result, impairs and sometimes precludes proper interpretation of chromatograms. Furthermore, during the determination of PCB-group chemicals in sediment samples, sulfur should be removed from the extracts in order to protect the detector (Mechlińska et al. 2012).

S8 determination in purified solvent extracts showed that the sulfur is present at very low levels, below limit of quantification. This means that the use of the approx. 200 mg of activated copper is enough to remove elemental sulfur from sediment samples. The applied method of purifying extracts is effective and can be successfully used.

Conclusions

Despite the increasingly rapid development of a numerous techniques and analytical methods for the determination of a wide spectrum of compounds at ever lower levels, there are still problems related to the marking of some compounds in environmental matrices. One of such analyte is elemental sulfur. Other problems are related to the proper analytical design chromatographic process, in order to avoid losses of analyte. Both, the excessive temperature programs of GC and injection temperature causes the elemental sulfur breaks down into other sulfur species.

Determination of elemental sulfur in environmental samples is essential due to the fact that it is interferent in the analysis, e.g., compounds of the group PAHs and PCBs, and may affect the operation and cleanliness of the detector. Presence of sulfur in the extracts disrupts a proper analysis and prevents obtaining reliable and accurate results. Moreover, the presence of elemental sulfur in the sediments may affect on their toxicity. Consequently, elemental sulfur should be removed before chromatographic determination. The application of proper procedure for determining the S8 is important in two aspects:

-

The need for determination of the S8 in environmental samples

-

To confirm the removal S8 from extracts, before PAHs and PCBs determination

In such cases, the following conditions of GC-MS analysis must be used: the injector temperature—180 °C, the column temperature—180 °C, and the ion sources temperature—180 °C.

References

Al-Zahrani I, Aneel Mohammed MH, Basheer C, Siddiqui MN, Al-Arfaj A (2015) Membrane assisted simultaneous extraction and derivatization with triphenylphosphine of elemental sulfur in arabian crude samples by gas chromatography/mass spectrometry. J Chem Doi. doi:10.1155/2015/792914

Burton ED, Bush RT, Sullivan LA (2006a) Elemental sulfur in drain sediments associated with acid sulfate soils. Appl Geochem 21:1240–1247

Burton ED, Bush RT, Sullivan LA (2006b) Fractionation and extractability of sulfur, iron and race elements in sulfidic sediments. Chemosphere 64:1421–1428

Cetkauskaite A, Pessala P, Södergren A (2004) Elemental sulfur: toxicity in vivo and in vitro to bacterial luciferase, in vitro yeast alcohol dehydrogenase, and bovine liver catalase. Environ Toxicol 19:372–386

Chen YW, Joly H, Belzile N (1997) Determination of elemental sulfur in environmental samples by gas chromatography-mass spectrometry. Chem Geol 137:195–200

Chou C-L (2012) Sulfur in coals: a review of geochemistry and origins. Int J Coal Geol 100:1–13

Fabbri D, Locatelli C, Tarabusi SA (2001) A new procedure, based on combustion to sulphate and ion chromatography for the analysis of elemental sulfur in sediments. Chromatographia 53:119–121

Giordano M, Norici A, Hell R (2005) Sulfur and phytoplankton: acquisition, metabolism and impact on the environment. New Phytol 166:371–382

Hua R, Li Y, Liu W, Zheng J, Wei H, Wang J, Lu X, Kong H, Xu G (2003) Determination of sulfur-containing compounds in diesel oils by comprehensive two-dimensional gas chromatography with a sulfur chemiluminescence detector. J Chromatogr A 1019:101–109

Jasińska A, Burska D, Bolałek J (2012) Sulfur in the marine environment. Oceanol Hydrobiol St 41:72–82

Kudłak B, Rogowska J, Wolska L, Kałas M, Łęczyński L, Namieśnik J (2012) Toxicity assessment of sediments associated with the wreck of s/s Stuttgart in the Gulf of Gdańsk (Poland). J Environ Monit 14:1231–1236

Kuklińska K, Cieszyńska M, Wolska L, Namieśnik J (2013) Analytical and bioanalytical problems associated with the toxicity of elemental sulfur in the environment. Trac-Tren. Anal Chem 48:14–21

Madigan MT, Martinko JM, Parker J (1997) Brock biology of microorganisms. Prentice-Hall, London

Mechlińska A, Wolska L, Namieśnik J (2012) Removal of sulfur from a solvent extract. Trac-Tren. Anal Chem 31:129–133

Meyer B (1976) Elemental sulfur. Chem Rev 76:367–388

Nair KK, Siddiqi WA, Kumar R, Niwas R, Gogoi R, Srivastava C, Gopal M (2014) Sensitive and rapid determination of elemental nanosulfur/sulfur by liquid chromatography. J Sep Sci 37:1126–1133

Norici A, Hell R, Giordano M (2005) Sulfur and primary production in aquatic environments: an ecological perspective. Photosynth Res 86:409–417

Pardos M, Benninghoff C, Thomas RL, Khim-Heang S (1999) Confirmation of elemental sulfur toxicity in the Microtox® assay during organic extracts assessment of freshwater sediments. Environ Toxicol Chem 18:188–193

Pauls RE (2010) Determination of elemental sulfur in gasoline by gas chromatography with on-column injection and flame ionization detection following derivatization with triphenylphosphine. J Chromatogr Sci 48:284–288

Ranzan C, Ranzan L, Trierweiler LF, Trierweiler JO (2015) Sulfur determination in diesel using 2D fluorescence spectroscopy and linear models IFAC-papers On Line 48–8: 415–420

Ricking M, Neumann-Hensel H, Schwarzbauer J, Svenson A (2004) Toxicity of octameric elemental sulfur in aquatic sediments. Environ Chem Lett 2:109–112

Rogowska J, Wolska L, Namieśnik J (2010) Impacts of pollution derived from ship wrecks on the marine environment on the basis of s/s Stuttgart (Polish coast, Europe. Sci Total Environ 408:5775–5783

Rogowska J, Mechlińska A, Wolska L, Namieśnik J (2013) Polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs): sediments and water analysis. In: Jorgensen SE (ed) Encyclopedia of environmental management. Taylor & Francis, New York, pp. 2186–2207

Svenson A, Viktor T, Remberger M (1998) Toxicity of elemental sulfur in sediments. Environ Toxicol Water Qual 13:217

Van Stempvoort DR, Kwong YTJ (2010) Sulfur analyses as tracers of microbial degradation of hydrocarbons in the capillary fringe. J Contam Hydrol 114:1–17

Wardencki W (1998) Problems with the determination of environmental sulfur compounds by gas chromatography. J Chromatogr A 793:1–19

Welz B, Lepri FG, Araujo RGO, Ferreira SLC, Huang MD, Okruss M, Becker-Ross H (2009) Determination of phosphorus, sulfur and the halogens using high-temperature molecular absorption spectrometry in flames and furnaces—a review. Anal Chim Acta 647:137–148

Yin C, Li H, Liu H, Zhao L, Bai Z, Wang Y, Zhang S, Liu C (2014) Study on the formation, determination, and removal of elemental sulfur in ultra-low sulfur gas oil. Fuel Process Technol 120:16–20

Yücel M, Konovalov S, Moore T, Janzen C, Luther GW (2010) Sulfur speciation in the upper Black Sea sediments. Chem Geol 269:364–375

Acknowledgments

The authors would like to thank for the financial support to the Polish Ministry of Science and Higher Education (project MN–01-0095/08).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Rogowska, J., Sychowska, J., Cieszynska-Semenowicz, M. et al. Elemental sulfur in sediments: analytical problems. Environ Sci Pollut Res 23, 24871–24879 (2016). https://doi.org/10.1007/s11356-016-7739-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7739-1