Abstract

Dry anaerobic digestion of sewage sludge can recover biogas as energy; however, its low C/N ratio limits it as a single substrate in the anaerobic digestion. Rice straw is an abundant agricultural residue in China, which is rich in carbon and can be used as carbon source. In the present study, the performance of dry co-digestion of sewage sludge and rice straw was investigated under mesophilic (35 °C) and thermophilic (55 °C) conditions. The operational factors impacting dry co-digestion of sewage sludge and rice straw such as C/N ratio, moisture content, and initial pH were explored under mesophilic conditions. The results show that low C/N ratios resulted in a higher biogas production rate, but a lower specific biogas yield; low moisture content of 65 % resulted in the instability of the digestion system and a low specific biogas yield. Initial pH ranging 7.0–9.0 did not affect the performance of the anaerobic digestion. The C/N ratio of 26–29:1, moisture content of 70–80 %, and pH 7.0–9.0 resulted in good performance in the dry mesophilic co-digestion of sewage sludge and rice straw. As compared with mesophilic digestion, thermophilic co-digestion of sewage sludge and rice straw significantly enhanced the degradation efficiency of the substrates and the specific biogas yield (p < 0.05) at the conditions of C/N ratio 26:1, moisture content 80 %, and natural initial pH. Although high concentrations of ammonia–nitrogen (NH4–N, 1500 mg/kg wet weight) were formed during thermophilic digestion, there was no obvious inhibition occurred. The results indicated that rice straw can be used as carbon source for the dry co-digestion of sewage sludge under mesophilic and thermophilic conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

According to the statistics of the Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD), until the end of March 2014, a total of 3622 wastewater treatment plants (WWTPs) have been constructed in China and the treatment capacity is 153 million m3/day. The sewage sludge generated in these WWTPs is nearly 30 million tons per year (wet weight) (http://www.mohurd.gov.cn/zxydt/201405/t20140519_217947.html). The disposal of sewage sludge is a challenge for these WWTPs. Rice straw is a very abundant agricultural waste in China and its disposal is also a challenge (Huang et al. 2013).

Conventionally, sewage sludge is disposed of via incineration, landfill, and ocean disposal or is reused as soil conditioner in agriculture through land application. However, due to the contamination, the sludge dumping to the sea has been banned. With the concern to groundwater contamination, sludge landfilling has been gradually reduced (Kelessidis and Stasinakis 2012). Because sewage sludge contains organic matters, it has been recognized as resources for reutilization (Karthikeyan and Visvanathan 2013). Energy recovery from sewage sludge can be achieved through anaerobic digestion, incineration, gasification, and pyrolysis (Tyagi and Lo 2013). Among them, anaerobic digestion is the most popular sludge stabilization technology currently used in the market, recovering biogas as energy and recycling nutrients as organic fertilizer (Zhang et al. 2013). The combustion of methane for power generation can offset the energy consumed during wastewater treatment in WWTPs (Bennett 2007; Rojas and Zhelev 2012), and the use of residue from anaerobic digestion of sewage sludge as fertilizing nutrients in agriculture can also save energy associated industrial fertilizer production (Chen and Chen 2013).

According to the moisture content of the feedstock, anaerobic digestion can be categorized into wet anaerobic digestion if the moisture content is more than 85 % and dry anaerobic digestion if the moisture content is less than 85 % (Kothari et al. 2014). Dry anaerobic digestion can even handle about 30–35 % of dry solid content. Dry anaerobic digestion has many advantages over wet digestion, such as a smaller reactor volume, less liquid digestate arising, higher biogas production rate, and easy handling of digested residues (Zeshan and Visvanathan 2012). Dry anaerobic digestion is usually operated under mesophilic (35–40 °C) or thermophilic (50–55 °C) conditions (Cavinato et al. 2013). Until the beginning of the 1990s, all plants were operated under mesophilic conditions. After then, the advantages of thermophilic operation were investigated and reported, such as offering higher biomass conversion efficiency and more net energy (Fdez-Gueelfo et al. 2010). The number of plants using thermophilic operation was then increased remarkably during the past two decades.

The performance and stability of dry anaerobic digestion are affected by many factors, and the characteristic of feedstock is one of vital factors (Rajagopal et al. 2013). Sewage sludge is composed of organic matter and inorganic matter, and organic matter contains high contents of protein, so sewage sludge has a low C/N ratio (Murray et al. 2008). Low C/N ratio results in the release and accumulation of NH4–N during anaerobic digestion. High concentrations of NH4–N have been reported as the primary cause of digester failure because of its direct inhibition on microbial activities, especially on methanogens’ activity (Rajagopal et al. 2013). The optional C/N ratio of the feedstock for anaerobic digestion is around 25–40 (Zeshan and Visvanathan 2012). Therefore, organic matter rich in carbohydrates needs to be added to adjust the low C/N ratio of sewage sludge. Rice straw is rich in cellulose, hemicellulose, and lignin and has a high ash content (Huang et al. 2013). The dry anaerobic digestion of composting rice straw has been reported recently (Yan et al. 2015). Sasaki et al. (2011, 2010) have reported that carbon fiber textiles (CFT) can medicate the toxicity of NH4–N to microorganisms in wet anaerobic digestion systems. Their results showed that there was stable removal of organic compounds and biogas production under ammonia–nitrogen (NH4–N) concentration of 3000 mg/L in the reactors containing CFT. However, the removal of organic compounds and biogas production was inhibited under NH4–N concentration of 1500 mg/L in the reactors without CFT. The moisture content affected the digestibility and digestion time for the dry anaerobic digestion (Li et al. 2014). Therefore, it can be supposed that the fiber of rice straw not only supplies carbon source for microorganisms, but also mediates the ammonia inhibition in the dry digestion system. Up to date, the performance of dry co-digestion of sewage sludge and rice straw has not been reported.

Therefore, in this study, the feasibility using rice straw as carbon source to adjust the C/N ratio of sewage sludge was investigated. The performance of the co-digestion of sewage sludge and rice straw under mesophilic and thermophilic conditions was explored and compared.

Materials and method

Characteristics of sewage sludge and rice straw

The sewage sludge used in this study was collected from the Chengbai Wastewater Treatment Plant, located in Lu’an City, Anhui Province, China, which uses the oxidation ditch technology with a treatment capacity of 80,000 m3/day. After thickened in the thickening tank, the excess sludge in the plant was dewatered by a belt press filter and the moisture content of the dewatered sludge was around 78–85 %. The fresh dewatered sludge was collected, and the dry matter content of the sludge used in this study was 15.6 ± 1.0 %. Dry rice straw, collected from the suburb of Hefei City, Anhui Province, China, was grounded to <1 cm small pieces. The characteristics of sewage sludge and rice straw are listed in Table 1. The C/N ratios of the sewage sludge and rice straw were 5.2 and 47.0, respectively.

Inoculums of mesophilic and thermophilic anaerobic digestion

The original inoculums were collected from the mesophilic and thermophilic anaerobic reactors treating sewage sludge in the laboratory. Two kinds of acclimated anaerobic inoculums were used in this experiment. One was the mesophilic inoculums, which was acclimated at 35 ± 3 °C for 2 months with sewage sludge and rice straw as substrate. The other was the thermophilic inoculums, which was acclimated at 55 ± 3 °C for 2 months with the same substrate as the mesophilic conditions. After the acclimation, both the mesophilic and thermophilic inoculums showed stable methanogenic activities. The characteristics of inoculums are listed in Table 1.

Experimental setup of dry co-digestion

Dry co-digestion was carried out in batch reactors made of glass with internal diameter of 8.0 cm and height of 25.0 cm. The working capacity of the reactors was 1.2 L. The reactors were placed in two incubators in the laboratory where the temperatures were controlled at 35 ± 3 and 55 ± 3 °C respectively. The volume of biogas generated was collected using 10.0 L sampling bags.

Experimental design

This experiment consisted of three parts. In the first part, the anaerobic digestion of sewage sludge, sewage sludge, and inoculums was separately investigated under mesophilic and thermophilic conditions as the control, as listed in Table 2. The aim of assays 1, 2, and 3 was to investigate the potential of biogas production and degradation efficiency of the inoculums, sewage sludge, and rice straw under mesophilic and thermophilic conditions. For the digestion of sewage sludge and inoculums, the moisture content was not adjusted, while for the rice straw, the moisture content was adjusted to 80 %. The incubation time lasted 75 days for the mesophilic digestion and 25 days for the thermophilic digestion.

In the second part, the influence of C/N ratio, initial pH, and moisture content on the performance of dry co-digestion was investigated under mesophilic condition (35 ± 3 °C). Four levels of C/N ratios, moisture content, and initial pH values were studied respectively. The experimental design and the composition of the feedstocks and the addition of inoculums are listed in Table 3.

In the third part, based on the determined C/N ratio, moisture content, and initial pH obtained in the second part, the performance of dry co-digestion of sewage sludge and rice straw under mesophilic (35 ± 3 °C) and thermophilic (55 ± 3 °C) conditions was investigated and compared. The composition of the substrates used in the third part is listed in Table 4.

Analysis

The solid samples collected during digestion were diluted with deionized water at a ratio 1:10, and the mixture was centrifuged at 10,000 rpm for 10 min (Centrifuge 5810R, Eppendorf). The supernatant was collected for the analysis of volatile fatty acids (VFAs), NH4–N, soluble phosphorus, and pH. Dry matter, total solids (TS), volatile solids (VS), NH4–N, and soluble phosphorus were analyzed according to the Standard Methods (APHA 1998). Biogas was collected by 10-L gas sampling bag during the digestion (Safelab Ltd., China). The volume of the collected biogas was measured using water displacement method everyday (Hu et al. 2012; Hu and Yu 2005). The composition of biogas was determined using a gas chromatography with a TCD detector (SP-6800, Lulan Co., China). VFAs were determined with a gas chromatography using a FID detector (GC-6890N, Agilent Inc., USA). The total kjeldahl nitrogen (TKN) was analyzed by acid digestion and distillation procedure using a semi-automatic nitrogen analyzer.

Statistical analysis

All the assays were carried out in triplicate and means were reported here. The differences of degradation efficiency and biogas yield of co-digestion of sewage sludge and rice straw between means were analyzed by one-way analysis of variance (ANOVA), followed by Duncan’s multiple range test at a significance level of 0.05 using SPSS 17.0 Statistical Software Program (SPSS Incorporated, Chicago).

Results and discussion

Anaerobic digestion of the substrates

The anaerobic digestion of sewage sludge, rice straw, or inoculums was carried out for 75 days. Table 5 lists the result of degradation efficiency and biogas yield of the substrates. It can be found that the degradation efficiency was enhanced by thermophilic conditions as compared with mesophilic conditions. However, the degradation efficiency varied from 28.5 to 41.3 %, which was relatively low as compared with previous report (Karthikeyan and Visvanathan 2013). Anaerobic digestion of sewage sludge resulted in the accumulation of NH4–N (Rajagopal et al. 2013), which might inhibit the methanogenic activities. While for rice straw, the very high C/N ratio limited the microbial growth and inhibited the methanogenic activities, resulting in low degradation efficiency. Therefore, the co-digestion of sewage sludge and rice straw might improve the degradation efficiency and biogas yield.

Dry co-digestion under mesophilic conditions

Effect of C/N ratio

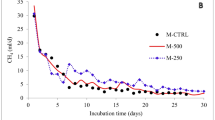

C/N ratio is an important factor affecting the performance of anaerobic treatment system. Figure 1 shows the biogas production at various C/N ratios. As shown in Fig. 1a, the startup of dry co-digestion was obviously affected by the C/N ratio. Low C/N ratios had a shorter startup time, and the reactors quickly reached the highest daily biogas production. For example, at the C/N of 18:1, the maximum daily biogas production appeared on the 4th day after digestion, while at C/N ratios of 23:1, 26:1, and 29:1, the maximum daily biogas production appeared approximately on the 13th, 38th, and 43rd days respectively. The phenomenon can be attributed to the difference in the substrate composition. The assay with lower C/N ratio contained higher percentage of sewage sludge, which contributed to more easily biodegradable organic matter, such as digestible microbial protein. The assay with higher C/N ratio contained higher percentage of rice straw. Because the cellulose and hemicellulose are covered by lignin, rice straw is recalcitrant to be decomposed by microorganisms (Hu et al. 2008). Based on the performance of biogas production, it can be deduced that the carbon source contained in the rice straw was not effectively utilized by microorganisms at the beginning of the co-digestion under mesophilic conditions.

Figure 1b shows specific biogas production (biogas production per gram of VS). It can be found that at low C/N ratios, there were high biogas production rates, which might be due to the easy decomposition of sewage sludge. However, for the specific biogas production, the biogas yield at C/N ratios of 26:1 and 29:1 was higher than that at 18:1 and 23:1, as listed in Table 6. The low biogas yield at low C/N ratio may be due to the inhibition of ammonia to the anaerobic microbial activities. The highest yield of 520 mL per gram of VS was obtained at C/N ratio of 26:1, while the corresponding yield at C/N ratio of 18:1 was 375 mL per gram of VS, but they all were higher than the digestion with single substrate, as listed in Table 5. Therefore, it can be concluded that the co-digestion enhanced the degradation efficiency of VS and biogas production. The C/N ratio of 26:1 was selected for the experiment in the third part.

Effect of moisture content

The moisture content influences the transfer and diffusion of mass and energy in the anaerobic digesters (Bollon et al. 2011; Le Hyaric et al. 2012; Pommier et al. 2007). Figure 2 depicts the biogas production of mesophilic anaerobic digestion at moisture contents of 65, 70, 80, and 85 % respectively. It can be found that with the increase of moisture content, the startup time was shortened. At the assay of 65 % moisture content, the highest daily biogas production was still not reached until the 60th day of the operation. Moreover, the biogas production was not stable with 65 % moisture content. Bollon et al. (2013) investigated the diffusion coefficients of the feedstock of dry anaerobic digestion and found that effective diffusion coefficients decreased drastically when TS contents increased from 8 to 25 %. Le Hyaric et al. (2012) reported that in the batch mesophilic dry co-digestion, the low moisture content affected the degradation kinetics and extended the digestion time. Previous investigation indicated that the mass diffusion was seriously limited by the dry feedstock at 65 % moisture content (Bollon et al. 2011; Garcia-Bernet et al. 2011), which was consistent with the result obtained in this study. The highest daily biogas production at the moisture contents of 65, 70, 80, and 85 % occurred on the 61st day, 47th day, 38th day, and 31st day, respectively. Therefore, moisture content is a very important factor for the economic operation of dry anaerobic digestion system.

Figure 2b shows the specific biogas production. At the assay of 85 % moisture content, there was a high biogas production rate at the early stage, but after approximately 40 days, the specific biogas production was exceeded by the assays of other moisture content. As listed in Table 6, in all four moisture content levels, high specific biogas yield of 475–485 mL/g VS was obtained at moisture contents of 70 and 80 %, and a higher biogas production rate was observed at moisture content of 80 %. Therefore, 80 % moisture content was selected in the third part of the experiment.

Effect of initial pH

Figure 3 shows the biogas production at various initial pH values. As shown in Fig. 3a, biogas production was not obviously affected by the initial pH 7.0, 8.0 and 9.0, but at initial pH 10.0, the startup was seriously delayed. pH is one of most important factors influencing microorganisms’ activities, and the optional pH for anaerobic digestion is in the range of 6.5–7.5 (Vavilin et al. 2003). However, the initial pH 8.0 and 9.0 did not inhibit the microbial activity. This might be due to the buffer capacity of sewage sludge, which results in the pH coming back to normal pH values with the proceeding of digestion. However, at pH 10.0, the methanogens’ activities were seriously inhibited, and a long time was needed to recover the methanogens’ activities, as shown in Fig. 3b. However, the specific biogas yield was not obviously influenced by the initial pH (p > 0.05, Table 6).

Dry co-digestion under mesophilic and thermophilic conditions

Temperature is an important factor influencing the degradation rate and digestibility of the substrate for the anaerobic digestion (Mu et al. 2006, 2007). From the mesophilic dry co-digestion, the C/N ratio of 26:1, moisture content of 80 %, and naturally initial pH was selected to compare the performance of dry co-digestion of sewage sludge and rice straw between mesophilic and thermophilic conditions. The composition of the substrates is listed in Table 4. The dry co-digestion was operated at 35 ± 3 and 55 ± 3 °C respectively.

VFA production

Figure 4 shows the profiles of individual and total VFAs production of co-digestion of sewage sludge and rice straw under mesophilic and thermophilic conditions. The accumulation of individual VFA was detected in the first 18 days in the mesophilic digestion, as shown in Fig. 4a. The main individual VFA was acetate and butyrate with highest concentrations of 5500 mg/kg wet weight and 6500 mg/kg wet weight, respectively. The highest total VFAs concentration was over than 15,000 mg/kg wet weight, as shown in Fig. 4c, indicating that serious inhibition might occur during mesophilic dry co-digestion, which can partly explain the low biogas yield at low C/N ratios in the second part. The accumulation of VFAs is due to the two-stage fermentation of organic matter during anaerobic digestion (Li and Yu 2011). In the first stage, the organic matter is hydrolyzed and acidified into VFAs (Yue et al. 2007), which is further converted into methane and carbon dioxide by methanogens in the second stage (Mu et al. 2007). After 18 days, the concentration of individual VFA began to decline, which was because the VFAs generated were less than the consumed, suggesting that the inhibition was mitigated with the extension of the incubation time.

Figure 4b shows the profile of individual VFA production under thermophilic conditions. Compared with mesophilic condition, the concentrations of individual VFA were far low in the thermophilic digestion. The main VFA was acetate and propionate, which was different from the mesophilic dry co-digestion. The highest total VFAs concentration was as low as 5500 mg/kg wet weight, which appeared on the 14th day. The total VFAs concentration then decreased to less than 2000 mg/kg after 20 days. The low total VFAs in the reactor suggest that there was no obvious inhibition occurred under thermophilic dry co-digestion.

pH variation

Figure 5 shows the pH variation of the dry co-digestion under mesophilic and thermophilic conditions. As shown in Fig. 5a, the pH in the mesophilic digestion first declined from 7.0 at day 0 to 5.6 at day 17, corresponding to the formation and accumulation of VFAs in the reactor in Fig. 4a. Previous investigation has observed that the pH < 6.0 in anaerobic digestion reactor seriously inhibited the activity of methanogens (Hu and Yu 2005). After day 17, the pH gradually rose from 5.6 to 8.3 on day 40, indicating that the accumulated VFAs were utilized and converted by methanogenic microorganisms. While for thermophilic dry co-digestion, there was no pH decrease during the incubation. On the contrary, the pH in the reactor began to increase from 7.1 at the beginning of the digestion to 8.7 on day 11, and then leveled at around 8.6. The increase of pH in the reactor was attributed to the formation of NH4–N released from the degradation of protein and nucleic acids.

Release of NH4–N and soluble phosphorus

Figure 6 shows the evolution of NH4–N and soluble phosphorus in the reactors. As shown in Fig. 6a, for the mesophilic dry co-digestion, the concentration of NH4–N on the 6th day reached 750 mg/kg, and then gradually declined to 450 mg/kg on the 23rd day of the incubation. While for the thermophilic co-digestion, the concentration of NH4–N increased from 460 mg/kg on the 1st day to 1530 mg/kg on the 10th day and then fluctuated around 1500 mg/kg. Ammonia–nitrogen in the digester comes from the decomposition of organic matter such as protein and nucleic acids (Gonzalez-Fernandez and Garcia-Encina 2009). Thermophilic condition enhanced the degradation of organic matter, which resulted in the rapid accumulation of NH4–N in the reactor. It has been reported that high concentration of NH4–N inhibits the activities of anaerobic microorganisms, especially for methanogens in thermophilic anaerobic digestion, because high temperature results in more release of NH4–N in the form of free ammonia (Fig. 6b) (Rajagopal et al. 2013). However, no obvious inhibition occurred in this study, which might be due to the absorption of fiber in the rice straw to ammonia, like the medication of carbon fiber textiles to ammonia toxicity for microorganisms in the wet anaerobic digestion systems (Sasaki et al. 2010, 2011).

Figure 6c shows the soluble phosphorus concentration during the mesophilic and thermophilic dry co-digestion. The rapid release of soluble phosphorus was found at the initial stage of mesophilic digestion. In the activated sludge process, the anaerobic process enhanced the release of phosphorus into the aqueous solution, which can explain the increase of soluble phosphorus concentration in the reactors. While for the thermophilic anaerobic digestion, the concentration of soluble phosphorus showed a slight fluctuation at a lower concentration as compared with mesophilic digestion. Combined the VFAs production and NH4–N formation, it can be deduced that sewage sludge and rice straw were rapidly broke down at the initial stage of thermophilic digestion, but the rapid increase of soluble phosphorus was not observed in this study. This may be because the released phosphorus reacts with other chemicals to form insoluble phosphoric compounds under alkaline conditions for thermophilic digestion (as shown in Fig. 5).

Biogas production

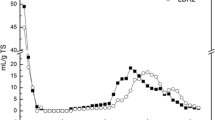

Figure 7 shows the biogas production and methane composition of co-digestion under mesophilic and thermophilic conditions. Daily biogas production was significantly affected by the operation temperature (p < 0.05). As shown in Fig. 7a, the maximum daily biogas production under thermophilic conditions was 12.2 L/day L, as observed on the 11th day of the digestion, while under mesophilic conditions, the maximum value was only 2.0 L/day L. Compared with mesophilic digestion, the treatment duration was reduced by 3 times from average 75 days under mesophilic conditions to average 25 days under thermophilic conditions, indicating that thermophilic dry co-digestion can significantly improve the utilization efficiency of reactors.

Figure 7b shows specific biogas production under both digestion conditions. Under mesophilic conditions, the specific biogas yield reached 518 ml/g VS for mesophilic digestion. While under thermophilic condition, the yield increased to 602 ml/g VS, indicating that biogas production was significantly enhanced by the increasing treatment temperature (p < 0.05). More importantly, the degradation efficiency correspondingly increased from 60.1 % under mesophilic conditions to 70.2 % under thermophilic conditions (p < 0.05), as listed in Table 7.

The methane content in the biogas is shown in Fig. 7c. For the mesophilic dry co-digestion, the methane content gradually increased from 36 % at the beginning to 59 % on the 38th day. While for the thermophilic dry co-digestion, the methane content rapidly increased from 41 % at the beginning to 60 % at the 5th day, and then fluctuated and declined gradually. The methane content in the biogas was affected by the composition of the decomposed feedback. Protein has a higher methane production potential than carbohydrate (Yu and Fang 2003). As compared with mesophilic digestion, thermophilic digestion had high methane content at the beginning of digestion, meaning that all the composition of the substrates, especially microbial protein was quickly broken down. Therefore, thermophilic co-digestion significantly enhanced the degradation efficiency of VS and biogas production from the dry co-digestion of sewage sludge and rice straw.

Conclusions

The co-digestion of sewage sludge and rice straw under mesophilic conditions was significantly affected by C/N ratio and moisture content. Substrates at low C/N ratio resulted in a high biogas production rate and a low specific biogas yield. At the moisture content of 65 %, the biogas production was inhibited, and the digestion system was in an unstable state. At the moisture content of 70 and 80 %, the dry co-digestion of sewage sludge and rice straw obtained high degradation efficiency and specific biogas yield. In comparison with mesophilic digestion, thermophilic digestion resulted in the higher biogas production rate and specific biogas yield accompanied with high NH4–N accumulation and concentration. It is very interesting that the activity of methanogens was not inhibited by the high NH4–N concentration in the substrate, but the mechanism of the medication effect by rice straw needs further investigation. The disposal of sewage sludge and rice straw is a big challenge in China. The dry co-digestion of sewage sludge and rice straw under thermophilic conditions not only reduces the volume of the wastes, but also recovers biogas as energy. The recovered energy can be used for electricity generation, which will reduce the greenhouse gas emission from wastewater treatment plants.

References

APHA (1998) Standard methods for the examination of water and wastewater, nineteenthth edn. American Public Health Association, Washington DC

Bennett A (2007) Energy efficiency: wastewater treatment and energy production. Filtr Sep 44:16–19

Bollon J, Le-hyaric R, Benbelkacem H, Buffiere P (2011) Development of a kinetic model for anaerobic dry digestion processes: focus on acetate degradation and moisture content. Biochem Eng J 56:212–218

Bollon J, Benbelkacem H, Gourdon R, Buffiere P (2013) Measurement of diffusion coefficients in dry anaerobic digestion media. Chem Eng Sci 89:115–119

Cavinato C, Bolzonella D, Pavan P, Fatone F, Cecchi F (2013) Mesophilic and thermophilic anaerobic co-digestion of waste activated sludge and source sorted biowaste in pilot- and full-scale reactors. Renew Energy 55:260–265

Chen S, Chen B (2013) Net energy production and emissions mitigation of domestic wastewater treatment system: a comparison of different biogas-sludge use alternatives. Bioresour Technol 144:296–303

Fdez-Gueelfo LA, Alvarez-Gallego C, Sales Marquez D, Romero Garcia LI (2010) Start-up of thermophilic-dry anaerobic digestion of OFMSW using adapted modified SEBAC inoculum. Bioresour Technol 101:9031–9039

Garcia-Bernet D, Buffiere P, Latrille E, Steyer JP, Escudie R (2011) Water distribution in biowastes and digestates of dry anaerobic digestion technology. Chem Eng J 172:924–928

Gonzalez-Fernandez C, Garcia-Encina PA (2009) Impact of substrate to inoculum ratio in anaerobic digestion of swine slurry. Biomass Bioenergy 33:1065–1069

Hu ZH, Yu HQ (2005) Application of rumen microorganisms for enhanced anaerobic fermentation of corn stover. Process Biochem 40:2371–2377

Hu ZH, Liu SY, Yue ZB, Yan LF, Yang MT, Yu HQ (2008) Microscale analysis of in vitro anaerobic degradation of lignocellulosic wastes by rumen microorganisms. Environ Sci Technol 42:276–281

Hu Z-H, Yue Z-B, Yu H-Q, Liu S-Y, Harada H, Li Y-Y (2012) Mechanisms of microwave irradiation pretreatment for enhancing anaerobic digestion of cattail by rumen microorganisms. Appl Energy 93:229–236

Huang Y-F, Chiueh P-T, Kuan W-H, Lo S-L (2013) Microwave pyrolysis of rice straw: products, mechanism, and kinetics. Bioresour Technol 142:620–624

Karthikeyan OP, Visvanathan C (2013) Bio-energy recovery from high-solid organic substrates by dry anaerobic bio-conversion processes: a review. Rev Environ Sci Bio-Technol 12:257–284

Kelessidis A, Stasinakis AS (2012) Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag 32:1186–1195

Kothari R, Pandey AK, Kumar S, Tyagi VV, Tyagi SK (2014) Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew Sustain Energy Rev 39:174–195

Le Hyaric R, Benbelkacem H, Bollon J, Bayard R, Escudie R, Buffiere P (2012) Influence of moisture content on the specific methanogenic activity of dry mesophilic municipal solid waste digestate. J Chem Technol Biotechnol 87:1032–1035

Li WW, Yu HQ (2011) From wastewater to bioenergy and biochemicals via two-stage bioconversion processes: a future paradigm. Biotechnol Adv 29:972–982

Li C, Mortelmaier C, Winter J, Gallert C (2014) Effect of moisture of municipal biowaste on start-up and efficiency of mesophilic and thermophilic dry anaerobic digestion. Bioresour Technol 168:23–32

Mu Y, Zheng XJ, Yu HQ, Zhu RF (2006) Biological hydrogen production by anaerobic sludge at various temperatures. Int J Hydrog Energy 31:780–785

Mu Y, Yu HQ, Wang G (2007) A kinetic approach to anaerobic hydrogen-producing process. Water Res 41:1152–1160

Murray A, Horvath A, Nelson KL (2008) Hybrid life-cycle environmental and cost inventory of sewage sludge treatment and end-use scenarios: a case study from China. Environ Sci Technol 42:3163–3169

Pommier S, Chenu D, Quintard M, Lefebvre X (2007) A logistic model for the prediction of the influence of water on the solid waste methanization in landfills. Biotechnol Bioeng 97:473–482

Rajagopal R, Masse DI, Singh G (2013) A critical review on inhibition of anaerobic digestion process by excess ammonia. Bioresour Technol 143:632–641

Rojas J, Zhelev T (2012) Energy efficiency optimisation of wastewater treatment: study of ATAD. Comput Chem Eng 38:52–63

Sasaki K, Morita M, S-i H, Sasaki D, Ohmura N, Igarashi Y (2010) Efficient degradation of rice straw in the reactors packed by carbon fiber textiles. Appl Microbiol Biotechnol 87:1579–1586

Sasaki K, Morita M, S-i H, Ohmura N, Igarashi Y (2011) Decreasing ammonia inhibition in thermophilic methanogenic bioreactors using carbon fiber textiles. Appl Microbiol Biotechnol 90:1555–1561

Tyagi VK, Lo SL (2013) Sludge: a waste or renewable source for energy and resources recovery? Renew Sust Energ Rev 25:708–728

Vavilin VA, Rytov SV, Lokshina JY, Pavlostathis SG, Barlaz MA (2003) Distributed model of solid waste anaerobic digestion—effects of leachate recirculation and pH adjustment. Biotechnol Bioeng 81:66–73

Yan ZY, Song ZL, Li D, Yuan YX, Liu XF, Zheng T (2015) The effects of initial substrate concentration, C/N ratio, and temperature on solid-state anaerobic digestion from composting rice straw. Bioresour Technol 177:266–273

Yu HQ, Fang HHP (2003) Acidogenesis of gelatin-rich wastewater in an upflow anaerobic reactor: influence of pH and temperature. Water Res 37:55–66

Yue ZB, Yu HQ, Harada H, Li YY (2007) Optimization of anaerobic acidogenesis of an aquatic plant, Canna indica L., by rumen cultures. Water Res 41:2361–2370

Zeshan KOP, Visvanathan C (2012) Effect of C/N ratio and ammonia-N accumulation in a pilot-scale thermophilic dry anaerobic digester. Bioresour Technol 113:294–302

Zhang CS, Xiao G, Peng LY, Su HJ, Tan TW (2013) The anaerobic co-digestion of food waste and cattle manure. Bioresour Technol 129:170–176

Acknowledgments

This research was partially supported by the Key Special Program on the S&T for the Pollution Control (2012ZX07103-001), the NSFC (51078122, 41372246), and the Program for New Century Excellent Talents in University (NCET-11-0624).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Gerald Thouand

Rights and permissions

About this article

Cite this article

Chu, X., Wu, G., Wang, J. et al. Dry co-digestion of sewage sludge and rice straw under mesophilic and thermophilic anaerobic conditions. Environ Sci Pollut Res 22, 20143–20153 (2015). https://doi.org/10.1007/s11356-015-5074-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5074-6