Abstract

In this study, the efficiency of Moringa stenopetala seed extract was compared with alum and M. stenopetala-alum hybrid coagulant to remove Direct Red 23 azo dye from textile wastewater. The effects of parameters such as pH, coagulant dose, type of salt used for the extraction of coagulant and initial dye concentration on dye removal efficiency were investigated. Moreover, the existing functional groups on the structure of M. stenopetala coagulant (MSC) were determined by Fourier transform infrared spectroscopy, and the morphology of sludge produced by MSC, alum, and hybrid coagulant was characterized by scanning electron microscopy. Ninhydrin test was also used to determine the quantity of primary amines in the MSC and Moringa oleifera coagulant (MOC). According to the results, with increasing the coagulant dose and decreasing the initial dye concentration, dye removal efficiency has increased. The maximum dye removal of 98.5, 98.2, and 98.3 % were obtained by using 240, 120, and 80 mg/L MSC, alum and hybrid coagulant at pH 7, respectively. The results also showed MSC was much more effective than MOC for dye removal. The volume of sludge produced by MSC was one fourth and half of those produced by alum and hybrid coagulant, respectively. Based on the results, hybrid coagulant was the most efficient coagulant for direct dye removal from colored wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Textile industries consume large amounts of chemical dyes. Most dyes are not biodegradable (Mahvi et al. 2009), and their presence in water, in addition to adverse esthetic effects, reduces light penetration into water and interfere with aquatic life (Dalvand et al. 2011; Maleki et al. 2010). Additionally, some dyes are toxic (Dalvand et al. 2016), carcinogenic, and mutagenic to human (Ashrafi et al. 2013; Mahmoodi and Dalvand 2013; Shirmardi et al. 2013).

Chemical coagulation, chemical oxidation, and adsorption are conventional methods for dye removal from wastewater, but the disadvantages of these methods are a main challenge to their use for color removal (Gholami-Borujeni et al. 2011). Advanced oxidation processes are extremely costly. Adsorption with activated carbon is expensive and adsorbent regeneration is difficult (Kim et al. 2002). Chemical coagulation/flocculation is the most widely used technique for textile wastewater treatment. Although inorganic coagulants, such as alum, ferric chloride, and ferric sulfate, are the most common practiced coagulants in wastewater treatment processes (Huang et al. 2014b; Imen et al. 2011), they have some disadvantages, such as need to pH adjustment before and after treatment, producing large amounts of sludge, and adding undesirable inorganic chemicals like aluminum, iron, sulfate, and chloride to the environment (Chu 2001; Huang et al. 2014a).

Moringa is a plant whose seeds contain a protein that can be used as a natural organic coagulant to treat water and wastewater (Hellsing et al. 2013; Sajidu et al. 2006). Moringa has 14 known species (Bhatia et al. 2007). Moringa stenopetala grows in some African countries, like Ethiopia and Kenya, but Moringa oleifera grows in India, Brazil, and some parts of Iran. M. stenopetala seeds contain higher protein and lower fat compared to M. oleifera (Seifu 2014). In comparison with conventional inorganic coagulants, Moringa has advantages, such as inexpensive, non-corrosive, non-toxic to the environment and biodegradable (Devesa-Rey et al. 2012; Verma et al. 2012).

In recent years, a lot of studies have been successfully conducted on coagulation of different pollutants, such as sodium lauryl sulfate (Beltrán-Heredia and Sánchez-Martín 2009), pesticides (Zolgharnein et al. 2011), long chain anionic surfactants (Beltrán-Heredia et al. 2012), palm oil mill (Bhatia et al. 2007), color, turbidity (Madrona et al. 2010), dissolved organic carbon (Sánchez-Martín et al. 2010), enteric bacteria (Pavankumar et al. 2014), and helminth egg (Sengupta et al. 2012) by extracted coagulant from M. oleifera. However, very few studies have been conducted on the removal of pollutants from water and wastewater by M. stenopetala.

Direct dyes are completely soluble in water and common methods for wastewater treatment are not able to remove them from water and wastewater effectively. Direct Red 23 (DR 23) is an azo dye that is not biodegradable and has carcinogenic nature (Wojciech et al. 2012). This dye is widely used for dyeing fibers by textile industries.

According to literature review, no previous studies have been conducted on coagulation of DR 23 by M. stenopetala coagulant (MSC) or M. stenopetala-alum hybrid coagulant. Thus, in this study, (1) the efficiency of M. stenopetala seed extract was compared with alum and M. stenopetala-alum hybrid coagulant to remove DR 23 from synthetic textile wastewater; (2) the effect of parameters, such as pH, coagulant dose, storage condition of coagulant, type of salt used for coagulant extraction, salt solution concentration, and initial dye concentration on dye removal efficiency, was investigated; 3) In addition, the final pH, electrical conductivity, and the volume of sludge produced by alum, MSC, and hybrid coagulant were measured.

Materials and methods

Materials

Direct Red 23 was obtained from Ciba. The properties of DR 23 are shown in Table 1. M. stenopetala and M. oleifera seeds were purchased from local markets in Ethiopia (Konso area of southern Ethiopia) and Iran (Bushehr area), respectively. NaCl, KCl, NaNO3, KNO3, NaOH, HCl, and Al2(SO4)3·18H2O were obtained from the Merck Company (Germany). 2,2-Dihydroxyindane-1,3-dione (ninhydrin), 3-aminopropyltriethoxysilane (APTES), Na2HPO4.12H2O, KH2PO4, and potassium iodate (KIO3) were provided from Sigma-Aldrich.

Preparation of coagulant

The M. stenopetala and M. oleifera seeds were deshelled by hand, and the kernels were washed with distilled water to remove any dirt and air dried for 24 h at room temperature. The seed kernels were ground to a fine powder using mortar and pestle. Coagulant was extracted using different salts (NaCl, KCl, NaNO3, and KNO3). For extraction of coagulant, 2 g of seed powder was added to the 100 mL of NaCl, KCl, NaNO3, and KNO3 salt solutions (in various concentrations of 0.5–2 M) and the whole mixture was stirred for 30 min using a magnetic stirrer. Then, the suspension was filtered through Whatman No. 42 filter paper. This filtrate was used as Moringa coagulant. A 2 % stock solution of alum was prepared by adding 2 g alum (Al2(SO4)3 · 18 H2O) to 100 mL distilled water. M. stenopetala-alum hybrid coagulant was prepared by mixing alum and MSC in various M. stenopetala/alum ratios.

Coagulation test

All tests were carried out in 1 L beaker by a standard jar test apparatus. Each beaker was filled with 500 mL synthetic wastewater containing a specific amount of dye. A pre-determined amount of coagulant was added to each beaker by a pipette and mixture was stirred at rapid speed of 100 rpm for 2 min, followed by slow speed of 40 rpm for 30 min and flocs were allowed to settle for 60 min. After the settling, 20 mL of sample was withdrawn by a pipette at 3 cm below the supernatant surface. Samples were centrifuged (4000 rpm, 5 min) and analyzed by spectrophotometer for detecting residual dye. All experiments were done at room temperature (25 °C).

Ninhydrin test

In order to determine the quantity of primary amines in the MSC and M. oleifera coagulant (MOC), the ninhydrin test was used. Ninhydrin test was carried out according to the following procedures:

-

1

Preparation of the reagents

-

a.

Ninhydrin color reagent: 10 g of Na2HPO4.12H2O, 6 g KH2PO4, 0.5 g ninhydrin, and 3 g fructose were dissolved in 1000 mL distillated water. The obtained solution was stored in a dark bottle under refrigeration (4 °C).

-

b.

Dilution solution: 2 g of potassium iodate (KIO3) was dissolved in 600 mL distilled water and 400 mL 96 % ethanol was added.

-

a.

-

2

Preparation the standard APTES solution and plotting the standard curve

0.1 mL of APTES was diluted into 10 mL (final volume) with distillated water. The resulting stock APTES solution was used to prepare four working sample tests. Four samples including 0.3, 0.5, 0.7, and 1 mL of the stock APTES solution were taken. Each sample diluted to 10 mL with distilled water and 2 mL transferred to the test tubes. Then, a 1 mL of the ninhydrin color reagent solution was added. The sealed test tubes were placed in a boiling water bath for 16 min. After heating, immediately, the tubes were cooled by immersing for 20 min in a water bath (20 °C). Five milliliter of the dilution solution was added and mixed contents manually and then the solution was placed in a cuvette. The absorbance was read by a spectrophotometer at 570 nm. In order to prepare a standard calibration curve, the values of absorbance were plotted against the APTES concentration (Fig. 1).

-

3

Determination of amine concentration

Three milligrams of MSC or MOC sample, the concentration of nitrogen was unknown, was dispersed into a total volume of 100 mL distillated water and 2 mL of resulting suspension was put inside the test tubes. Then, 1 mL of the ninhydrin color reagent solution was added and mixed. After mixing, the tube was placed in a boiling water bath for 16 min. It was observed that the solution color turned to purple blue; this color is due to reaction of the amino groups with the hydrated ninhydrin. After heating, immediately, the tube was cooled by immersing for 20 min in a water bath (20 °C). Five milliliter of the dilution solution was added to the mixture and mixed manually, and then the solution was placed in a cuvette. The amount of absorbance for MSC and MOC was 0.8 and 0.68, respectively. By using the obtained equation from standard curve (Fig. 1), the total content of the primary amines in the samples were calculated. The concentration of primary amines in MSC and MOC was determined to be around 0.66 and 0.57 mmol/L. Based on the obtained data, the primary amines concentration was found to be 0.0017 and 0.00153 mmol per milligram MSC and MOC sample, respectively.

Analytical methods

Dye concentration was determined by measuring of dye absorbance at maximum wavelength using spectrophotometer (HACH/ DR 5000, USA). For pH adjustment, 0.1 M NaOH and 0.1 M HCl were used. pH and electrical conductivity were measured by pH meter (Kent ell, England) and conductivity meter (Hach sens ION 5, USA), respectively. Microscopic images of flocs formed by different coagulants were taken using a microscope equipped with a digital camera (Olympus, Japan) at a magnification of ×400. A Fourier transform infrared (FTIR) spectrometer was employed to determine the functional groups existing in the structure of M. stenopetala seed extract.

The percentage of dye removal was determined according to Eq. 1:

where η is dye removal efficiency (%), C 0 and C are dye concentration before and after coagulation (mg/L), respectively.

Results and discussion

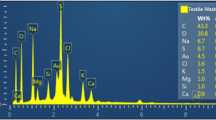

FTIR spectra of M. stenopetala seed extract

Figure 2 depicts the FTIR spectra for the M. stenopetala seed extract. In Fig. 2, the peak at 3419 cm−1 cab be attributed to the –OH and N-H stretching of amide groups in the structure of proteins (Araujo et al. 2010). The bands at 2925 and 2856 cm−1 correspond to the C-H stretching of the CH2 group in the fatty acids. The peak at 1737 cm−1 is related to the C = O stretching of COOH (Degefu and Dawit 2013). The bands at 1657 and 1535 cm−1 are ascribed to the amide I and amide II in the proteins. The peak at 1060 cm−1 is due to the –CN stretching functional group. These peaks confirm the presence of proteins containing amino groups in the structure of MSC.

Effect of coagulant dose

The effect of coagulant dose on dye removal efficiency is given in Figs. 3 and 4. These Figures indicate that dye removal efficiency was significantly affected by coagulant dose. It should be mentioned that 1 M NaCl salt solution was utilized for the extraction of coagulant from MSC and MOC. As shown in Fig. 3, when MSC dose increases from 20 to 240 mg/L, dye removal efficiency enhances from 5.3 to 98.57 %, and after that, by increasing more coagulant, the dye removal efficiency remains constant.

The Moringa cationic proteins due to presence of amino groups in their structure have positive charge (Mataka et al. 2006) and DR 23 dye molecules have negative charge (DR 23 contains two anionic sulfonate groups). Adsorption, charge neutralization, and bridging of destabilized particles are the main mechanisms of coagulation by Moringa (Bhatia et al. 2007; Ndabigengesere et al. 1995). By increasing the MSC, more dye molecules destabilize through electrostatic attraction between Moringa cationic proteins and anionic dye molecules. Consequently, higher charge neutralization lead to higher dye removal. For M. oleifera coagulant (MOC), MSC and alum, maximum dye removal efficiencies 98, 98.5, and 98.2 % were achieved by applying doses 300, 240, and 120 mg/L, respectively.

These results show that MSC is much more effective than MOC for dye removal. The higher dye removal efficiency using MSC can be attributed to the higher protein content of M. stenopetala seeds (Seifu 2014) that is responsible for the charge neutralization mechanism. Thus, the MSC was used alone for dye removal in the subsequent studies.

Figure 3 shows that dye removal is enhanced by increasing the alum dose up to 120 mg/L. The further increases in alum dose retard dye removal. In fact, when the optimum dose of alum is exceeded, the restabilization of dye molecules was occurred, which caused a decrease in dye removal. The effect of hybrid coagulant dose on dye removal efficiency is presented in Fig. 4. Hybrid coagulant was prepared by mixing alum and MSC in different ratios of 1:1, 1:2, and 2:1. As shown in Fig. 4, the highest dye removal efficiency 98.3 % was achieved by applying 80 mg/L hybrid coagulant in M. stenopetala/alum ratio of 1:1. According to the results, the hybrid coagulant needed to achieve 98.3 % dye removal was three times lower than that of MSC.

Although the MSC dose needed to achieve dye removal efficiency of 98 % was two times higher than that of alum, the volume of sludge produced by MSC was one fourth of that produced by the alum (the volume of sludge produced by alum was 60 mL/L treated wastewater). This finding is because of the difference between flocs formed by the different coagulants. The observations and microscopic images (Figs. 5 and 6) revealed that the MSC has porous and layered nature (Fig. 6a, b), and the flocs that were formed in coagulating color by alum were light, needle-shaped, dispersed, and fragile, but MSC and hybrid coagulant formed strong, porous, and dense flocs that could settle rapidly. Also, MSC produced dense sludge and high quality supernatant for discharge into water bodies. To overcome the problems related to alum (high sludge production) and MSC (need to high doses), hybrid coagulant was utilized for DR 23 dye removal. The use of cationic polymer extracted from Moringa with alum supplied to increase density and settle ability of flocs formed by alum. As a result, the volume of sludge produced by hybrid coagulant was half of that produced by alum. Compare with alum, hybrid coagulant could form stronger and heavier flocs.

Effect of initial pH

It is confirmed that pH plays an important role in coagulation process and it is a parameter which affect removing pollutants from aqueous solutions. The effect of pH on coagulation process was investigated over a pH range of 3–10 (Fig. 7). As seen in Fig. 7, pH did not have any significant effect on the efficiency of MSC and hybrid coagulant for dye removal, but coagulation by alum showed that dye removal decreased with increasing pH, from 98.2 % at pH 7 to 96.9 % at pH 10. The optimum performance of all coagulants was found in the pH 7. As mentioned in literature, the protein extracted from Moringa has isoelectric points between 10 and 11; therefore, this protein has cationic nature at pH < 11 (Mataka et al. 2006; Ndabigengesere et al. 1995). This cationic nature causes MSC to have good performance in removal of an anionic dye in a wide range of pH.

The measurements indicate that MSC does not change final pH of wastewater, whereas alum and hybrid coagulant cause to final pH decreases from 7 to 4 and 4.2. When alum is added to wastewater, it first produces Al3+ and SO4 2−, which Al3+ react with OH− or alkalinity presented in water to produce Al(OH)3 (Baskan and Pala 2010). So, consumption of hydroxyl ions will result in a decrease in the alkalinity and final pH of wastewater. Cationic protein extracted from Moringa acts like a polymer (Beltrán-Heredia et al. 2012). Therefore, MSC does not hydrolysis (does not react with alkalinity in the solution) and has no effect on the pH of wastewater. Based on our results, by using MSC for coagulation, standard pH to discharge of effluent in water sources can be achieved without pH neutralization.

Effect of initial dye concentration

In order to assess the effect of initial dye concentration on dye removal efficiency and determine the mg dye removed per mg coagulant, five dye solutions with different initial dye concentrations (25, 50, 75, 100, and 200 mg/L) were treated in optimum condition (pH 7, coagulant dose 240, 120, and 80 mg/L for MSC, alum, and hybrid coagulant, respectively). 1 M NaCl salt solution was used for the extraction of coagulant from M. stenopetala seeds. The results in Fig. 8a showed that in case of MSC, by increasing initial dye concentration from 25 to 200 mg/L, dye removal efficiency decreased from 99.2 to 20 %.

As mentioned before, one of the most important mechanisms of dye removal by MSC is adsorption and charge neutralization of dye molecules. Therefore, a known amount of coagulant is able to neutralize the charge of specific amounts of dye molecules. By increasing dye concentration, amount of presented coagulant in the solution is not enough to neutralize charge of all dye molecules and dye removal diminishes. In case of hybrid coagulant, the growth of dye concentration from 25 to 200 mg/L leads to dye removal decreases from 98.6 to 78.19 %. This result indicates that the efficiency of hybrid coagulant for dye removal lower than that of MSC has been affected by initial dye concentration.

In case of alum, with increasing initial dye concentration from 25 to 200 mg/L, dye removal efficiency decreased from 98.5 to 96 %. According to the results, dye removal efficiency by alum was less affected by initial dye concentration. This result can be attributed to mechanisms of pollutant removal by alum, which are charge neutralization, adsorption, entrapment, and complexation (Xiaoxiao et al. 2012). Furthermore, an increase in the initial dye concentration may accelerate self-coagulation and this would result in low change in the performance of alum for dye removal. Figure 8b reveals that mg dye removed per mg coagulant was highest for hybrid coagulant. These data indicates that the hybrid coagulant is the most effective coagulant for DR 23 dye removal.

Effect of salt (type and concentration) on coagulant extraction

It has been proven that the cationic protein in Moringa seeds does not dissolve well in water without using salt (Madrona et al. 2010). Thus, in order to extract active coagulant proteins from M. stenopetala seeds, four different salts (NaCl, KCl, NaNO3, and KNO3), in similar concentration of 1 M, were used (Fig. 9). Figure 9 suggests that NaCl is the best salt for the extraction of coagulant from M. stenopetala seeds. This finding agrees with the result which was reported by previous study for M. oleifera (Sajidu et al. 2006).

To determine the effect of salt solution concentration on coagulant extraction, four NaCl salt solutions in various concentrations of 0.5, 1, 1.5, and 2 M were chosen (Fig. 10). The results indicate that the coagulation activity of MSC enhances with increasing salt concentration up to 1 M and maximum of 98.5 % dye removal was achieved by 1 M NaCl. The enhancement in extraction efficiency by salt is due to the salting-in mechanism and an increase in ionic strength by salt that result in an increase in the solubility of active coagulant components (Prasad 2009). At higher NaCl concentrations which cause higher ionic strength, the chloride ions can compete with dye molecules for binding with the positive charges on coagulant and the reduction of positive charges on the surface of coagulant lead to decrease the dye removal.

The final EC of treated wastewater by alum, MSC, and hybrid coagulant was 155, 1420, and 341 μs/cm, respectively. The high EC of treated wastewater by MSC can be attributed to using salt for extraction of coagulant.

Effect of storage condition of MSC and hybrid coagulant on dye removal efficiency

The effect of storage conditions, such as storage duration (0–60 day) and storage temperature (refrigerator: 4 °C and room temperature: 25 °C) on the efficiency of MSC and hybrid coagulant to remove dye from textile wastewater, was investigated and results are presented in Fig. 11.

According to Fig. 11, storage duration and temperature do not have any significant effect on the efficiency of MSC and hybrid coagulant to remove dye from wastewater till 30 days, but after 60 days, the MSC and hybrid coagulant which were kept at room temperature produced an offensive odor, and their efficiency for dye removal decreased from 98.5 and 98.3 % to 96 and 97.46 %, respectively. These results are in agreement with the reported findings by Prasad for M. oleifera coagulant (Prasad 2009), which found that storage duration could affect M. oleifera coagulant efficiency and MOC had the highest dye removal efficiency up to 3 days, and after that, its efficiency decreased. These results indicate that MSC and hybrid coagulant are more stable than MOC, and parameters like temperature and storage duration cannot highly affect their efficiency for dye removal.

Conclusions

-

Coagulation of DR 23 by M. stenopetala coagulant, alum, and hybrid coagulant was an effective method for dye removal from colored wastewater.

-

FTIR spectra and ninhydrin test confirmed the presence of amino groups in the structure of MSC and MOC.

-

NaCl in a concentration of 1 M was the most efficient salt for coagulant extraction from M. stenopetala seeds.

-

At optimal condition, MSC, alum, and hybrid coagulant were able to remove dye as high as 98.5, 98.2, and 98.3 %, in doses 240, 120, and 80 mg/L, respectively.

-

Higher dye removal efficiency of MSC in comparison to MOC can be attributed to higher amine content of MSC.

-

Initial pH did not have any significant effect on dye removal efficiency by MSC and hybrid coagulant, but coagulation of color by alum was pH dependent.

-

Compare to alum, M. stenopetala coagulant has some advantages including no need to pH neutralization after treatment, environmental friendly, and lower sludge production.

-

Hybrid coagulant in lower doses was able to remove DR 23 as well as MSC or alum.

References

Araujo C, Alves V, Rezende H, Almeida I, De Assuncao R, Tarley C, Segatelli M, Coelho N (2010) Characterization and use of Moringa oleifera seeds as biosorbent for removing metal ions from aqueous effluents. Water Sci Technol 62(9):2198–2203

Ashrafi SD, Rezaei S, Forootanfar H, Mahvi AH, Faramarzi MA (2013) The enzymatic decolorization and detoxification of synthetic dyes by the laccase from a soil-isolated ascomycete, Paraconiothyrium variabile. Int Biodeterior Biodegrad 85:173–181

Baskan MB, Pala A (2010) A statistical experiment design approach for arsenic removal by coagulation process using aluminum sulfate. Desalination 254:42–48

Beltrán-Heredia J, Sánchez-Martín J (2009) Removal of sodium lauryl sulphate by coagulation/flocculation with Moringa oleifera seed extract. J Hazard Mater 164:713–719

Beltrán-Heredia J, Sánchez-Martín J, Barrado-Moreno M (2012) Long-chain anionic surfactants in aqueous solution. Removal by Moringa oleifera coagulant. Chem Eng J 180:128–136

Bhatia S, Othman Z, Ahmad AL (2007) Coagulation–flocculation process for POME treatment using Moringa oleifera seeds extract: optimization studies. Chem Eng J 133:205–212

Chu W (2001) Dye removal from textile dye wastewater using recycled alum sludge. Water Res 35:3147–3152

Dalvand A, Gholami M, Joneidi A, Mahmoodi NM (2011) Dye removal, energy consumption and operating cost of electrocoagulation of textile wastewater as a clean process. Clean: Soil, Air, Water 39:665–672

Dalvand A, Nabizadeh R, Ganjali MR, Khoobi M, Nazmara S, Mahvi AH (2016) Modeling of reactive blue 19 azo dye removal from colored textile wastewater using l-arginine-functionalized Fe3O4 nanoparticles: optimization, reusability, kinetic and equilibrium studies. J Magn Magn Mater 404:179–189

Degefu DM, Dawit M (2013) Chromium removal from Modjo Tannery wastewater using Moringa stenopetala seed powder as an adsorbent. Water Air Soil Pollut 224:1–10

Devesa-Rey R, Cruz GBJM, Moldes AB (2012) Evaluation of non-conventional coagulants to remove turbidity from water. Water Air Soil Pollut 223:591–598

Gholami-Borujeni F, Mahvi AH, Nasseri S, Faramarzi MA, Nabizadeh R, Alimohammadi M (2011) Enzymatic treatment and detoxification of acid orange 7 from textile wastewater. Appl Biochem Biotechnol 165:1274–1284

Hellsing MS, Kwaambwa HM, Nermark FM, Nkoane BBM, Jackson AJ, Wasbrough MJ, Berts I, Porcar L, Rennie AR (2013) Structure of flocs of latex particles formed by addition of protein from Moringa seeds. Colloids Surf A 460:460–467

Huang X, Bo X, Zhao Y, Gao B, Wang Y, Sun S, Yue Q, Li Q (2014a) Effects of compound bioflocculant on coagulation performance and floc properties for dye removal. Bioresour Technol 165:116–121

Huang X, Gao B, Wang Y, Yue Q, Li Q, Zhang Y (2014b) Coagulation performance and flocs properties of a new composite coagulant: Polytitanium–silicate–sulfate. Chem Eng J 245:173–179

Imen K, Benoît M, Philippe M, Raja BA (2011) Decolourization of the reconstituted textile effluent by different process treatments: enzymatic catalysis, coagulation/flocculation and nanofiltration processes. Desalination 68:27–37

Kim T-H, Park C, Shin E-B, Kim S (2002) Decolorization of disperse and reactive dyes by continuous electrocoagulation process. Desalination 150:165–175

Madrona GS, Serpelloni GB, Vieira AMS, Cardoso LNKC, Bergamasco R (2010) Study of the effect of saline solution on the extraction of the Moringa oleifera seed’s active component for water treatment. Water Air Soil Pollut 211:409–415

Mahmoodi NM, Dalvand A (2013) Treatment of colored textile wastewater containing acid dye using electrocoagulation process. Desalin Water Treat 51:5959–5964

Mahvi AH, Ghanbarian M, Nasseri S, Khairi A (2009) Mineralization and discoloration of textile wastewater by TiO2 nanoparticles. Desalination 239:309–316

Maleki A, Mahvi AH, Ebrahimi R, Zandsalimi Y (2010) Study of photochemical and sonochemical processes efficiency for degradation of dyes in aqueous solution. Korean J Chem Eng 27:1805–1810

Mataka L, Henry E, Masamba W, Sajidu S (2006) Lead remediation of contaminated water using Moringa Stenopetala and Moringa oleifera seed powder. Int J Environ Sci Technol 3:131–139

Ndabigengesere A, Narasiah KS, Talbot BG (1995) Active agents and mechanism of coagulation of turbid waters using Moringa oleifera. Water Res 29:703–710

Pavankumar AR, Norén J, Singh L, Gowda NKC (2014) Scaling-up the production of recombinant Moringa oleifera coagulant protein for large-scale water treatment applications. RSC Adv 4:7136–7141

Prasad RK (2009) Color removal from distillery spent wash through coagulation using Moringa oleifera seeds: use of optimum response surface methodology. J Hazard Mater 165:804–811

Sajidu SMI, Henry EMT, Persson I, Masamba WRL, Kayambazinthu D (2006) pH dependence of sorption of Cd2+, Zn2+, Cu2+ and Cr3+ on crude water and sodium chloride extracts of Moringa stenopetala and Moringa oleifera. Afr J Biotechnol 5:2397–2401

Sánchez-Martín J, Ghebremichael K, Beltrán-Heredia J (2010) Comparison of single-step and two-step purified coagulants from Moringa oleifera seed for turbidity and DOC removal. Bioresour Technol 101:6259–6261

Seifu E (2014) Actual and potential applications of Moringa stenopetala, underutilized indigenous vegetable of Southern Ethiopia: a review. Int J Agric Food Res 3:8–19

Sengupta ME, Keraita B, Olsen A, Boateng OK, Thamsborg SM, Pálsdóttir GR, Dalsgaard A (2012) Use of Moringa oleifera seed extracts to reduce helminth egg numbers and turbidity in irrigation water. Water Res 46:3646–3656

Shirmardi M, Mahvi AH, Hashemzadeh B, Naeimabadi A, Hassani G, Niri MV (2013) The adsorption of malachite green (MG) as a cationic dye onto functionalized multi walled carbon nanotubes. Korean J Chem Eng 30:1603–1608

Verma AK, Dash RR, Bhunia P (2012) A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J Environ Manage 93:154–168

Wojciech K, Iwona P, Ewa M, Izabella J (2012) Adsorption of anionic dye Direct Red 23 onto magnetic multi-walled carbon nanotubes-Fe3C nanocomposite: kinetics, equilibrium and thermodynamics. Chem Eng J 210:87–95

Xiaoxiao Z, Zhonglian Y, Yan W, Bao-Yu G, Qinyan Y (2012) The removal efficiency and reaction mechanism of aluminum coagulant on organic functional groups-carboxyl and hydroxyl. Chem Eng J 211–212:186–194

Zolgharnein J, Shahmoradi A, Ghasemi J (2011) Pesticides removal using conventional and low‐cost adsorbents: a review. Clean: Soil, Air, Water 39:1105–1119

Acknowledgments

The authors would like to thank Tehran University of Medical Sciences for financial support of this study (Grant no: 94-02-61-28559). The authors are deeply grateful to Mr. Mekdimu Mezemir for providing Moringa stenopetala.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Rights and permissions

About this article

Cite this article

Dalvand, A., Gholibegloo, E., Ganjali, M.R. et al. Comparison of Moringa stenopetala seed extract as a clean coagulant with Alum and Moringa stenopetala-Alum hybrid coagulant to remove direct dye from Textile Wastewater. Environ Sci Pollut Res 23, 16396–16405 (2016). https://doi.org/10.1007/s11356-016-6708-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-6708-z