Abstract

Purpose

Various publications indicate that the operation of laser printers and photocopiers may be associated with health effects due to the release of gaseous components and fine and ultrafine particles (UFP). However, only sparse studies are available that evaluate the possible exposure of office workers to printer emissions under real conditions. Therefore, the aim of our study was to assess the exposure of office workers to particulate matter released from laser printers and photocopiers.

Methods

Concentrations of fine particles and UFP were measured before, during, and after the operation of laser printing devices in 63 office rooms throughout Germany. Additionally, the particles were characterized by electron microscopy and energy-dispersive X-ray spectroscopy.

Results

A significant increase of fine particles and UFP was identified in ambient workplace air during and after the printing processes. Particle fractions between 0.23 and 20 μm emitted by the office machines significantly affect particle mass concentrations while printing 500 pages, i.e., during the printing process, PM0.23–20, PM2.5, and PM10 concentrations increased in 43 out of the evaluated 62 office rooms investigated. Additionally, a significant increase was observed in submicrometer particles, with median particle number concentrations of 6,503 particles/cm3 before and 18,060 particles/cm3 during the printing process.

Conclusions

Our data indicate that laser printers and photocopiers could be a relevant source of fine particles and particularly UFP in office rooms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, exposure to toner dust and volatile organic compounds (VOC) emitted into the air of office rooms during operation and maintenance of laser printers or photocopiers has been discussed as a possible cause of health complaints, not only those affecting the respiratory tract, but also the immunological and nervous systems (Ewers and Nowak 2006; Gminski and Mersch-Sundermann 2006; Wolkoff et al. 1992).

While so far there is no evidence showing a relationship between emissions from printers and photocopiers and health effects, test chamber investigations and indoor air measurements have been conducted to define typical emissions from these office machines. The studies have shown that not only significant amounts of fine particles and ultrafine particles (UFP) are released into ambient air, but also gases such as ozone and various VOC (Caesar and Schmitt 2009; He et al. 2007; Kagi et al. 2007; Lee et al. 2001; Morawska et al. 2009; Schripp et al. 2008; Wensing et al. 2008; Wolkoff 1999). Additionally, a study published by He et al. (2007) found that almost one third of 62 printers investigated for particle emissions released high levels of UFP with diameters <100 nm. Numerous other studies in different parts of the world have found similar results (Kagi et al. 2007; Lee and Hsu 2007; Schripp et al. 2009; Wensing et al. 2008).

Particles with an aerodynamic diameter of <2.5 μm (and VOC) reach the lower respiratory tract, and consequently, the small airways of the lungs after inhalation of polluted indoor air. Under consideration of studies dealing with the biological effects of fine particles and UFP (Nel et al. 2006; Schulz et al. 2005), inhaled particles of laser printers may pose health risks in humans. Symptoms such as rhinitis, sore throat, initiation of asthma attacks, and pseudoallergic inflammations of the respiratory tract as well as irritations of the skin and eyes, headache, and sick building syndrome are suspected to be associated with exposure to laser printer emissions (Gminski and Mersch-Sundermann 2006).

The results of the chamber emission studies mentioned above demonstrate the need to investigate the influence of laser printer and photocopier operation on the quality of indoor air under real office conditions. However, resilient studies on printer and photocopier emissions in office rooms are still relatively scarce (Kagi et al. 2007; Schripp et al. 2009; Stefaniak et al. 2000; Wensing et al. 2008). Currently, only two field studies (Fiedler et al. 2009; McGarry et al. 2011) are available, of which the former was only published in the German language.

Therefore, the objective of the present study, which was commissioned by the German Federal Institute for Risk Assessment (BfR), was to investigate the quality of indoor air at the workplace in a representative number of office rooms to obtain information on the concentrations of airborne particulates emitted by laser printers and photocopying machines (referred to as printers in the following) during the printing process.

2 Methods

Particle release into the ambient air of 63 German office rooms before, during, and after printer operation was investigated between January and October 2006.

2.1 Sampling sites and buildings

Sixty-three offices in 9 multifloor, frequently air-conditioned office buildings were investigated at four locations in Germany, i.e., Gießen (Central), Freiburg (South), Trier (West), and Berlin (North). All the offices were government-run. Information on general conditions in the offices were collected by a standardized questionnaire, which included important facts such as the size of the rooms, the number of occupants, type and material of furniture, types of printers and photocopiers used, etc.

2.2 Laser printer and photocopier models used

A total of 59 laser printers and 4 photocopiers of different makes and models were tested. Most were tabletop units; some, however, were high-throughput, floor-mounted devices. All the devices were from current series production.

2.3 Measurement of particle concentrations and their characteristics

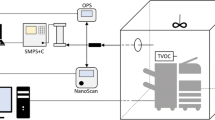

2.3.1 Particle monitoring

Continuous measurements were taken of number concentrations of particles with an optical diameter between 0.23 and 20 μm (PM0.23–20) using an optical laser aerosol spectrometer (LAS; Dust Monitor, Model 1.108, Grimm Technologies Inc., Ainring, Germany). The number concentration of the particles was determined for 15 different channels (sampling interval, 6 s). Data conversion from particle number (PN) concentrations to mass concentrations was achieved under the premise of spherical particles using Eq. 1:

where N i is the number concentration of particles, M i is the mass concentration, and D i is the geometric mean diameter of the i-th channel. ρ is the mean density estimated by gravimetry performed before printer measurements in selected rooms of the four locations using the gravimetric unit integrated in the Grimm aerosol spectrometer.

PM2.5 and PM10 were calculated using Eq. 2 as described by Grimm Technologies Inc.:

where F i is the weighting factor of the i-th channel. To calculate PM10, the factor is 1 for channels 1 to 7 and 0.942, 0.922, 0.893, 0.8345, 0.724, 0.4486, 0.041, and 0, respectively, for channels 8 to 15. To calculate PM2.5, the factor is 1 for channels 1 to 6 and 0.995, 0.855, and 0.48, respectively, for channels 7 to 9; the factor is 0 for channels 10 to 15.

In recent studies, the Grimm model 1.108 was compared to other optical particle counters, and PM10 and PM2.5 measurements were determined to be accurate (Cheng 2008; Peters et al. 2006).

For continuous measurement of the total number concentrations of submicrometer particles (0.01 to 1 μm), a condensation particle counter (CPC; Model TSI 3007, TSI Incorporated, St. Paul, USA) was used (measurement interval, 1 s).

2.3.2 Particle morphology and element composition analysis

Particle morphology, geometric size, and element composition were analyzed by scanning electron microscopy/energy-dispersive X-ray spectroscopy (SEM-EDX; Hitachi S2300, Hitachi, Japan) and transmission electron microscopy (TEM; Hitachi H600, Hitachi, Japan). SEM imaging was performed with 1,000-fold and 10,000-fold magnification; standardized TEM imaging was performed with 40,000-fold magnification as described by Rödelsperger et al. (2003). Both toner powder from the cartridges and air samples from the office rooms were analyzed. Particles in air samples were collected with nucleopore filters (flow rate, 1.2 mL/min; sampling time, between 30 and 50 min). For direct analyses of the filter deposits by TEM, 50 vision fields were evaluated for each filter. The concentrations of primary particles (PT), aggregates and agglomerates (A + A) as well as the mass-weighted PT diameters were determined.

2.4 Study design

To monitor the particle concentrations in the office rooms, the Grimm particle counter 1.108 and the TSI CPC 3007 were placed in the middle of a desk to include the office worker’s normal breathing zone. The two devices were placed about 1 m apart. Before each measurement, the windows and doors of the respective office were closed for the whole night. Staff were not permitted to enter the room during the night or before the measurement. This standard procedure for indoor air measurements is useful to minimize the influence of outdoor particles on the indoor environment. During standby and printing measurements, the experimenter was advised to minimize any movement to avoid particle release from the floor and other surfaces. Additionally, analytical staff wore particle-free protective clothing.

According to the definition given by the Standard ECMA-328 (ECMA International 2007), the printers under test were switched on during the preoperation period. Continuous particle measurement by LAS and TSI CPC 3007 was initiated about 30 min before starting the printing process, i.e., during the standby period. Thus, measurements were done before (standby phase), during (printing phase), and after (working phase) the printing process. In order to simulate worst case but realistic conditions commonly encountered in normal office rooms, 500 pages were printed with each printer during the printing phase.

For the printing procedure, a standard page with 5% black covering was used according to DIN 33870. The printers operated at normal speed; thus, it took 10 to 100 min to complete the printing process (see Supplemental Material Table 1). If available, the room ventilation system was switched on during the measurements.

SEM and TEM analyses were performed exemplarily for three offices in which particle collection was carried out during the printing process.

2.5 Statistical methods

All the statistical analyses were conducted with SPSS software, version 15.0™ (SPSS Inc., Chicago, IL, USA). Paired t tests on particle mass (PM) and PN concentrations were performed at a 95% confidence level to examine the differences in results obtained for the standby, printing, and working phases. The Kolmogorov–Smirnov test, which considers the normal distribution of data, was conducted beforehand to ensure that data on the differences between the three phases could be processed by paired t test. Significance was accepted for P < 0.05.

3 Results

3.1 Conditions in the office rooms

The conditions in the office rooms varied considerably in terms of size, furnishing, and equipment. The office volumes ranged from 20 to 170 m3. One of the investigated offices was an open-plan room with a volume of about 1,000 m3. The offices were occupied by 1 or 2 persons, and in the case of the open-plan office, by 17 persons. The furnishing consisted of file cabinets, chairs, and desks. As electronic devices, desktop computers, laser printers, photocopiers, and telephone/fax machines were present in most of the office rooms. Some rooms had wood or carpet floorings, while others had PVC or linoleum. Smoking was not permitted in any of the office rooms.

Neither the background particle concentrations nor their development after starting the printing process showed a relationship to the recorded room conditions (Supplemental Material Table 1).

3.2 Particle mass concentrations

Altogether, PM concentrations in the office rooms ranged between 19.1 and 231 μg/m3. In comparison to the standby phase, 43 of the 62 investigated office rooms from which a full data set was obtained, i.e., about 70%, showed an increase in PM0.23–20 particles during the printing process. In 16 of 62 (26%) office rooms, the PM0.23–20 concentration decreased slightly during the printing process, while 3 rooms (5%) did not show any significant difference between the standby and printing phases (Fig. 1). Thus, significantly higher (P < 0.001) mean concentrations were observed during the printing and working phases than during the standby phase related to all PM parameters (Table 1).

PM0 .23–20 concentrations of operation-specific phases (standby phase, printing phase, and working phase) expressed as the mean ± SD in the indoor air of 62 office rooms (A1–A12 rooms in the office building in Gießen, B13–B26 rooms in the six office buildings in Berlin, C27–C37 rooms in the office building in Freiburg, D38–D63 rooms in the two office buildings in Trier). Due to a technical failure, data from C-30 are missing

3.3 Particle number concentrations

Especially the PN concentrations of the small particles increased in the course of the printing phase (Supplemental Material Tables 1 and 2, showing the mean PN concentrations of the smallest fractions measured by LAS). When the office staff entered the room and started working immediately after the printing phase—often opening the windows because of poor air quality—the average values of these small particle fractions further considerably increased.

Figure 2 shows, on the example of room D-48, the time-dependent changes in the PN concentrations regarding the different particulate fractions. Soon after printing started, the PM0.23–0.3 concentration increased from a background concentration of about 150 particles/cm3 to 270 particles/cm3 at the end of the printing process. After printing stopped, the airborne particle count for this size fraction increased to a maximum of 320 particles/cm3 and then slowly decayed. This example demonstrated that small particles may persist in the office air after printing and may, therefore, be responsible for at least part of the particle burden.

Determination of submicrometer particles was accomplished in 31 out of the 63 offices investigated. Altogether, the PN concentrations of UFP ranged between 1,000 and 80,000 particles/cm3. In comparison to the standby phase, the PN concentration of UFP was found to be significantly higher (P < 0.001) during the printing process in 30 of the 31 rooms (Supplemental Material Fig. 1). During the working phase, the mean PN concentration of UFP unexpectedly but significantly decreased in comparison to the printing phases (Table 1).

In Fig. 3, the time-dependent changes in UFP concentrations are exemplarily shown for office room B-14. In this case, the PN concentrations increased as an “initial burst” to a nearly 20-fold increase in UFP PN concentration immediately after print start. Maximum UFP concentrations were reached after approximately 2 min of printing, with 190,000 particles/cm3 being detected in the ambient air. In contrast, only 10,000 particles/cm3 were found before and after printing.

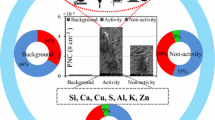

3.4 SEM-EDX and TEM results

The toner particle diameters were in the range of 10 μm, while the measurements of particles from indoor air merely show UFP (Fig. 4). However, submicrometer particles can also be observed in the toner powder, as shown in Fig. 4, especially on the surfaces of the coarser particles. This observation is in agreement with SEM analyses of toner powder conducted by Caesar and Schmitt (2009) and Gminski et al. (2011), which show that the micrometer-sized toner particles are covered by UFP.

The element composition measured by EDX shows that iron is the most abundant element in the investigated toner material (Supplemental Material Fig. 2). Silicon was also detected in the original toner powders. While the iron originates from the black colorant, silica particles are used as charge control additives (Pettersson and Fogden 2005). In contrast to toner material, iron did not play a role in the aggregates and agglomerations (A + A) found in the air samples; those particles consisted mainly of silicon and aluminum (Supplemental Material Fig. 4). In order to explain this discrepancy, both toner materials and air samples were reanalyzed with TEM. EDX element spectra showed element contents in the order Fe >> Al > Si for the large black toner particles, whereas Fe, Si > Al was identified for the optically smaller toner components. If it represents the dominant fraction in the large black particles, iron may possibly interfere with the analysis of other elements.

Both the EDX results for the sampled aerosols and the toner material agree with the XRF analysis results of Barthel et al. (2011). However, due to the better sensibility of their method, they detected additional elements, e.g., Ca, Cl, and Br, which were attributed to the paper and to the flame retardants used in the printing devices.

As shown in Table 2, the CPC measurements produced significantly higher PN concentrations, i.e., around 100 times higher for A + A and about 10 times higher for PT concentrations in comparison to the quantitative UFP analyses by TEM.

4 Discussion

The present study revealed elevated concentrations of fine particles and UFP at office workplaces due to the use of laser printers. However, a large variation in PM concentrations was observed between the different office rooms investigated. Various factors, e.g., printer, toner, paper type, and maintenance cycles or air exchange rate, may affect particle concentrations. Similar conclusions have also been drawn by authors of recent publications (Fiedler et al. 2009; Schripp et al. 2009; Stefaniak et al. 2000; Wensing et al. 2008).

The results of particle measurements showed that the mean concentrations of particulate pollution in the investigated office rooms were in the same range as reported for other rooms, e.g., classrooms (Fromme et al. 2007), private residential buildings (Morawska and Salthammer 2003), or office rooms in Australia (He et al. 2007). A study of other typical indoor activities in a 60-m3 laboratory room under controlled conditions yielded comparable or higher PM and PN concentrations for processes such as candle burning or onion frying (Glytsos et al. 2010). However, it should be noted that, depending on the distance of the workplace to the printer exhaust vent, for study design reasons, the measurements were either taken “near to source” or “far from source.” Therefore, from a statistical point of view, the results may by all means not reflect comparable mean concentrations in the offices under investigation. However, that was not the goal of the study.

The study allows an assessment of the exposure levels of the office workers under investigation; also, the results can be transferred to other office rooms with similar architecture. Destaillats et al. (2008) pointed out that aerosol particle levels were close to background room levels at a distance of 1.5 m from the printer. McGarry et al. (2011) also found a clear dependence of PN concentrations from the distance of the measurement points to the printers they investigated in office rooms. Therefore, possible health effects caused by emissions can be prevented by positioning the office devices at a safe distance.

Some studies have suggested that aerosolized toner powder, normally of a diameter >10 μm, can be emitted from printers (Caesar and Schmitt 2009; Lee et al. 2001; Wolkoff 1999). In contrast, Lee and Hsu (2007) found that the mean aerodynamic particle diameter shifted from 10.4 μm during the standby phase to 7.1 μm during the printing phase. In our study, the partial increase in the PM concentration of coarse particles, i.e., particles with a diameter of >10 μm, seems to be consistent with results of the studies suggesting that particulate matter emitted by laser printers consists of aerosolized toner powder that does not adhere to the photoconductive drum. However, if the PN is assessed instead of the PM, the fine particle fraction, i.e., particles with a diameter of <0.5 μm, shows a significantly stronger increase than the coarse fraction, pointing at further, albeit printing-related, sources of particle emission.

Generally, it is more probable that fragments or aggregates melted in the fuser unit are released into the indoor air rather than whole, undamaged toner particles. This assumption is in accordance with results obtained by Morawska et al. (2009), Caesar and Schmitt (2009), and Barthel et al. (2011). Comprehensive examination of the chemical composition of the toner material and the particles emitted from the printer in the latter two studies revealed distinct signs for a toner-based origin of a part of the emitted particles.

In addition to the fine particles, we measured distinct release of submicrometer UFP in the office rooms during the printing process. This is also in good accordance with other printer emission studies for office rooms (Fiedler et al. 2009; He et al. 2007; McGarry et al. 2011; Schripp et al. 2009). The authors of these studies noted that UFP emissions varied substantially even among the same printer models. Fiedler et al. (2009) and Schripp et al. (2009) concluded that there are many factors influencing the temporal development and distribution of particulate printer emissions, such as the printer use history, type of paper used, air flow and exchange rate in the room, and background concentrations, and that it is not possible to transfer test chamber results to real room conditions. On the basis of our results, we agree with this statement.

Furthermore, the number of pages printed may have an impact on the resulting maximum particle concentrations. But, according to the study by Wensing et al. (2008) and the temporal change of particle concentrations observed in the studied office rooms (Figs. 2 and 3), we assume that comparable curve progressions would result and that only the maximum concentrations reached after the initial phase of concentration increase would differ, if a different number of pages had been printed.

In many offices, the submicrometer PN concentrations increased significantly by about 1.1 to 42 times after printing process start and, in most cases, decreased to near background level by the end of the printing phase. This phenomenon of high peak concentrations soon after printing operation start was first identified as an “initial burst” within the scope of our investigations and has meanwhile been confirmed by controlled chamber measurements (He et al. 2007; Koivisto et al. 2010; Morawska et al. 2009; Schripp et al. 2008, 2009; Wensing et al. 2008). The origin and significance of the “initial burst” have not yet been explained, but may be caused by condensation of VOC. The suggestion was supported by the results obtained by Morawska et al. (2009) and He et al. (2010), which indicate a correlation between temperature fluctuations in the fuser roller and peaks in particle release. Presumably, the measured aerosols are at least partially made up of condensates and microaggregates of various substances, e.g., silicone oils, VOC, or semivolatile organic compounds (SVOC) or their oxidation products.

Such UFP are assumed to be formed during toner fixation. This process involves heating the fuser roller and the toner powder adhering to it as well as the paper and may result in a release of VOC, which are then possibly nucleated to form particles. The formation mechanisms of the printer-based UFP and their chemistry were intensely discussed by Lee and Hsu (2007), Morawska et al. (2009), and Wensing et al. (2008). In order to cast more light on this phenomenon, we performed electron microscope analyses of selected toners and office air samples.

In accordance with other studies (Barthel et al. 2011; Caesar and Schmitt 2009; Gminski et al. 2011), our SEM and TEM results show that the toner powders also contain submicrometer particles. Under consideration of the EDX results, the size distribution of solid particles sampled during the printing process in the office room air—with a large part in the UFP range—suggests that at least part of the printer emissions originates from toner powder.

However, the distinctly higher UFP concentrations measured by CPC than by electron microscopy indicate that liquid or volatile aerosols presumably account for the greatest portion of laser printer emissions. The aerosol formation from condensation and coagulation processes of VOC and SVOC originating from the chassis, fuser chemicals, paper, or toner that remained on the fuser roller is supported by reports on the missing correlation between particle emissions and toner consumption. Thus, the concentrations of UFP emitted showed no correlations with the toner coverage on the printed paper or the number of pages printed (Morawska et al. 2009; Schripp et al. 2008). As shown by Wensing et al. (2008), even the use of a modified printer without paper and toner resulted in no significant differences in particle emission behavior. Additionally, investigations of the chemical composition of the particles emitted from printers (Morawska et al. 2009; Wensing et al. 2008) and of VOC and particles released from individual heated components of printers (Barthel et al. 2011; Morawska et al. 2009) indicate that the greatest proportion of printer emissions can be explained in this way.

If our results for the office rooms are compared to other measurements, it becomes evident that comparable UFP levels have been found in other office rooms as well as inside residential and school buildings. For instance, Fromme et al. (2007) found a median particle concentration of 5,660 particles/cm3 (particle size between 10 and 500 nm) in Bavarian classrooms. Morawska and Salthammer (2003) measured particles ranging from 70 to 800 nm in Australian apartments at concentrations of between 12,400 and 18,200 particles/cm3. For Australian office workplaces, 8-h time-weighted background particle concentrations between 1,700 and 12,000 particles/cm3 with concentration peaks up to 99,000 particles/cm3 associated with discrete printing events were determined by McGarry et al. (2011). The office room UFP concentrations modeled by Koivisto et al. (2010) with maxima up to 26,000 particles/cm3 are also consistent with this order of magnitude.

However, the similar order of magnitude of PN concentrations in these rooms does not provide any information about the comparability of the qualitative aspects of the particles, i.e., physical and chemical properties. For this reason, the results of almost all studies published so far offer sparse information on the possible significance of these particles for room air hygiene or any hazards they may pose to human health.

Health effects from inhaling UFP depend on PN, size, surface area, shape, solubility, and chemical reactivity (Marconi 2006; Nel et al. 2009) and may range from sensory irritation of mucous membranes to more severe illness such as cardiovascular diseases or cancer. Three recent reviews (BfR 2008; Ewers and Nowak 2006; Gminski and Mersch-Sundermann 2006) summarized and evaluated studies that illuminate the significance of health effects caused both by direct exposure to toner particles and exposure to emissions from laser printers. The reviews critically analyzed data on exposure values by chamber and indoor measurements generated with in vitro studies using bacteria and cell models, in vivo studies with animals, human exposure studies, investigations dealing with human effect markers (biomonitoring), as well as epidemiological and occupational studies. From these studies, it can be surmised that emission rates and exposure to chemical compounds or substance classes released during operation of laser printers were related to biological threshold values.

However, the results of studies on the biological effects caused by exposure to toners outlined in these reviews are contradictory. Whereas the in vivo studies dealing with direct exposure to toner dusts led to the assumption that neither acute nor chronic oral, dermal, or inhalation toxicity can be expected even at high concentrations (Lin and Mermelstein 1994), human biomonitoring studies provided convincing indications for irritative and genotoxic effects related to exposure to the emissions from laser printers and photocopiers (Gadhia et al. 2005; Goud et al. 2001, 2004; Wolkoff et al. 1992).

While numerous studies dealing with the direct toxicity and inhalation toxicity of toner dust are available (Gminski et al. 2011; Lin and Mermelstein 1994; Nakadate et al. 2006), investigations evaluating the effects of exposure to emissions from office machines are scarce. The first report on human health effects due to printer emissions was published in 1992 (Wolkoff et al. 1992). In this study, 30 human subjects were exposed to increased levels of ozone, formaldehyde, TVOC, and particulate matter in a chamber experiment with operating office equipment. The exposed participants reported significantly increased perception of headache, mucous membrane irritation, dryness in the eyes, nose, and throat, and dry and tight facial skin. A population-based cross-sectional study (Jaakkola et al. 2007) showed that exposure to paper dust and to exhaust air from printers was associated with upper respiratory and skin symptoms, breathlessness, tonsillitis, and middle ear infections. Muñoz et al. (2007) found evidence that toner can cause asthma and even vocal cord dysfunction. However, Hänninen et al (2010) performed a risk estimate based on published printer emission rates and general toxicological and epidemiological data of nanoparticles and concluded that health effects due to printer particles are negligible.

5 Conclusions

Laser printers and photocopiers are a relevant source of fine particles and particularly UFP found as air contaminants in office rooms. However, with respect to UFP, this study indicates that liquid or volatile aerosols presumably account for the greatest portion of laser printer emissions.

There are only slight indications of health effects, and due to the lack of data, many questions regarding the association between emissions from laser printers and health effects cannot as yet be answered. While a comprehensive study is still required to provide a better database on laser printer emissions, exposure, and chemical characterization, this and other studies imply that particle concentrations in office rooms can be reduced by proper choice of printers (He et al. 2007) and probably by use of appropriate filter techniques (Caesar and Schmitt 2009; Wensing et al. 2008). However, to date, it remains unknown which component of printer emissions is responsible for the assumed adverse health effects. Since laser printers are being used increasingly, not only in offices but also in private homes, additional studies, such as in vitro studies with human cell lines, controlled human exposure studies using reliable biological markers, and epidemiological surveys are indispensable for human risk assessment.

References

Barthel M, Pedan V, Hahn O, Rothhardt M, Bresch H, Jann O et al (2011) XRF-analysis of fine and ultrafine particles emitted from laser printing devices. Environ Sci Technol 45:7819–7825

BfR (2008) BfR schließt Arbeiten zur „Toner“-Problematik mit einer gesundheitlichen Bewertung möglicher Risiken durch Druckeremissionen ab. Gesundheitliche Bewertung Nr. 014/2008 vom 31. März 2008. Press release, Berlin

Caesar T, Schmitt T (2009) Entwicklung eines Filters für Laserdrucker, Fax- und Kopiergeräte als wirkungsvoller Schutz vor Fein- und Tonerstaub in Innenräumen. Gefahrst Reinhalt L 69:110–114

Cheng YH (2008) Comparison of the TSI Model 8520 and Grimm Series 1.108 portable aerosol instruments used to monitor particulate matter in an iron foundry. J Occup Environ Hyg 5:157–168

Destaillats H, Maddalena RL, Singer BC, Hodgson AT, McKone TE (2008) Indoor pollutants emitted by office equipment: a review of reported data and information needs. Atmos Environ 42:1371–1388

ECMA International (2007) Standard ECMA-328. Determination of chemical emission rates from electronic equipment, 3rd edn. ECMA International, Geneva

Ewers U, Nowak D (2006) Health hazards caused by emissions of laser printers and copiers? Gefahrst Reinhalt L 66:203–210

Fiedler J, Kura J, Moriske HJ, Pietsch A (2009) Freisetzung feiner und ultrafeiner Partikeln aus Laserdruckern unter Realraumbedingungen. Gefahrst Reinhalt L 69:77–82

Fromme H, Twardella D, Dietrich S, Heitmann D, Schierl R, Liebl B et al (2007) Particulate matter in the indoor air of classrooms: exploratory results from Munich and surrounding area. Atmos Environ 41:854–866

Gadhia PK, Patel D, Solanki KB, Tamakuwala DN, Pithawala MA (2005) A preliminary cytogenetic and hematological study of photocopying machine operators. Indian J Occup Environ Med 9:22–25

Glytsos T, Ondráček J, Džumbová L, Kopanakis I, Lazaridis M (2010) Characterization of particulate matter concentrations during controlled indoor activities. Atmos Environ 44:1539–1549

Gminski R, Mersch-Sundermann V (2006) Gesundheitliche Bewertung der Exposition gegenüber Tonerstäuben und gegenüber Emissionen aus Laserdruckern und Kopiergeräten - Aktueller Erkenntnisstand. Umweltmed Forsch Prax 11:269–300

Gminski R, Decker K, Heinz C, Seidel A, Könczöl M, Goldenberg E et al (2011) Genotoxic effects of three selected black toner powders and their dimethyl sulfoxide extracts in cultured human epithelial A549 lung cells in vitro. Environ Mol Mutagen 52:296–309

Goud KI, Shankarapppa K, Vijayashree B, Rao K, Ahuja Y (2001) DNA damage and repair studies in individuals working with photocopying machines. Int J Hum Genet 1:139–143

Goud KI, Hasan Q, Balakrishna N, Rao KP, Ahuja YR (2004) Genotoxicity evaluation of individuals working with photocopying machines. Mutat Res 563:151–158

Hänninen O, Brüske-Hohlfeld I, Loh M, Stoeger T, Kreyling W, Schmid et al (2010) Occupational and consumer risk estimates for nanoparticles emitted by laser printers. J Nanopart Res 12:91–99

He C, Morawska L, Taplin L (2007) Particle emission characteristics of office printers. Environ Sci Technol 41:6039–6045

He C, Morawska L, Wang H, Jayaratne R, McGarry P, Johnson GR et al (2010) Quantification of the relationship between fuser roller temperature and laser printer emissions. J Aerosol Sci 41:523–530

Jaakkola MS, Yang LY, Ieromnimon A, Jaakkola JJK (2007) Office work, SBS and respiratory and sick building syndrome symptoms. Occup Environ Med 64:178–184

Kagi N, Fujii S, Horiba Y, Namiki N, Ohtani Y, Emi H et al (2007) Indoor air quality for chemical and ultrafine particle contaminants from printers. Build Environ 42:1949–1954

Koivisto AJ, Hussein T, Niemelä R, Tuomi T, Hämeri K (2010) Impact of particle emissions of new laser printers on modeled office room. Atmos Environ 44:2140–2146

Lee CW, Hsu DJ (2007) Measurements of fine and ultrafine particles formation in photocopy centers in Taiwan. Atmos Environ 41:6598–6609

Lee SC, Lam S, Fai HK (2001) Characterization of VOCs, ozone, and PM10 emissions from office equipment in an environmental chamber. Build Environ 36:837–842

Lin GHY, Mermelstein R (1994) Acute toxicity studies of Xerox reprographic toners. Int J Toxicol 13:2–20

Marconi A (2006) Fine, ultrafine and nano-particles in the living and working setting: potential health effects and measurement of inhalation exposure. G Ital Med Lav Ergon 28:258–265

McGarry P, Morawska L, He C, Jayaratne R, Falk M, Tran Q et al (2011) Exposure to particles from laser printers operating within office workplaces. Environ Sci Technol 45:6444–6452

Morawska L, Salthammer T (2003) Indoor environment: airborne particles and settled dust. Wiley-VCH, Weinheim

Morawska L, He C, Johnson G, Jayaratne R, Salthammer T, Wang H et al (2009) An investigation into the characteristics and formation mechanisms of particles originating from the operation of laser printers. Environ Sci Technol 43:1015–1022

Muñoz X, Roger A, De la Rosa D, Morell F, Cruz MJ (2007) Occupational vocal cord dysfunction due to exposure to wood dust and xerographic toner. Scand J Work Env Hea 33:153–158

Nakadate T, Yamano Y, Adachi C, Kikuchi Y, Nishiwaki Y, Nohara M et al (2006) A cross sectional study of the respiratory health of workers handling printing toner dust. Occup Environ Med 63:244–249

Nel A, Xia T, Mädler L, Li N (2006) Toxic potential of materials at the nanolevel. Science 311:622–627

Nel AE, Mädler L, Velegol D, Xia T, Hoek EM, Somasundaran P et al (2009) Understanding biophysicochemical interactions at the nano-bio interface. Nat Mater 8:543–557

Peters TM, Ott D, O'Shaughnessy PT (2006) Comparison of the Grimm 1.108 and 1.109 portable aerosol spectrometer to the TSI 3321 aerodynamic particle sizer for dry particles. Ann Occup Hyg 50:843–850

Pettersson T, Fogden A (2005) Spreading of individual toner particles studied using in situ optical microscopy. J Colloid Interface Sci 287:249–260

Rödelsperger K, Podhorsky S, Brückel B, Dahmann D, Hartfiel GD, Woitowitz HJ (2003) Physical characteristics and definitions of granular insoluble dusts. Eur J Oncol 8:103–112

Schripp T, Wensing M, Uhde E, Salthammer T, He C, Morawska L (2008) Evaluation of ultrafine particle emissions from laser printers using emission test chambers. Environ Sci Technol 42:4338–4343

Schripp T, Mulakampilly SJ, Delius W, Uhde E, Wensing M, Salthammer T et al (2009) Comparison of ultrafine particle release from hardcopy devices in emission test chambers and office rooms. Gefahrst Reinhalt L 69:71–76

Schulz H, Harder V, Ibald-Mulli A, Khandoga A, Koenig W, Krombach F et al (2005) Cardiovascular effects of fine and ultrafine particles. J Aerosol Med 18:1–22

Stefaniak AB, Breysse PN, Murray MPM, Rooney BC, Schaefer J (2000) An evaluation of employee exposure to volatile organic compounds in three photocopy centers. Environ Res 83:162–173

Wensing M, Schripp T, Uhde E, Salthammer T (2008) Ultra-fine particles release from hardcopy devices: sources, real-room measurements and efficiency of filter accessories. Sci Total Environ 407:418–427

Wolkoff P (1999) Photocopiers and indoor air pollution. Atmos Environ 33:2129–2130

Wolkoff P, Johnsen CR, Franck C, Wilhardt P, Albrechtsen O (1992) A study of human reactions to office machines in a climatic chamber. J Expo Anal Env Epid 1:71–97

Acknowledgments

We thank Thomas Eikmann, Caroline Herr, and Anja zur Nieden from the Department Hygiene and Environmental Health for their valuable help in examining the office workers regarding health effects as well as Anja Schnecko, Department of Environmental and Indoor Toxicology of the Gießen University Medical Center. Additionally, we thank numerous colleagues, especially Michael Wensing, Günter Oberdörster, Hans-Jörn Moriske, and Christine Däumling, who critically reviewed our data and discussed the outcome and implications with us within the BfR risk assessment process. Furthermore, we cordially thank Joachim Schneider, Bernd Brückel, and Klaus Rödelsperger from the Department of Occupational Medicine at Gießen University Medical Centre for the electron microscope analysis. Klaus Rödelsperger, expert for TEM and REM analysis, sadly died unexpectedly during the study. Additionally, we thank Dirk Bültermann, Thomas Kreis, and Hans von Rechenberg for their valuable contribution as occupational physicians. Last but not the least, we thank the heads of the office units who contributed to the study, i.e., allowed us to perform parts of the study in their buildings.

The research project was funded by the German Federal Environment Agency and the German Federal Institute for Risk Assessment, Berlin.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Euripides Stephanou

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM doc

(DOC 858 kb)

Rights and permissions

About this article

Cite this article

Tang, T., Hurraß, J., Gminski, R. et al. Fine and ultrafine particles emitted from laser printers as indoor air contaminants in German offices. Environ Sci Pollut Res 19, 3840–3849 (2012). https://doi.org/10.1007/s11356-011-0647-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-011-0647-5