Abstract

Total selenium removal by the activated sludge process, where selenite is reduced to colloidal elemental selenium nanoparticles (BioSeNPs) that remain entrapped in the activated sludge flocs, was studied. Total selenium removal efficiencies with glucose as electron donor (2.0 g chemical oxygen demand (COD) L−1) at neutral pH and 30 °C gave 2.9 and 6.8 times higher removal efficiencies as compared to the electron donors lactate and acetate, respectively. Total selenium removal efficiencies of 79 (±3) and 86 (±1) % were achieved in shake flasks and fed batch reactors, respectively, at dissolved oxygen (DO) concentrations above 4.0 mg L−1 and 30 °C when fed with 172 mg L−1 (1 mM) Na2SeO3 and 2.0 g L−1 COD of glucose. Continuously operated reactors operating at neutral pH, 30 °C and a DO >3 mg L−1 removed 33.98 and 36.65 mg of total selenium per gram of total suspended solids (TSS) at TSS concentrations of 1.3 and 3.0 g L−1, respectively. However, selenite toxicity to the activated sludge led to failure of a continuously operating activated sludge reactor at the applied loading rates. This suggests that a higher hydraulic retention time (HRT) or different reactor configurations need to be applied for selenium-removing activated sludge processes.

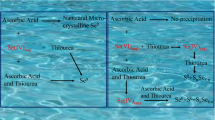

Scheme representing the possible mechanisms of selenite reduction at high and low DO levels in the activated sludge process

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The toxicity of selenate (SeO4 2-) and selenite (SeO3 2-) to the environment, including humans, aquatic life, and animals, has been well documented in the past few decades (Lenz and Lens 2009). Anaerobic biological reduction converts selenate (SeO4 2-) and selenite (SeO3 2-) to the more stable elemental selenium at a reasonable cost and acceptable remediation efficiency (Cantafio et al. 1996; Lenz et al. 2008a). However, the elemental selenium formed after microbial reduction is in the form of dispersed colloidal elemental selenium nanoparticles (BioSeNPs). These BioSeNPs wash out with the effluent of selenate- and selenite-reducing upflow anaerobic sludge blanket (UASB) reactors and can re-oxidize in the environment (Buchs et al. 2013; Jain et al. 2015b). The BioSeNPs have to be removed prior to discharge, thus, an additional coagulation step is required leading to increased treatment costs (Buchs et al. 2013; Staicu et al. 2015).

The reduction of selenium oxyanions under aerobic conditions has been well documented for axenic cultures (Jain et al. 2014). Selenium-tolerant bacteria can reduce selenite (SeO3 2-) to BioSeNPs, in which BioSeNPs remain entrapped within the biomass under aerobic and microaerobic conditions (Tejo Prakash et al. 2009; Dhanjal and Cameotra 2010). This could provide an alternative pathway of total selenium removal, without the need of a second step to remove the BioSeNPs as required in anaerobic removal processes.

In contrast to axenic cultures, the use of activated sludge does not require sterilization of the wastewater, and the process is more tolerant to shocks such as pH drops or spikes in the influent concentrations of toxic compounds. Moreover, activated sludge may have better trapping abilities of BioSeNPs due to its floc structure and higher content of extracellular polymeric substances (EPS) (Park et al. 2013). The entrapment of selenium nanoparticles improves the settling rates and hydrophilicity of activated sludge, which is important in developing activated sludge-based selenite removal processes (Jain et al. 2015c). However, the optimum carbon source and electron donor, temperature, and dissolved oxygen (DO) concentrations are not yet known for aerobic selenite reduction by activated sludge.

This study investigated the removal of the total selenium from a synthetic wastewater by the activated sludge system. Shake flask experiments were conducted to identify the temperature and electron donor type and concentration for total selenium removal from synthetic wastewater by activated sludge. The effect of the DO concentration on the total selenium removal from the synthetic wastewater was studied in fed batch reactors. A continuously operating activated sludge reactor with sludge recycle was operated to evaluate the total selenium removal by a continuously fed activated sludge system.

Materials and methods

Source of biomass and synthetic wastewater

Activated sludge was collected from a full-scale domestic wastewater treatment plant in Harnaschpolder (The Netherlands) (Karya et al. 2013). The synthetic wastewater for the shake flask experiments, batch reactors, and continuous reactor was prepared by dissolving 600 mg NH4Cl, 200 mg MgCl2 · 6H2O, 20 mg CaCl2 · 2H2O, and 1 mL micronutrient solution in 1.0 L of Milli-Q (18 MΩ cm) water. For the continuous reactor, 23 mg L−1 of Na2HPO4 was additionally added to the synthetic wastewater.

Shake flask experiments

The optimum electron donor, electron donor dosage, and temperature for total selenium removal were determined in shake flask experiments. The experimental design for the shake flask experiments is provided in Table 1. Glucose, lactate, and acetate were tested as different electron donors at 0.5, 1.0, and 2.0 g L−1. The experiments with glucose as the electron donor were incubated at 15 (±1), 30 (±1), and 45 (±1) °C, while experiments with lactate and acetate as the electron donors were incubated at 30 (±1) °C only. Selenite, in the form of sodium selenite (Na2SeO3), was added until achieving a final selenium concentration of 79 mg L−1 (1 mM). A high concentration of selenite was used to obtain larger differences in the total selenium removal with different electron donors, COD concentrations and operating temperatures. The initial pH was manually adjusted to around 7.5, if needed sodium carbonate (Na2CO3) was used to buffer the medium. For calculations of the amount of total selenium removed per unit of biomass, the total suspended solids (TSS) concentration measured at the end of each experiment was used. All shake flask experiments were done in triplicate.

Fed batch reactors

Fed batch reactors were used to make a mass balance of the selenium conversions by the activated sludge at two different DO levels (Table 1). Each reactor was closed and connected to two gas traps filled with 65 % concentrated nitric acid (100 and 50 mL, respectively) in order to trap the volatilized selenium species (dimethyl selenide and dimethyl diselenide) potentially generated inside the reactors as described by Winkel et al. (2010). DO levels were varied by controlling the airflow rate through a sparger, and DO levels were measured every 4 h. A low and high air flow rate of, respectively, 2–5 and 10–15 L h−1 were maintained. The details of fed batch reactor operations are summarized in Table 1. It is important to note that, like the shake flask experiments, selenite concentrations in the fed batch reactor experiments were 1 mM to trigger differences in the total selenium removal from aqueous phase at the low and high air flow rates. Fed batch reactors were operated in duplicate, and if the difference in measurements were more than 10 %, experiments were repeated. The average values are presented in the figures.

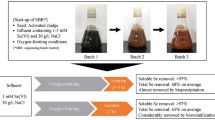

Continuously operating activated sludge reactors

The selenium removal efficiency of a continuously operating activated sludge system was investigated in a continuous-flow activated sludge reactor with complete sludge recycle (Fig. 1, Table 2). Like the fed batch reactors, gas traps (100 mL of concentrated HNO3) were used to capture volatile fractions of selenium. Synthetic wastewater supplemented with glucose (1 g COD L−1) and sodium selenite (17.2 mg L−1 or 0.1 mM) was pumped into a 1-L glass reactor operating at a hydraulic retention time (HRT) of 8 h. The influent selenium concentration in the continuously operating reactor was 7300 μg L−1 as this selenium concentration is in the same range as found in different selenium-containing wastewaters (Lenz and Lens 2009). The reactor was operated at 30 (±1) °C, mixed with a magnetic stirrer, and aerated at an air flow of 20–25 L h−1 through a sparger to keep the DO levels >3.0 mg L−1. The reactor was operated at a TSS concentration of 1.3 (±0.1) g L−1 for the first 28 days (Periods I to III; Table 3), followed by re-inoculation with biomass at a TSS concentration of 3.0 (±0.1) g L−1. The reactor was operated at these conditions for another 38 days (Periods IV to VI; Table 3). It should be noted that the selenite concentration in the continuous reactor was 10 times lower than that used in the fed batch reactors.

The difference between the continuous reactor and fed batch reactors was the biomass retention time. The HRT for the batch reactor amounted to 72 h, compared to 8 h of HRT for the continuous reactor. No biomass was withdrawn from the batch reactors, so the mean biomass retention time was 72 h. In contrast, the mean biomass retention time for the continuous reactor was set to 8 days when sodium selenite was not fed, whereas no biomass was manually withdrawn when sodium selenite was supplied to the synthetic wastewater, hence setting an infinite mean biomass retention time.

Analytical methods

The total selenium concentration from the supernatant, activated sludge and gas phase were measured using inductively coupled plasma mass spectrometry (ICP-MS) (Jain et al. 2015a). BioSeNPs were separated from the aqueous phase by centrifugation (37,000g, 15 min, Hermle Z36HK). The supernatant and pellet constitute the dissolved selenium and BioSeNPs, respectively, and their concentrations were determined by dissolving them in concentrated HNO3 prior to selenium concentration determination using ICP-MS. The trapped selenium concentration in the activated sludge flocs was measured after addition of HNO3, followed by microwave destruction of the biomass and then measuring the selenium concentration. The COD and total suspended solid measurements were carried out using standard methods (APHA 2005). Transmission electron microscopy-energy disperse X-ray (TEM-EDX) spectroscopy was carried on diluted samples as described in an earlier study by the same authors (Jain et al. 2015c).

DNA extraction for denaturing gradient gel electrophoresis (DGGE) analysis of selenite-fed and non-fed activated sludge in the fed batch reactors, incubated for 7 days at neutral pH, 2.0 g L−1 COD (glucose) and DO >4 mg L−1 was carried out using FAST DNA SPIN kit (MP Biomedicals, USA) as reported in Ahammad et al. (2013). The concentration of DNA in the isolated samples was 40 ng μL−1. A nested PCR strategy was employed in which the first round PCR (Bio-Rad, C1000 Thermocycler, USA) was performed with primer set PRA46f and PRA1100r of amplicon size of 1054 bp described in Øvreås et al. (1997). The following thermal cycling was used: initial denaturation at 92 °C for 3 min followed by 30 cycles of 92 °C for 1 min, annealing at 55 °C for 1 min, with a final elongation step at 72 °C for 7 min. In the second round, the PCR products of the first round were re-amplified with a set of universal primers PARCH340f-GC and PARCH519r with the following thermal cycling program: initial denaturation at 95 °C for 3 min followed by 30 cycles of 92 °C for 1 min, annealing at 55 °C for 1 min, with a final elongation step at 72 °C for 7 min.

Primers UNIBACT341f-GC and UNIBACT518r were used for amplification of bacterial (V3) 16S rRNA gene fragment (Lane 1991). The following thermocycler program was used for amplification of bacterial V3 region: 95 °C for 3 min initial denaturation followed by 35 cycles of 95 °C for 1 min, a touchdown protocol was used at annealing step with 65 to 55 °C for 30 s with a decrement of (−0.5 °C/step), elongation steps 72 °C for 1 min and 72 °C for 7 min for final elongation. The sizes of amplicon was checked by electrophoresis in 1.5 % (wt/V) agarose gel stained with ethidium bromide. DGGE was carried out as described in Muyzer et al. (1993).

Results

Selenite reduction by activated sludge

Figure 2a shows the developed red color when activated sludge is incubated with 172 mg L−1 (1 mM) sodium selenite at 30 °C for 144 h in the shake flask experiments, suggesting the reduction of selenite and formation of BioSeNPs. TEM-EDX analysis confirms the presence of spherical particles (Fig. 2b1) with a mean diameter of 180 nm in the activated sludge flocs, composed of selenium (Fig. 2b2). Note that the Cu signals observed in Fig. 2b2 are due to the use of a Cu grid for holding the samples.

a Selenite-fed activated sludge incubated at neutral pH and 30 °C for 144 h entrapping BioSeNPs (left) and control activated sludge fed no selenite (right); b1 TEM image of the activated sludge trapping BioSeNPs and b2 corresponding EDX spectrum of marked square of the sludge sample in b1. c Percent total selenium concentration as a function of time in the supernatant of the activated sludge in shake flask experiments performed at 15 (gray bar), 30 (white bar), and 45 °C (black bar) and 79 mg L−1 (1 mM) of initial selenium concentration; and d Total selenium removal per gram of TSS in the supernatant with increasing COD concentration of acetate (gray bar), lactate (white bar), and glucose (black bar) in shake flask experiments incubated for 144 h

The shake flask study at different temperatures and with 2.0 g COD L−1 glucose as electron donor showed that the total selenium removal efficiency of non-acclimated activated sludge from the aqueous phase amounted to 84 (±7), 79 (±3), and 31 (±4) % at 15, 30, and 45 °C, respectively (Fig. 2c). No total selenium removal was observed in the abiotic control experiments with killed and without biomass (data not shown), confirming the selenium removal is mediated by microbial activity.

Incubation with glucose removed 2.9 and 6.8 times more total selenium from the liquid phase per gram of TSS compared to lactate and acetate, respectively, at 2.0 g L−1 COD, suggesting that glucose was the best electron donor tested in this study (Fig. 2d). The selenium removal efficiency from the liquid phase per gram TSS at 2.0 g COD L−1 was 2.8 and 1.7 times higher than at 0.5 and 1.0 g L−1 COD with glucose as the electron donor, respectively (Fig. 2d). No detectable increase in the TSS concentration was observed for all experimental conditions.

Selenite reduction in fed batch reactors

The lower air flow rate (2–5 L h−1) resulted in DO concentrations of 3.0–4.0 mg L−1 for the entire duration of the experiment, except for a few hours when DO levels dropped to 0.1 mg L−1 (Fig. 3a). The higher air flow rate (10–15 L h−1) maintained DO levels consistently above 6 mg L−1, while the DO level lowered to 4 mg L−1 only for a few hours.

a Dissolved oxygen levels with time at high (white squares) and low (black squares) air flow rate. b Evolution of total selenium (white and black squares) and COD (white and black circles) concentration with time and dissolved selenium concentration at the end of incubation (white and black triangle) at DO levels always >4.0 mg L−1 (open symbols) and at DO levels <4.0 mg L−1 (closed symbols), and c Mass balance of total fed selenium in the aqueous phase to biomass, gas traps, and samples, remaining total selenium in the aqueous phase, and unaccounted selenium

In the fed batch reactors, with DO levels always exceeding 4.0 mg L−1 (Fig. 3a), the BioSeNPs after 96 h of incubation at 30 °C constitutes only 3 (±1) % of the total selenium supplied as compared to 17 (±1) % in the reactor with DO levels in the bioreactor mixed liquor below 4.0 mg L−1 (Fig. 3b). The total selenium removal efficiency from the influent was 86 (±1) and 67 (±2) % for the aerated batch reactors operating with DO levels higher and lower than 4.0 mg L−1, respectively (Fig. 3b).

The dissolved selenium removal efficiency for both DO levels was similar: 90 (±1) % for higher DO levels compared to 85 (±3) % for lower DO levels (Fig. 3b). This was further confirmed by the excess trapping of selenium in the biomass at higher DO levels: 65 (±1) % at DO levels >4.0 mg L−1 as compared to 48 (±2) % of total selenium at DO levels lower than 4.0 mg L−1 (Fig. 3c). At both DO levels, the COD removal profiles were similar (Fig. 3b). It should be noted that the fed batch reactors were operated at 2.0 g L−1 COD of glucose, because this concentration provided the best removal of total selenium per gram of TSS (Fig. 2d).

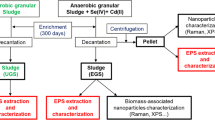

The DGGE analysis of the selenite-fed activated sludge and control activated sludge after 7 days incubation in the batch reactors revealed the presence of different bands in the gel (Fig. 4). This indicates that new bacterial populations developed in the selenite-fed activated sludge, suggesting the possible enrichment of selenite-reducing microorganisms in the selenium-fed activated sludge.

Continuously operating activated sludge reactor

The pH and DO of the continuous reactor was near neutral (7–7.5) and generally exceeding 3.0 mg L−1 at both the TSS 1.3 and 3.0 g L−1 values at which the continuous reactor was operated (Fig. 5a, b). In period I (Fig. 5c), no selenite was fed and a 90 % COD removal efficiency was achieved. The TSS concentration increased to 2500 mg L−1 due to biomass growth. On day 10 (Period II; Fig. 5c), the TSS concentration was set to 1.3 g L−1 in order to apply the same operational conditions as used in the batch reactors. In period II, a 77 % removal efficiency of total selenium (23.7 mg L−1 day−1 or 0.3 mM day−1 selenium fed in the form of selenite) was achieved in the first 2 days. Both the total selenium and COD removal dropped, however, afterwards and lowered to almost 0 and 20 %, respectively, on the 21st day of operation.

Dissolved oxygen concentration (left-hand Y-axis, black circles) and pH (right-hand Y-axis, red squares) in the continuous reactor for period I, II, and III at a TSS of a 1.3 g L−1 and b 3.0 g L−1. Evolution of the COD (black and white circles) and total selenium (black and white triangles) concentration in the influent (closed symbols) and effluent (open symbols) in a continuously aerated activated sludge reactor with complete sludge recycle at a TSS of c 1.3 g L−1 and d 3.0 g L−1, pH 7.3, and DO > 3.0 mg L−1

In period III (Fig. 5c), the selenite feed was stopped; however, the COD removal efficiency of the reactor did not recover. After 28 days of reactor operation, the COD removal efficiency was still below 10 %, suggesting an irreversible inactivation of the biomass. When the reactor was re-inoculated with fresh biomass at a higher TSS concentration (3.0 g L−1; Period IV–VI; Fig. 5d), a similar performance was observed. The COD removal efficiency dropped to 40 from 90 %, and the total selenium removal efficiency dropped from initially 60 to 0 % during period V (Fig. 5d). When the selenite feed was stopped in period VI, the COD removal efficiency did not improve, suggesting again an irreversible inhibition of the activated sludge population (Fig. 5d). The total selenium removed per unit of biomass in the aqueous phase was 33.98 mg Se g TSS−1 and 36.65 mg Se g TSS−1 when operating the continuous reactor at TSS concentrations of 1.3 (Period II; Fig. 5c) and 3.0 g L−1 (Period V; Fig. 5d), respectively. Activity tests on the biomass obtained after the 28th and 65th days of continuous activated sludge reactor operation were carried out accordingly to the conditions tested with the shake flask experiments (1 mM Na2SeO3 and 2.0 g L−1 chemical oxygen demand (COD) of glucose). The tests demonstrated that the biomass from the continuous reactor could reduce only 30 % of the selenite concentration in the first 48 h under batch conditions compared to 60 % by fresh biomass (data not shown).

Discussion

Removal of selenite by activated sludge

This study shows the removal of selenite by activated sludge in batch and a continuous system at different incubating conditions. The low total effluent selenium concentration suggests that the added selenium has formed BioSeNPs that were trapped in the biomass or have formed methylated selenium compounds that had volatilized and were subsequently trapped in gas traps (Fig. 3b). The negligible presence of selenium in these gas traps and the significant presence of selenium in the biomass (Fig. 3c) suggest that the majority of the supplied selenite is reduced and trapped in the activated sludge flocs as BioSeNPs. This confirms the trapping of BioSeNPs (78 % of added selenite) in the activated sludge observed during an earlier study (Jain et al. 2015c); however, this earlier study did not focus on total selenium removal under different operational conditions of an activated sludge system.

As selenite and selenate reduction has been mainly reported in anaerobic pure cultures and biofilms (Oremland et al. 2004; Lenz et al. 2008a; Pearce et al. 2009), its occurrence in activated sludge might at first sight be somewhat surprising. Reduction of selenite to BioSeNPs under aerobic conditions has, nevertheless, been reported by pure cultures of e.g., Bacillus sp. and Pseudomonas sp. (Hunter and Manter 2009; Dhanjal and Cameotra 2011). However, the effect of different operating conditions on the total selenium removal by mixed microbial cultures has not yet been reported before.

Selenite reduction and biomass yield

Selenite reduction was not accompanied by an increase in the TSS concentration at both DO levels investigated in the fed batch reactors even at high (4.0 g L−1) glucose concentrations (data not shown), suggesting that the selenite reduction was not coupled to microbial growth. Similarly, no TSS increase was observed in the continuous reactor at the two TSS concentrations tested (Fig. 5). Selenite reduction by Shewanella oneidensis using fumarate reductase under anaerobic respiration conditions was also not coupled to biomass growth (Li et al. 2014). Similarly, no biomass growth was observed for selenite-reducing Pseudomonas fluorescens (Belzile et al. 2006) and Phanerochaete chrysosporium (Espinosa-Ortiz et al. 2014) cultures under aerobic conditions. The later authors found that selenite not only induced zero biomass growth, but also yielded more compact fungal pellets, and suggested a potential application of selenite supplementation to control biomass growth in fungal bioreactors (Espinosa-Ortiz et al. 2014). Further research on the morphology, size, and rheology of activated sludge flocs is required to extrapolate these findings to activated sludge systems.

Selenite reduction mechanism

Strict aerobic selenite reduction through a detoxification mechanism carried out by some bacteria that can inhabit activated sludge, e.g., Bacillus cereus and Rhizobium sp., led to biomass growth. Thus, the absence of biomass growth in the batch as well as continuous reactors does not give an indication towards the potential selenite reduction mechanisms: detoxification or dissimilatory reduction. It should be noted that the glucose removal profile in both batch reactors operating at different DO levels followed a similar trend. COD was depleted much earlier as compared to total selenium, especially, in the case of the low-DO batch reactors. No biomass growth and different COD and total selenium profiles are indications of detoxification mechanisms. However, further research using e.g., isotopic labeling is required to confirm the role of this detoxification mechanism in the BioSeNPs’ formation.

Higher DO levels led to the trapping of BioSeNPs in the activated sludge flocs, suggesting the formation of BioSeNPs in the cytoplasm (Figs. 2c, 3b, c). Selenite reduction in the cytoplasm is usually carried out by thiols such as glutathione (Li et al. 2014). Indeed, the higher DO levels make the transfer of electrons from any non-specific extracellular or periplasmatic reductase to selenite very difficult. This implies that selenite needs to be transferred through the cell membrane into the cytoplasm (Fig. 6). Sulfate permease in Escherichia coli has been shown to transfer selenite across the membrane; however, not much is known about other possible transport mechanisms of selenite across the cell membranes of Gram positive and Gram negative bacteria (Rosen and Liu 2009).

Lower DO levels led to the extracellular production of BioSeNPs (Figs. 2c, 3b, c). Extracellular reduction of selenite by activated sludge can be carried out by c-type cytochromes, membrane reductases, and extracellular redox mediators such as anthraquinone-2,6-disulfonate (AQDS) (Fig. 6) (Oremland et al. 2004; Pearce et al. 2009; Li et al. 2014). Selenite reduction by c-type cytochromes in the outer membrane has been demonstrated by Geobacter sulfurreducens and S. oneidensis under anaerobic conditions. S. oneidensis also demonstrated selenite reduction by membrane reductase under anaerobic conditions (Li et al. 2014). The fed batch reactors were operated at low DO concentrations; pockets with anaerobic zones might have prevailed where extracellular production of BioSeNPs took place. It is important to note that selenite reduction by thiols and extracellular mechanisms might be taking place at both high and low DO levels, albeit at different percentages.

Practical implications

Glucose was the more favorable substrate for selenite reduction by activated sludge compared to lactate and acetate (Fig. 2d). A similar preference for glucose as the electron donor over lactose, cheese whey, acetate, and citrate was observed for a Cr(VI)-reducing activated sludge which was attributed to the fermentable nature of the tested substrates (Ferro Orozco et al. 2010).

The crashing and non-recoverability of the continuous activated sludge reactor at the two different TSS concentrations investigated (Fig. 5) and the lack of TSS growth can be partially attributed to selenite toxicity to the activated sludge biomass and its irreversible nature under continuous operation at the applied operational conditions. Anaerobic reduction of selenate and selenite in UASB reactors may remove such selenium loading rates without an apparent toxicity, but will lead to a wash out of the BioSeNPs with the effluent (Lenz et al. 2008b; Lenz et al. 2008a). It is also important to note that the continuous activated sludge reactor in this study was operated with a complete sludge recycle. As there was no net biomass growth during the selenite feeding periods, no sludge was wasted; hence, the mean biomass retention time for the continuous activated sludge reactor was set to infinite. The fact that the selenite toxicity could be overcome by the biomass under batch conditions and with higher initial selenite concentrations suggests that the crashing and non-recoverability of the continuous activated sludge reactor might also be linked to the operating parameters, e.g., HRT or selenite loading rate.

The crashing of the continuous activated sludge reactor could be overcome by applying a different strategy, i.e., using a sequencing batch reactor. Sequencing batch feeding using activated sludge inoculum allowed the treatment of Cr-rich wastewater (530 g Cr(VI) m−2 day−1) based on the reduction of Cr(VI) to Cr(III) (Dermou et al. 2005). An increase of the HRT may be another strategy to improve the performance of continuous activated sludge reactors, as shown for the reduction of Cr(VI), where the reduction efficiency increased from 38 to 50 % when the HRT was increased from 20 to 28 h at a 3 mg L−1 of Cr(VI) feed (Stasinakis et al. 2004). The likely presence of selenite-reducing microorganisms in the fed batch reactor suggests that the development of such a population in the continuously fed reactor is also possible (Fig. 4). This might also be possible by enriching the selenite-reducing microorganisms in the fed batch reactors and inoculating the continuous reactor with them. Further research identifying the microbial population and optimizing the operating conditions is required to enrich the selenite-reducing microorganisms in the continuously fed activated sludge reactor.

The higher DO requirement for trapping elemental selenium in the activated sludge flocs would entail higher costs for selenite reduction under aerobic conditions (Fig. 3b, c). This high cost can be offset by the use of the activated sludge trapping selenium as a slow release selenium fertilizer, which might require no further processing (Haug et al. 2007). The use of an alternative electron donor, such as cheese whey (Ferro Orozco et al. 2010), could further reduce the treatment costs without affecting the performance. The successful implementation of such a process would lead to a single-step selenium removal and recovery process (when applied as fertilizer) vis-à-vis the two-step anaerobic selenium removal, where high recovery efficiencies can only be achieved by applying a chemical (Buchs et al. 2013) or electrocoagulation (Staicu et al. 2015) post-treatment step. As elemental selenium nanoparticles are known to adsorb heavy metals such as Cu, Zn, and Hg (Johnson et al. 2008; Bai et al. 2011; Jain et al. 2015a; Jain et al. 2015c), the selenite fed activated sludge can also be used for the remediation of heavy metal polluted soils.

Conclusions

This study investigated the reduction of selenite by activated sludge at different DO and electron donor concentrations, reactors configuration, and temperature. The higher DO levels and lower temperature were required to ensure trapping of the produced BioSeNPs in the activated sludge flocs. This study also showed that glucose was the best electron donor to achieve maximum selenium removal per gram of COD. The toxicity of selenite and potential crashing of continuously operated reactors at two different TSS concentrations indicate different start-up (e.g., fed batch) or operational (e.g., longer HRT or higher selenite rates per unit of biomass) strategies are required for activated sludge systems treating selenite-rich wastewaters.

References

Ahammad SZ, Davenport RJ, Read LF, Gomes J, Sreekrishnan TR, Dolfing J (2013) Rational immobilization of methanogens in high cell density bioreactors. RSC Adv 3:774–781

APHA (2005) Standard methods for examination of water and wastewater, 5th edn. American Public Health Association, Washington, DC, USA

Bai Y, Rong F, Wang H, Zhou Y, Xie X, Teng J (2011) Removal of copper from aqueous solution by adsorption on elemental selenium nanoparticles. J Chem Eng Data 56:2563–2568

Belzile N, Wu GJ, Chen Y-W, Appanna VD (2006) Detoxification of selenite and mercury by reduction and mutual protection in the assimilation of both elements by Pseudomonas fluorescens. Sci Total Environ 367:704–14

Buchs B, Evangelou MW-H, Winkel L, Lenz M (2013) Colloidal properties of nanoparticular biogenic selenium govern environmental fate and bioremediation effectiveness. Environ Sci Technol 47:2401–2407

Cantafio AW, Hagen KD, Lewis GE, Bledsoe TL, Nunan KM, Macy JM (1996) Pilot-scale selenium bioremediation of San Joaquin drainage water with Thauera selenatis. Appl Environ Microbiol 62:3298–303

Dermou E, Velissariou A, Xenos D, Vayenas DV (2005) Biological chromium(VI) reduction using a trickling filter. J Hazard Mater 126:78–85

Dhanjal S, Cameotra SS (2010) Aerobic biogenesis of selenium nanospheres by Bacillus cereus isolated from coalmine soil. Microb Cell Fact 9:52

Dhanjal S, Cameotra SS (2011) Selenite stress elicits physiological adaptations in Bacillus sp. (Strain JS-2). J Microbiol Biotechnol 21:1184–1192

Espinosa-Ortiz EJ, Gonzalez-Gil G, Saikaly PE, van Hullebusch ED, Lens PNL (2014) Effects of selenium oxyanions on the white-rot fungus Phanerochaete chrysosporium. Appl Microbiol Biotechnol. doi:10.1007/s00253-014-6127-3

Ferro Orozco AM, Contreras EM, Zaritzky NE (2010) Cr(Vi) reduction capacity of activated sludge as affected by nitrogen and carbon sources, microbial acclimation and cell multiplication. J Hazard Mater 176:657–65

Haug A, Graham RD, Christophersen OA, Lyons GH (2007) How to use the world’s scarce selenium resources efficiently to increase the selenium concentration in food. Microb Ecol Health Dis 19:209–228

Hunter WJ, Manter DK (2009) Reduction of selenite to elemental red selenium by Pseudomonas sp. Strain CA5. Curr Microbiol 58:493–8

Jain R, Gonzalez-Gil G, Singh V, van Hullebusch, ED, Farges, F, Lens PNL (2014) Biogenic selenium nanoparticles: production, characterization and challenges. In: Kumar A, Govil JN (eds) Nanobiotechnology. Studium Press LLC, USA, pp 361–390

Jain R, Jordan N, Schild D, van Hullebusch ED, Weiss S, Franzen C, Hubner R, Farges F, Lens PNL (2015a) Adsorption of zinc by biogenic elemental selenium nanoparticles. Chem Eng J 260:850–863

Jain R, Jordan N, Weiss S, Foerstendorf H, Heim K, Kacker R, Hübner R, Kramer H, van Hullebusch ED, Farges F, Lens PNL (2015b) Extracellular polymeric substances govern the surface charge of biogenic elemental selenium nanoparticles. Environ Sci Technol 49:1713–1720

Jain R, Seder-colomina M, Jordan N, Dessi P, Cosmidis J, van Hullebusch ED, Weiss S, Farges F, Lens PNL (2015c) Entrapped elemental selenium nanoparticles affect physicochemical properties of selenium fed activated sludge. J Hazard Mater 295:193–200

Johnson NC, Manchester S, Sarin L, Gao Y, Kulaots I, Hurt RH (2008) Mercury vapor release from broken compact fluorescent lamps and in situ capture by new nanomaterial sorbents. Environ Sci Technol 42:5772–5778

Karya NGA, van der Steen NP, Lens PNL (2013) Photo-oxygenation to support nitrification in an algal-bacterial consortium treating artificial wastewater. Bioresour Technol 134:244–50

Lane DJ (1991) 16S/23S rRNA sequencing. In: Stackebrandt E, Goodfellow M (eds) Nucleic acid techniques in bacterial systematic. John Wiley & Sons, New York, pp 115–175

Lenz M, Lens PNL (2009) The essential toxin: the changing perception of selenium in environmental sciences. Sci Total Environ 407:3620–33

Lenz M, van Hullebusch ED, Hommes G, Corvini PFX, Lens PNL (2008a) Selenate removal in methanogenic and sulfate-reducing upflow anaerobic sludge bed reactors. Water Res 42:2184–2194

Lenz M, Smit M, Binder P, van Aelst AC, Lens PNL (2008b) Biological alkylation and colloid formation of selenium in methanogenic UASB reactors. J Environ Qual 37:1691–700

Li D-B, Cheng Y-Y, Wu C, Li W-W, Li N, Yang Z-C, Tong Z.-H, Yu H-Q (2014) Selenite reduction by Shewanella oneidensis MR-1 is mediated by fumarate reductase in periplasm. Sci Rep 4:3735

Muyzer G, de Waal E, Uitterlinden AG (1993) Profiling of complex microbial populations by denaturing gradient gel electrophoresis analysis of polymerase chain. Appl Environ Microbiol 59:695–700

Oremland RS, Herbel MJ, Blum JS, Langley S, Beveridge TJ, Ajayan PM, Sutto T, Ellis AV, Curran S (2004) Structural and spectral features of selenium nanospheres produced by Se-respiring bacteria. Appl Environ Microbiol 70:52–60

Øvreås L, Forney L, Daae FL, Torsvik V (1997) Distribution of bacterioplankton in meromictic Lake Saelenvannet, as determined by denaturing gradient gel electrophoresis of PCR-amplified gene fragments coding for 16S rRNA. Appl Environ Microbiol 63:3367

Park HJ, Kim HY, Cha S, Ahn CH, Roh J, Park S, Kim S, Choi K, Yi J, Kim Y, Yoon J (2013) Removal characteristics of engineered nanoparticles by activated sludge. Chemosphere 92:524–528

Pearce CI, Pattrick RAD, Law N, Charnock JM, Coker VS, Fellowes JW, Oremland RS, Lloyd JR (2009) Investigating different mechanisms for biogenic selenite transformations: Geobacter sulfurreducens, Shewanella oneidensis and Veillonella atypica. Environ Technol 30:1313–26

Rosen BP, Liu Z (2009) Transport pathways for arsenic and selenium: a minireview. Environ Int 35:512–515

Staicu LC, van Hullebusch ED, Lens PNL, Pilon-Smits EA, Oturan MA (2015) Electrocoagulation of colloidal biogenic selenium. Environ Sci Pollut Res Int 22:3127–3137

Stasinakis AS, Thomaidis NS, Mamais D, Lekkas TD (2004) Investigation of Cr(VI) reduction in continuous-flow activated sludge systems. Chemosphere 57:1069–1077

Tejo Prakash N, Sharma N, Prakash R, Raina KK, Fellowes J, Pearce CI, Lloyd JR, Pattrick RAD (2009) Aerobic microbial manufacture of nanoscale selenium: exploiting nature’s bio-nanomineralization potential. Biotechnol Lett 31:1857–62

Winkel L, Feldmann J, Meharg AA (2010) Quantitative and qualitative trapping of volatile methylated selenium species entrained through nitric acid. Environ Sci Technol 44:382–7

Acknowledgments

The authors are thankful to Ferdi Battles, Lyzette Robbemont, Berend Lolkema (UNESCO-IHE, Delft) for the ICP-MS measurements, as well as Marina Seder-Colomina (Université Paris-Est, Marne la Vallée) and Julie Cosmidis (UPMC Univ Paris 06, Paris) for TEM-EDX measurements. This research was supported through the Erasmus Mundus Joint Doctorate Environmental Technologies for Contaminated Solids, Soils, and Sediments (ETeCoS3) (FPA no. 2010-0009) and the lifelong Learning Program (LLP) Erasmus Placement, both financed by the European Commission.

Authors’ contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Bingcai Pan

Rights and permissions

About this article

Cite this article

Jain, R., Matassa, S., Singh, S. et al. Reduction of selenite to elemental selenium nanoparticles by activated sludge. Environ Sci Pollut Res 23, 1193–1202 (2016). https://doi.org/10.1007/s11356-015-5138-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5138-7