Abstract

In contaminated soils, excessive concentrations of metals and their high mobility pose a serious environmental risk. A suitable soil amendment can minimize the negative effect of metals in soil. This study investigated the effect of different biochars on metal (Cu, Pb, Zn) immobilization in industrial soil. Biochars produced at 300 and 600 °C from conventional (MS, maize silage; WP, wooden pellets) and alternative (SC, sewage sludge compost; DR, digestate residue) feedstocks were used as soil amendments at a dosage of 10 % (w/w). The type of feedstock and pyrolysis temperature affected the properties of the biochars and their ability to immobilize metal in soil. Compared to production at 300 °C, all biochars produced at 600 °C had higher pH (6.2–10.7), content of ash (7.2–69.0 %) and fixed carbon (21.1–56.7 %), but lower content of volatile matter (9.7–37.2 %). All biochars except DR biochar had lower dissolved organic carbon (DOC) content (1.4–2.3 g C/L) when made at 600 °C. Only MS and SC biochars had higher cation exchange capacity (25.2 and 44.7 cmol/kg, respectively) after charring at 600 °C. All biochars contained low concentrations of Cd, Cu, Ni, Pb and Zn; Cd was volatilized to the greatest extent during pyrolysis. Based on FTIR analysis and molar ratios of H/C and O/C, biochars had a greater degree of carbonization and aromaticity after charring at 600 °C. The efficiency of the biochars in metal immobilization depended mainly on their pH, ash content, and concentration of DOC. SC and DR biochars were more effective for Cu and Zn immobilization than MS and WP biochars, which makes them attractive options for large-scale soil amendment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The mining and smelting of non-ferrous elements is a major cause of soil pollution around the world. In Europe, the estimated number of brownfields and other contaminated industrial sites be over 1 million (CLARINET 2002), and soil contamination has been identified as an important issue for action in the European Community strategy for soil protection and remediation.

The Polish metallurgical industry has become one of the largest in Europe, and many contaminated soils are found near the Legnicko-Głogowski industrial district, where copper ores are mined and processed. In this district, precipitation of metallurgical dust has led to excessive concentrations of Cu, Pb and Zn in the soil surface layer (Karczewska 1996). Around mining and smelting sites, large areas tend to be polluted with metals, which makes in situ application of soil amendments a good strategy for soil remediation (Dybowska et al., 2006). To immobilize metals in soil by transforming them into less mobile fractions, organic (e.g. sewage sludge, composts) and inorganic (e.g. Fe, Al, Mn oxides, phosphate, lime) materials have been used (Bolan et al. 2014), and biochar has recently been considered for this use.

Biochar is produced by pyrolysis of two kinds of feedstocks, either waste biomass or biomass that is mostly non-waste (Brick 2010). Crop residues, forestry waste, animal manure, food processing waste, paper mill waste, municipal solid waste, and sewage sludge have all been extensively evaluated for biochar production (Ahmad et al. 2014). The properties of biochars and their suitability for soil remediation are strongly affected by the temperature of pyrolysis and the type of feedstock. Because almost any form of organic material can be pyrolyzed, alternative feedstocks have recently been used. For biochar production, compost and the solid fraction of anaerobic digestate are attractive feedstocks due to their availability and the presence of recalcitrant organic compounds (i.e. lignin) that undergo thermal destruction during pyrolysis. Although a few studies have shown that biochars produced from compost Pellera et al. (2012)) or digestate (Zhang and Luo 2014) are suitable for removing metals (e.g. Cu, Zn and Mn) from wastewater, their use as an amendment in metal-contaminated soil has not been investigated.

Compost has certain physicochemical properties (e.g. lignin content) that are desirable for pyrolysis (Barneto et al. 2010), and pyrolyzed compost can have higher pH, thus avoiding a potential increase in metal mobility after soil amendment with non-pyrolyzed compost. For example, soil amendment with pine bark compost increased Cu and Zn bioavailability, which was probably due to the low pH of the compost (pH 5.6) and its low humification ratio, which favored formation of soluble organo-metallic complexes (Pérez-Esteban et al. 2012). To raise the pH of the compost and avoid this problem, it can be charred to decrease the amount of dissolved organic carbon that was in it. In the case of anaerobic digestate, the rapid development of biogas production makes it likely that there will be a need for ways to dispose of the digestate other than agricultural use. It is estimated that by 2020 over 2.5 thousand agricultural biogas plants will be built in Poland, which corresponds to an annual production of about 25 million tons of post-fermentation residues (Czekała et al. 2012).

The aim of the present study was to determine how the physico-chemical properties of biochars and their suitability for immobilization of metals in soil from a smelting area are affected by the temperature of pyrolysis (300 or 600 °C) and the type of feedstock. To this end, biochars produced from conventional (maize silage, wooden pellets) and alternative (sewage sludge compost and the solid fraction of digestate residues) feedstocks were compared.

Materials and methods

Feedstock for biochar production

Four types of feedstock were used to prepare biochar: maize silage (MS), sewage sludge compost (SC), wooden pellets (WP) and the solid fraction of digestate residues (DR). MS was collected directly from silos in a farmstead in Komorowo, Kujawsko-Pomorskie Province, Poland. SC was produced from sewage sludge mixed with wood chips, rape straw and grass. The composting process was conducted in a two-stage system with an aerated bioreactor (1 m3 (Bahng et al. 2011)) and a periodically-turned windrow (Kulikowska and Klimiuk 2011). SC was collected 12 months after the start of maturation in the windrow. WP (1–1.8 cm in length and 0.5 cm in diameter), produced from oak and pine (60:40 % w/w), were commercially available on the local market. Dewatered DR was obtained from a biogas plant in Kalsk (Lubelskie Province, Poland), which uses mixture of cattle manure, pig manure and maize silage for biogas production. Before pyrolysis, all feedstocks were dried at 60 °C for 48 h and kept in plastic containers.

Pyrolysis

The slow pyrolysis of individual feedstocks was carried out in a stainless steel reactor with a total volume of 3 L. The reactor was heated with a three phase electrical heater controlled by a power system cabinet equipped with a computer. The mass of pyrolysed material was recorded by a balance to a precision of 0.001 g. To examine the effect of pyrolysis temperature on the properties of biochar and its suitability as a soil amendment, each feedstock was pyrolysed at both 300 and 600 °C. The heating rate was 5 °C/min. And the holding time was 30 min.

The initial mass of feedstock was 300 g. The biochar yield (% ww) was calculated as the ratio of the mass of the biochar obtained to the mass of the feedstock used for pyrolysis. The biochar yields varied depending on feedstock type and were lower at higher pyrolysis temperatures: 52 % (MS300) and 34 % (MS600), 79 % (SC300) and 61 % (SC600), 61 % (WP300) and 41 % (WP600), and 51 % (DR300) and 50 % (DR600). After cooling, biochars were kept in plastic containers.

Soil

The soil was collected in the vicinity of the Legnica Copper Smelter (51°11′6″N, 16°6′46″E) in the Lower Silesia region of SW Poland. The sampling site was 70 m from the emission source, within the former protection zone that surrounds the smelter. The soil surface samples (0–30 cm) were collected with a plastic spade to avoid any contamination with heavy metals. In total, the soil sample consisted of five sub-samples taken within a 1 × 1 m square. All together, about 10 kg of representative soil was collected. In the laboratory, the soil was air-dried (2 weeks), ground, and sieved before its physicochemical properties were characterized.

Metal immobilization with biochars

Nine different variants were prepared: soil without biochar (S) as control, and soil with biochars: S + MS300, S + MS600, S + SC300, S + SC600, S + WP300, S + WP600, S + DR300 and S + DR600. Each type of biochar was used at a dosage of 10 % (w/w) (Houben et al. 2013). In each variant, the total mass of control soil or soil amended with biochar was 300 g. The soil and biochar were mixed thoroughly on a rotary shaker for 2 h and then wetted with deionized water to keep moisture at 60 % of maximum water holding capacity, which was 50 % for soil alone, and from 55 to 68 % for the soils amended with biochar. Therefore, in unamended soil, the mass of water added at the beginning of the experiment was 90 g, whereas in amended soil, depending on biochar type, it ranged from 99 to 122 g. For one month, soils with amendments were incubated at room temperature (22–24 °C) in pots that had a volume of 500 ml and were covered with porous covers. Small holes in the cover allowed gas exchange while minimizing moisture loss. During incubation, the pots were weighed every week and water was added to maintain constant moisture. For physico-chemical characterization, soil samples were collected from the pots at the first and the last (30th) day of incubation. Next, the samples were air-dried, ground and stored in covered plastic vessels.

Physico-chemical analysis

Particle size distribution in soil was determined using a Mastersizer 2000 laser particle-size analyzer (Malvern Instruments, UK). In soil and biochar samples, pH and electrical conductivity (EC) were determined in 1 M KCl and distilled water extracts, respectively (1:2.5 w/v for soil and 1:10 w/v for biochar) using a pH-meter (HI 221) and a conductivity meter (HI 8733). Moisture content (M) was determined using the weight loss after heating samples at 105 °C. Organic matter (OM) and ash content in soil and feedstocks were determined by sample combustion at 550 °C in a muffle furnace (Carbolite ESM-9920).

To determine volatile matter content, biochars were placed in covered ceramic crucibles, then combusted in the muffle furnace at 950 °C for 6 min. To determine ash content, the biochars were placed in uncovered ceramic crucibles, and then combusted in the furnace at 750 °C for 2 h (Zhang et al. 2014). The fixed carbon (FC) content was calculated as FC (%) = 100 – [%VM + %moisture + %ash].

The cation exchange capacity (CEC) was calculated as the sum of hydrolytic acidity (in 1 M Ca(CH3COO)2) and exchangeable bases (in 0.1 M HCl) (Ostrowska et al. 1991). Dissolved organic carbon (DOC) in water extracts was determined according to Beesley et al. (2010) using a TOC analyzer (VCSN, Shimadzu). By using a FLASH 2000 elemental analyzer (Thermo Scientific, USA), the moisture free content of carbon (C), hydrogen (H) and nitrogen (N) (weight percentage) was determined. The oxygen content was calculated by using the following formula: O (%) = 100 – [%C + %H + %N + %ash] (Calvelo Pereira et al. 2011).

To indicate the aromaticity of the biochars, the molar ratio of H/C in each biochar was determined, while the polarity of the biochars and their resulting hydrophobic or hydrophilic properties were assessed on the basis of molar O/C ratios (Uchimiya et al. 2013). For functional groups, the biochars were scanned with an FTIR spectrometer (Nicolet 6700, Thermo Scientific) equipped with Smart Multi-Bounce HATR™ at wave numbers from 3600 to 600 cm−1. Spectra were collected at 4 cm−1 resolution with 32 scans and a mirror velocity of 0.6329 cm/s.

For determination of total metal content, soil and biochar samples were digested with aqua regia in a microwave oven (MARSXpress, CEM USA). To accomplish this, 1 g of soil or 0.25 g of biochar were weighed and placed in polytetrafluoroethylene vessels, treated with 2 ml of 30 % H2O2 and HCl/HNO3 mixture (Sigma-Aldrich) (3:1 v/v ratio) and then heated using a one-stage microwave program (T = 170 °C, P = 800 W, t = 30 min). After cooling, the extracts were filtered through Whatman 42 filter papers (pore size 8 μm) into 50-mL glass flasks, which were filled to the mark with distilled water. Metal concentrations in the extracts were determined with a flame atomic absorption spectrometer (FAAS) (Varian, AA28OFS). Metal concentration in the mobile fraction was determined through extraction of unamended and amended soil with 0.01 M CaCl2 at a ratio of 1:10 (w/v) in 50 mL polyethylene tubes for 2 h at 40 rpm. The concentrations of individual metals were determined by the FAAS method.

All measurements were performed in triplicate. Data were statistically evaluated using STATISTICA 12.0 (StatSoft, Inc.). One-way analysis of variance (ANOVA) was employed. To elucidate significant differences between means (p < 0.05) post hoc comparisons were made using Tukey’s HSD test.

Results and discussion

Soil characterization

Selected properties of the soil from the vicinity of the Legnica smelter industrial area are presented in Table 1. Based on textural analysis the soil was classified as silt loam (sand 25.6 %, silt 67.0 %, clay 5.7 %). The soil had neutral pH and low OM content. These results are consistent with observations made by Karczewska et al. (2009). Soils like the one used in this experiment, with less than 10–20 % clay and low OM, are permeable and the metals they contain are mobile.

The Cu concentration in the soil was 13.5 times higher than the quality standard for industrial soil in the Polish Ordinance of the Minster of Environment (OME 2002). The concentration of Pb was 2.5 times higher than the standard. The concentration of Zn, in contrast, was below the industrial area standard, but above the standard for agricultural areas. This intensive contamination is due to long-term copper smelting. Cd was also present in the soil, although at a much lower concentration, because it is present as a minor constituent in copper sulfide ore (Scoullos 2000). The concentration of Ni in the soil indicated that this metal was of natural origin.

The effect of temperature pyrolysis on biochar properties

The chemical rather than the physical properties of biochar determine its ability to immobilize heavy metals in soil (Uchimiya et al. 2013). For decreasing the mobility of metals and increasing their stability in amended soil, biochar should have an alkaline pH, a high content of ash to promote metal precipitation, more functional groups to better complex the metals, less labile carbon to decrease metal mobility, and a suitable cation exchange capacity (CEC) to provide more available sites for ion exchange. In addition, for general soil quality, it is better for biochar to have a lower EC to reduce the salinity of the soil. Finally, a high carbon content in biochar allows it to be sequestered soil for a long time. Based on these criteria, biochars produced at 600 °C had better properties than biochars after pyrolysis at 300 °C. Overall, biochar that was produced from SC at 600 °C had the best properties for heavy metal immobilization in amended soil. The detailed properties of the biochars are given in Tables 2 and 3.

pH and EC

Before pyrolysis, MS, SC and WP had mildly acidic pH (Table 2). The higher temperature of pyrolysis (600 °C) resulted in an increase in pH in all biochars. Compared to the feedstocks, the highest increase in pH was with MS and SC biochars. With DR biochars, pH increased to a lesser extent, because the feedstock was already alkaline before pyrolysis. The alkaline character of the biochars obtained at higher temperatures results mainly from the loss of acidic functional groups and the increase in ash content during pyrolysis. In biomass heated at approximately 400 °C, most oxygenated aliphatic functional groups are degraded (Keiluweit et al. 2010). Due to their higher content of neutralizing compounds like carbonates and oxides, MS, SC and DR biochars may increase pH in amended soil to a greater extent than WP biochars. The WP biochars remained slightly acidic, regardless of the temperature of pyrolysis. Similarly, Yargicoglu et al. (2015) found that biochars from pinewood pellets produced at 520 °C were slightly acidic (pH 6.24–6.78).

The EC estimates the total amount of dissolved salts or ions in biochar. MS and SC contained more dissolved ions than the other feedstocks. The EC of MS, SC and WP biochars was lower at the increased temperature of pyrolysis. The opposite trend was seen in DR biochars. An increase in the EC of biochars when pyrolysed at higher temperatures can be due to an increase of highly soluble and exchangeable base cations (Al-Wabel et al. 2013). However, the changes in the EC of biochar can also depend on the type of feedstock used for pyrolysis. Luo et al. (2014) found that when the temperature of pyrolysis was increased from 200 to 700 °C, the EC of corn stalk biochar increased from 1090 to 2685 μS/cm, whereas that of sewage sludge biochar decreased from 477 to 166 μS/cm. This was probably due to loss of organic matter and an increase in the concentration of salts and metals in the ash fraction.

VM, ash, FC and DOC

MS, WP and DR contained more volatile matter than SC. After pyrolysis at 600 °C, VM content was less than after pyrolysis at 300 °C, whereas the contents of ash and FC were greater. Ash is the inorganic, non-combustible portion of biochar that remains after VM is removed (Yargicoglu et al. 2015). During pyrolysis, cellulose, hemicellulose, and lignin start to become ash, and carbonates and alkali ions began to separate from organic materials (Cao and Harris 2010; Jung and Kim 2014). The content of ash determines the pH of biochar, whereas the content of FC determines the amount of stable carbon (Al-Wabel et al. 2013).

SC biochar had the highest content of ash and the lowest content of VM and FC (Table 2). This could result from the fact that the compost used for pyrolysis already had high ash content compared to the other feedstocks. Pyrolysis, especially at 600 °C, led to effective decomposition of organic matter. Meng et al. (2013) also observed that biochar produced from swine manure composted for 84 d had a high content of ash and a low content of VM and FC: when it was produced at 400 °C, it contained 57.6 % ash, 30.8 % VM and 9.3 % FC; at 700 °C, 71.8 % ash, 16.4 % VM and 9.9 %.

In the case of the WP300 and WP600 biochars, the content of VM was 57.3 and 37.2 %, respectively, and FC content was 36.8 and 55.0 %, respectively. The WP biochars had the lowest ash content in this study (Table 2). Enders et al. (2012) also found that increasing the pyrolysis temperature led to similar differences in the contents of these biochar constituents. They pyrolysed oak and pine wood at temperatures from 300 to 600 °C; at these temperatures, VM content was 65 and 30 %, respectively, FC content was 40 and 70 %, respectively, and ash content was below 10 %. Keiluweit et al. (2010) reported even lower contents of ash: they found that pyrolysis of pinewood biochar at 200 and 600 °C gave ash contents of 1.5 and 3.7 %, respectively, whereas pyrolysis of Fescue straw resulted in ash contents of 5.7 and 18.9 %, respectively. Yargicoglu et al. (2015) obtained 1.5–4.6 % ash content in biochars from pinewood pellets produced at 520 °C. These differences in the ash content of biochars are related to lignin content in the feedstock. Biochars from grasses have higher ash content (up to 20 %) than those from woody feedstocks because the grasses have a lower content of lignin (Keiluweit et al. 2010).

In contrast to the biochars from other feedstocks, DR300 and DR600 had the smallest differences in content of VM and FC (Table 2). This suggests that most lignocellulosic residues present in the digestate were already decomposed at the lower temperature of pyrolysis. It is known that hemicellulose undergoes extensive devolatilization and carbonization at 300 °C, whereas cellulose undergoes these processes at 300–400 °C. Although lignin is more thermally stable, it exhibits intermediate thermal degradation at 300 °C (Koukios 1993). The type of feedstock used for anaerobic digestion could affect changes in the properties of biochar produced at different pyrolysis temperatures. Nansubuga et al. (2015) found that changing the temperature of pyrolysis of anaerobic municipal sludge from 300 to 600 °C caused a decrease in VM from about 30 % to 5.9 %, and increases in ash content and FC from 50 % to over 70 %, and 15 to 20 %, respectively.

DOC concentrations were affected by pyrolysis temperature and type of feedstock. Among the tested substrates, MS contained the highest content of DOC (Table 2). This was due to ensiling of plant biomass. In contrast, SC had the lowest concentration of DOC due to its long maturation phase during the composting process (12 months). After pyrolysis at both 300 °C and 600 °C, DOC in MS and SC biochars was substantially lower than in the feedstock. In contrast, DOC in WP biochars was higher than in the feedstock, although it was lower after pyrolysis at 600 °C than at 300 °C. Although DOC concentration in biochar usually decreases with an increase in the temperature of pyrolysis, it was higher in DR600 than in the feedstock and in DR300. This may be due to release of soluble lignin derivates at high temperature (Lou et al. 2010). Lignin is randomly linked to phenolic macromolecules; these structures decompose and release monomeric phenol units in two steps, first at 300–480 °C, and second at >500 °C (Bahng et al. 2011). Although DOC made up a small proportion of the organics in the biochars, it can increase metal mobility in soil amended with biochar.

Elemental composition

Normally, the percent content of C and N in biochar is higher after pyrolysis at higher temperatures than after pyrolysis at lower temperatures. In the present study, this was observed with respect to the content of C in all biochars, but these differences were statistically significant with only the MS and WP biochars (Table 2). The C content in biochars produced at 300 °C and 600 °C from WP, DR and MS ranged from 56.3 % to 76.5 %, whereas C content was markedly lower in SC biochars (26.4 and 27.9 %). Changes in the percent content of N in biochar depended on the type of feedstock. Nitrogen content was similar in MS300 and MS600 and in WP300 and WP600 biochars. N content was lower in SC600 than in SC300, and lower in DR600 than in DR300. A lower percent content of N after pyrolysis at a higher temperature is typical of ash-rich feedstocks like compost or digestate, which are further enriched in ash during pyrolysis.

MS300, SC300 and WP300 were less aromatic (0.89 < H/C < 1.02) than DR300 (H/C = 0.68) (Fig. 1a). After pyrolysis at 600 °C, the H/C ratio in all biochars was lower than after pyrolysis at 300 °C, and SC600 had the lowest H/C ratio (0.34). This decrease in H/C ratio indicates that biochars produced at 600 °C had a greater degree of carbonization and aromaticity than those produced at 300 °C. Thus, the biochars produced at 600 °C are more recalcitrant than those produced at 300 °C. According to Srinivasan and Sarmah (2015), biochars produced from green waste at 350, 450 and 550 °C had H/C ratios of 0.79, 0.55 and 0.45, respectively, indicating that higher temperatures increased their aromaticity. Jassal et al. (2015) reported an increase in the aromaticity and hydrophobicity of biochars produced from poultry litter, spruce-pine-fir wood waste, or a mixture of the two, when pyrolysis temperature was raised from 400 to 600 °C. Al-Wabel et al. (2013) found similar increases in these properties in biochar produced from conocarpus wastes when the temperature of pyrolysis was increased from 200 to 800 °C.

Molar ratios (H/C, O/C) of biochars produced from different feedstocks. In the figure, different letters above bars representing biochars produced at the same temperature indicate that they differ significantly (ANOVA followed by Tukey’s HSD test, p < 0.05). The lines at 0.6 and 0.4 show the limits recommended by the European Biochar Certificate

MS300 had a higher O/C ratio than SC300, WP300 and DR300 (Fig. 1b). After pyrolysis at 600 °C, MS, SC and WP biochars were more hydrophobic than after pyrolysis at 300 °C. There was no significant difference in O/C ratio for DR300 and DR600. According to the requirements for the European Biochar Certificate, the molar H/C ratio for biochars must be less than 0.6 and the molar O/C ratio less than 0.4, whereas the International Biochar Initiative only recommends a maximum value of 0.7 for the H/C ratio, and does not give a limit for the O/C ratio (Schmidt et al. 2012). In the present study, the H/C ratio of MS300, SC300 and WP300 was far above 0.6. A high H/C ratio suggests that biochar still contains some amount of the original organic residues, such as polymeric CH2 and fatty acids, lignin (aromatic core), and some cellulose (polar fractions) (Chen et al. 2008). In the present study, however, the biochars pyrolysed at 300 °C had O/C ratios within the recommended values.

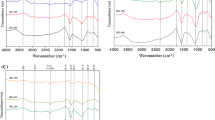

Functional groups

The surface functional groups in the biochars were examined with Fourier Transform Infrared spectroscopy (FT-IR) (Fig. 2). In general, most of the spectra from the biochars were fairly similar, but those from SC biochars had some marked differences. The spectra from SC biochars also changed markedly when the temperature of pyrolysis was raised from 300 °C to 600 °C, as discussed below.

MS600 had a more pronounced aromatic character than MS300. With MS300, a weak peak at 1560 cm−1 indicated some aromatic C = O and C = C bonds, and a weak peak at 669 cm−1 showed the presence of some aromatic C-H bonds. With MS600, a medium peak at 1563 cm−1 indicated an increase in the amount of aromatic C = C bonds and C = O bonds in the biochar, and the appearance of a medium peak at 1250 cm−1 also showed the formation of aromatic C = O bonds. Furthermore, weak to medium peaks at 651–870 cm−1 suggested an increase in the amount of aromatic C-H bonds.

Also with MS biochars, a medium peak at 1032 cm−1 with MS300 and a strong peak at 1067 cm−1 with MS600 indicated an increased amount of aliphatic C-O groups or Si-O bonds after pyrolysis at the higher temperature. Several sources suggest that these peaks could indeed be attributed to Si-O bonds. Silica is an important component in plants that is responsible for carbon stability (Wilding et al. 1969 cited in Jindo et al. 2014), and Masia et al. (2007) reported that ash from corn straw contained almost 50 % SiO2. Similarly, Mahmoud et al. (2011) obtained strong peaks at 1035 and 1091 cm−1 with uncharred rice husks, and rice husk biochar, respectively, and stated that the peaks indicated the presence of Si-O bonds. Additionally, with MS300, weak peaks at 2922 cm−1 indicated aliphatic C-H bonds. With MS600, medium peaks at 1399 cm−1 indicated the formation of aliphatic CH3 groups.

The FTIR spectra from SC300 and SC600 differed markedly. First, when the pyrolysis temperature was increased from 300 °C to 600 °C, the strong peaks at 2921 and 2852 cm−1 disappeared, and the medium peaks at 1457 and 1376 cm−1 were replaced by a weak peak at 1445 cm−1. Taken together, these changes suggest a decrease in the amount of aliphatic –CH3 and –CH2 groups. Second, a medium peak at 1099 cm−1 was visible with SC300, whereas a very strong peak at 1093 cm−1 was seen with SC600, probably indicating an increase in the amount of inorganic Si-O bonds. The intensity of this peak can be attributed to the fact that the SC biochars had the highest content of ash (Table 2). Third, SC600 contained more peaks at 694–887 cm−1 than SC300, which indicates the presence of more aromatic C-H bonds and the greater aromaticity of this biochar.

Aromatic C-O groups were detected in WP300, as shown by a weak peak at 1156 cm−1. With WP300, weak peaks at 2923 cm−1 and at 1433 cm−1 were also detected indicating the presence of aliphatic C-H bonds. A medium peak at 1591 cm−1 showed that aromatic C = O and C = C bonds were present. Although WP biochars contained the least amount of ash (Table 2), the strong peak at 1035 cm−1 (WP300) could be related to Si-O bonds, as with MS and SC biochars. This is because the WP used in the present study were produced from oak and pine wood, and the ash of these species is rich in SiO2 (Vassilev et al. 2010). Weak to medium peaks at 666–752 cm−1 (WP300) could be attributed to the presence of aromatic C-H bonds. With WP600, there were no peaks indicating aliphatic C-H bonds, but there were medium peaks at 1558 cm−1 (aromatic C = O and C = C bonds), at 1154 cm−1 (aromatic C-O bonds) and at 676–874 cm−1 (aromatic C-H bonds).

The temperature of pyrolysis only slightly affected the content of functional groups in DR biochars. DR300 and DR600 contained both aliphatic C-O or Si-O bonds (peaks at 1056 and 1046 cm−1), aromatic C = C groups (1416 and 1402 cm−1) and aromatic C = O and C = C bonds (1570 and 1560 cm−1). In contrast to the other biochars, the spectra of DR300 had some weak peaks at 3347 cm−1, indicating a trace amount of hydroxyl groups. However, these groups disappeared when the temperature of pyrolysis was increased to 600 °C.

Data from both FTIR and elemental composition indicated an increased degree of condensation of biochars after charring at higher temperature. Similarly, Novak et al. (2009) reported that pyrolysis below 400 °C resulted in aliphatic C structures for biochar, but when done above 400 °C gave poly-condensed aromatic C-type structures.

CEC

A high CEC of biochar is desirable for immobilizing pollutants. At both pyrolysis temperatures, SC biochars had a higher CEC than all the other biochars (Fig. 3). Three trends were noted: First, feedstocks with a higher CEC produced biochars with a higher CEC.

Cation exchange capacity (CEC) of feedstocks and biochars (Kh - hydrolytic acidity, S - exchangeable bases). In the figure, different letters above bars representing biochars produced from the same feedstock (e.g. MS, MS300, MS600) indicate that they differ significantly (ANOVA followed by Tukey’s HSD test, p < 0.05)

Second, charring decreased the CEC of the feedstocks. The decline in hydrolytic acidity (Kh) was generally larger than the increase in exchangeable bases (S). These changes were more pronounced after charring at 600 °C than after charring at 300 °C. With MS and SC biochars, the increase in S when the pyrolysis temperature was raised to 600 °C was so large that it led to higher CEC values after charring at 600 °C than at 300 °C. The decline in Kh and the resulting decrease in CEC is likely due to the loss of oxygen-containing functional groups during pyrolysis (Naeem et al. 2014). In the present study, this was indicated by the molar ratios and the higher degree of biochar aromaticity shown by FTIR. In contrast, the increase in the exchangeable bases was a result of an increase in ash content, especially in MS and SC biochars.

Third, MS600 and SC600 had a higher CEC than MS300 and SC300, whereas WP600 had a lower CEC than WP300. DR600 and DR300 had similar CECs. Similarly, Jassal et al. (2015) found that the CEC of biochar from poultry litter remained at 48 cmol/kg despite an increase in the temperature of pyrolysis from 400 to 600 °C.

Heavy metals

Heavy metal concentrations differed in the various feedstocks and biochars (Table 3), but in all materials the individual metal concentrations were below the permissible values for organic fertilizers (OMARD 2004; OMARD 2008). SC and DR had the highest total metal concentrations (as a sum), due to the use of sewage sludge as a substrate for composting and maize silage with animal manures for anaerobic digestion. In most of the biochars, the concentrations of the individual metals were higher than in the feedstock, except for Cd in MS, SC and WP biochars, and Cu in MS biochar, in which concentrations were lower than in the feedstocks.

To identify the degree of enrichment of metals in the biochars and to reveal the volatility of metals, relative enrichment factors (RE) were calculated (Table 3). The RE is defined as the biochar yield multiplied by the ratio of the metal concentration in the biochar to that in the feedstock (Hossain et al. 2011). An RE value above 1 indicates metal enrichment in the biochar, whereas a value below 1 indicates metal volatilization. Cd was volatilized to the greatest extent (RE < 0.1), and other metals also demonstrated some volatility. Ni was volatilized to the least extent, especially in MS300, SC300, WP300 and WP600. These results confirm the tendency of metals to volatilize, as also reported by Hossain et al. (2011) and Luo et al. (2014); both groups of authors speculated that, during pyrolysis, metals might be lost with vapor and bio-oil phases. With DR biochars in the present study, Ni and Zn volatilized to a lesser extent at 600 °C than at 300 °C, as biochar yields were similar at both temperatures but the content of these two metals was higher at 600 °C.

The effect of biochar amendment on soil properties

To further investigate the suitability of the biochars for amendment of soil contaminated with heavy metals, the biochars were added to soil contaminated by a copper smelter, and changes in soil pH, OM and DOC were determined (Table 4). Biochars did not significantly increase total metal content in amended soil (data not shown) because their dosage was 10 % (w/w).

One day after WP300 and WP600 were added to soil, the pH was similar to that in the control, whereas with the other biochars, especially those produced at higher temperature, the pH was higher. During short-term incubation (30 d), the pH increased more in amended than in unamended soil. However, this increase was the smallest in soil amended with WP300 biochar. The change of pH in amended soil should affect metal mobility.

One day after amendment with biochar, the soil samples had increased concentrations of OM and DOC (Table 4). This increase was especially pronounced after MS, WP and DR biochars were added, which is due to the higher VM and DOC content of these biochars compared to SC biochar. In the amended soils, OM decreased slightly over the 30d of incubation, which is a further indication of the stability of the biochars. In all samples, including the control, the concentration of DOC decreased during the 30 d incubation. A decrease in DOC concentration can lead to a decrease in metal mobility in soil.

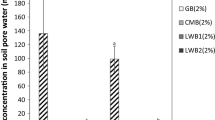

The effect of biochar amendement on metal mobility

In the present study, metals were extracted from soil with 0.01 M CaCl2 to determine their mobility. The metals in the CaCl2-extractable fraction are not only weakly bound to the soil, but are also in equilibrium with the aqueous phase, which makes them even more readily bioavailable (Houben et al. 2013). In unamended soil, the concentration of Zn and Cu in the mobile fraction was greater than that of Pb (Fig. 4). Although the concentration of Zn in the mobile fraction was even higher than that of Cu, it was just as important to reduce the mobility of Cu for two environmental reasons. First, the total concentration of Cu in the soil was extremely high (8109 mg/kg). Second, our previous research with soil from this source found that nearly 76 % of Cu was in the exchangeable and acid soluble fraction based on the BCR fractionation procedure. Although most of the Zn was also in this fraction, its total concentration was 16 times lower than that of Cu (Gusiatin et al. 2014). The exchangeable and acid soluble fraction includes metals co-precipitated with carbonates and metals weakly adsorbed by relatively weak electrostatic interactions, which are both susceptible to changes in pH. Thus, there is a risk of Cu migration in this soil after altering soil properties.

The effect of soil amendment with different biochars on metal concentration in the mobile fraction (0.01 M CaCl2) during short-term immobilization: a Cu, b Zn, c Pb. In the figure, different letters adjacent to a pair of bars indicate that the metal concentrations in the mobile fraction of this variant differed significantly at 1 and 30 days (ANOVA followed by Tukey’s HSD test, p < 0.05)

The mobility of Pb in soil, based on CaCl2 extraction, was very low, as most Pb was associated with oxides in the reducible fraction (Gusiatin et al. 2014). In soil, Pb is usually associated with oxides regardless of its total concentration. Houben et al. (2013) revealed that the Pb content in the fraction extracted with CaCl2 was only 0.1 % of its total concentration (3110 mg/kg) in sandy loam (pH = 6.57) that had been intensively subjected to atmospheric fallout from the adjacent zinc and lead smelting plant. However, Pb is prone to release when subjected to reducing conditions or soil acidification.

The effect of biochar on metal mobility in soil depended on both the type of metal and the type of amendment. In amended soil, most biochars better reduced the mobility of Cu and Zn after pyrolysis at 600 °C than after pyrolysis at 300 °C (Fig. 4). The most suitable biochars for this soil were SC300 and SC600, which reduced Cu mobility similarly to DR biochars on the first day after amendment and reduced Cu mobility the most after 30 days of immobilization. These effects are due to the fact that SC biochars had the lowest concentration of DOC and the highest content of ash. Biochar ashes are rich in mineral salts (Gaskin et al. 2008). On the surface of the ash, the functional groups are oxides, mainly SiO2. The oxygen atoms that are bound to the silicon ions have a low basicity, which causes the silica surface to act as a weak acid. Because the soil was moist during immobilization, these oxygen atoms could react with water to form silanol (SiOH) surface groups. At high pH, these groups are negatively charged and have a high affinity for metal cations, such as those of Zn, Cu and Pb (Mohan and Gandhimathi 2009). In the present study, amendment with SC biochars did not significantly affect the concentration of Pb in the mobile fraction, but this value was already low in unamended soil (Fig. 4c). Overall, these results indicate that SC biochar can be a useful material for amendment of industrial soil.

The second best biochar for reducing Cu mobility was DR biochar (Fig. 4a). One day after amendment with DR biochars, Cu mobility was 64 % lower (on average) than in the unamended soil. However, this measure had increased at the end of immobilization, which could have resulted from the formation of soluble complexes of Cu and DOC. Although DOC content decreased in soil amended with DR biochars, it was relatively high after 30 days of immobilization (81 % and 57 % of initial DOC in S + DR300 and S + DR600, respectively).

In contrast, Zn mobility decreased by 98 % after the first day of immobilization with the DR biochars, and this value continued to decrease (Fig. 4b). This effect was probably related to the high pH in the amended soil, which favors Zn precipitation. These results suggest that DR is a promising amendment for remediating soil contaminated with Zn. In addition, DR300 and DR600 did not differ in their effectiveness at immobilizing Zn, which suggests that it may be possible to save costs by producing DR biochar at lower temperature. However, DR600 was better for reducing the mobility of Pb than DR300 (Fig. 4c). This may be because Pb can precipitate with phosphorus (P), and DR600 may have had a higher P content than DR300. The content of P was not measured in the present study, but the digestate used for biochar production came from anaerobic digestion of mixtures of cattle manure, pig manure and maize silage, which could be rich in P. Similarly, Cao and Harris (2010) found that biochar from dairy manure was very effective for removing Pb, although in this case the metal was removed from an aqueous solution. The authors wrote that one of the possible reasons for this could be that Pb precipitated with P, due to the high P content in the biochar, and that P content increased from 0.9 to 2.7 % when the pyrolysis temperature was increased from 100 to 500 °C.

In soil amended with MS300 and MS600, Cu mobility was greater than in unamended soil, and this effect was more pronounced with MS300 (Fig. 4a). However, amendment with MS300 and MS600 reduced the mobility of Zn. This difference could be because Cu has a greater affinity for DOC than Zn (You et al. 2001). The content of DOC in soil amended with MS biochars was higher than in all other amended soils. DOC usually contains low molecular weight organic compounds (e.g. polysaccharides, polyphenols), which form complexes with metals and increase their solubility. In this study, MS600 biochar was especially effective for reducing Zn and Pb mobility. Zn mobility was almost completely reduced after the first day of immobilization (Fig. 4b), and that of Zn and Pb was completely reduced after 30 days (Fig. 4b-c). MS600 was probably more effective than MS300 at reducing the mobility of Zn and Pb because the pH was higher in soil amended with MS600 (pH 8.12) than in soil amended with MS300 (pH 7.42), and higher pH favors precipitation of both metals.

Overall, the biochars produced from WP were the least effective for decreasing the mobility of Cu and Zn. At the beginning of immobilization with WP300, Cu and Zn concentrations extracted with 0.01 M CaCl2 from amended soil were substantially higher than they were in the unamended soil. After 30 days of immobilization, the Cu concentration in the mobile fraction was still higher in the amended soil, whereas the concentration of Zn was slightly lower (11.3 mg/kg) than in the unamended soil (12.6 mg/kg). WP600 was somewhat more effective at reducing the mobility of these metals, but even after 30 days of immobilization it was still less effective than SC300 and SC600 at reducing Cu mobility, and less effective than all the other biochars at reducing Zn mobility. The lesser effectiveness of WP biochars could be due to the properties of these amendments. Compared to soils amended with other biochars, the soil amended with WP300 had the lowest pH throughout the immobilization process and a relatively high concentration of DOC (Table 4). Beesley et al. (2010) also found that Cu mobility increased in contaminated soil amended with hardwood-derived biochar because the biochar increased DOC in soil-pore water. Finally, although the WP biochars initially decreased the mobility of Pb when compared to the control, this value had begun to increase after 30 days of immobilization.

Conclusions

This study examined how the type of feedstock and the temperature of pyrolysis affect the physico-chemical properties of biochar and its suitability for amendment of industrial soil that is heavily contaminated with Cu, and also contaminated with Zn and Pb. In general, the properties of all feedstocks improved after pyrolysis, and were better after charring at 600 °C than at 300 °C. SC and DR biochars very effectively reduced the mobility of Cu and Zn during short-term amendment (30 d), most likely due their high pH, high ash content and, in the case of SC biochar, very low DOC content. Interesting, SC300 was almost as effective as SC600, probably due to the much higher ash content of both biochars, which suggests that it may be possible to save costs by pyrolyzing SC at lower temperatures.

References

Ahmad M, Rajapaksha AU, Lim JE, Zhang M, Bolan N, Mohan D, Vithanage M, Lee SS, Ok YS (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere 99:19–33

Al-Wabel MI, Al-Omran A, El-Naggar AH, Nadeem M, Usman AR (2013) Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour Technol 131:374–379

Bahng MK, Donohoe BS, Nimlos MR (2011) Application of an Fourier transform infrared imaging tool for measuring temperature or reaction profiles in pyrolyzed wood. Energ Fuel 25:370–378

Barneto AG, Carmona JA, Jesús Díaz Blanco M (2010) Effect of the previous composting on volatiles production during biomass pyrolysis. J Phys Chem A 114:3756–3763

Beesley L, Moreno-Jiménez E, Gomez-Eyles JL (2010) Effects of biochar and greenwaste compost amendments on mobility, bioavailability and toxicity of inorganic and organic contaminants in a multi-element polluted soil. Environ Pollut 158:2282–2287

Bolan N, Kunhikrishnan A, Thangarajan R, Kumpiene J, Park J, Makino T, Kirkham MB, Scheckel K (2014) Remediation of heavy metal(loid)s contaminated soils – to mobilize or to immobilize? J Hazard Mater 266:141–166

Brick S (2010) Biochar: assessing the promise and risks to guide US policy. Natural Resource Defense Council, USA

Calvelo Pereira R, Kaal J, Camps Arbestain M, Pardo Lorenzo R, Aitkenhead W, Hedley M, Macías F, Hindmarsh J, Maciá-Agulló JA (2011) Contribution to characterisation of biochar to estimate the labile fraction of carbon. Org Geochem 42:1331–1342

Cao XD, Harris W (2010) Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresour Technol 101:5222–5228

Chen B, Zhou D, Zhu L (2008) Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperature. Environ Sci Technol 42:5137–5143

CLARINET (2002) Brownfields and Redevelopment of Urban Areas, Federal Environment Agency, Austria, On line:http://www.commonforum.eu/Documents/DOC/Clarinet/brownfields.pdf

Czekała W, Pilarski K, Dach J, Janczak D, Szymańska M (2012) Analysis of the possibilities of anaerobie digestate management from biogas plant. Agr Hortic Forest Eng 4:6–8 in Polish

Dybowska A, Farago M, Valsami-Jones E, Thornton I (2006) Remediation strategies for historical mining and smelting sites. Sci Prog 89:71–138

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour Technol 114:644–653

Gaskin J, Steiner C, Harris K, Das K, Bibens B (2008) Effect of low-temperature pyrolysis conditions on biochar for agricultural use. Trans ASABE 51:2061–2069

Gusiatin ZM, Bułkowska K, Pokój T (2014) Tannic acid as a cost-effective substitute for saponin in soil remediation. Environ Biotech 10:66–72

Hossain MK, Strezov V, Chan KY, Ziolkowski A, Nelson PF (2011) Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J Environ Manag 92:223–228

Houben D, Evrard L, Sonnet P (2013) Mobility, bioavailability and pH-dependent leaching of cadmium, zinc and lead in a contaminated soil amended with biochar. Chemosphere 92:1450–1457

Jassal RS, Johnson MS, Molodovskaya M, Black TA, Jollymore A, Sveinson K (2015) Nitrogen enrichment potential of biochar in relation to pyrolysis temperature and feedstock quality. J Environ Manag 152:140–144

Jindo K, Mizumoto H, Sawada Y, Sanchez-Monedero MA, Sonoki T (2014) Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 11:6613–6621

Jung S-H, Kim J-S (2014) Production of biochars by intermediate pyrolysis and activatedcarbons from oak by three activation methods using CO2. J Anal Appl Pyrolysis 107:116–122

Karczewska A (1996) Metal species distribution in top- and sub-soil in an area affected by copper smelter emissions. Appl Geochem 11:35–42

Karczewska A, Gałka B, Kabała C, Szopka K, Kocan K, Dziamba K (2009) Effects of various chelators on the uptake of Cu, Pb, Zn and Fe by maize and indian mustard from silty loam soil polluted by the emissions from copper smelter. Fresen Environ Bull 18:1967–1974

Keiluweit M, Nico PS, Johnson MG, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253

Kulikowska D, Klimiuk E (2011) Organic matter transformations and kinetics during sewage sludge composting in a two-stage system. Bioresour Technol 102:10951–10958

Koukios EG (1993) Progress in thermochemical, solid-state refining of biomass – from research to commercialization. In: Bridgwater AV (ed) Advances in thermochemical biomass conversion, 1st edn. Springer Science + Business Media Dordrecht, Netherlands, pp. 1678–1692

Lou R, Wu S-B, Lv G-J, Guo D-L (2010) Pyrolytic products from rice straw and enzymatic/mild acidolysis lignin (EMAL). Bioresources 5:2184–2194

Luo F, Song J, Xia W, Dong M, Chen M, Soudek P (2014) Characterization of contaminants and evaluation of the suitability for land application of maize and sludge biochars. Environ Sci Pollut Res Int 21:8707–8717

Mahmoud AH, Saleh ME, Abdel-Salam AA (2011) Effect of rice husk biochar on cadmium immobilization in soil and uptake by wheat plant grown on lacustrine soil. Alex J Agric Res 56:117–125

Masia AAT, Buhre BJP, Gupta RP, Wall TF (2007) Characterizing ash of biomass and waste. Fuel Process Technol 88:1071–1081

Meng J, Wang L, Liu X, Wu J, Brookes PC, Xu J (2013) Physicochemical properties of biochar produced from aerobically composted swine manure and its potential use as an environmental amendment. Bioresour Technol 142:641–646

Mohan S, Gandhimathi R (2009) Removal of heavy metal ions from municipal solid waste leachate using coal fly ash as an adsorbent. J Hazard Mater 169:351–359

Naeem MA, Khalid M, Arshad M, Ahmad R (2014) Yield and nutrient composition of biochar produced from different feedstocks at varying pyrolytic temperatures. Pak J Agri Sci 5:75–82

Nansubuga I, Banadda N, Ronsse F, Verstraete W, Rabaey K (2015) Digestion of high rate activated sludge coupled to biochar formation for soil improvement in the tropics. Water Res 81:216–222

Novak JM, Lima I, Xing B, Gaskin JW, Steinem C, Das KC, Ahmedna M, Rehrah D, Watts DW, Busscher WJ, Schomberg H (2009) Characterization of designer biochar produced at different temperatures and their effects on a loamy sand. Ann Environ Sci 3:195–206

OMARD (2004) Ordinance of the minister of agriculture and rural development on fertilizers and fertilization. J Law 236:16834–16839 in Polish

OMARD (2008) Ordinance of the minister of agriculture and rural development on fertilizers and fertilization. J Law 119:6515–6520 in Polish

OME (2002) The ordinance of the Ministry of Environment on soil quality. J Law 165:10561–10564 (in Polish)

Ostrowska A, Gawliński S, Szczubiałka Z (1991) Methods of analysis and assessment of soil properties and plants. Institute of Environmental Protection, Warsaw, Poland in Polish

Pellera FM, Giannis A, Kalderis D, Anastasiadou K, Stegmann R, Wang JY, Gidarakos E (2012) Adsorption of Cu(II) ions from aqueous solutions on biochars prepared from agricultural by-products. J Environ Manag 96:35–42

Pérez-Esteban J, Escolástico C, Masaguer A, Moliner A (2012) Effects of sheep and horse manure and pine bark amendments on metal distribution and chemical properties of contaminated mine soils. Eur J Soil Sci 63:733–742

Schmidt HP, Abiven S, Kamman C, Glaser B, Bucheli T, Leifield J (2012) Guidelines for biochar production: European biochar certificate version 4.2. Delinat Institute und Biochar Science Network

Scoullos M (2000) Data and trends on cadmium. Synopsis prepared as a background document for the International EUPHEMET’s Workshop (Toward an Integrated EU Policy for Heavy Metals), Athens, Greece

Srinivasan P, Sarmah AK (2015) Characterisation of agricultural waste-derived biochars and their sorption potential for sulfamethoxazole in pasture soil: a spectroscopic investigation. Sci Total Environ 502:471–480

Uchimiya M, Orlov A, Ramakrishnan G, Sistani K (2013) In situ and ex situ spectroscopic monitoring of biochar’s surface functional groups. J Anal Appl Pyrolysis 102:53–59

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933

Wilding LP, Brown RE, Holowaychuk N (1969) Asccesibility and properties of occluded carbon in biogenetic opal. Soil Sci 103:56–61

Yargicoglu EN, Sadasivam BY, Reddy KR, Spokas K (2015) Physical and chemical characterization of waste wood derived biochars. Waste Manag 36:256–268

You S-J, Lee S-Z, Allen HE, Yin Y (2001) Determinants of metal retention to and release from soils. In: Iskandar IK (ed) Environmental restoration of metals-contaminated soils. CRC Press LLC, pp 77–91

Zhang Y, Luo W (2014) Adsorptive removal of heavy metal from acidic wastewater with biochar produced from anaerobically digested residues: kinetics and surface complexation modeling. Bioresources 9:2484–2499

Zhang J, Liu J, Liu R (2014) Effect of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour Technol 176:288–291

Acknowledgments

This work was supported by the Faculty of Environmental Sciences, University of Warmia and Mazury in Olsztyn, Poland (No. GW/2014/24). The authors thank the Director of Legnica Copper Smelter and Refinery for permission to collect and use soil samples and to publish the results.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Hailong Wang

Rights and permissions

About this article

Cite this article

Gusiatin, Z.M., Kurkowski, R., Brym, S. et al. Properties of biochars from conventional and alternative feedstocks and their suitability for metal immobilization in industrial soil. Environ Sci Pollut Res 23, 21249–21261 (2016). https://doi.org/10.1007/s11356-016-7335-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7335-4