Abstract

In recent years, oyster mushroom (Pleurotus ostreatus) has become one of the most cultivated mushrooms in the world, mainly in Brazil. Among many factors involved in a mushroom production, substrate preparation is the most critical step, which can be influenced by composting management techniques. Looking forward to optimizing the substrate preparation process, were tested different composting conditions (7 and 14 days of composting with or without conditioning), potential raw materials (decumbens grass, brizantha grass and sugarcane straw) and nitrogen supplementation (with or without wheat bran) on oyster mushroom yield and biological efficiency (BE). The substrate composted for 7 days with conditioning showed higher yield and biological efficiency of mushroom (24.04 and 100.54 %, respectively). Substrates without conditioning (7 and 14 days of composting) showed smaller mushroom yield and biological efficiency. Among the raw materials tested, brizantha grass showed higher mushroom yield followed by decumbens grass, sugarcane straw and wheat straw (28.5, 24.32, 23.5 and 19.27 %, respectively). Brizantha grass also showed higher biological efficiency followed by sugarcane straw, decumbens grass and wheat straw (123.95, 103.70, 96.90 and 86.44 %, respectively). Supplementation with wheat bran improved yield and biological efficiency in all substrate formulations tested; thus, oyster mushroom yield and biological efficiency were influenced by substrate formulation (raw materials), supplementation and composting conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the last 10 years, oyster mushroom (Pleurotus ostreatus) has become one of the most cultivated mushrooms in the world, mainly in Brazil (Lee et al. 2002; Sánchez 2010; Royse 2013). There are many reasons for this production increase, certainly, the capability of oyster mushroom to grow in a wide range of agricultural and forest wastes through different production methods, as well as its nutritional and medicinal benefits are the highlights (Bonatti et al. 2004; Chang and Miles 2004; Sánchez 2010). In addition, importation of canned champignon (Agaricus bisporus) from Asia at low-cost showed a massive migration of Brazilians champignon growers to oyster mushroom cultivation.Footnote 1

In a large-scale mushroom production, substrate preparation is the most critical and expensive step, which demand years of experience, knowledge and investment in infrastructure (Van Griensven 1988; Chang and Miles 2004). A survey carried out with producers in Sao Paulo (Brazil’s largest producer state) during 2009 to 2014 showed that lack of knowledge about substrate preparation and poor technical support is a big challenge for oyster mushroom growers.Footnote 2

Oyster mushroom (primary decomposer) has a powerful enzymatic machinery allowing then to grow in a wide range of agro-wastes through different substrate preparation methods (Chang and Miles 2004; Sánchez 2010). However, the mushroom industry has employed the composting substrate preparation method because is less expensive, decrease chances of subsequent infections with competitor species (Choi 2007; Hernández et al. 2003; Vajna et al. 2010), and allows the utilization of existing champignon farm infrastructure.2, Footnote 3

Substrate preparation through composting is carried out in two phases: Phase I—carried out in rick (outdoor) or bunker (forced aeration system, indoor). Self-heating by microbial activity can reach 80 °C in few days. This intense microbial activity causes the breakdown of complex carbohydrates (e.g. cellulose, hemicellulose and lignin) releasing nutrients for mushroom cultivation; Phase II—carried out in a controlled environment (pasteurization tunnel) in two stages, pasteurization and conditioning. Pasteurization stage is responsible to kill insect, nematodes, competitor fungi and others pests (temperature ~60 °C) and; conditioning is necessary to reduce the free ammonia formed during phase I and to improve the biological environment of substrate (beneficial microbiota to mushroom cultivation) (Van Griensven 1988; Straatsma et al. 1994, 2000; Oei 2003).

Substrate preparation through composting was developed for champignon cultivation (secondary decomposer) and has been constantly improved in the last 70 years (Sinden and Hauser 1950; Van Griensven 1988; Sharma et al. 2000; Straatsma et al. 2000). On the other hand, limited information’s are available about substrate preparation through composting to oyster mushroom cultivation (primary decomposer), which has physiological characteristics completely different than champignon. Among many factors regulatory of a mushroom production, composting management techniques, as well as raw materials and supplementation are crucial to reach optimum cost-effective and high-yield mushroom (Oei 2003; Chang and Miles 2004; Choi 2007). Looking forward to optimizing the composting process to oyster mushroom cultivation, were tested different composting conditions, potential raw materials and substrate supplementation on mushroom yield and biological efficiency.

Materials and methods

Pleurotus ostreatus strains and spawn preparation

The oyster mushroom strains were collected in a commercial cultivation (Sao Paulo state, Brazil), renamed (POS 09/101 and POS 09/102) and appropriately storage in the fungal genetic bank at the Mushroom Module, Sao Paulo State University (Department of Plant Production). Both strains were characterized by ‘Random Amplification of Polymorphic DNA—RAPD and tested to mushroom production performance previously (Vieira et al. 2012). Spawn was based on wheat grains, which were boiled in water for 35 min and pH adjusted to 7 adding 10 g kg−1 calcium carbonate and 10 g kg−1 gypsum (wet grains). Thermo-resistant plastic bags were filled with 1 kg cooked grains and autoclaved for 4 h at 121 °C. After cool down, these sterile grains were inoculated with P. ostreatus mycelia (10 medium culture pieces, PDA—Potato Dextrose Agar) and incubated at 25 °C for 15 days in darkness (Royse and Schisler 1987).

Substrate preparation (composting phases I and II)

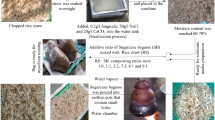

Substrate applied to evaluated oyster mushroom production under different substrate composting conditions was based on sugarcane straw (Saccharum officinarum), sugarcane bagasse, wheat bran and rice bran (Table 1). Two substrate ricks (2 m width × 3 m length × 1.2 m height) were composted for different periods (7 and 14 days). Briefly, was composted a rick for 7 days and then assembled the second rick (14 days of phase I), allowing the phase II execution at the same time for both substrates rick (Fig. 1). At the end of phase I, thermo-resistant grid plastic boxes were filled with ~10 kg substrate and randomly placed in an acclimatized chamber model Dalsem Mushroom to phase II execution (chamber with environmental control through VEC 32 software—by Dalsem, Woudseweg 9, The Netherlands). Phase II was adjusted following pasteurization at 59.5 ± 1 °C for 8 h and conditioning at 46.5 ± 1 °C for 3 days (Fig. 1).

Different substrate formulations were prepared following the shorter composting condition applied previously (7 days of composting with conditioning) to evaluate potential raw materials and supplementation level on mushroom yield (Fig. 1). Were formulated substrates based on decumbens grass (Brachiaria decumbes), sugarcane straw, brizantha grass (Brachiaria brizantha), wheat straw (Triticum aestivum), and sugarcane bagasse, supplemented or not with wheat bran, totalizing 8 different substrate formulations (Table 2).

Spawning, spawn run and mushroom production

Spawning was carried out manually applying 20 g kg−1 spawn/kilogram of substrate (wet substrate, 68 % of moisture). Plastic bags (grey color, rectangular block) were filled with 8 kg of spawned substrate and placed in an acclimatize chamber (Model Dalsem Mushroom, mentioned above) to spawn run at 25 ± 1 °C, 85 % humidity, in darkness for 13 days (full colonization). The plastic bags had 24 holes of 1 cm of diameter placed 10 cm each other. After complete substrate colonization, those blocks were transferred to a production room, which has humidification and gases exchange system. Thermal shocks to induce mushroom fructification was under environmental temperature, which ranged between 15 and 29 °C (night and daytime). Relatively humidity was managed between 70 and 90 % through nebulization. Mushroom harvest started 5 days at the end of spawn run. Mushrooms were harvested manually when they reached the range size between 2 and 3.5 cm of diameter pileus, counted and weighed before yield and biological efficiency (BE) calculation.

Substrate and mushroom production analysis

Were collected substrate samples at the beginning and at the end of phase I, after pasteurization and conditioning (4 sampled points). Samples were dehydrated at 105 °C for 72 h, milled in knife mill with 30 mesh sieve and stored at −20 °C until physicochemical analyses. To evaluate organic matter, carbon, nitrogen and C/N ration were used loss ignition and Kjeldahl (Brasil 2007). The pH was calculated using 10 g of substrate (fresh substrate) added at 50 ml of CaCl2 0.01 mol/L, stirring for 30 min and subsequently measured with a pH meter (model Micronal B474) (Brasil 2007). Crude energy was measured by calorimeter bomb method (model IKA C200). Soluble sugar was measured by colorimetric method modified (glucose and xylose standard curve) to determine soluble carbohydrate (Johnson et al. 1966). Temperature during the phase I composting was measured by thermometer (PT 100) in six different points in the ricks. Mushroom yield was calculated by fresh weight mushroom/fresh weight substrate × 100 and BE fresh weight mushroom/dry weight substrate × 100 (Royse et al. 2004).

Statistical analysis

Two statistical designs were applied to data comparison under different composting conditions. Mushroom production (yield and biological efficiency) was a factorial 2 × 2 (two phase I periods × two phase II periods) with 10 replicates. Physicochemical composition of substrate was a factorial 2 × 4 (2 substrate × 4 stages of composting) with 3 replicates. Comparisons among different substrate formulations (yield and biological efficiency) were designed a factorial 2 × 4 (2 C/N ratio × 4 raw materials) with 13 replicates. Means were analyzed by ANOVA (Tukey test, 5 %).

Results

The temperature of substrate under different composting conditions (phase I) reached the peak heating on day 7 (Fig. 2), for both ricks (7 and 14 days). Among all substrate physicochemical analysis, organic matter and C/N ratio were not influenced by different composting conditions (Fig. 3a, b), while crude energy, soluble sugars and pH showed significant changes (Fig. 3c–e).

Composting temperature (phase I). Peak heating of substrate ricks are indicated per arrows on top of graphic (7 D—7 days of phase I; 14 D—14 days of phase I, following experimental design mentioned in Fig. 1)

Physicochemical composition of the substrate during composting (phases I and II). a—organic matter; b—C/N ratio; c—pH; d—crude energy (calories g−1); e—soluble sugars. Dry basis substrate. 7 D—seven days of phase I; 14 D—14 days of phase I. 1 Means followed by same uppercase letter indicate no statistical difference across 7 D of composting; 2 Means followed by same italic uppercase letter indicate no statistical difference across 14 D of composting; 3 Means followed by same lowercase letter indicate no statistical difference between 7 D and 14 D at the same composting stage

Mushroom yield and BE were significantly influenced under different substrate preparation conditions (Fig. 4). The conditioning absence decreased mushroom yield and BE in the substrate composted for 7 days (phase I). However, conditioning absence showed not influenced on mushroom yield in the substrate composted for 14 days, only to BE. The different phase I conditions (7 and 14 days) with conditioning showed not influence on mushroom yield and BE.

Yield and biological efficiency (BE) of Pleurotus ostreatus cultivated under different composting conditions. The legend on top of graphic indicates how long substrates were composted (7 and 14 days, 7 D and 14 D, respectively). Means followed by same lowercase letter indicate no statistical difference at the same phase II condition (7 D and 14 D with conditioning—normal lowercase; 7 D and 14 D without conditioning—italic lowercase). Means followed by same uppercase letter indicate no statistical difference at the same phase I condition (7 D without and with conditioning—normal uppercase; 14 D without and with conditioning—bold uppercase)

Different substrate formulations showed statistically difference on mushroom yield and BE (Fig. 5). Substrate based on brizantha grass with supplementation showed higher mushroom yield and BE (28.50 and 123.95 %, respectively), while non supplementation decreased mushroom yield and BE to 16.02 and 77.43 %, respectively (Fig. 5). Substrate based on wheat straw in these experimental conditions showed smaller yield, with or without supplementation, 19.27 and 12.26 %, respectively (Fig. 5). Biological efficiency also was smaller in wheat straw substrate, 86.40 and 65.57 % with and without supplementation, respectively (Fig. 5).

Yield and biological efficiency (BE) of Pleurotus ostreatus cultivated in different substrate formulations with or without supplementation. Substrates: SDEC—decumbens grass; SCAN—sugarcane straw; SBRI—brizantha grass; SWHE—wheat straw. Substrate supplementation: C/N ratio of 60:1—with supplementation; C/N ratio of 90:1—without supplementation. Means followed by same lowercase letter indicate no statistical difference at the same C/N ratio (60:1) between different substrates. Means followed by same italic lowercase letter indicate no statistical difference at the same C/N ratio (90:1) between different substrates. Means followed by same uppercase letter indicate no statistical difference at the same substrate and different C/N ratio

All substrates supplemented with wheat bran (C/N ratio of 60:1) showed higher temperature during phase I composting than substrates without supplementation (Fig. 6a, b). Brizantha grass substrate showed higher temperature followed by decumbens grass, sugarcane straw and wheat straw (Fig. 6a, b). Brizantha grass also showed higher C/N ratio reduction during composting, while wheat straw substrate showed lower C/N ratio reduction (Fig. 6c, d).

Temperature of substrate (phase I) and C/N ratio changes in the different substrate formulations. a—Temperature during phase I, substrates with supplementation (C/N ratio—60:1); b—Temperature during phase I, substrates without supplementation (C/N ratio—90:1); c—C/N ratio changes during composting in the substrates with supplementation (C/N ratio—60:1); d—C/N ratio changes during composting in the substrates without supplementation (C/N ratio—90:1). Substrates: SDEC—decumbens grass; SCAN—sugarcane straw; SBRI—brizantha grass; SWHE—wheat straw

Discussion

Biological substrate transformation during composting process can be monitored by physicochemical analysis such as, organic matter, pH, C/N ratio, soluble sugars, crude energy, temperature, among others (Sharma et al. 2000; Lyons et al. 2006). Temperature measurement during composting (phase I) indicates an intense microbial activity (Fig. 1). Mesophilic and thermophilic microorganisms metabolizes easily degradable carbon sources such as soluble sugars (Fig. 3E) during initial composting stages (Sharma et al. 2000; Ryckeboer et al. 2003). Others metabolic events involved in the microbial activity during composting causes carbon and nitrogen losses, decreasing organic matter, C/N ratio and crude energy (Bertoldi et al. 1983; Tuomela et al. 2000). Carbon is mainly lost by CO2 emission upon microbial respiration while nitrogen can be lost by NH3 emission or biologically recycled (Thambirajah et al. 1995; Ryckeboer et al. 2003).

Among different composting conditions applied in this study, 7 or 14 days of phase I with conditioning showed not statistical difference on mushroom yield and BE (Fig. 4). However, mushroom yield and BE in the substrates composted during 7 and 14 days without conditioning showed statistical difference (Fig. 4). The combination of shorter composting period (7 days) and conditioning step notably improved the mushroom yield and BE (24.04 and 100.54 %, respectively) (Fig. 4). The shorter composting (7 days) condition without conditioning showed be not enough composting time to prepare the substrate for oyster mushroom cultivation, while 7 days with conditioning (11 days, composting + conditioning) and 14 days with or without conditioning (14–18 days, respectively) improved the mushroom yield and BE. Hernández et al. (2003) testing a substrate based on 70 % pangola grass (Digitaria decumbens), 30 % coffee pulp and 2 % Ca(OH)2 composted under different conditions (3, 4 and 5 days) reported highest BE in the substrate composted for 3 days (93.83 %).

Among the raw materials tested with supplementation, brizantha grass showed higher mushroom yield (28.5 %) and BE (123.95 %) and, substrates without supplementation, decumbens grass showed higher mushroom yield (18.97 %) and sugarcane straw higher BE (84.92 %) (Fig. 5). Obodai et al. (2003) testing different substrate formulations (fresh sawdust, composted sawdust, rice husk, corn husk, banana leaves, maize stover, rice straw and elephant grass) by sterilization method reported highest BE (61.04 %) in the substrate based on composted sawdust (28 days of composting previously). The higher temperature (self-heating) during composting (Fig. 6a, b) and C/N ratio reduction (Fig. 6c, d) indicates brizantha grass as easily metabolized during composting (microbial activity). On the other hand, wheat straw substrate showed low temperature during composting (Fig. 6a, b), a slight decrease of C/N ratio (Fig. 6c, d) and smaller yield and BE (Fig. 5). Sugarcane straw and decumbens grass showed mushroom yield similar with a commercial production (24.22 %) in substrate based on wheat straw and alfalfa (5 % w/w of dry straw) composted for 7 days followed by pasteurization and conditioning (Vajna et al. 2010). The sugarcane straw has a big potential in Brazil to be used in the mushroom industry because sugar/ethanol industry generate millions of tons every year (Santos et al. 2012).

Substrate supplementation with an organic nitrogen source (wheat bran) increases yield and BE (Fig. 5). The main reason is because organic nitrogen sources are easily metabolized by oyster mushroom (Curvetto et al. 2002; Bonatti et al. 2004; Rizki and Tamai 2011). In addition, metabolizing easy degradable carbon sources (wheat bran) is energetically efficient than breakdown complex carbohydrate as cellulose, hemicellulose and lignin (Nunes et al. 2012). Zervakis et al. (2013) testing different supplementation levels (20, 40 and 60 %) of composted (90 days) and noncomposted raw olive mill waste in a substrate based on wheat straw (sterile substrate) reported BE of 135.34 % (substrate supplemented with 5 % of wheat bran plus 20 % of olive mill waste composted, C/N ratio of 40:1). Philippoussis et al. (2001) tested wheat straw, cotton waste and peanut shell supplemented with wheat bran (C/N ratio between 30 and 60:1) through sterilization method (1.5 h at 1.1 atm) reported highest BE of 116.70 and 70.61 % for two commercial strains of P. ostreatus, HK35 and P69, respectively. Comparisons with other studies were hindered by the fact that most of them were carried out using laboratory model conditions (small bags and high spawn concentration), different substrate preparation methods (sterilization, only pasteurization by steam or unpasteurized substrate), different strains, different production condition etc.

Conclusions

Seven days of composting with conditioning showed higher mushroom yield and biological efficiency, as well as low environmental pollution (less emission of NH3 and CO2). In addition, shorter composting period contribute to reduce cost production. Brizantha grass and sugarcane straw showed potential to be applied for oyster mushroom industry. Supplementation of composted substrate improved yield and biological efficiency of mushroom. Looking forward, future research should include microbial community activity and carbohydrates changes during composting process and its effects on oyster mushroom yield.

Notes

A personal communication with mushroom growers of the Sao Paulo state, Brazil.

A survey carried out by technical assistance with oyster mushroom growers, SEBRAETec program (Expert in Micro Enterprises and Small Businesses in Brazil).

A personal communication with mushrooms producers of Brazil, Europe, and North America.

References

Bertoldi M, Vallini G, Pera A (1983) The biology of composting: a review. Wast Manag Res 1(2):157–176

Bonatti M, Karnopp P, Soares HM, Furlan SA (2004) Evaluation of Pleurotus ostreatus and Pleurotus sajor-caju nutritional characteristics when cultivated in different lignocellulosic wastes. Food Chem 88(3):425–428

Brasil (2007) Ministério da Agricultura, Pecuária e Abastecimento – Manual de métodos analíticos oficiais para fertilizantes minerais, orgânicos, organominerais e corretivos. http://www.agricultura.pr.gov.br/arquivos/File/PDF/in_28_07_anexo.pdf. Accessed 25 May 2013

Chang ST, Miles PG (2004) Mushrooms: cultivation, nutritional value, medicinal effect, and environmental impact. CRC Press, Boca Raton

Choi KW (2007) Shelf cultivation of oyster mushroom. In: MushWorld (ed) Mushroom growers’ handbook 1. Oyster mushroom cultivation, MushWorld—Heineart Inc, Seoul

Curvetto NR, Figlas D, Devalis R, Delmastro S (2002) Growth and productivity of different Pleurotus ostreatus strains on sunflower seed hulls supplemented with N-NH4 + and/or MN (II). Bioresour Technol 84(2):171–176

Hernández D, Sánchez JE, Yamasaki K (2003) A simple procedure for preparing substrate for Pleurotus ostreatus cultivation. Bioresour Technol 90:145–150

Johnson RR, Balwani TL, Johnson LJ, McClume KE, Dehority BA (1966) corn plant maturity II. Effect on In vitro cellulose digestibility and soluble carbohydrate content. J Anim Sci 25:617–623

Lee HY, Won-Rok K, Min BH (2002) Automation of solid-state bioreactor for Oyster Mushroom composting. Microbiol 30:228–232

Lyons GA, Sharma HSS, Kilpatrick M, Cheung L, Moore S (2006) Monitoring of changes in substrate characteristics during mushroom compost production. J Agric Food Chem 54:4658–4667

Nunes MD, Da Luz JMR, Paes SA, Ribeiro JJO, Silva MCS, Kasuya MCM (2012) Nitrogen supplementation on the productivity and the chemical composition of oyster mushroom. J food Res 1(2):113–119

Obodai M, Cleland-Okine J, Vowotor KA (2003) Comparative study on the growth and yield of Pleurotus ostreatus mushroom on different lignocellulosic by-products. J Ind Microbiol Biotechnol 30:146–149

Oei P (2003) Mushroom cultivation. Backhuys Publishers, Leiden

Philippoussis A, Zervakis G, Diamantopoulou P (2001) Bioconversion of agricultural lignocellulosic wastes through the cultivation of the edible mushrooms Agrocybe aegerita, Volvariella volvacea and Pleurotus spp. World J Microbiol Biotechnol 17:191–200

Rizki M, Tamai Y (2011) Effects of different nitrogen rich substrates and their combination to the yield performance of oyster mushroom (Pleurotus ostreatus). World J Microbiol Biotechnol 27:1695–1702

Royse DJ (2013) Trends in Mushroom production worldwide. In: Sales-Campos C, Abreu RLS, Vianez BF, Urben AF (eds) Anais do VII Simpósio internacional sobre cogumelos no Brasil, 6th edn. Embrapa, Brasilia, pp 38–47

Royse DJ, Schisler LC (1987) Yield and size of Pleurotus ostreatus and Pleurotus sajor- caju as effected by delayed-release nutrient. Appl Microbiol Biotechnol 26(2):191–194

Royse DJ, Rhodes TW, Ohga S, Sanchez JE (2004) Yield, mushroom size and time to production of Pleurotus cornucopiae (oyster mushroom) grown on switch grass substrate spawned and supplemented at various rates. Bioresour Technol 91(1):85–91

Ryckeboer J, Mergaert J, Vaes K, Klammer S, De Clercq D, Coosemans J, Insam H, Swings J (2003) A survey of bacteria and fungi occurring during composting and self-heating processes. Ann Microbiol 53(4):349–410

Sánchez C (2010) Cultivation of Pleurotus ostreatus and other edible mushroom. Appl Microbiol Biotechnol 80:1321–1337

Santos FA, Queiróz JH, Colodette JL, Fernandes SA, Guimarãrs VM, Rezende ST (2012) Potential of sugarcane straw for ethanol production. Quim Nova 35(5):1004–1010

Sharma HSS, Lyons G, Chambers J (2000) Comparison of the changes in mushroom (Agaricus bisporus) compost during windrow and bunker stages of phase I and II. Ann Appl Biol 136(1):59–68

Sinden JW, Hauser E (1950) The short method of composting. Mushroom Sci 1:52–59

Straatsma G, Samson RA, Olijnsma TW, Op Den Camp HJM, Gerrits JPG, Van Griensven LJLD (1994) Ecology of thermophilic fungi in mushroom compost, with emphasis on Scytalidium thermophilum and growth stimulation of Agaricus bisporus mycelium. Appl Environ Microbiol 60(2):454–458

Straatsma G, Gerrits JPG, Thissen JTNM, Amsing JGM, Loeffen H, Van Griensven LJLD (2000) Adjustment of the composting process for mushroom cultivation based on initial substrate composition. Bioresour Technol 72(1):67–74

Thambirajah JJ, Zulkali MD, Hashim MD (1995) Microbiological and biochemical changes during the composting of oil palm empty-fruit-bunches. Effect of nitrogen supplementation on the substrate. Bioresour Technol 52(2):133–144

Tuomela M, Vikman M, Hatakka A, Itavaara M (2000) Biodegradation of lignin in a compost environment: a review. Bioresour Technol 72(2):169–183

Vajna B, Nagy A, Sajben E (2010) Microbial community structure changes during oyster mushroom substrate preparation. Appl Microbiol Biotechnol 86:367–375

Van Griensven LJLD (1988) The cultivation of mushrooms. Rustington, Sussex

Vieira FR, Pereira DM, Andrade MCN, Minhoni MTA (2012) Molecular characterization of Pleurotus ostreatus commercial strains by random amplified polymorphic DNA (RAPD). Afr J Agric Res 8(24):3146–3150

Zervakis GI, Koutrotsios G, Katsaris P (2013) Composted versus raw olive mill waste as substrate for the production of medicinal mushrooms: an assessment of selected cultivation and quality parameters. Biomed Res Int. doi:10.1155/2013/546830

Acknowledgments

This research was supported by Coordination for the Improvement of Higher Level Personnel (CAPES Foundation), No. 005707/2012-05. We are grateful to Graduate Program (Energy in Agriculture) of College of Agronomic Sciences, Sao Paulo State University, for constantly financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vieira, F.R., de Andrade, M.C.N. Optimization of substrate preparation for oyster mushroom (Pleurotus ostreatus) cultivation by studying different raw materials and substrate preparation conditions (composting: phases I and II). World J Microbiol Biotechnol 32, 190 (2016). https://doi.org/10.1007/s11274-016-2152-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-016-2152-y