Abstract

Pollution resulting from hazardous glass (HG) is widespread across the globe, both in terms of quantity and associated health risks. In waste cathode ray tube (CRT) and fluorescent lamp glass, mercury and lead are present as the major pollutants. The current review discusses the issues related to quantity and associated risk from the pollutant present in HG and proposes the chemical, biological, thermal, hybrid, and nanotechniques for its management. The hybrid is one of the upcoming research models involving the compatible combination of two or more techniques for better and efficient remediation. Thermal mercury desorption starts at 100 °C but for efficient removal, the temperature should be >460 °C. Involvement of solar energy for this purpose makes the research more viable and ecofriendly. Nanoparticles such as Fe, Se, Cu, Ni, Zn, Ag, and WS2 alone or with its formulation can immobilize heavy metals present in HG by involving a redox mechanism. Straight-line equation from year-wise sale can provide future sale data in comparison with lifespan which gives future pollutant approximation. Waste compact fluorescent lamps units projected for the year 2015 is 9,300,000,000 units and can emit nearly 9,300 kg of mercury. On the other hand, CRT monitors have been continuously replaced by more improved versions like liquid crystal display and plasma display panel resulting in the production of more waste. Worldwide CRT production was 83,300,000 units in 2002 and can approximately release 83,000 metric tons of lead.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of glass products in household and industrial appliances is continuously popular among us from thirty-fifth century BC (Before Christ). In 1994, approximately 9,200,000 tons of postconsumer glass was discharged in the USA alone (Shi and Zheng 2007) and this figure is expected to touch 40,000,000 tons of flat glass as a current global demand (http://www.tatachemicals.com/europe/touching_lives/pdf/glass_industry.pdf). Waste thus obtained can be managed by any of the following techniques:

-

1.

Mechanical recycling (remelting and shaping)

-

2.

As a material resource to make concrete admixture/aggregates (Terro 2006; Disfani et al. 2011a), masonry blocks (Turgut 2008), and ceramic tiles (Matteucci et al. 2002); as flux in metallurgical processes (Mostaghel and Samuelsson 2010), foam glass (Chen et al. 2009), footpath/pavement base material (Arulrajah et al. 2013; Imteaz et al. 2012), road building material (Disfani et al. 2011b; Disfani et al. 2012), and adsorbent (Pant 2009); and for decorative purposes (Nnorom et al. 2011), and;

-

3.

Land filling.

Various colorless glass, such as soda lime, borosilicate, vitreous silica, etc. (McLellan and Shand 1984; Shi and Zheng 2007), are broadly nonhazardous, with respect to metal, and can be managed by any of the above three techniques. Fluorescent light (contains hazardous mercury) is made up of various materials with 20–59 wt% of glass, which varies from type (i.e., compact fluorescent to fluorescent lamp), design, and capacity of the lamp. An 11 W capacity fluorescent lamp contains 46 and 14 W compact fluorescent lamp has 65 g glass (Welz et al. 2011). Many other glasses like colored, light-emitting diode, and cathode ray tube (CRT) also contains heavy metals (Cheng et al. 2007; Lim et al. 2013; Romero et al. 2013).

Due to the limitation in proper management system, nearly 78 % of resultant waste is dumped in a municipal landfill (Nnorom et al. 2011). A recent study economically validated closed-loop recycling, pyrometallurgy, and hydrometallurgy techniques (110–450 $/t) with landfill options (45 $/t) (Xu et al. 2013). So there is a continuous requirement towards an appropriate management option to extend the applications of these techniques. The current review discusses the issues related to quantity and associated risks from pollutants present in hazardous glass (HG) and proposes a plan for its management.

Heavy metal pollutant in glass

Different heavy metal compounds are mixed in the glass for imparting colors and specific applications (Table 1). Iron, in its trivalent form, in combination with barium oxide, gives a reddish brown color to the glass matrix; in its divalent form, with chromium, produces a deep green color; and with sulfur, it gives a dark amber color. Manganese imparts a purple and a weak yellow or brown color in its trivalent and divalent stages, respectively, and provides stability and strength to the glass object. Chromium(VI) imparts a dark green color, and on excess it gives a black color. It is one of the most powerful coloring and corrosion resistance metals in the glass-making industry. Copper imparts turquoise blue tones to the glass and improves its strength. Cobalt with potash produces a rich blue color and green with iodine. Uranium produces a yellow color and is used in making fluorescent glasses, while with lead it gives a deep red color.

The glass of a fluorescent lamp is coated with phosphor powder containing mercury vapor from the inside. Mercury is added to the lamp in the form of solid, liquid, or amalgam (Parsons 2006). It emits ultraviolet light (Fig. 1) upon excitation by electric current which fluoresces phosphor; the resultant gives an emission of visible light (Hildenbrand and Denissen 2000; Nance et al. 2012). Elemental mercury (Hg0) during lamp operation is oxidized and adsorbed onto the glass, phosphor powder, and metal component of the lamp (Aucott et al. 2003; Jang et al. 2005; Nance et al. 2012; Hu and Cheng 2012) and makes them polluted. The amount of mercury in fluorescent lamp varies according to lamp type, wattage, brand, and manufacturer (Stahler et al. 2008; Culver 2008; Newmoa 2008). Fluorescent lamps consist of 0.7–115 mg of mercury per lamp (Jang et al. 2005; Johnson et al. 2008). Mercury that is present in different lamps can also vary in different countries because of technology and associated environmental legislations. According to the United Nations Environment Program (UNEP), the mercury used in fluorescent tube lights in the European Union was 15 mg/lamp in 1997 which gets reduced to 10 mg/lamp in 2002. Russia, USA, Canada, and India used 15–45, 10–20, 23–46, and 5–60 mg/lamp in fluorescent tube lights (double end), respectively. In compact fluorescent lamp, mercury content varies accordingly such as 5 mg/lamp in the European Union, 10 mg/lamp in Canada, 12–30 mg/lamp in Russia, and 3–12 mg/lamp in India. High-intensity discharge lamps have more mercury content as compared to fluorescent lamps (Hu et al. 2012).

Mercury is hazardous to both infants as well as adults (Fig. 2). It affects neural development in unborn and growing children (Johnson et al. 2008; Clarkson 1993; Wang et al. 2011a) and may cause problems to aquatic and terrestrial ecosystems both in organic (methyl mercury) and inorganic (elemental mercury and mercury vapor) forms (Boening 2000; Tchounwou et al. 2003). Inorganic mercury is methylated in aquatic ecosystem and thus being accumulated to a high degree in aquatic food chains resulting in the highest concentration of mercury in marine fish and mammals (Clarkson 1993; Tchounwou et al. 2003; Sams 2007). It can affect the brain, the central nervous system, cause tremor, depression, and behavioral disturbances (Langford and Ferner 1999; Gupta 2007; Tsydenova and Bengtsson 2011; Pant et al. 2012).

Lead (in the form of PbO) is widely used in CRT glass due to its specific property to protect harmful exposure of X-rays generated from electron gun inside the tube (USEPA 1999; Musson et al. 2000). Lead content in CRT monitor varies from black and white towards colored, older towards newer, size, etc. Black and white and color funnel CRT consists of 2.8–4.4 and 19–23 % PbO, respectively, in terms of net oxide content (Mear et al. 2006). In black and white CRTs, lead is present in the glass part of the panel, funnel, and neck; in colored CRTs, it is present only in the funnel and neck (Corcoran 2001; Andreola et al. 2005a; Mear et al. 2006). The panel, funnel, and neck are joined together with a solder glass called frit which is highly leaded (Monitor 2001). Older CRT monitor contains 2–3 kg lead whereas this amount is decreased to 1 kg in the more recent one (Tsydenova and Bengtsson, 2011). Lead content may also vary according to the size of the television (TV) screen such as 13, 17, 27, and 32 in. contains 0.5, 0.7, 1.8, and 2.9 kg of lead, respectively (Karagiannidis et al. 2005).

The oxide composition in colored CRT glass consist of about 64 % SiO2, 9 % SrO, 8 % Na2O, 8 % K2O, 3 % PbO, 3 % CaO, 2 % BaO, 1 % Al2O3, and 2 % of other oxides such as Sb2O3, As2O3, TiO2, Li2O, ZnO, MgO, Fe2O3, CeO2, and ZrO2 (Brain 1990). The chemical composition of oxides present in CRT glass are classified into three groups: (1) network formers, responsible to form the glassy structure such as SiO2 and B2O3; (2) network modifiers, terminator for glassy network by requiring fewer oxygen to balance the valency such as CaO, MgO, Na2O, and K2O; and (3) network intermediates, modify the glass network for its specific application as Al2O3 and PbO (Mear et al. 2006, 2007).

Humans can be exposed to lead from air and food in roughly equal proportions (Jarup 2003). Children particularly are very susceptible to lead exposure due to high gastrointestinal (GI) uptake and the permeable blood–brain barrier (INSA 2011). Almost 20–30 % lead in adults and 50 % in children is absorbed through the GI track. Lead can cross blood–brain barrier as well as placental barrier (http://www.atsdr.cdc.gov/toxfaq.html). Pregnant women and young children having iron deficiency (anemia) are more susceptible to lead toxicity (Flora et al. 2006). Exposure to lead can cause intellectual impairment in children and damage either nervous, blood, or reproductive systems in adults (Poon 2008; Barbosa et al. 2005; Chen et al. 2011). Recent data indicates that there may be neurotoxic effects of lead at lower levels of exposure (Jarup 2003). The toxic effects of lead includes anemia, kidney damage, hypertension, cardiac disease, immune system suppression (antibody inhibition), and neurological damage (Quaterman 1986) with skin damage, headache, nausea, gastric, and duodenal ulcers (Monika 2010).

Quantification and risk assessment of pollutant in HG

Environmental pollution caused by mercury is a serious problem around the globe. Elemental mercury can be retained in atmosphere between 6 to 24 months before redeposition on the earth’s surface, it can be transported to over tens of thousands of kilometers (Schroeder and Munthe 1998; Dastoor and Larocque 2004; Carpi 1997). Fluorescent glass waste management requires awareness from consumer to manufacturer level so that they do not break or mix this waste with municipal trash bin and hand them over to authorized recycling unit. According to a survey conducted by Raposo and Roeser (2001) in Minas Gerais, Brazil, fluorescent lamps are disposed: (1) straight into garbage bins from public (41 %), hospital (80 %), commercial (100 %), and industrial sources (32 %); (2) recycling by public (51 %) and industrial sources (56 %); and (3) use of other disposal methods including private landfills, old and out of use wells, destroyed and buried in the ground, incinerated with other hazardous materials, dropped in junk yards, burned on corporate dumping grounds, and given away to service companies that replace burned out lamps under contract by public (8 %), hospital (20 %), and industrial sources (12 %).

Table 2 represents the worldwide production and associated waste data of fluorescent devices in terms of real and projected data. Worldwide production of compact fluorescent lamps (CFL) in the year 2001 was 820,000,000 pieces (CPCB 2008). China is the world’s largest CFL manufacturer; in the year 2009, it produced over 3,650,000,000 pieces of CFL bulbs out of which 80 % were exported (Chen 2010; Hu and Cheng 2012). The average life span of CFL is usually 8,000 h (Welz et al. 2011; Duff 2012), i.e., approximately 1 year. Straight-line equation from year-wise sales (2001–2006; Fig. 3) gives the future sale data of CFL in comparison with its lifespan that provides the resultant future waste data (Pant 2013a; CPCB 2008).

Technological advancement has been continuously replacing CRT with more improved versions like liquid crystal display (LCD) and plasma display panel thus generating enormous amount of waste CRT (Chen et al. 2009). In 2002, 83,300,000 of CRT was produced worldwide (Socolof et al. 2005). The amount of CRT glass generated in Asia will increase with a factor of 2 and will climb up from 800 to 1,500 metric tons by 2020 (Gregory et al. 2009). China is at the forefront of CRT production and covers about 90 % of the global CRT demand (Widmer et al. 2005; He et al. 2006). International business management estimated that in 2008, about 294,000,000 CRTs were discarded in the USA (Mizuki et al. 1997; Mueller et al. 2012). Asian countries like Japan generated 8,896,000 TVs in 2001, out of which 3,080,000 were taken into recycling facilities and the rest, which is 4,270,000 were exported to other countries (Tasaki et al. 2004). Taiwan generated 1,030,000 units of TV in 2002 (Hsu and Kuo 2005); Korea generated more than 8,000,000 units of TV waste in 2004–2005 out of which less than 3,000,000 units were recycled (Lee et al. 2007). In the USA, approximately 20,000,000 TVs become obsolete each year (Jefferies 2006). Year-wise production of CRT unit (leaded panel, nonleaded panel, and funnel glass) in the USA is represented in Fig. 4 (Monchamp et al. 2001). This figure shows data from the year 1990 to 2000:

-

1.

There was a continuous increase in CRT glass production from183,565 to 530,904 tons.

-

2.

The amount of leaded panel glass increased up to 1997; then from 1998 to 2000, its production is continuously declined.

-

3.

No-lead panel glass production increases rapidly from 30,137 to 256,358 tons.

-

4.

The amount of funnel glass production increased from 78,967 to 183,906 tons.

Only few developed countries have effective management program for CRT waste while large quantities are transferred to the developing countries like China for its management (Chen et al. 2009). These countries are deficient in recycling infrastructures and waste is processed in backyard or small workshops using manual disassembly and/or open burning. Such crude recycling techniques creates environmental pollution by affecting the air, soil, and water bodies (Nnorom et al. 2011).

Pollutant management

Mercury-containing glass waste (MCGW) can be managed by dry crushing and heating technology in a fluidized bed reactor. Countries have their own practices for the treatment, collection, and disposal of spent fluorescent lamps. Developed countries like the European Union and the USA have proper legal back up for the safe disposal of mercury-contaminated used lamps. The United States Environmental Protection Agency recommends that fluorescent lamps should be segregated from general waste for recycling or safe disposal (USEPA 1998). The European Union has developed the Waste Electrical and Electronic Equipment and Restriction of Hazardous Substances directives that producers should setup collection system for their household electronic waste. In the USA and Sweden, generator has to hand over the used lamps to authorized recyclers (Luther 2008); in Germany, the used fluorescent lamps are being collected at various collection centers (following the Recovery and Disposal Act for recycling). Russia, China, and Japan follow the regulations of Federal Law-Waste of Production and Consumption, Law of Environmental Protection, and Law for Promotion of Effective Utilization of Resources, respectively (CPCB 2008).

Recycling of waste fluorescent lamps may include the following steps:

-

1.

Feeding of used lamps in a recycling unit and pulverizing it.

-

2.

Sieving/separation of glass, metal, phosphor powder, and mercury vapors.

-

3.

Distillation to recover mercury from phosphor powder.

Other techniques like production of glass ceramics as valuable recycled products are also in practice (Yun et al. 2002). A recent research proposed a low-cost process to remove phosphor powder attached to the glass and removal of mercury by extraction (Rey-Raap and Gallardo 2013).

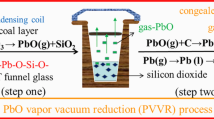

Lead-containing glass waste (LCGW) can be managed by various strategy involving reusing, recycling, and land filling (Zhang et al. 2000; Nnorom et al. 2007; ICER 2004; Smith et al. 1996; Andreola et al. 2005a). Reusing involves the replacement of previously used electronic gun from the waste CRT to manufacture local brand TVs and screens for video games (Ahluwalia and Nema 2006; Nnorom et al. 2011). Also, the reuse of secondhand TVs in developing countries has been reported as Japan in 2008 exported secondhand TVs to the Philippines (Yoshida and Atsushi 2010). Recycling is another way to manage CRT glasses into various value-added products like flux in metallurgical processes (lead and copper smelting; Mostaghel and Samuelsson 2010; Weitzman 2003; ICF Incorporated Fairfax 1999; Andreola et al. 2008), glass ceramics (Andreola et al. 2005b; Bernardo et al. 2006), glass matrix composites (Bernardo et al. 2003), glass beads for reflective elements and shot peening (Balcar and Dunkirk 1997), cement, clay brick, tile mixture, and glass wool (Lairaksa et al. 2013; Seo et al. 2011; Chen et al. 2002; Dondi et al. 2009; Luz and Ribeiro 2007); aggregate and mortars in concrete (Romero et al. 2013; Maschio et al. 2013); biopolymer-modified concrete (Kim et al. 2005), foam glass (Chen et al. 2009; Bernardo and Albertini 2006; Bernardo et al. 2005), fiber glass highway-reflective products (Dillon 1998), adsorbent (Pant and Singh 2013); and for decorative purposes such as tiles, glass, and lightening products (Nnorom et al. 2011). Smelting, a recycling technique is also used to separate toxic lead from the waste CRT glass (Chatterjee and Kumar 2009). For recycling of CRT, the USA has developed two techniques (Fig. 5; Menad 1999): (1) closed-loop recycling (glass to glass recycling) and (2) open-loop recycling (glass to lead recycling). In closed-loop recycling, whole recovered glass is grounded into cullets and used for the production of new CRT glass; in open-loop recycling, the glass is used for the production of secondary materials (Siikamaki et al. 2002; ICER 2004). Geskin et al. (2002) described the development of recycling technology (water jet technologies) for the efficient recovery of LCGW. This recycling technique involves separation of CRT at the frit line or just below it in order to achieve both high- and low-lead cullet compositions. Land filling methods are potentially unacceptable as it may cause heavy metal pollution which results in contamination of ground water (Noon et al. 2011; Poon 2008). Methods like reduction melting process (Okada and Yonezawa 2013), mechanochemical sulfidization (Yuan et al. 2013a), and mechanical activation as pretreatment followed by nitric acid leaching (Yuan et al. 2013b) are also proposed recently by some researchers to recover Pb from funnel glass of CRT.

The possible remediation techniques to manage hazardous pollutant from glass waste are broadly classified as (Fig. 6):

-

1.

Chemical remediation involving stabilization/solidification and immobilization

-

2.

Biological remediation involving microremediation, phytoremediation, and animal remediation;

-

3.

Thermal desorption

-

4.

Nanotechnology

-

5.

Hybrid technique

Chemical remediation

Chemical remediation technique involves the use of various chemicals for the removal of toxic and hazardous substances from environment. It may be done by the use of acid, base, chelating agents, and inorganic compounds by leaching and/or precipitation.

Remediation of MCGW

Table 3 represents the list of various chemicals used for Hg remediation from waste. It is found that for mercury remediation, EDTA and activated carbon have very extensive research level. Perusal of this table reveals that:

-

1.

Acids like HF and aqua regia, nitric and perchloric acid form soluble compounds with mercury for its removal.

-

2.

Mercury can be precipitated as Hg(OH)2 by using NaOH or at higher pH.

-

3.

Chelating agent increases the concentration and mobility of certain metal atom using coordination (Wenzel et al. 2003). Some biodegradable ligands like diethylene triamine penta-acetate (DTPA), nitrilotriacetic acid (NTA), along with oxalate and citrate have also been used as chelating agents for the extraction of mercury.

-

4.

Various inorganic compounds as KI/I can also be used as leaching agent.

-

5.

Sulfide can be used to remediate Hg by the formation of less toxic HgS (Piao and Bishop 2006; Bower et al. 2008).

-

6.

Various adsorbents like activated carbon, coal and coal fly ash, bamboo charcoal modified with KI , powdered sulfur polymer cement and sulfide, zeolites, sulfur-impregnated activated carbon with zeolites, and rice husk ash can remove mercury from its aqueous solution as well as in vapor form.

For the soils which have high elemental mercury content, methods such as stabilization/solidification and immobilization are suitable remediation options (Wang et al. 2012). It involves chemical reactions between the stabilizing agent and the contaminants to reduce Hg mobility. Powder-activated carbon with cement (Zhang and Bishop 2002) and thiol-functionalized zeolite (Zhang and Bishop 2002; Zhang et al. 2009) can be used to stabilize mercury.

Chemical remediation technique is primarily applied if the target metal is in the ionic form (Dermont et al. 2008a, b). Sierra et al. (2011) investigated the feasibility of physicochemical procedures by involving physical separation followed by chemical process.

Remediation of LCGW

Table 4 represents the list of various chemicals used for lead removal from waste. EDTA is widely used for Pb removal of the waste with very extensive research level. A perusal of this table reveals that:

-

1.

Acids like HCl, HNO3 alone/or with H2SO4, and acetic acid form soluble compounds with lead for its removal.

-

2.

Extract lead as lead hydroxide by NaOH.

-

3.

Synthetic chelators like DTPA, hydroxylethyl ethylenediamine-triacetic acid (HEDTA), propylene diamine tetraacetic acid, ethyleneglycol-bis(2-aminoethylether) tetraacetic acid and biodegradable synthetic chelating agents, such as ethylenediaminedisuccinic acid (EDDS), citric acid and NTA, can also be used for the removal of lead from LCGW.

-

4.

Pyrolusite, calcite, kaolinitic clay, kaolinite with alumina, zeolites, glass, and biosorbents like rice husk ash, Syzygium cumini L., and Coir (fibers from Coco nucifera) can act as adsorbents for Pb removal.

Biological remediation

Bioremediation technique involves the use of living organisms (microbe, plant, and animal) to remove pollutants from the environment.

Remediation of MCGW

Table 5 represents the various biological species involved in the remediation of MCGW. Some biological species develop resistance mechanism to overcome Hg toxicity by biosorption, bioleaching, and enzyme-catalyzed transformation. At neutral pH, microbial cell surface carries a net negative charge due to the presence of carboxyl, amine, hydroxyl, phosphate, and sulfhydryl groups able to adsorb positively charged cationic metals. Alginate immobilized mercury-tolerant Bacillus cereus cells (Sinha et al. 2012), magnetically modified yeast cells (Yavuz et al. 2006), alga like Spirogyra (Rezaee et al. 2006), and autotrophic microorganism like Thiobacillus (Lloyd 2002) are some popular microbes used for the biosorption of mercury. Enzyme-catalyzed transformation involves the reduction of the toxic mercuric ion (Ehrlich 1997) Hg(II) to less toxic Hg(0). In some studies, elemental mercury is trapped by using mercury-resistant bacteria like Pseudomonads (Wagner-dobler et al. 2000; Lloyd 2002), Bacillus, Closteridium, and Escherichia spp. (Cunningham and Ow 1996) as biofilm in bioreactor.

Phytoremediation is widely viewed as the ecologically responsible alternative to the currently practiced environmental methods (Meagher 2000). Plants can manage mercury by the following three ways:

-

1.

Phytostabilization is the involvement of roots of a plant to limit contaminant mobility and bioavailability in the soil (www.itrcweb.org). It can occur either by the process of complexation, sorption, precipitation, or metal valence reduction (Henry 2000).

-

2.

Phytoextraction is the use of plants to accumulate contaminants in their tissues. Phytoextaction can occur naturally or by the addition of certain chemicals or chelating agents to the plants.

-

3.

Phytovolatilization is the process by which the plant can uptake the volatile metal from the soil. This technique is important for remediation of mercury as some plants may naturally interact with mercury present in the soil (Wang et al. 2012). Five plant species Lepidium latifolium, Artemisia douglasiana, Caulanthus sp., Fragaria vesca, and Eucalyptus globules were grown in the soil contaminated with mercury (450–1,605 mg/kg). Among these plant species, Caulanthus sp. showed a higher mercury emission rate of 92.6 ng/m2/h in the daytime (Leonard et al. 1998).

Insertion of bacterial genes to design the genetically engineered plants for detoxifying mercury is another important area of research (Raskin and Ensley 2000). An extensively resistance system based on clustered genes in an operon (i.e., Mer), allows bacteria to detoxify Hg2+ into volatile mercury by enzymatic reduction (Komura and Izaki 1971; Summers 1986; Misra 1992; Silver 1996; Barkay et al. 2003). The organic methyl mercury (R-CH2Hg) is the most toxic form than all the other forms of mercury. To detoxify this toxin, transgenic plants (Arabidopsis and tobacco) are engineered (Table 6) with bacterial genes merB (organomercurial lyase) and merA (mercuric ion reductase). In these modified plants, merB catalyzes the protonolysis of the carbon–mercury bond with the generation of Hg2+ (100 times less toxic than methylmercury) and subsequently MerA converts Hg(II) to Hg(0), a less toxic, volatile element (Heaton et al. 1998; Fox and Walsh 1982; Rugh et al. 1996; Bizily et al. 1999). By genetic engineering, other genes like MerC, MerF, and MerT (membrane transporter genes) are also being introduced in the plants which are involved in the process of translocating Hg2+ into the plant cell (Bizily et al. 1999, 2000; Ruiz and Daniell 2009; Liebert et al. 2000; Morby et al. 1995; Wilson et al. 2000; Fig. 7). Recently, two other Mer genes, mer E and mer H (membrane bound), assisting in the membrane transport of mercury has been reported in the bacteria (Kiyono et al. 2009; Schue et al. 2009).

Animal remediation of mercury mainly involves the use of earthworms to biotransform the metals to its less harmful form (Ireland 1983, 1979). They generate and exude carboxylic acid which acidify soil and activate heavy metals. Many earthworm species such as Eisenia fetida, Eisenia tetraedra, Lumbricus terrestris, Lumbricus rubellus, and Allobophora chlorotica have been used for this purpose (Sinha et al. 2008). Relevant concentration of metal in tissues might prove earthworms as efficient bioindicator of soil contamination by heavy metals (Suthar et al. 2008). Hartenstein et al. (1980) reported that earthworms can bioaccumulate high concentration of metals in their tissues without affecting their physiology.

Remediation of LCGW

Table 7 represents the various biological species involved in the remediation of LCGW. Microbes like Acidithiobacillus ferrooxidan, Acidithiobacillus thiooxidans, Aspergillus niger, Penicillium bilaiae and other Penicillium sp., and Aspergillus fumigates can efficiently leach out Pb from LCGW (Ehrlich 1997; Pant 2013b).

Phytoremediation techniques are found to be effective for the removal of lead from various contaminants (Blaylock and Huang 2000). In 2005, business associated with phytoremediation received 214–370 million dollars in the USA (Henry 2000). Brassicaceae plays a key role in phytoremediation (Blaylock et al. 1997; Kumar et al. 1994); in a report by Henry (2000), Brassica juncea is capable of removing 11,550 kg of lead per acre. Some other plant species like Ageratum houstonianum Mill., Potamogeton oxyphyllus Miq. and Petris vittata (Ha et al. 2011), Zea mays and Ambrosia artemisiifilia (Huang and Cunningham 1996), and Atriplex halimus L. (Manousaki and Kalogerakis 2009) can also be used for this purpose. Perveen et al. (2011) studied Pb phytoremediation in Jasminum saambac and found that the plant accumulate Pb in the root, leaf, and stem. A recent study on the comparison of lead phytoremediation by two plant species Picea abies and Pinus sylvestris was performed. The result showed that P. sylvestris is more suitable for Pb phytoremediation than P. abies (Maddah and Moraghebi 2013). The phytoremediation potential of a Mediterranean saltbush A. halimus L. was investigated for Pb removal from saline lead-contaminated soils (Manousaki and Kalogerakis 2009). Rhizofiltration is a process to remove toxic substances through the mass of roots from contaminated aqueous samples by absorption, concentration, and precipitation of the metal (Dushenkov et al. 1995). Various wetland species of plants like Carex pendula (Yadav et al. 2011), Pistia stratiotes L., Salvinia auriculata AubL, Salvinia minima Baker, and Azolla filiculoides Lam (Vesely et al. 2011) can efficiently remove lead from contaminated waste water.

Cellular membranes of the plant are lipophilic in nature so the Pb ion cannot move freely across it. For its movement, it requires transporter proteins and chelating agents like phytochelatin (PC), metallothioniens (MT), and organic acids present within the plant. These transporter molecules consist of extracellular binding domains (–COOH) to which Pb ion binds and forms complexes. This facilitates the transfer of Pb from extracellular to the intracellular environment of the plant cell (Blaylock et al. 1997, 1999; Kagi 1991). A fraction of the metal absorbed in the roots may either be sequestered in the root vacuole or it may pass through xylem and gets translocated from the root to the aerial parts (stem and leaves) of the plants (Figs. 8 and 9).

Many marine algae such as Laminaria japonica and Ecklonia radiate; green seaweed such as Ulva, Cladophora crispate, and Caulerpa lentillifera; and freshwater green algal species such as Chlamydomonas reinhardtii, Spirogyra species, and Cladophora fascicularis can also be used for the removal of lead through biosorption.

Earthworm species like as L. rubellus, E. fetida, Eudrilus eugeniae, and Perionyx excavates (Udovic and Lestan 2007; Sinha et al. 2008; Pattnaik and Reddy 2011) are also used for the remediation of lead by the formation of Pb–metallothionein complex which gets concentrated in chloragogen cells of the animal (Ireland 1979).

Thermal remediation

Thermal treatment processes are commonly used to treat mercury-contaminated pollutant by thermal desorption, retorting/roasting (Washburn and Hill 2003; George et al. 1995; Kunkel et al. 2006), or distillation under controlled temperature, pressure, and reactor conditions (Yamaguchi et al. 2005). The resultant mercury vapor thus obtained is condensed and collected (Morris et al. 1995). Table 8 represents mercury removal rate at different experimental sites. This table reveals that thermal desorption of mercury is started at 100 °C but for efficient removal, the temperature should be >460 °C. Chang and Yen (2006) performed onsite pilot plant thermal desorption experiments on mercury-contaminated soils from alkali chlorine factory in Taipei at a cost of 834/m3 US dollar.

Solar energy can also be used for thermal remediation of mercury from contaminants (Navarro et al. 2009). Two thermal desorption systems, constituting low-temperature solar furnace (28–280 °C) and a middle-temperature solar furnace (20–502 °C) were designed for this purpose with removal rate of 4.5–76 and 12.1–87 %, respectively.

Nanotechnology

The advantages of nanotechnology in the field of environmental remediation are inevitable. Nanoparticles have unique properties like their size (10–100 nm), larger surface area, high surface reactivity, and adsorptivity along with photoelectronic and photocatalytic properties which assists in analytical detection and effective remediation of environmental pollutants (Cabrejo and Phillips 2010; Stone et al. 2010; Wang et al. 2010; Nurmi et al. 2009; Liu et al. 2011). Many researchers proved significance of nanoscale zerovalent iron particles for remediation of various heavy metals including lead and mercury, using redox reaction (Eqs. 1, 2, and 3), where metals are reduced while nanoparticles get oxidized ( Zhang 2003; Tratnyek and Johnson 2006; Karn et al. 2009). Iron sulfide (FeS) nanoparticles can be used to immobilize mercury in the mercury-contaminated sites (Wang et al. 2012; Fig. 10). As the standard reduction potential (E0) of mercury (Hg2+/Hg) is 0.85 V which is more than zerovalent iron nanoparticles (Fe2+/Fe = −0.44 V) so it can be reasonably reduced by zerovalent iron nanoparticles.

According to Xiong et al. (2009), FeS nanoparticles (molar ratio of 26.5 FeS to Hg) has the potential to reduce the concentration of mercury up to 97 % in mercury-contaminated substrates, while nanosorbent Fe3O4–silica shows a removal efficiency of 97.34 and 90 % for Pb(II) and Hg(II), respectively (Ambashta and Sillanpaa 2010). Nanoscale formulations of S, Se, Cu, Ni, Zn, Ag, and WS2 were used for in situ capture of Hg vapor from broken CFLs. It is found that unstabilized nanoselenium in two forms (dry powder and impregnated cloth) gave the best result over the other sorbents (Johnson et al. 2008). Functionalized nanoporous ceramic sorbents (mercaptopropyl–trismethoxy silane) having pore sizes (2–10 nm) and very high surface areas (∼1,000 m2/g) are used for the removal of mercury from aqueous waste streams (Mattigod et al. 2006). Citrate-coated gold nanoparticles are used as scavengers for removal of mercury (II) from polluted water (Ojea-Jimenez et al. 2012). In a study by Parham et al. (2012), a method was proposed for fast and efficient removal of mercury from water samples using magnetic iron oxide nanoparticles modified with 2-mercaptobenzothiazole.

The E0 of lead (Pb2+/Pb) is −0.13 V which is more than zerovalent iron (Fe2+/Fe) −0.44 V hence it is possible to reduce lead of LCGW by using zerovalent iron nanoparticles (Fig. 10). Kaolinite-supported nanoscale zerovalent iron can be used to remove high concentration of Pb2+ from aqueous solution with 98 % removal efficiency (Zhang et al. 2010). Resin-supported zero-valent iron nanoparticles (Ponder et al. 2000, 2001) rapidly separate and immobilize Pb(II) from aqueous solution reducing Pb(II) to Pb(0). It was found that the maximum adsorption capacity for Pb(II) ions was 36.0 mg/g by Fe3O4 nanoparticles, which was much higher than that of reported low-cost adsorbents (Nassar 2010).

In addition to self-aggregation, nanoparticles could associate with suspended solids or sediment, thereby can bioaccumulate and enter the food chain or drinking water sources (Karn et al. 2009; Xu et al. 2012). Such uncertainties complicate the assessment of the risks involved in technology over environment and human health (Kotnala 2009).

Hybrid technique

Both chemical and biological remediation of heavy metals have their own limitations as biological leaching (involving microbes) is time taking and complete recovery of metal alone is not possible; on the other hand, chemical leaching have its own environmental consequences. These problems can be overcome by a compatible combination of chemical with biological techniques and these techniques are proposed to be hybrid (Pant et al. 2012). Various chemicals such as EDTA, sodium thiosulfate, thiosulfate, aqua regia, iodide and nitric acid, hydrochloric acid, sodium hydroxide, and potassium iodide have been tested for their ability to uptake and transport mercury from plants (Wang et al. 2011b; Moreno et al. 2004, 2005a; Wallschlger et al. 1998; Wang and Greger 2006). Some possible combinations of hybrid technique for mercury removal are as follows:

-

1.

Chemical leaching (HCl and FeCl3) and volatilization of mercury by bacteria (Nakamura et al. 1999).

-

2.

Addition of 1 mM KI to mercury-contaminated soil increased the mercury concentration in Willow plant by a factor of 5, 3, and 8 times in the leaves, branches, and roots, respectively (Wang and Greger 2006).

-

3.

Chemicals as sodium thiosulfate, ammonium thiocyanate, potassium iodide, EDTA, NTA, dimercaptosuccinic acid, mercaptopropionic acid, mercaptoethanol, thiourea, thiocyanate and hydrogen peroxide, ammonium thiosulfate, and urease for chelating mercury have been used widely to enhance the plant uptake of mercury (Meers et al. 2009; Moreno et al. 2004, 2005a, b; Wang et al. 2011b, Ohki et al. 2003). These chemicals increase the solubility of mercury and enhance the plant uptake of mercury from the soil (Table 9).

Table 9 Hybrid technique for remediation of MCGW

Table 10 represents various hybrid combination for Pb removal with either chemical with microbial or plant combination. Chemical and microbial combinations involving the use of EDTA (Wasay et al. 1998) with either Acidithiobacillus ferrooxidans (Cheikh et al. 2010) or bacterial strain DSM 9103 (Satroutdinov et al. 2000). Many fungi (A. niger, P. bilaiae, and other Penicillium sp.) secrets various organic acids like citric, tartaric, and oxalic acids which can act as chelating agents hence employed for the extraction of Pb (Arwidsson and Allard 2009; Wasay et al. 1998; Elliott and Shastri 1999). Oxalate along with ammonium citrate can be used for the extraction of Pb (Wasay et al. 1998); the efficiency of this process is reasonably enhanced by adding A. niger or Penicillium species (Arwidsson and Allard 2009). Hybrid combination involving chemically assisted phytoextraction is nowadays in practice for the removal and detoxification of Pb from the contaminated sites (Ghosh and Singh 2005; Blaylock and Huang 1999). In order to enhance the availability of Pb in soil and translocation from root to shoot, chelating agents are applied in small doses such as EDTA, DTPA, NTA, CDTA, EDDS, and citric acid (Huang et al. 1997; Saifullah et al. 2009; Grcman et al. 2001, 2003; Puschenreiter et al. 2001; Shen et al. 2002; Kos and Lestan 2003; Luo et al. 2006a, b; Meers et al. 2004, 2005; Tandy et al. 2006). EDTA being the most efficient chelator for Pb is used widely to solubilize Pb in the soil (Salt et al. 1998; Marschner 1995; Vassil et al. 1998). The order of effectiveness in increasing Pb desorption from the soil was EDTA > HEDTA > DTPA > EDDHA (ethylenediamine di(o-hyroxyphenylacetic acid) (Huang et al. 1997). There was a twofold increase in the accumulation of Pb by applying EDTA with acetic acid in Indian mustard shoots as compared with the application of EDTA alone (Blaylock et al. 1997). Plant waste adsorbents like rice husks, spent grain, sugarcane bagasse, fruit wastes, and weeds can be modified chemically by mineral and organic acids, bases, oxidizing agents, and organic compound for the removal of Pb from wastewater (Ngah and Hanafia 2008).

Conclusion

Management issues of heavy metal pollutant from HG are still unimpaired and require special attention due to its hazardous nature. This research proposes possible plans for the management of hazardous glass waste (Fig. 11) by pollutant recovery techniques followed by mechanical treatment. Pollutant recoveries are broadly chemical or biological techniques and can be modified by thermal, nano, and/or hybrid combination. Furthermore, the study has the following outcomes:

-

1.

Mercury pollutants can be managed by dry crushing and heating technology in a fluidized bed reactor, while reduction melting process and mechanochemical sulfidization technique are proposed to recover Pb from funnel glass of CRT.

-

2.

High elemental mercury content can remediate by stabilization/solidification and immobilization involving chemical reactions between the stabilizing agent and the contaminants to reduce Hg mobility.

-

3.

For mercury detoxification, transgenic plants (Arabidopsis and tobacco) are engineered with bacterial genes merB and merA. In these modified plants, merB catalyzes the protonolysis of the carbon–mercury bond with the generation of Hg2+ (100 times less toxic than methyl mercury) and subsequently MerA converts Hg(II) to Hg(0) a less toxic, volatile element.

-

4.

Transporter proteins and chelating agents like PC, MT, and organic acids present within the plant facilitates the transfer of Pb from extracellular to the intracellular environment of the plant cell. These transporter molecules consist of extracellular binding domains (–COOH) to which Pb ion binds and form complexes.

-

5.

In chemical remediation technique, the use of sodium hypochlorite, EDTA, KI/I, coal and coal fly ash, and rice fly ash are found to be more applicable.

-

6.

Thermal treatment processes that are commonly used to treat volatile metals like mercury from contaminated wastes are thermal desorption, retorting/roasting, at a cost of around $834/m3.

-

7.

Solar furnace, constituting low temperature (28–280 °C) and a middle temperature (20–502 °C) have mercury removal capacity of 4.5–76 and 12.1–87 % respectively.

-

8.

Nanoparticles efficiently remove heavy metals by immobilization; for example, nanoscale formulations of S, Se, Cu, Ni, Zn, Ag, and WS2 were used for in situ capture of Hg vapor from broken CFLs, while kaolinite-supported nanoscale zero-valent iron can be used to remove high concentration of Pb2+ from aqueous solution with 98 % removal efficiency.

-

9.

Hybrid combination involves various compatible combination techniques for better and safe removal of metal pollutant from glass. These techniques are found to be most promising both in terms of efficiency and environmental issues. For example, there was a twofold increase in the accumulation of Pb by applying EDTA with acetic acid in Indian mustard shoots as compared with the application of EDTA alone.

-

10.

Plant waste adsorbents like rice husks, spent grain, sugarcane bagasse, fruit wastes, and weeds can be modified chemically by mineral and organic acids, bases, oxidizing agents, and organic compound for the removal of Pb from wastewater.

References

Ahluwalia PK, Nema AK (2006) Multi-objective reverse logistics model for integrated computer waste management. Waste Manage Res 24:514–527

Ajmal M, Rifaqt AK, Siddiqui BA (1995) Adsorption studies and removal of dissolved metals using pyrolusite as adsorbent. Environ Monit Ass 38:25–35

Al-Garni SM, Ghanem KM, Ibrahim AS (2010) Biosorption of mercury by capsulated and slime layer forming Gram nagative bacilli from an aqueous solution. African J Biotech 9:6413–6421

Al-Qahtani KM (2012) Biosorption of Cd+2 and Pb+2 on Cyperus laevigatus: application of factorial design analysis. Life Sci J 9:860–868

Ambashta RD, Sillanpaa M (2010) Water purification using magnetic assistance: a review. J Hazard Mater 180:38–49

Anderson CG, Twidwell LG (2008). The alkaline sulfide hydrometallurgical separation, recovery and fixation of tin, arsenic, antimony, mercury and gold. South Afric Instit Min and Metalur. pp 121–132

Andreola F, Barbieri L, Corradi A, Lancellotti I, Falcone R, Hreglich S (2005a) Glass-ceramics obtained by the recycling of end of life cathode ray tubes glasses. Waste Manage 25:183–189

Andreola F, Barbieri L, Corradi A, Lancellotti I (2005b) Cathode ray tubes recycling: an example of clean technology. Waste Manage Res 23:314–321

Andreola F, Barbieri L, Karamanova E, Lancellotti I, Pelino M (2008) Recycling of CRT panel glass as fluxing agent in the porcelain stoneware tile production. Ceram Int 34:1289–1295

Anjum NA, Ahmad I, Valega M, Pacheco M, Figueira E, Duarte AC, Pereira E (2011) Impact of seasonal fluctuations on the sediment-mercury, its accumulation and partitioning in Halimione portulacoides and Juncus maritimus collected from Ria de Aveiro Coastal Lagoon (Portugal). Water, Air, Soil Pollut 222:1–15

Arulrajah A, Ali M, Piratheepan J, Bo M (2013) Geotechnical performance of recycled glass-waste rock blends in footpath bases. J Mater Civ Eng 25:653–661

Arwidsson Z, Allard B (2009) Remediation of metal-contaminated soil by organic metabolites from fungi II-metal redistribution. Water Air Soil Pollut 207:5–18

Aucott M, McLinden M, Winka M (2003) Release of mercury from broken fluorescent bulbs. J Air Waste Manag Assoc 53:143–151

Azhar N, Ashraf MY, Hussain M, Hussain F (2006) Phytoextraction of lead (Pb) by EDTA application through sunflower (Helianthus annuus L.) cultivation: seedling growth studies. Pak J Bot 38:1551–1560

Baba AA, Adekola FA, Atata RF, Ahemad RN, Panda S (2011) Bioleaching of Zn(II) and Pb(II) from Nigerian sphalerite and galena ores by mixed culture of acidophilic bacteria. Trans Nonf Met Soc Chi 21:2535–2541

Balcar GP, Dunkirk NY (1997). Glass beads having improved fracture toughness. US patent number 5674616

Barbosa FJ, Tanus-Santos JE, Gerlach RF, Parsons PJ (2005) A critical review of biomarkers used for monitoring human exposure to lead: advantages, limitations, and future needs. Environ Health Perspect 113:1669–1674

Barkay T, Susan MM, Summers AO (2003) Bacterial mercury resistance from atoms to ecosystems. FEMS Microbiol Rev 27:355–384

Barrer RM, Whiteman JL (1967) Mercury uptake in various cationic forms of several zeolites. J Chem Soc A Inorg Phys Theor 13:19–25

Bayat B, Sari B (2010a) Bioleaching of dewatered metal plating sludge by Acidithiobacillus ferrooxidans using shake flask and completely mixed batch reactor. African J Biotechnol 9:7504–7512

Bayat B, Sari B (2010b) Comparative evaluation of microbial and chemical leaching processes for heavy metal removal from dewatered metal plating sludge. J Hazard Mater 174:763–769

Bernardo E, Albertini F (2006) Glass foams from dismantled cathode ray tubes. Ceram Int 32:603–608

Bernardo E, Castellan R, Hreglich S, Lancellotti I (2006) Sintered sanidine glass ceramics from industrial wastes. J Eur Ceram Soc 26:3335–3341

Bernardo E, Scarinci G, Hreglich S (2003) Mechanical properties of metal–particulate lead–silicate glass matrix composites obtained by means of powder technology. J Eur Ceram Soc 23:1819–1827

Bernardo E, Scarinci G, Hreglich S (2005) Foam glass as a way of recycling glasses from cathode ray tubes. Glass Sci Technol 8:7–11

Bizily SP, Rugh CL, Meagher RB (2000) Phytodetoxification of hazardous organomercurials by genetically engineered plants. Nat Biotechnol 18:213–217

Bizily SP, Rugh CL, Summers AO, Meagher RB (1999) Phytoremediation of methylmercury pollution: merB expression in Arabidopsis thaliana confers resistance to organomercurials. Proc Natl Acad Sci U S A 96:6808–6813

Blaylock MJ, Elless MP, Huang JW, Dushenkov SM (1999) Phytoremediation of lead-contaminated soil at a New Jersey brownfield site. Remediation 9:93–101

Blaylock MJ, Huang JW (1999) Phytoextraction of metals. In: Raskin I, Ensley BD (eds) Phytoremediation of toxic metals: using plants to clean up the environment. Wiley, New York, pp 53–70

Blaylock MJ, Huang JW (2000) Phytoextraction of metals. In: Raskin I, Ensley BD (eds) Phytoremediation of toxic metals: using plants to clean up the environment. Wiley, New York, pp 53–70

Blaylock MJ, Salt DE, Dushenkov S, Zakharova O, Gussman C (1997) Enhanced accumulation of Pb in Indian mustard by soil-applied chelating agents. Environ Sci Technol 31:860–865

Boening DW (2000) Ecological effects, transport, and fate of mercury: a general review. Chemosphere 40:1335–1351

Bower J, Savage KS, Weinman B, Barnett MO, Hamilton WP, Harper WF (2008) Immobilization of mercury by pyrite (FeS2). Environ Pollut 156:504–514

Brain J (1990) From cups to CAD: a history of glass with CRTs in mind. Inform Display 6:12–15

Brandl H, Bosshard R, Wegmann M (2001) Computer-munching microbes: metal leaching from electronic scrap by bacteria and fungi. Hydrometallurgy 59:319–326

Brenni P (2007) Uranium glass and its scientific uses. Bull Sci Inst Soc 92:34–39

Busto Y, Cabrera X, Tack FMG, Verloo MG (2011) Potential of thermal treatment for decontamination of mercury containing wastes from chlor-alkali industry. J Hazard Mater 186:114–118

Cabrejo E, Phillips E (2010). In situ remediation and stabilization technologies for mercury in clay soils. Student summer internship technical report, DOE-FIU Science & Technology Workforce Development Program, U.S. Department of Energy

Carpi A (1997) Mercury from combustion sources: a review of the chemical species emitted and their transport in the atmosphere. Water Air Soil Pollut 98:241–245

Chang T, Yen J (2006) On-site mercury-contaminated soils remediation by using thermal desorption technology. J Hazard Mater 128:208–217

Chatterjee S, Kumar K (2009) Effective electronic waste management and recycling process involving formal and non-formal sectors. Internat J Physical Sci 4:893–905

Cheikh M, Magnin JP, Gondrexon N, Willisn J, Hassen A (2010) Zinc and lead leaching from contaminated industrial waste sludges using coupled processes. Environ Technol 31:1577–1585

Chen A, Dietrich KN, Huo X, Ho SM (2011) Developmental neurotoxicants in E waste: an emerging health concern. Environ Health Perspect 119:431–433

Chen C, Leea H, Younga KL, Yuea PL, Wong A, Taob T, Choib KK (2002) Glass recycling in cement production—an innovative approach. Waste Manage 22:747–753

Chen M, Zhang F-S, Zhu J (2009) Lead recovery and the feasibility of foam glass production from funnel glass of dismantled cathode ray tube through pyrovacuum process. J Hazard Mater 161:1109–1113

Chen Y (2010) Status and trend of the lighting industry. Zhejiang Zhaoming Dianqi Xinxi 11:12–13 (in Chinese)

Cheng TW, Huang MZ, Tzeng CC, Cheng KB, Ueng TH (2007) Production of coloured glass–ceramics from incinerator ash using thermal plasma technology. Chemosphere 68:1937–1945

Clarkson TW (1993) Mercury: major issues in environmental health. Environ Health Perspect 100:31–38

Conrad K, Hansen HCB (2007) Sorption of zinc and lead on coir. Biores Technol 98:89–97

Coolidge AS (1927) The adsorption of mercury vapor by charcoal. J American Chemical Society 49:1949–1952

Corcoran CH (2001). Communication in Western Electronic Product Stewardship Initiative (WEPSI) Multi-Stakeholder Meeting 3, Portland, OR, USA

CPCB (2008). Technical guidelines for environmentally sound mercury management in FL Sector Central Pollution Control Board, Delhi. www.cpcb.nic.in

Culver A (2008). Mercury content in lamps. Conference Presentation. EBB Conference. Mercury Containing Lamps under the Spotlight. Brussels. Available at: http://zeromercury.org/EU_developments/MercuryContent_in_Lamps.GPI.Brussels.062708.pdf

Cunningham SD, Ow DW (1996) Promises and prospects of phytoremediation. Plant Physiol 110:715–719

Czako M, Feng X, He Y, Liang D, Marton L (2006) Transgenic Spartina alterniflora for phytoremediation. Environ Geochem Health 28:103–110

Dastoor AP, Larocque Y (2004) Global circulation of atmospheric mercury: a modeling study. Atmos Environ 38:147–161

Deng L, Sua Y, Sua H, Wanga X, Zhua X (2007) Sorption and desorption of lead (II) from wastewater by green algae Cladophora fascicularis. J Hazard Mater 143:220–225

Dermont G, Bergeron M, Mercier G, Richer-Lafleche M (2008a) Soil washing for metal removal: a review of physical/chemical technologies and field applications. J Hazard Mater 152:1–31

Dermont G, Bergeron M, Mercier G, Richer-Lafleche M (2008b) Metal-contaminated soils: remediation practices and treatment technologies. Pract Period Hazard Tox Radioact Waste Manage 12:188–210

Dillon P (1998). Potential markets for CRTs and plastics from electronics demanufacturing: an initial scoping report. Chelsea Center for Recycling and Economic Development: Chelsea. pp 1–2

Disfani MM, Arulrajah A, Ali M, Bo M (2011a) Fine recycled glass: a sustainable alternative to natural aggregates. Internat J Geotech Engineer 12:255–266

Disfani MM, Arulrajah A, Bo MW, Hankour R (2011b) Recycled crushed glass in road work applications. Waste Manag 31:2341–2351

Disfani MM, Arulrajah A, Bo MW, Sivakugan N (2012) Environmental risks of using recycled crushed glass in road applications. J Cleaner Production 20:170–179

Dondi M, Guarini G, Raimondo M, Zanelli C (2009) Recycling PC and TV waste glass in clay bricks and roof tiles. Waste Manage 29:1945–1951

Duff JT (2012) An examination into the use of compact fluorescent lamps in the domestic environment. J Sust Eng Des 7:1–12

Durga DK, Veeraiah N (2003) Role of manganese ions on the stability of ZnF2–P2O5–TeO2 glass system by the study of dielectric dispersion and some other physical properties. J Phys Chem of Solids 64:133–146

Dushenkov V, Kumar PBAN, Motto H, Raskin I (1995) Rhizofiltration: the use of plants to remove heavy metals from aqueous streams. Environ Sci Technol 29:1239–1245

Ehrlich HL (1997) Microbes and metals. Appl Microbiol Biotechnol 48:687–692

Elliott HA, Shastri NL (1999) Extractive decontamination of metal-polluted soils using oxalate. Water Air Soil Pollut 110:335–346

Feng Q, Lin Q, Gong F, Sugita S, Shoya S (2004) Adsorption of lead and mercury by rice husk ash. J Colloid Interface Sci 278:1–8

Flora SJS, Flora G, Saxena G (2006) Environmental occurrence, health effects and management of lead poisoning. In: Cascas SB, Sordo J (eds) Lead chemistry, analytical aspects, environmental impacts and health effects. Elsevier, Netherlands, pp 158–228

Fox B, Walsh CT (1982) Mercuric reductase: purification and characterisation of a transposon-encoded flavoprotein containing an oxidation-reduction active disulfide. J Biol Chem 257:2498–2503

Fuhrmann M, Melamed D, Kalb PD, Adams JW, Milian LW (2002) Sulfur polymer solidification/stabilization of elemental mercury waste. Waste Manage 22:327–333

George C, Azwell DE, Adams PA, Rao GVN, Averett DE (1995) Evaluation of steam as a sweep gas in low temperature thermal desorption processes used for contaminated soil clean up. Waste Manage 15:407–416

Geskin ES, Goldenberg B, Caudill R (2002). Development of advanced CRT disassembly technology. In: Proceeding of the international symposium on electronics and the environment. pp. 249–253

Ghorishi B, Gullett BK (1998). An experimental study on mercury sorption by activated carbons and calcium hydroxide. Acurex Environmental Corp., Research Triangle Park, NC; Environmental Protection Agency, Research Triangle Park, NC. Air Pollution Prevention and Control Div. EPA-68-D4-0005; EPA/600/A-98/011, 99 795–808

Ghosh M, Singh SP (2005) A review on phytoremediation of heavy metals and utilization of its byproducts. Appl Ecol Environ Res 3:1–18

Gomez-Serrano V, Macias-Garcia A, Espinosa-Mansilla A, Valenzuela-Calahorro A (1998) Adsorption of mercury, cadmium and lead from aqueous solution on heat-treated and sulphurized activated carbon. Water Res 32:1–4

Grcman H, Velinkonja-Bolta S, Vodnik D, Lestan D (2001) EDTA enhanced heavy metal phytoextraction: metal accumulation, leaching and toxicity. Plant Soil 235:105–114

Grcman H, Vodnik D, Velinkonja-Bolta S, Lestan D (2003) Ethylenediaminedisussuccinate as a new chelate for environmentally safe enhanced lead phytoextraction. J Environ Qual 32:500–506

Gregory J, Nadeau M-C, Kirchain R (2009) Evaluating the economic viability of a material recovery system: the case of cathode ray tube glass. Environ Sci Technol 43:9245–9251

Gupta RK (2007). E-waste recycling and health effects: a review. Centre for Education and Communication—working paper (http://cec-india.org/images/stories/pdf/CECWork_paper/e_waste_report.pdf)

Gupta VK, Rastogi A (2008) Biosorption of lead from aqueous solutions by green algae Spirogyra species: kinetics and equilibrium studies. J hazard Mater 152:407–441

Ha NTH, Sakakibara M, Sano S, Nhuan MT (2011) Uptake of metals and metalloids by plants growing in a lead–zinc mine area Northern Vietnam. J Hazard Mater 186:1384–1391

Hafshejani MK, Khandani F, Heidarpour R, Sedighpour A, Fuladvand H, Shokuhifard R, Arad A (2012) Study of the health threatening mercury effective parameters for its removal from the aqueous solutions by using activated carbons. Life Sci J 9:1789–1791

Hall MJ (1998) Kaolinite sorbent for the removal of heavy metals from incinerated lubricating oils. Project, University of Texas

Harikumar PS, Dhruvan A, Sabna V, Babitha A (2011) Study on the leaching of mercury from compact fluorescent lamps using stripping voltammetry. J Toxicol Environ Health Sci 3:8–13

Hartenstein R, Neuhauser EF, Collier J (1980) Accumulation of heavy metals in the earthworm E. foetida. J Environ Qual 9:23–26

He W, Li G, Ma X, Wang H, Huang J, Xu M, Huang C (2006) WEEE recovery strategies and the WEEE treatment status in China. J Hazard Mater 136:502–512

Heaton ACP, Rugh CL, Wang NJ, Meagher RB (1998) Phytoremediation of mercury and methylmercury-polluted soils using genetically engineered plants. J Soil Cont 7:497–509

Henry JR (2000) An overview of the phytoremediation of lead and mercury, National Network of Environmental Management Studies (NNEMS) Status Report. U.S. EPA Office of Solid Waste and Emergency Response and Technology Innovation, Washington, DC

Hildenbrand VD, Denissen CJM (2000) Interactions of thin oxide films with a low-pressure mercury discharge. Thin Solid Films 371:295–302

Holan ZR, Volesky B (1994) Biosorption of lead and nickel by biomass of marine algae. Biotechnol Bioeng 43:1001–1009

Hong KJ, Tokunaga S, Kajiuchi T (2000) Extraction of heavy metals from MSW incinerator fly ashes by chelating agents. J Hazard Mater 75:57–73

Hong PKA, Li C, Banerji SK, Wang Y (2002) Feasibility of metal recovery from soil using DTPA and its biostability. J Hazard Materi 94:253–272

Hsu E, Kuo C-M (2005) Recycling rates of waste home appliances in Taiwan. Waste Manage 25:53–65

Hu Y, Cheng H (2012) Mercury risk from fluorescent lamps in China: current status and future perspective. Environ Internat 44:141–150

Huang CC, Chen MW, Hsieh JL, Lin WH, Chen PC, Chien LF (2006) Expression of mercuric reductase from Bacillus megaterium MB1 in eukaryotic microalga Chlorella sp. DT: an approach for mercury phytoremediation. Appl Microbiol Biotechnol 72:197–205

Huang JW, Chen J, Berti WR, Cunningham SD (1997) Phytoremediation of lead contaminated soils: role of synthetic chelates in lead phytoextraction. Environ Sci Technol 31:800–805

Huang JW, Cunningham SD (1996) Lead phytoextraction: species variation in lead uptake and translocation. New Phytol 134:75–84

Huang YT, Hseu ZY, Hsi HC (2011) Influences of thermal decontamination on mercury removal, soil properties, and repartitioning of coexisting heavy metals. Chemosphere 84:1244–1249

ICER (2004). Materials recovery from waste cathode ray tubes (CRTs). In: The waste and resource action programme, UK. http://www.icer.org.uk/IcerMaterialsRecoveryFromCRTs.pdf

ICF Incorporated Fairfax (1999) General background document on cathode ray tube glass-to-glass recycling. ICF Incorporated Fairfax VA Office of Solid Waste US Environmental Protection Agency

Imteaz MA, Ali MM, Arulrajah A (2012) Possible environmental impacts of recycled glass used as a pavement base material. Waste Manag Res 30:917–921

Inbaraj BS, Sulochana N (2006) Mercury adsorption on a carbon sorbent derived from fruit shell of Terminalia catappa. J Hazard Mater 133:283–290

INSA (2011). A position paper. Hazardous metals and minerals pollution in India: Sources, toxicity and management. Indian National Science Academy, New Delhi. http://insaindia.org/pdf/Hazardous_Metals.pdf

Ireland MP (1979) Metal accumulation by the earthworms Lumbricus rubellus, Dendrobaena veneta and Eiseniella tetraedra living in heavy metal polluted sites. Environ Pollut 19:201–206

Ireland MP (1983) Heavy metals uptake in earthworms; earthworm ecology. Chapman & Hall, London

Issitt DM (2005). Substance used in making of coloured glass. http://1st-glass.1st-things.com/articles/glasscolouring.html

Jalali R, Ghafourian H, Asef Y, Davarpanah SJ, Sepehr S (2002) Removal and recovery of lead using nonliving biomass of marine algae. J Hazard Mater 92:253–262

Jang M, Hong SM, Park JK (2005) Characterization and recovery of mercury from spent fluorescent lamps. Waste Manage 25:5–14

Jarup L (2003) Hazards of heavy metal contamination. Br Med Bull 68:167–182

Jefferies E (2006) E-wasted. Toys and gadgets become toxic junk thanks to the circuit bored. Worldwatch 19:21–25, Worldwatch Institute www.worldwatch.org

Johnson NC, Manchester S, Sarin L, Gao Y, Kulaots I, Hurt RH (2008) Mercury vapor release from broken compact fluorescent lamps and in situ capture by new nanomaterial sorbents. Environ Sci Technol 42:5772–5778

Kagi JHR (1991) Overview of metallothionein. Methods Enzymol 205:613–626

Kannan N, Kanimozhi R, Xavier A (2010) Studies on the removal of mercury (II)-EDTA complex by coal and coal-flyash belends. Internat J Environ Pollut 30:719–724

Karagiannidis A, Perkoulidis G, Papadopoulos A, Moussiopoulos N, Tsatsarelis T (2005) Characteristics of wastes from electric and electronic equipment in Greece: results of a field survey. Waste Manage Res 23:381–388

Karn B, Kuiken T, Otto M (2009) Nanotechnology and in situ remediation: a review of the benefits and potential risks. Environ Health Perspect 117:1813–1831

Kelly DJA, Budd K, Lefebvre DD (2007) Biotransformation of mercury in pH-stat cultures of eukaryotic freshwater algae. Arch Microbiol 187:45–53

Kim D, Pertrisor IG, Yen TF (2005) Evaluation of biopolymer-modified concrete systems for disposal of cathode ray tube glass. J Air Waste Manage Assoc 55:961–969

King P, Rakesh N, Beenalahari S, Kumar YP, Prasad VSRK (2007) Removal of lead from aqueous solution using Syzygium cumini L.: equilibrium and kinetic studies. J Hazard Mater 142:340–347

Kiyono M, Sone Y, Nakamura R, Pan-Hou H, Sakabe K (2009) The Mer E protein encoded by transposon Tn21 is a broad mercury transporter in Escherichia coli. FEBS Lett 583:1127–1131

Klasson KT, Koran LJ, Jr. Gates DD, Cameron PA (1998). Removal of mercury from solids using the potassium iodide/iodine leaching process. Oak Ridge National Laboratory, U.S. Department of Energy

Kocialkowski WZ, Diatta JB, Grzebisz W (1999) Evaluation of chelating agents as heavy metals extractants in agricultural soils under threat of contamination polish. J Environ Stud 8:149–154

Komura I, Izaki K (1971) Mechanism of mercuric chloride resistance in microorganisms I. Vaporization of a mercury compound from mercuric chloride by multiple drug resistance strain of Escherichia coli. J Biochem 70:885–893

Kos B, Lestan D (2003) Influence of a biodegradable ([S, S]-EDDS) and nondegradable (EDTA) chelate and hydrogel modified soil water sorption capacity on Pb phytoextraction and leaching. Plant Soil 253:403–411

Kotnala RK (2009) New nanotechniques, ethical issues of nanotechnology. Nova Science, New York (Chapter 7). ISBN 978-1-60692-516-4

Kucharski R, Zielonka U, Sas-Nowosielska A, Kuperberg JM, Worsztynowicz A, Szdzuj J (2005) A method of mercury removal from topsoil using low-thermal application. Environ Monit Assess 104:341–351

Kumar J, Srivastava A, Singh VP (2011) EDTA enhanced phytoextraction of Pb by Indian mustard (Brassica juncea L.). Plant Sci Feed 1:160–166

Kumar PBAN, Dushenkov S, Salt DE, Raskin I (1994) Crop Brassicas and phytoremediation—a novel environmental technology. Cruciferae Newsl Eucarpia 16:18–19

Kumar PBAN, Dushenkov V, Motto H, Raskin I (1995) Phytoextraction: the use of plants to remove heavy metals from soils. Environ Sci Technol 29:1232–1238

Kunkel AM, Seibert JJ, Elliott LJ, Ricci-Kelley KLE, Pope GA (2006) Remediation of elemental mercury using in situ thermal desorption (ISTD). Environ Sci Technol 40:2384–2389

Lai HY, Chen ZS (2004) Effects of EDTA on solubility of cadmium, zinc, and lead and their uptake by rainbow pink and vetiver grass. Chemosphere 55:421–430

Lai HY, Chen ZS (2005) The effect of EDTA on phytoextraction of single and combined metals-contaminated soils by rainbow pink. Chemosphere 60:1062–1071

Lai HY, Chen ZS (2007) The effect of multi-dose EDTA application on the phytoextraction of Cd, Zn and Pb by rainbow pink (Dianthus chinensis) in contaminated soil. Desalination 210:236–247

Lairaksa N, Moon AR, Makul N (2013) Utilization of cathode ray tube waste: encapsulation of PbO-containing funnel glass in Portland cement clinker. J Environ Manag 117:180–186

Langford LJ, Ferner RE (1999) Toxicity of mercury. J Human Hypertension 13:651–656

Lee C-H, Chang S-L, Wang K-M, Wen L-C (2007) Present status of the recycling of waste electrical and electronic equipment in Korea. Res Conserv Recycl 50:380–397

Leonard TL, Taylor GE, Gustin MS, Fernandez GCJ (1998) Mercury and plants in contaminated soils: uptake, partitioning, and emission to the atmosphere. Environ Toxicol Chem 17:2063–2071

Li X, Chang C, Kubota T, Qin C, Makino A, Inoue A (2008) Effect of Cr addition on the glass-forming ability, magnetic, mechanical and corrosion properties of (Fe0:76Si0:096b0:096p0:048)100-xCrx bulk glassy alloys. Mater Transac 49:2887–2890

Liebert CA, Watson AL, Summers AO (2000) The quality of merC, a module of the Mer mosaic. J Mol Evol 51:607–622

Lim S-R, Kang D, Ogunseitan OA, Schoenung JM (2013) Potential environmental impacts from the metals in incandescent, compact fluorescent lamp (CFL), and light-emitting diode (LED) bulbs. Environ Sci Technol 47:1040–1047

Liu Y, Su G, Zhang B, Jiang G, Yan B (2011) Nanoparticle-based strategies for detection and remediation of environmental pollutants. Analyst (Cambridge, U K) 136:872–877

Lloyd JR (2002) Bioremediation of metals; the application of micro-organisms that make and break minerals. Microbiol Today 29:67–69

Luo CL, Shen ZG, Baker AJM, Li XD (2006a) A novel strategy using biodegradable EDDS for the chemically enhanced phytoextraction of soils contaminated with heavy metals. Plant Soil 285:67–80

Luo CL, Shen ZG, Li XD, Baker AJM (2006b) Enhanced phytoextraction of Pb and other metals from artificially contaminated soils through the combined application of EDTA and EDDS. Chemosphere 63:1773–1784

Luo F, Liu Y, Li X, Xuan Z, Ma J (2007) Biosorption of lead ion by chemically modified biomass of marine brown alga Laminaria japonica. Chemosphere 64:1122–1127

Luther L (2008). Compact fluorescent light bulbs (CFLs): issues with use and disposal. CRS report for congress.

Luz AP, Ribeiro S (2007) Use of glass waste as a raw material in porcelain stoneware tile mixtures. Ceramics Int 33:761–765

Maddah SM, Moraghebi F (2013) The comparisons between Picea abies and Pinus sylvestris in respect of lead phytoremediation potential. Internat J Biosci 3:35–41

Manousaki E, Kalogerakis N (2009) Phytoextraction of Pb and Cd by the Mediterranean saltbush (Atriplex halimus L.): metal uptake in relation to salinity. Environ Sci Pollut Res Int 16:844–854

Marques B, Lillebo AI, Pereira E, Duarte AC (2011) Mercury cycling and sequestration in salt marshes sediments: an ecosystem service provided by Juncus maritimus and Scirpus maritimus. Environ Pollut 159:1869–1876

Marschner H (1995) Mineral nutrition of higher plants. Academic, London

Maschio S, Tonello G, Furlani E (2013) Recycling glass cullet from waste CRTs for the production of high strength mortars. J Waste Manag. doi:10.1155/2013/102519

Massacci P, Piga L, Ferrini M (2000) Applications of physical and thermal treatment for the removal of mercury from contaminated materials. Miner Eng 13:963–967

Matheickal JT, Yu Q (1996) Biosorption of lead from aqueous solutions by marine algae Ecklonia radiate. Water Sci Technol 34:1–7

Matteucci F, Dondi M, Guarini G (2002) Effect of soda-lime glass on sintering and technological properties of porcelain stoneware tiles. Ceramics Internat 28:873–880

Mattigod SV, Fryxell GE, Skaggs R, Parker KE (2006) Functionalized nanoporous ceramic sorbents for removal of mercury and other contaminants. NSTI-Nanotech 1:355–357

McLellan GW, Shand EB (1984) Glass engineering handbook. McGraw-Hill, Inc

Meagher RB (2000) Phytoremediation of toxic elemental and organic pollutants. Curr Opin Plant Biol 3:153–162

Mear F, Yot P, Cambon M, Ribes M (2006) The characterization of waste cathode-ray tube glass. Waste Manage 26:1468–1476

Mear FO, Yot PG, Kolobov AV, Ribes M, Guimon G-M, Gonbeau D (2007) Local structure around lead, barium and strontium in waste cathode-ray tube glasses. J Non-Crystalline Solids 353:4640–4646

Meers E, Hopgood M, Lesage E, Vervaeke P, Tack FMG, Verloo MG (2004) Enhanced phytoextraction: in search of EDTA alternatives. Int J Phytoremediat 6:95–109

Meers E, Lesage E, Lamsal S, Hopgood M, Vervaeke P, Tack FMG, Verloo MG (2005) Enhanced phytoextraction: I. Effect of EDTA and citric acid on heavy metal mobility in a calcareous soil. Int J Phytoremediat 7:129–142

Meers E, Qadir M, De-Caritat P, Tack F, Du-Laing G, Zia M (2009) EDTA-assisted Pb phytoextraction. Chemosphere 74:1279–1291

Menad N (1999) Cathode ray tube recycling. Res Conserv Recycl 26:143–154

Misra TK (1992) Bacterial resistance to inorganic mercury salts and organomercurials. Plasmid 27:4–16

Mizuki C, Pitts G, Aanstoos T, Nichols S (1997). CRT disposition: an assessment of limitations and opportunities in reuse, refurbishment, and recycling. In: U.S. Proceedings of the 1997 I.E. International Symposium on Electronics and the Environment. 73–78

Monchamp A, Evans H, Nardone J, Wood S, Proch E, Wagner T (2001). Cathode ray tube manufacturing and recycling: analysis of industry survey. Electronic Industries Alliance Arlington, VA, USA

Monika JK (2010) E-waste management: as a challenge to public health in India. Indian J Community Med 35:382–385

Monitor of the electronics recycling issues (2001) CRT glass to CRT glass recycling. In: Materials for the Future Foundation Issue #1, September 2001. http://www.epa.gov/epaoswer/non-hw/reduce/wstewise/pubs/g2gfinal.pdf

Morby AP, Hobman JL, Brown NL (1995) The role of cysteine residues in the transport of mercuric ions by the Tn501 MerT and MerP mercury-resistance proteins. Mol Microbiol 17:25–35

Moreno FN, Anderson CWN, Stewart RB, Robinson BH, Ghomshei M, Meech JA (2005a) Induced plant uptake and transport of mercury in the presence of sulphur-containing ligands and humic acid. New Phytol 166:445–454

Moreno FN, Anderson CWN, Stewart RB, Robinson BH, Nomura R, Ghomshei M, Meech JA (2005b) Effect of thioligands on plant–Hg accumulation and volatilisation from mercury-contaminated mine tailings. Plant Soil 275:233–246

Moreno FN, Anderson CWN, Stewart RB, Robinson FN (2004) Phytoremediation of mercury-contaminated mine tailings by induced plant–mercury accumulation. Environ Pract 6:165–175

Moreno-Jimenez E, Gamarra R, Carpena-Ruiz RO, Millan R, Pealosa JM, Esteban E (2006) Mercury bioaccumulation and phytotoxicity in two wild plant species of Almaden area. Chemosphere 63:1969–1973

Morris M, Sams R, Gillis G, Helsel R, Alperin E, Geisler T, Groen A, Root D (1995) Bench and pilot-scale demonstration of thermal desorption for removal of mercury from the Lower East Fork Poplar Creek Floodplain soils CONF-950216-129. Martin Marietta Energy Systems, Oak Ridge, TN

Mostaghel S, Samuelsson C (2010) Metallurgical use of glass fractions from waste electric and electronic equipment (WEEE). Waste Manag 30:140–144

Mueller JR, Boehm MW, Drummond C (2012) Direction of CRT waste glass processing. Electron Recycl Ind Commun 32:1560–1565

Mulligan CN, Kamali M (2003) Bioleaching of copper and other metals from low grade oxidized mining ores by Aspergillus niger. J Chem Technol Biotech 78:497–503

Musson SE, Jang Y-C, Townsend TG, Chung I-H (2000) Characterization of lead leachability from cathode ray tubes using the toxicity characteristic leaching procedure. Environ Sci Technol 34:4376–4381

Nagib S, Inoue K (2000) Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching. Hydrometallurgy 56:269–292

Naiya TK, Bhattacharya AK, Mandal S, Das SK (2009) The sorption of lead(II) ions on rice husk ash. J Hazard Mater 163:1254–1264

Nakamura K, Hagimine M, Sakai M, Furukawa K (1999) Removal of mercury from mercury contaminated sediments using a combined method of chemical leaching and volatilization of mercury by bacteria. Biodegradation 10:443–444

Nance P, Patterson J, Willis A, Foronda N, Dourson M (2012) Human health risks from mercury exposure from broken compact fluorescent lamps (CFLs). Regul Toxicol Pharmacol 62:542–552

Nassar NN (2010) Rapid removal and recovery of Pb(II) from wastewater by magnetic nanoadsorbents. J Hazard Mater 184:538–546

Navarro A, Caadas I, Martinez D, Rodriguez J, Mendoza J (2009) Application of solar thermal desorption to remediation of mercury-contaminated soils. Sol Energy 83:1405–1414

Newmoa (2008). Northeast Waste Management Officials Association. mercury use in lighting. Factsheet. Northeast Waste Management Officials’ Association, Boston, USA. http://www.newmoa.org/prevention/mercury/imerc/FactSheets/lighting.cfm

Ngah WSW, Hanafia MAKM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Bioresour Technol 99:3935–3948

Nhapi I, Banadda N, Murenzi R, Sekomo CB, Wali UG (2011) Removal of heavy metals from industrial wastewater using rice husks. Open Environ Eng J 4:170–180

Niinae M, Nishigaki K, Aoki K (2008) Removal of lead from contaminated soils with chelating agents. Mater Trans 49:2377–2382

Nnorom IC, Osibanjo O (2009) Toxicity characterization of waste mobile phone plastics. J Hazard Mater 161:183–188

Nnorom IC, Osibanjo O, Nnorom SO (2007) Achieving resource conservation in electronic waste management: a review of options available to developing countries. J Appl Sci 20:2918–2933

Nnorom IC, Osibanjo O, Okechukwu K, Nkwachukwu O, Chukwuma RC (2010) Evaluation of heavy metal release from the disposal of waste computer monitors at an open dump. Internat J Environ Sci Dev 1:227–233

Nnorom IC, Osibanjob O, Ogwuegbua MOC (2011) Global disposal strategies for waste cathode ray tubes. Resour Conserv Recycl 55:275–290

Noon MS, Lee S-J, Cooper JS (2011) A life cycle assessment of end-of-life computer monitor management in the Seattle metropolitan region. Resour Conserv Recycl 57:22–29

Nortemann B (2005) Biodegradation of chelating agents: EDTA, DTPA, PDTA, NTA, and EDDA, Chapter 8: biogeochemistry of chelating agents. In: Nowack B, VanBriesen JM (eds) ACS Symposium Series 910. American Chemical Society, Washington, D.C., pp pp 150–pp 169

Nurmi JT, Tratnyek PG, Sarathy V, Baer DR, Amonette JE, Pecher K, Wang C, Linehan JC, Matson DW, Penn RL, Driessen MD (2009) Characterization and properties of metallic iron nanoparticles: spectroscopy, electrochemistry, and kinetics. Environ Sci Technol 39:1221–1230

Ohki A, Iwashita A, Tanamachi S, Nakajima T, Takanashi H (2003) Removal of mercury from coal by mild pyrolysis and chelate extraction. Fuel Chem Division Preprints 48:354–355

Ojea-Jimenez I, Lopez X, Arbiol J, Puntes V (2012) Citrate-coated gold nanoparticles smart scavengers for mercury(II) removal from polluted waters. ACS Nano 6:2253–2260

Okada T, Yonezawa S (2013) Energy-efficient modification of reduction-melting for lead recovery from cathode ray tube funnel glass. Waste Manag 33:1758–1763

Orumwense FFO (1996) Removal of lead from water by adsorption on a kaolinitic clay. J Chem Tech Biotech 65:63–69

Otani Y, Kanaoka C, Emi H, Uchijima I, Nishino H (1998) Removal of mercury vapor from air with sulfur-impregnated adsorbents. Environ Sci Technol 22:708–711

Oubagaranadin JU, Sathyamurthy N, Murthy ZVP (2007) Evaluation of Fuller’s earth for the adsorption of mercury from aqueous solutions: A comparative study with activated carbon. J Hazard Mater 142:165–174

Ozer D, Asksu Z, Kutsal T, Caglar A (1994) Adsorption isotherms of lead(II) and chromium(VI) on Cladophora crispate. Environ Technol 15:439–448

Pacholewska M (2004) Bioleaching of galena flotation concentrate. Physicochem Pro Min Process 38:281–290

Paez-Hernandez ME, Aguilar-Arteaga K, Galan-Vidal CA, Palomar-Pardave M, Romero-Romo M, Ramirez-Silva MT (2005) Mercury ions removal from aqueous solution using an activated composite membrane. Environ Sci Technol 39:7667–7670

Pant D (2009) Waste glass as absorbent for thin layer chromatography (TLC). Waste Manage 29:2040–2041

Pant D (2013a) E-waste projection using life span and population statistics. Int J Life Cycle Assess 18:1465–1469

Pant D (2013b). A review of electronic waste management microbial participation: a green technology. Int J Env Waste Manag. http://www.inderscience.com/info/ingeneral/forthcoming.php?jcode=ijewm

Pant D, Joshi D, Upreti MK, Kotnala RK (2012) Chemical and biological extraction of metals present in E waste: a hybrid technology. Waste Manage 32:979–990

Pant D, Singh P (2013) Chemical modification of waste glass from cathode ray tubes (CRTs) as low cost adsorbent. J Environ Chem Engineer 1:226–232

Parham H, Zargar B, Shiralipour R (2012) Fast and efficient removal of mercury from water samples using magnetic iron oxide nanoparticles modified with 2-mercaptobenzothiazole. J Hazard Mater 205–206:94–100

Parsons D (2006) The environmental impact of compact fluorescent lamps and incandescent lamps for Australian conditions. Environ Eng 7:8–14