Abstract

Prior to the application of biochar as an agricultural improver, attention should be paid to the potential introduction of toxicants and resulting unintended impacts on the environment. In the present study, the concentrations of polycyclic aromatic hydrocarbons (PAHs), heavy metals, and mineral elements were determined in maize and sludge biochars produced at 100 °C increments between 200 and 700 °C. The concentration ranges of total PAHs were 358–5,136 μg kg−1 in maize biochars and 179–70,385 μg kg−1 in sludge biochars. The total heavy metals were detected at the following concentrations (mg kg−1): Cu, 20.4–56.7; Zn, 59.7–133; Pb, 1.44–3.50; Cd, <0.014; Cr, 8.08–21.4; Ni, 4.38–9.82 in maize biochars and Cu, 149–202; Zn, 735–986; Pb, 54.7–74.2; Cd, 1.06–1.38; Cr, 180–247; Ni, 41.1–56.1 in sludge biochars. The total concentrations of PAHs and heavy metals in all maize biochars and most sludge biochars were below the control standards of sludge for agricultural use in China, the USA, and Europe. The leachable Mn concentrations in sludge biochars produced at below 500 °C exceeded the groundwater or drinking water standards of these countries. Overall, all the maize biochars were acceptable for land application, but sludge biochars generated at temperatures between 200 and 500 °C were unsuitable for application as soil amendments due to their potential adverse effects on soil and groundwater quality.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biochar is a carbon-rich product of the thermal degradation of organic materials in an oxygen-limited environment (Lehmann et al. 2011). It has been shown that biochar can contribute positively to the mitigation of climate change, biomass waste management, and soil fertilization and remediation (Keiluweit et al. 2012; Lehmann 2007). The positive effects of biochars on soil fertility can be attributed to an increase in the pH of acid soils, the supply of soil nutrients, enhancement of soil nutrient retention, and improvement of physical properties (Sohi et al. 2010; Van Zwieten et al. 2010). In addition to these agronomical benefits, the potential environmental benefits in terms of immobilization of both organic contaminants and heavy metals have been highlighted recently. Biochar has a very high affinity and capacity for adsorbing organic components in soils due to its large specific surface area and rich nanoporosity. Pesticides have been shown to be effectively immobilized by biomass-derived biochars added to soils (Sheng et al. 2005). As a soil amendment, biochar may also reduce the availability of heavy metals (e.g., Cd, Ni, Pb, and Cu) in soils via surface adsorption, complexation, and precipitation (Cao et al. 2011; Uchimiya et al. 2010).

Despite the abovementioned benefits, biochars may be formed with some contaminants during the pyrolysis process. Polycyclic aromatic hydrocarbons (PAHs) are likely to be formed during the pyrolysis process and are present in the biochar matrix. Some studies have observed measurable quantities of PAHs in biochars of different origins. The PAH concentrations ranged from 3 to 16 mg kg−1 in wood biochars (Brown et al. 2006), from 0.05 to 30.2 mg kg−1 in grass biochars (Keiluweit et al. 2012), and from 0.07 to 45 mg kg−1 in biochars produced from dairy manures, crop residues, sawdust, wood, and grass (Hale et al. 2012). It is noteworthy that the feedstock sources may influence the nature and extent of contaminants present in the final biochars, especially when the biochars are produced from waste materials (e.g., solid waste, sewage sludge, or industrial waste) (Kookana et al. 2011). However, to the best of our knowledge, there has been no report on the formation and composition of PAHs in sewage sludge-derived biochars or the evaluation of the suitability of biochars for land application.

Metals can be concentrated in the biochars during pyrolysis. Koppolu et al. (2003) demonstrated the concentrations of Cu, Zn, Ni, Cr, and Co increased by four to six times in char relative to its feedstock. Singh et al. (2010) found high amounts of Zn and Cu in biosolid-derived biochars. In addition, several studies have demonstrated the presence of other trace elements (e.g., Pb, Cd, As,) in biochars (Cantrell et al. 2012; Hossain et al. 2011). Earlier studies on suitability assessment of biochar as a soil amendment have always been based on the total contaminant concentrations present in the biochar (Cantrell et al. 2012; Freddo et al. 2012), but there is a consensus that ecological and environmental risks are more closely related to the bioavailable fractions or the mobility of the contaminants. Until now, little attention has been given to the measurement of bioavailable fractions of heavy metals in biochars which can be taken up by plants and lead to bioaccumulation or phytotoxicity. Although application of biochar can reduce the leaching of contaminants in soil (Cao et al. 2011), the heavy metals and mineral elements within biochars may also be released into the soil solution and subsequently leached through unsaturated soil or even into groundwater. Yet, information on the leachability of biochar-borne metals and minerals is still lacking.

To evaluate the potential impacts of biochar-borne contaminants on the quality of soil and groundwater, a range of biochars was produced from corn stalks (agricultural waste) and sewage sludge (municipal waste) at different pyrolysis temperatures. The total concentrations of PAHs, heavy metals and minerals, as well as the contents of plant available and leachable elements present in the biochars were quantified and compared with relevant guideline values or standards. Finally, the suitability of maize and sludge biochars for land application was assessed.

Material and methods

Preparation and characterization of biochars

Corn stalks were collected from a local farmland in Nanjing, China and washed with tap water three times to remove soil and dust. After air-drying for 2 days and subsequent oven-drying for 48 h at 80 °C, the stalks were ground and then passed through a 0.450-mm sieve. The sewage sludge, obtained from a wastewater treatment plant in Nanjing without any digestion treatment, was air-dried and then ground to pass through a 0.450-mm sieve.

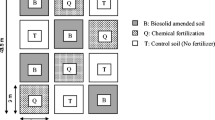

Biochars were produced by slowly pyrolyzing the corn stalks and sewage sludge in 100 °C increments across a temperature range (200 to 700 °C) under oxygen-limited conditions. Briefly, the feedstock was loaded into a ceramic crucible and then placed into an electric quartz tube furnace. The furnace was ramped at 5 °C min−1 to the desired pyrolysis temperature and held for 6 h then cooled to room temperature. Purified nitrogen (99.99 %) was purged into the quartz tube at 300 mL min−1 to maintain anoxic conditions during the entire process. Triplicate batches were produced separately at each desired temperature. Samples were then ground to pass a 0.154-mm sieve and stored in the desiccator prior to analysis. The maize and sludge biochar samples are hereafter referred to as C200, C300, C400, C500, C600, C700, and S200, S300, S400, S500, S600, S700, respectively, where the suffix number represents the pyrolysis temperature. The feedstocks of corn stalks and sewage sludge are represented by C025 and S025, respectively.

After each pyrolysis treatment, the biochar yield was calculated by dividing the final weight of the char by the weight of the feedstock. The pH and electrical conductivity (EC) of the biochars were measured using a biochar-to-water ratio of 1:100 (w/v) (Cantrell et al. 2012). The suspension was then agitated on a rotary shaker for 2 h at 200 rpm and filtered before the measurement.

Quantification of PAHs in biochars

Biochar (0.20 g) together with anhydrous sodium sulfate (0.20 g) was wrapped in a filter paper and placed in a Soxhlet system. They were extracted with 80 mL acetone/n-hexane mixture (1:1, v/v) at 70 °C for 24 h. The extraction solvent was evaporated to almost dryness using rotary evaporator (500 mbar, 35 rpm, 40 °C) and then redissolved in 2.00 ml cyclohexane. One milliliter of cyclohexane was cleaned up by a silica gel column and eluted with a 1:1 acetone/n-hexane mixture. About 4 ml eluent was collected and subsequently evaporated to dryness under a gentle stream of purified nitrogen. It was then diluted to a constant volume of 2.00 ml with acetonitrile.

A high performance liquid chromatograph equipped with fluorescence and diode-array detectors (HPLC-FLD-DAD) was used to determine the concentration of the 16 USEPA priority PAHs, namely naphthalene (NAP), acenaphthylene (ACY), acenaphthene (ACE), fluorene (FLU), phenanthrene (PHE), anthracene (ANT), fluoranthene (FLA), pyrene (PYR), benzo(a)anthracene (BaA), chrysene (CHR), benzo(b)fluoranthene (BbF), benzo(k)fluoranthene (BkF), benzo(a)pyrene (BaP), dibenzo(a,h)anthracene (DahA), benzo(g,hi)perylene (BghiP), and indeno(1,2,3-cd)pyrene (InP). The analytical conditions were described in detail by Huang et al. (2013). ACY was determined by DAD with a detection limit of 2.3 μg L−1, and the remaining 15 PAHs were quantified by FLD with a detection limit of 0.01–0.10 μg L−1.

Quantification of the total elements in biochars

Biochar (0.10 g) was placed in a 50-mL polytetrafluoroethylene digestion crucible followed by addition of 8 mL of HNO3/HF mixture (3:1, v/v). After cold digestion overnight, the mixture was heated on a hotplate at 120 °C for 2 h and evaporated to almost dryness at 180 °C. The residue was subsequently digested with 10 mL HNO3/HClO4 mixture (1:1, v/v) at 180 °C until a clear solution was obtained. The solution was evaporated at 220 °C until no white smoke was emitted. The digested sample was dissolved with 0.5 % HNO3 solution then filtered into a volumetric flask and diluted to 50 mL. The concentrations of the elements were determined by inductively coupled plasma-mass spectrometry (ICP-MS) (USEPA 2007).

The relative enrichment factors (REF) of the heavy metals and minerals in biochars were calculated by the equation below (Hossain et al. 2011):

Determination of bioavailable and leachable elements in biochars

The diethylene triamine pentaacetic acid (DTPA) extraction method is frequently used to estimate the bioavailability of elements for plant uptake (Lindsay and Norvell 1978; Walter et al. 2006). A synthetic precipitation leaching procedure (SPLP) is proposed by the USEPA to evaluate the mobility of inorganic compounds in soils and wastes (USEPA 1994). In the present study, DTPA extraction was used to estimate the concentrations of plant available elements in biochar, and the SPLP method was adopted to evaluate the contents of leachable elements. DTPA extract consisted of 0.005 mol L−1 DTPA, 0.01 mol L−1 CaCl2, and 0.1 mol L−1 triethanolamine (TEA) buffered at pH 7.30. The SPLP extraction was undertaken by adding a H2SO4/HNO3 mixture (3:2, w/w) to deionized water then the pH was adjusted to 3.20 which represented the lowest pH in the acid rain region of China (MEPPRC 2007). The experiment was conducted in a 50-mL polypropylene tube by mixing 1.00 g of biochar with 20.0 mL of DTPA or SPLP extraction. The DTPA-biochar mixture and SPLP-biochar mixture were separately agitated on a rotary shaker at 120 rpm for 2 h and at 30 rpm for 18 h, respectively, then the extract was filtered and subsequently quantified by ICP-MS (USEPA 2007).

Data analysis and graphical production

Results are expressed as the averages of the replicate analyses with standard deviations. The one-way ANOVA with Duncan’s multiple range test (p = 0.05) was performed using SPSS (Version 19) to determine the significant differences in the concentrations of the contaminants in the maize biochars and sludge biochars at different pyrolytic temperatures. OriginPro 8 was used to produce the figures.

Results and discussion

General properties of biochars

An increase in pyrolysis temperature led to a decrease in the yield of biochars (Table 1). The yield of both types of biochar declined significantly from 200 to 300 °C, by 35.8 % for maize biochar and 11.2 % for sludge biochar, and remained relatively stable above 600 °C. The maximum weight loss was observed at 700 °C, approximately 71 and 32 % of the initial mass of corn stalks and sewage sludge, respectively. The yields of sludge biochars were much higher than those of maize biochars across the entire temperature range. The pH of biochars was found to increase with increasing pyrolysis temperature. The maize biochar was acidic when produced at 200 °C and shifted to alkaline above 300 °C. The pH values of sludge biochars were less than 7 at temperatures below 500 °C but sharply increased to above 10 from 600 to 700 °C. These increases in pH values are mainly due to the enrichment of carbonates at high pyrolysis temperature (Yuan et al. 2011), and similar trend had also been demonstrated by Zheng et al. (2013) and Hossain et al. (2011). The acidity and alkalinity of biochar indicated its potential use as an amendment in alkaline or acidic soil. Electrical conductivity (EC) is used as an indicator of salinity. EC values in the maize biochars increased with the pyrolysis temperature, and this trend is consistent with the biochar produced from conocarpus wastes (Al-Wabel et al. 2013). However, the opposite trend was observed in sludge biochars and similar results had been obtained by Hossain et al. (2011). Overall, maize biochars had much larger EC values than sludge biochars (by a factor of 16 at 700 °C), indicating that maize biochars contained much more soluble ions.

Total PAH concentrations in biochars

All biochar samples analyzed here contained measurable quantities of PAHs varying with the feedstock and pyrolysis temperature (Table 2). The total concentration of 16 USEPA priority PAHs (denoted Σ16PAHs) in maize biochar was low at 200 °C, reached a significant peak at 300 °C, then decreased markedly from 400 to 700 °C. In contrast, the Σ16PAHs concentrations in sludge biochar were low between 200 and 400 °C, increased significantly at 500 °C, then decreased dramatically from 600 to 700 °C. The Σ16PAHs concentrations spanned the ranges of 358–5,136 μg kg−1 in maize biochars and 179–70,385 μg kg−1 in sludge biochars, falling within the range of Σ16PAHs concentrations in other biochars reported in the literature (Brown et al. 2006; Hale et al. 2012), with the exception of a surprisingly high amount in S500.

In addition, the highest Σ16PAHs concentrations were observed at 300 and 500 °C for maize and sludge biochars, respectively, while the lowest concentrations were formed at 700 °C for both types of biochar. This observation disagrees with the study of Sharma and Hajaligol (2003) in which large amounts of PAHs were formed at temperatures higher than 700 °C. However, Brown et al. (2006) and Keiluweit et al. (2012) demonstrated that the highest concentration of PAHs in biochars was generated at a lower temperature between 400 and 500 °C, a result very similar to our findings.

Characterization of PAHs in biochars by ring size

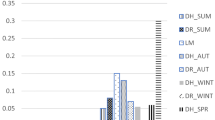

The concentration and distribution of PAHs by ring size largely depended upon the feedstock and pyrolytic temperature. As shown in Fig. 1a, the maize biochar had a low concentration (54.1 μg kg−1) of 2-ring PAH (NAP) at 200 °C. However, the content increased significantly from 300 to 500 °C with a range of 2,073–2,347 μg kg−1 and markedly decreased between 600 and 700 °C. A similar trend was observed for 3-ring PAHs (ACY, ACE, FLU, PHE, and ANT) across the temperature range. The highest concentration (1,378 μg kg−1) of 4-ring PAHs (FLA, PYR, BaA, and CHR) was obtained at 300 °C then significantly decreased above 400 °C. Certain amounts of 5-ring (BbF, BkF, BaP, and DahA) and 6-ring PAHs (BghiP and InP) were generated (110–168and 50.0–59.9 μg kg−1 for 5-ring and 6-ring, respectively) between 300 and 400 °C, but very low concentrations of these PAHs were formed at other temperatures. Nakajima et al. (2007) demonstrated that high pyrolysis temperatures (>600 °C) resulted in a dominance of low-ring (2- and 3-ring) PAHs in cypress, chestnut, and bamboo biochars. In our study, however, the maize biochars produced at low temperatures (<500 °C) contained higher amounts of low-ring PAHs than those at high temperatures. This observation is likely due to the volatilization of low-ring PAHs at high temperatures.

The relationship between PAH composition and temperature were remarkably similar in sludge biochars (Fig. 1b). The contents of 2-ring to 6-ring PAHs gradually increased between 200 and 400 °C and reached their significant peak at 500 °C then decreased dramatically from 600 to 700 °C. The PAH concentrations decreased in the order 3-ring > 4-ring > 2-ring > 5-ring > 6-ring at all pyrolysis temperatures except 500 and 700 °C. Notably, the contents of high-ring (4- to 6-ring) PAHs in the sludge feedstock (S025) were significantly higher than those in sludge-derived biochars (except S500). It has been shown that both PAH formation and volatilization occur during the pyrolysis process and the PAHs can be found in the gaseous phase, bio-crudes, and residue chars (Mastral and Callén 2000; Pittman et al. 2012; Singh et al. 2010). In the present study, it is speculated that the volatilization of high-ring PAHs was greater than the formation of these compounds at all pyrolysis temperatures except 500 °C. However, further research is required on the mass balance of PAHs in the biochar, bio-oil, and gaseous phases.

Allowable concentration of PAHs in biochars

Both from legislative and environmental standpoints, it is unacceptable to apply PAH-containing soil amendments as they may pose a threat to the environment. However, until now, no countries have regulations regarding the application of biochar to soil. In many respects, the application of biochar as a soil fertilizer is similar to using sewage sludge for agricultural improvement (Freddo et al. 2012), and technical guidance on soil application of sewage sludge already exists in China, the USA, and Europe. The maximum permissible concentration (MPC) for PAHs in sludge is 6,000 μg kg−1 according to the USEPA and European Communities (EC 2003; USEPA 2002). These PAHs are the sum of 11 constituents (denoted Σ11PAHs), comprising ACE, FLU, PHE, FLA, PYR, BbF, BjF, BkF, BaP, BghiP, and InP. The MPC of BaP has been established separately due to its high toxicity and the values are 3,000, 1,100, and 1,500 μg kg−1 in China, Belgium, and France, respectively (EC 2001; PRC 1984).

With the exception of S500, the concentrations of Σ11PAHs and BaP in both maize and sludge biochars fell below these MPC values (Table 2), indicating that the biochars may be acceptable as soil amendments as far as PAHs are concerned. Special attention should be paid to the sludge biochar produced at 500 °C in which the Σ11PAHs concentration greatly exceeded the MPC by a factor of 6.3, and soil application of this biochar is unacceptable.

Recently, soil microorganisms, fauna, and plant roots have been found to be influenced by biochar additions (Lehmann et al. 2011). Yet, no evidence exists so far for potential adverse effects on soil biota with respect to the biochar-borne PAHs, and further studies are still needed on this topic.

Moreover, little is known about the mobility and leachability of PAHs within biochars. Hale et al. (2012) found that the total PAH concentrations ranged from 0.07 to 45 mg kg−1 in biochars, but the bioavailable PAHs (extracted with supercritical water) were <10.0 ng L−1, much lower than the drinking water standards of 100 ng L−1 (sum of BbF, BkF, BghiP, and InP) in European countries and 200 ng L−1 (BaP) in the USA (CEC 1998; USEPA 2009). Based on the existing study and considering strong adsorption of PAHs by biochars, the levels of PAHs in groundwater leached from biochars may be acceptable. However, further investigation is needed to confirm this, especially for the sludge-derived biochars with high contents of total PAHs.

Potential impact of biochar on PAHs source apportionment

Biochar as an amendment may also mislead the source apportionment of PAHs in soil due to the specific composition of biochar-borne PAHs. Based on the formation mechanisms, PAHs can be classified as pyrogenic and petrogenic PAHs. Pyrogenic PAHs are formed as a consequence of incomplete combustion whereas petrogenic PAHs are derived mainly from crude oil and its refined products (Doong and Lin 2004). Determining the possible sources of PAHs in the environment is necessary to understand the reasons of their presence and can provide valuable information for pollution abatement. Source diagnostic ratios such as fluoranthene to pyrene (FLA/PYR) and phenanthrene to anthracene (PHE/ANT) are extensively employed to distinguish the pyrogenic from petrogenic sources of PAHs in soil and sediment systems. PAHs are probably related to pyrogenic origin as the ratio of FLA/PYR >1 or PHE/ANT <10, while PAHs are most likely attributed to petrogenic sources if FLA/PYR <1 or PHE/ANT >10 (Doong and Lin 2004; Lima et al. 2005; Savinov et al. 2003; Yang 2000).

In our study, the ratios of FLA/PYR and PHE/ANT in biochars (except S500, C300, and C400) ranged from 0.28 to 0.87 and from 10.5 to 2,258, respectively; therefore, PAHs in these biochars were theoretically classified as petrogenic (Fig. 2). This finding indicates that land application of maize or sludge biochars may mislead the traditional source apportionment of PAHs in soils.

Total concentrations of heavy metals and mineral elements in biochars

Heavy metals and mineral elements were concentrated in both maize and sludge-derived biochars (Tables 3 and Online Resource Table 1). The concentrations of all elements in the biochars were higher than those in their feedstocks with the exception of Cd in S700. Specifically, the amounts of Cu, Pb, and Ni in maize biochars gradually increased between 200 and 600 °C then decreased at 700 °C. The contents of heavy metals (except Cd and Ni) in sludge biochars were found to increase with increasing pyrolysis temperature. The concentrations of all mineral elements increased with increasing pyrolysis temperature for both types of biochars. The concentrations of all heavy metals and mineral elements (except K) in sludge biochars were much higher than those in maize biochars, indicating that the amounts of these elements are strongly dependent upon the feedstock material.

Elements with a lower relative enrichment factor (REF) in biochars indicate higher volatility. As shown in Table 3, Cd in S700 demonstrated significant volatility, and its concentration was the lowest among all the sludge biochars. Vaporization of Cd has been reported during the pyrolysis of contaminated plants, livestock wastes, and wastewater sludge at temperatures as low as 300 °C (Cantrell et al. 2012; Hossain et al. 2011; Lievens et al. 2008). Other elements (e.g., Cu, Zn, Pb, Ni, Na, Fe, Mn) also demonstrated a certain degree of volatility in our study. They might be lost in vapor and bio-oil phases during pyrolysis. Further investigations are required to understand the fate and transformation mechanisms of elements in the biochar production process.

Bioavailable concentrations of heavy metals and mineral elements in biochars

DTPA-extractable concentrations of heavy metals in most biochars were lower than those in the original feedstocks (Table 4). The pyrolysis process appeared to reduce the bioavailability of many elements, especially at lower temperatures. However, the DTPA-extractable concentrations in biochars produced at high temperatures were found to exceed those in their feedstocks, e.g., Pb, Cr, and Ni in C500 and C600 and Cd in S700. This observation was not unusual because biochars generated at high temperature (>500 °C) had significantly higher total concentrations of heavy metals compared with their mother materials (Table 3), which may contribute to higher DTPA-extractable metals. However, the extractable proportions of plant available heavy metals in most biochars were lower than those in their feedstocks (Online Resource Table 2), indicating that the bioavailability decreased under pyrolysis conditions.

The contents of plant available mineral elements in many biochars largely exceeded those in their source materials (Online Resource Table 3). For instance, maize biochars produced at 300 to 700 °C showed a high availability of Mn and sludge biochars generated at 700 °C had higher concentrations of available Fe. These minerals are important for plant growth and application of these biochars may help to increase soil fertility.

Leachability of heavy metals and mineral elements in biochars

The leachability of heavy metals in both types of biochar as indicated by the SPLP test was significantly lower than those in their feedstocks and decreased with increasing pyrolysis temperature, with the sole exceptions of Cr in maize biochars and Cd in sludge biochars (Table 5). Considering the biochars had a stronger enrichment of heavy metals at higher temperatures (Table 3), the leachability of these elements was largely reduced at high temperatures. This was likely due to the fact that biochars produced at high temperature had higher pH values (Table 1) which may greatly reduce the solubility of heavy metals. Similarly, Kloss et al. (2012) demonstrated that pyrolysis temperature had a strong effect on water extractable heavy metals in biochars. The pH values of spruce wood-derived biochars increased with pyrolysis temperature, but the water extractable concentrations of Cu and Ni (Pb and Cd were below the detection limit) decreased with increasing temperature.

Most leachable mineral elements in biochars were found to decrease in concentration with increasing temperature (Online Resource Table 4). Interestingly, SPLP-extractable cations, especially K, Na, Ca, and Mg, in the maize biochars increased with temperature, but the opposite trend was observed in sludge biochars. The SPLP results were in agreement with the EC data listed in Table 1 which show that maize biochars had much higher EC values than sludge biochars.

Allowable concentrations of heavy metals and mineral elements in biochars

To evaluate the suitability of biochars for land application, the heavy metal concentrations in biochars were compared with their respective maximum permissible concentrations (MPC) in sewage sludge for agricultural use in China, the USA, and Europe (CEC 1986; PRC 1984; USEPA 1993). With regard to maize biochars, the total concentrations of all heavy metals reported here were far below their respective MPC in sludge in these countries (Table 3) which implies that the short term application of biochars would not lead to unacceptable metal accumulation in soil. With respect to sludge biochars, concentrations of Cu, Pb, Cd, Cr and Ni were lower than their respective MPC values. Moreover, Zn was the only element that exceeded the Chinese MPC for acid agricultural soils (Table 3). However, Zn concentrations fell below the MPC for neutral and alkaline agricultural soils, indicating their potential for application under specific conditions.

Notably, the MPC of heavy metals in sewage sludge is dependent on the assumed annual application rate and allowable application year. For instance, the Chinese MPC is based on 30 t ha−1 for 20 consecutive years, but the US MPC is assumed to be 10 t ha−1 for 100 consecutive years. Glaser et al. (2002) summarized that adding biochar at 0.5 to 135 t ha−1 could increase plant growth and crop yields. Therefore, special attention should be paid to the agronomic practice if the annual application rate is >30 or 10 t ha−1 when applying the Chinese or US MPC.

The total heavy metal concentrations in biochar are useful as an overall pollution indicator, but the environmental impact always depends on the bioavailability and leachability of metals within biochars. Although the production of biochars largely reduced the amounts of DTPA-extractable heavy metals (Table 4), so far, no guideline values are available for evaluation of potential phytotoxicity based on DTPA-extractable concentrations. Future work is needed to quantify the available metals in biochars and to link this to the actual phytotoxic effects.

Inorganic contaminants within biochars may enter the groundwater via leaching. As shown in Table 5, concentrations of leachable heavy metals in all biochars were far below the groundwater or drinking water standards in China, the USA, and Europe (CEC 1998; PRC 1993; USEPA 2009), implying that application of biochars to the surface soil is unlikely to have an adverse impact on soluble metals in the groundwater. With respect to leachable minerals, only Mn in sludge biochars generated at low temperatures (200–500 °C) exceeded the groundwater/drinking water quality standards (Online Resource Table 4). Considering that the vadose zone can act as a buffer between surface soil and groundwater, the chances that Mn represents an unacceptable risk to groundwater quality are low. However, to obtain a conservative result, it is assumed that the location of the biochar was at or near the groundwater table and the pollutants could directly leach into the groundwater. Although manganese was classified as the pollutants in non-enforceable guidelines according to the USEPA and European Communities (CEC 1998; USEPA 2009), appropriate groundwater monitoring is still recommended to avoid any potential risk to human health.

Conclusion

Biochars can be produced from various feedstocks with the generation of organic compounds and the concentration of inorganic constituents. Therefore, the potential introduction of biochar-borne contaminants needs careful consideration before soil application of biochars can commence. In the present study, the amounts of total PAHs and heavy metals in all maize biochars and most sludge biochars (except PAHs in S500) were below the maximum permissible concentrations for land application. The concentrations of leachable elements in all maize biochars fell below the groundwater or drinking water standards. However, manganese in some sludge biochars (S200–S500) might potentially affect groundwater quality. Maize biochar may be a suitable soil amendment, but application of sludge biochar should be evaluated carefully to avoid potential negative environmental impacts.

References

Al-Wabel MI, Al-Omran A, El-Naggar AH, Nadeem M, Usman ARA (2013) Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour Technol 131:374–379

Brown RA, Kercher AK, Nguyen TH, Nagle DC, Ball WP (2006) Production and characterization of synthetic wood chars for use as surrogates for natural sorbents. Org Geochem 37(3):321–333

Cantrell KB, Hunt PG, Uchimiya M, Novak JM, Ro KS (2012) Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour Technol 107:419–428

Cao X, Ma L, Liang Y, Gao B, Harris W (2011) Simultaneous immobilization of lead and atrazine in contaminated soils using dairy-manure biochar. Environ Sci Technol 45(11):4884–4889

CEC (1986) Council directive of 12 June 1986 on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture. Commission of the European Communities. Official Journal of the European Communities, Brussel

CEC (1998) Council directive 98/83/EC of 3 November 1998 on the quality of water intended for human consumption. Commission of the European Communities. Official Journal of the European Communities, Brussel

Doong RA, Lin YT (2004) Characterization and distribution of polycyclic aromatic hydrocarbon contaminations in surface sediment and water from Gao-ping River, Taiwan. Water Res 38(7):1733–1744

EC (2001) Disposal and recycling routes for sewage sludge: part 2-regulatory report. European Communities, Luxembourg

EC (2003) Proposal for a Directive of the European Parliament and of the Council on spreading of sludge on land. European Communities, Brussels

Freddo A, Cai C, Reid BJ (2012) Environmental contextualisation of potential toxic elements and polycyclic aromatic hydrocarbons in biochar. Environ Pollut 171:18–24

Glaser B, Lehmann J, Zech W (2002) Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal—a review. Biol Fert Soils 35(4):219–230

Hale SE, Lehmann J, Rutherford D, Zimmerman AR, Bachmann RT, Shitumbanuma V, O’Toole A, Sundqvist KL, Arp HPH, Cornelissen G (2012) Quantifying the total and bioavailable polycyclic aromatic hydrocarbons and dioxins in biochars. Environ Sci Technol 46(5):2830–2838

Hossain MK, Strezov V, Chan KY, Ziolkowski A, Nelson PF (2011) Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J Environ Manag 92(1):223–228

Huang Y, Wei J, Song J, Chen M, Luo Y (2013) Determination of low levels of polycyclic aromatic hydrocarbons in soil by high performance liquid chromatography with tandem fluorescence and diode-array detectors. Chemosphere 92(8):1010–1016

Keiluweit M, Kleber M, Sparrow MA, Simoneit BRT, Prahl FG (2012) Solvent-extractable polycyclic aromatic hydrocarbons in biochar: influence of pyrolysis temperature and feedstock. Environ Sci Technol 46(17):9333–9341

Kloss S, Zehetner F, Dellantonio A, Hamid R, Ottner F, Liedtke V, Schwanninger M, Gerzabek MH, Soja G (2012) Characterization of slow pyrolysis biochars: effects of feedstocks and pyrolysis temperature on biochar properties. J Environ Qual 41(4):990–1000

Kookana RS, Sarmah AK, Van Zwieten L, Krull E, Singh B (2011) Biochar application to soil: agronomic and environmental benefits and unintended consequences. In: Donald LS (ed) Advances in Agronomy, vol 112. Academic Press, San Diego, pp 103-143

Koppolu L, Agblevor FA, Clements LD (2003) Pyrolysis as a technique for separating heavy metals from hyperaccumulators. Part II: lab-scale pyrolysis of synthetic hyperaccumulator biomass. Biomass Bioenergy 25(6):651–663

Lehmann J (2007) A handful of carbon. Nature 447(7141):143–144

Lehmann J, Rillig MC, Thies J, Masiello CA, Hockaday WC, Crowley D (2011) Biochar effects on soil biota—a review. Soil Biol Biochem 43(9):1812–1836

Lievens C, Yperman J, Vangronsveld J, Carleer R (2008) Study of the potential valorisation of heavy metal contaminated biomass via phytoremediation by fast pyrolysis: Part I. Influence of temperature, biomass species and solid heat carrier on the behaviour of heavy metals. Fuel 87(10–11):1894–1905

Lima ALC, Farrington JW, Reddy CM (2005) Combustion-derived polycyclic aromatic hydrocarbons in the environment—a review. Environ Forensic 6(2):109–131

Lindsay WL, Norvell WA (1978) Development of a DTPA soil test for zinc, iron, manganese, and copper. Soil Sci Soc Am J 42(3):421–428

Mastral AM, Callén MS (2000) A review on polycyclic aromatic hydrocarbon (PAH) emissions from energy generation. Environ Sci Technol 34(15):3051–3057

MEPPRC (2007) Solid waste-extraction procedure for leaching toxicity-sulphuric acid & nitric acid method (in Chinese). Ministry of Environmental Protection of the People’s Republic of China, Beijing

Nakajima D, Nagame S, Kuramochi H, Sugita K, Kageyama S, Shiozaki T, Takemura T, Shiraishi F, Goto S (2007) Polycyclic aromatic hydrocarbon generation behavior in the process of carbonization of wood. B Environ Contam Tox 79(2):221–225

Pittman CU, Mohan D, Eseyin A, Li Q, Ingram L, Hassan E-BM, Mitchell B, Guo H, Steele PH (2012) Characterization of bio-oils produced from fast pyrolysis of corn stalks in an auger reactor. Energ Fuel 26(6):3816–3825

PRC (1984) Control standards for pollutants in sludges from agricultural use (in Chinese). The People’s Republic of China, Beijing

PRC (1993) Quality standard for ground water (in Chinese). The People’s Republic of China, Beijing

Savinov VM, Savinova TN, Matishov GG, Dahle S, Næs K (2003) Polycyclic aromatic hydrocarbons (PAHs) and organochlorines (OCs) in bottom sediments of the Guba Pechenga, Barents Sea, Russia. Sci Total Environ 306(1–3):39–56

Sharma RK, Hajaligol MR (2003) Effect of pyrolysis conditions on the formation of polycyclic aromatic hydrocarbons (PAHs) from polyphenolic compounds. J Anal Appl Pyrol 66(1–2):123–144

Sheng G, Yang Y, Huang M, Yang K (2005) Influence of pH on pesticide sorption by soil containing wheat residue-derived char. Environ Pollut 134(3):457–463

Singh B, Singh BP, Cowie AL (2010) Characterisation and evaluation of biochars for their application as a soil amendment. Soil Res 48(7):516–525

Sohi SP, Krull E, Lopez-Capel E, Bol R (2010) A review of biochar and its use and function in soil. In: Donald LS (ed) Advances in Agronomy, vol 105. Academic Press, San Diego, pp 47-82

Uchimiya M, Lima IM, Thomas Klasson K, Chang S, Wartelle LH, Rodgers JE (2010) Immobilization of heavy metal ions (CuII, CdII, NiII, and PbII) by broiler litter-derived biochars in water and soil. J Agr Food Chem 58(9):5538–5544

USEPA (1993) Part 503—standards for the use or disposal of sewage sludge. U.S. Environmental Protection Agency, Washington, DC

USEPA (1994) Method 1312: synthetic precipitation leaching procedure. U.S. Environmental Protection Agency, Washington, DC

USEPA (2002) Biosolids applied to land: advancing standards and practices. U.S. Environmental Protection Agency, National Research Council, Washington, DC

USEPA (2007) Method 6020A: inductively coupled plasma-mass spectrometry. U.S. Environmental Protection Agency, Washington, DC

USEPA (2009) National primary/secondary drinking water regulations. U.S. Environmental Protection Agency, Washington, DC

Van Zwieten L, Kimber S, Morris S, Chan KY, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327(1–2):235–246

Walter I, Martínez F, Cala V (2006) Heavy metal speciation and phytotoxic effects of three representative sewage sludges for agricultural uses. Environ Pollut 139(3):507–514

Yang GP (2000) Polycyclic aromatic hydrocarbons in the sediments of the South China Sea. Environ Pollut 108(2):163–171

Yuan JH, Xu RK, Zhang H (2011) The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresour Technol 102(3):3488–3497

Zheng H, Wang Z, Deng X, Zhao J, Luo Y, Novak J, Herbert S, Xing B (2013) Characteristics and nutrient values of biochars produced from giant reed at different temperatures. Bioresour Technol 130:463–471

Acknowledgments

The authors thank Prof. Peter Christie (Agri-Environment Branch, Agri-Food and Biosciences Institute, Belfast, UK) for linguistic improvement of the manuscript. This work was supported by the National Environmental Protection Public Welfare Industry Targeted Research Fund (201309005), the National High Technology Research and Development Programs (863 Program) (2013AA062608, 2012AA101402-2), the Knowledge Innovative Project of the Chinese Academy of Sciences (KZCX2-YW-BR-19), and the Sino-Czech Cooperation Project (40-4).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Zhihong Xu

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Luo, F., Song, J., Xia, W. et al. Characterization of contaminants and evaluation of the suitability for land application of maize and sludge biochars. Environ Sci Pollut Res 21, 8707–8717 (2014). https://doi.org/10.1007/s11356-014-2797-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-2797-8