Abstract

On-site cellulase and hemicellulase production is a promising way to reduce enzyme cost in the commercialization of the lignocellulose-to-ethanol process. A hemicellulase-producing fungal strain suitable for on-site enzyme production was selected from cultures prepared using wet disc-milling rice straw (WDM-RS) and identified as Trichoderma asperellum KIF125. KIF125 hemicellulase showed uniquely high abundance of β-xylosidase in the xylanolytic enzyme system compared to other fungal hemicellulase preparations. Supplementation of Talaromyces cellulolyticus cellulase with KIF125 hemicellulase was more effective than that with the hemicellulases from other fungal sources in reducing the total enzyme loading for the improvement of xylose yield in the hydrolysis of ball-milling RS, due to its high β-xylosidase dominance. β-Xylosidase in KIF125 hemicellulase was purified and classified as a glycosyl hydrolase family 3 enzyme with relatively high specificity for xylobiose. The production of KIF125 β-xylosidase in the fermentor was estimated as 118 U/g-WDM-RS (2350 U/L culture) at 48 h. These results demonstrate that KIF125 is promising as a practical hemicellulase source to combine with on-site cellulase production using T. cellulolyticus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulosic biomass is an abundant renewable source for obtaining fermentable sugars as substrates for fuel ethanol production. Enzymatic hydrolysis of lignocellulose using cellulases and hemicellulases is a key technology for the lignocellulose-to-ethanol process. However, it has been pointed out that the industrial enzyme cost in the commercialization of ethanol production from lignocellulose is still high (Klein-Marcuschamer et al. 2012). There are two strategies to reduce enzyme cost. One is on-site enzyme production because of its simplified purification and logistics, as well as the potential cheap carbon source utilization from lignocellulosic substrates (Merino and Cherry 2007; Hong et al. 2013; Liu et al. 2016). Another way is the improvement of cellulase performance by cocktails or component optimization, leading to the reduction of enzyme loading and an increase of fermentable sugar yield in the hydrolysis of lignocellulose (Banerjee et al. 2010; Klein-Marcuschamer et al. 2012; Liu et al. 2016).

Filamentous fungi are good sources of cellulases and hemicellulases. The cellulase preparations derived from industrial fungal strains such as the genera Trichoderma, Talaromyces, and Myceliophthora are widely used for the hydrolysis of pretreated lignocellulose (Gusakov 2011). These enzyme preparations generally contain lower amounts of hemicellulases, and their compositions are not necessarily suitable for the efficient hydrolysis of pretreated lignocellulose. For this reason, supplementation of the cellulase preparations with external hemicellulases, including accessory enzymes, is essential to increase sugar yields in hemicellulose hydrolysis. Notably, the synergistic interactions between the cellulases and hemicellulases increase the accessibility of cellulose by cellulases due to removal of hemicellulose, which results in reduction of cellulase loading (Selig et al. 2008; Gao et al. 2011; Hu et al. 2011; Van Dyk and Pletschke 2012; Hu et al. 2013). Furthermore, the enhanced production of monomeric sugars from hemicellulose by the hemicellulase supplementation is important not only for increasing the total sugar yields, but also for reducing the strong inhibition of cellulase by xylan, mannan, and their oligomers in pretreated lignocellulose (Qing and Wyman 2011; Xin et al. 2015). Therefore, on-site enzyme production would be required for hemicellulase as well as cellulase. Selection of hemicellulase-producing fungal strains should be considered with respect to the enzyme productivity using a cheap carbon source and the efficient hydrolysis of the target substrate in combination with the cellulase preparation.

Talaromyces cellulolyticus is one of the most promising fungi for use in industrial production of cellulases (Inoue et al. 2014). T. cellulolyticus mutant strain CF-2612 secretes a large amount of cellulases, including relatively high activities of xylanase and β-glucosidase, using cellulose as a carbon source, while β-xylosidase and β-mannosidase activities are detected only in trace amounts in the cellulase preparations (Fang et al. 2009; Fujii et al. 2009; Inoue et al. 2015b). Supplementations of T. cellulolyticus cellulase with purified or crude fungal hemicellulases have been reported to enhance total sugar yields from woody biomass (Yano et al. 2009; Inoue et al. 2015b). Homologous expression of β-xylosidase in T. cellulolyticus has been found to improve the hydrolysis of xylo-oligosaccharides by the recombinant cellulase preparation (Kanna et al. 2011). It should be noted that pretreated rice straw (RS) is a promising carbon source in on-site cellulase production of T. cellulolyticus cellulase (Hideno et al. 2011). The cellulase preparation produced using wet disc-milling RS (WDM-RS) exhibited higher hemicellulase activity compared to the preparation using cellulose, and has been proposed to be more suitable for the hydrolysis of pretreated RS (Hideno et al. 2011). However, its β-xylosidase activity is still insufficient. On the other hand, RS has been reported as a carbon source for hemicellulase production, mainly xylanase (Knob et al. 2014). In addition, Kang et al. (2004) have reported relatively high β-xylosidase production by Aspergillus niger KK2 using RS in an earlier study.

To enhance hemicellulase activity in T. cellulolyticus cellulase, fungal strains were screened in this study for β-xylosidase activity in cultures prepared using WDM-RS as carbon source, and the selected strain was identified as Trichoderma asperellum KIF125. KIF125 hemicellulase produced xylose more efficiently from RS xylan in combination with on-site T. cellulolyticus cellulase prepared using WDM-RS. The identification of β-xylosidase purified from KIF125 and the production of KIF125 β-xylosidase using bench-scale fermentor were also examined. Our results demonstrate that T. asperellum KIF125 is a promising candidate for on-site hemicellulase production.

Materials and methods

Fungal strains

The 132 fungal strains in the laboratory culture collection (KIF strains), which were isolated on agar plates including Avicel, ball-milled eucalyptus, birchwood xylan, or lignin from soil samples and decaying plant materials collected in Japan (Yano et al. 2009), were used for β-xylosidase activity screening. T. asperellum KIF125, a strain selected by screening, was used to produce β-xylosidase. Aspergillus aculeatus KIF78, which was isolated and identified as a hemicellulase producer for the enzymatic hydrolysis of woody biomass (Yano et al. 2009), and A. niger KIF109 were used as reference strains for the production of hemicellulolytic enzymes. KIF 78, KIF109 and KIF125 strains were deposited at HUT culture collection from Hiroshima University (Higashi-Hiroshima, Japan) as HUT2365, HUT2366 and HUT5132, respectively. T. cellulolyticus CF-2612 (FERM BP-10848) was used for the production of cellulolytic enzymes (Fang et al. 2009; Hideno et al. 2011). All the strains used were stored on potato dextrose agar plates.

Pretreatment of rice straw

WDM-RS was prepared using the Supermasscolloider MKZA10 (Masuko Sangyo Co., Kawaguchi, Japan) as described previously (Hideno et al. 2009). The composition (% dry weight) of structural carbohydrates in the pretreated RS was analyzed based on the standard NREL laboratory analytical procedure (Sluiter et al. 2008) and consisted of 32.7 % glucan, 19.4 % xylan, 2.5 % arabinan, and 1.5 % galactan.

Dry ball-milling (DBM) treatment of RS was performed using the TI-300 system (CMT Co., Iwaki, Japan). The air-dried sample (50 g), which was from a different lot than the RS used for WDM treatment, was added to a pod containing 90 stainless steel balls (diameter 2 cm) and milled continuously for 2 h at 1700 rpm. The composition (% dry weight) of structural carbohydrates in DBM-RS consisted of 34.3 % glucan, 16.3 % xylan, 2.8 % arabinan, and 2.1 % galactan.

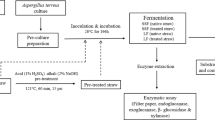

Production of cellulolytic and hemicellulolytic enzymes

Medium (pH 5.0) for β-xylosidase activity screening of KIF strains contained (per liter): 40 g WDM-RS as a carbon source, 10 g tryptone, 0.5 g yeast extract, 10 g corn steep liquor, 24 g KH2PO4, 4.7 g C4H4K2O6·½H2O, 1 g Tween 80, 5 g (NH4)2SO4, 1.2 g MgSO4·7H2O, 0.01 g ZnSO4·7H2O, 0.01 g MnSO4·6H2O, 0.01 g CuSO4·5H2O. The KIF strains were cultured in 20 mL of medium at 30 °C, 200 rpm, for 7 days using 100-mL Erlenmeyer flasks. The whole broth was centrifuged at 13,500 ×g and the resulting supernatant was filtered through a 0.22-μm polyether sulfone membrane (Thermo Fisher Scientific, Rockford, IL, USA) under sterile conditions. The culture filtrate containing hemicellulolytic enzymes was stored at 4 °C.

Cellulase from T. cellulolyticus CF-2612 was produced in a medium containing 100 g/L WDM-RS as carbon source (Hideno et al. 2011). CF-2612 was cultured for 7 days using a 2-L BMJ-02PI laboratory fermentor (ABLE Co., Tokyo, Japan) containing 1 L of medium as described previously (Fang et al. 2009). The temperature, pH, and agitation were held at 30 °C, 4.0, and 600 rpm, respectively, by a DPC-2 controller (ABLE). The air-flow rate was maintained at 1.0 vvm. The culture filtrate containing cellulolytic enzymes was prepared as described above and stored at 4 °C.

β-Xylosidase production of T. asperellum KIF125 was evaluated using a 2-L BMJ-02PI laboratory fermentor with 1 L of medium (pH 5.0) containing (per liter): 20 g WDM-RS, 5 g polypeptone, 4 g urea, 2 g (NH4)2SO4, 5 g (NH4)2HPO4, 5 g KNO3, 15 g KH2PO4, 1 g Tween 80. The fermentor was inoculated with a 40 mL preculture of KIF125, which was cultured in medium containing 2 % (w/v) glycerol instead of WDM-RS. The culture was incubated for 96 h at 28 °C, pH 4.8, and 300 rpm and parameters were held constant by a DPC-2 controller. The air-flow rate was maintained at 1.6 vvm. The culture filtrate containing crude enzyme was prepared as described above and stored at 4 °C.

The ATP concentration in the fermentor culture was determined using the CheckLite 250 Plus (Kikkoman, Noda, Japan) and Lumitester C-100 (Kikkoman) kits based on the luciferin–luciferase reaction (Fang et al. 2009). The urea concentration was determined using the QuantiChrom Urea assay Kit (BioAssay Systems, Hayward, CA, USA). Protein concentration was determined by using the BCA protein assay reagent (Pierce, Rockford, IL, USA), using bovine serum albumin as the protein standard.

Enzyme activity assays

The filter paper cellulase (FPase) activity was measured according to the standard procedure recommended by the Commission on Biotechnology, IUPAC (Wood and Bhat 1988), and was represented in filter paper units (FPU). Carboxymethyl cellulase (CMCase), and xylanase activities were assayed in 50 mM sodium acetate buffer (pH 5.0) containing 1 % (w/v) carboxymethyl cellulose (CMC, low viscosity), and 1 % (w/v) birchwood xylan, respectively, at 45 °C for 30 min. The xylan substrate was prepared by boiling 2 % (w/v) birchwood xylan for 5 min in distilled water. The resulting reducing sugars in the reaction mixture were measured using 3,5-dinitrosalicylic acid (DNS). Xylose produced from xylan was also determined using a high-performance liquid chromatography (HPLC) system (JASCO, Tokyo, Japan). In the assay using HPLC, the reaction was stopped in boiling water for 5 min. One unit of xylanase activity was defined as the amount of enzyme necessary to produce 1 μmol of reducing sugar (DNS method) or xylose (HPLC analysis) per minute.

The enzyme activity assays using 1 mM p-nitrophenol (PNP)-based chromogenic glycosides were performed at 45 °C for 10 min as described previously (Hideno et al. 2011). PNP-β-d-xylopyranoside (PNP-X), PNP-β-d-glucoside (PNP-G) and PNP-α-l-arabinofuranoside (PNP-A) were used as substrates for β-xylosidase, β-glucosidase and α-l-arabinofuranosidase activity, respectively. One unit of activity toward PNP-glycosides was defined as the amount of enzyme necessary to produce 1 μmol of PNP per minute.

β-Xylosidase activity using xylobiose and xylotriose, and β-glucosidase activity using cellobiose were assayed in 50 mM sodium acetate buffer (pH 5.0) with 10 mM oligosaccharide substrate. The reaction mixture was incubated at 45 °C for 30 min in a total volume of 1 mL, and the reaction was stopped in boiling water for 5 min. Xylose and glucose released in the mixture were determined using a BF-5 biosensor with a pyranose oxidase electrode and glucose oxidase electrode, respectively (Oji Scientific Instruments, Amagasaki, Japan). Xylose was also determined using a Dionex ICS 3000 chromatograph system (Dionex, Sunnyvale, CA, USA) for calculation of kinetic parameters of β-xylosidase activity using xylobiose. One unit of activity toward disaccharide and trisaccharide was defined as the amount of enzyme necessary to produce 2 μmol (from xylobiose or cellobiose) and 1.5 μmol (from xylotriose) of monomeric sugar per minute, respectively.

Enzymatic hydrolysis of DBM-RS

The hydrolysis of DBM-RS was carried out at a solid loading of 5 % (w/v) in 50 mM sodium acetate buffer (pH 5.0) as described previously (Hideno et al. 2009). In the standard assay, enzymatic hydrolysis was performed in a final volume of 1 mL. The reaction mixture containing cellulase from T. cellulolyticus (5 FPU/g-DBM-RS) was supplemented with hemicellulase (0–2 mg/g-DBM-RS) from KIF78, KIF109, KIF125, or the commercial enzyme Optimash BG (Genencor International, Palo Alto, CA, USA). The reaction mixture was incubated at 45 °C for 72 h with agitation using a rotator and the hydrolysate was analyzed using an HPLC system. The experiments were performed in duplicate. The sugar yields were calculated based on the amount of glucan and xylan in DBM-RS.

Purification of β-xylosidase from KIF125

All purification procedures were carried out using an ÄKTA Purifier Chromatography System (GE Healthcare, Buckinghamshire, UK). The culture filtrate from KIF125 was loaded onto a HiPrep 26/10 desalting column (GE Healthcare) equilibrated with 20 mM 2-(N-morpholino) ethanesulfonic acid (MES) buffer, pH 6.0 (buffer A). The desalted sample was subjected to anion-exchange chromatography on a HiTrap Q HP 5 ml column (GE Healthcare) equilibrated with buffer A, and the protein was eluted with a linear gradient of 0.025–0.25 M NaCl. Fractions with β-xylosidase activity were determined using PNP-X. The β-xylosidase fractions were pooled, desalted and subjected to anion-exchange chromatography on a Source 15Q column (GE Healthcare) equilibrated with 20 mM sodium acetate buffer, pH 5.5 (buffer B). The protein was eluted with a linear gradient of 0–0.125 M NaCl. The β-xylosidase fractions were pooled, brought to 2.0 M (NH4)2SO4, and subjected to hydrophobic interaction chromatography on a Source 15Phe column (GE Healthcare) with a 2.0–1.0 M (NH4) 2SO4 gradient in buffer B. The β-xylosidase fractions were pooled, desalted, and stored in buffer B containing 0.01 % NaN3 at 4 °C. The purity and size of the protein were analyzed by sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) using NuPage 4–12 % Bis–Tris gels (Invitrogen, Carlsbad, CA, USA). The amino acid sequence of a peptide fragment from β-xylosidase digested by lysyl endopeptidase was determined by using a Procise 494-HT protein sequencer (Applied Biosystems, Foster City, CA, USA).

Identification of KIF125

Fungal genomic DNA was prepared by the method of Zhu et al. using benzyl chloride (Zhu et al. 1993). The rDNA Internal Transcribed Spacer (ITS) region was amplified using the universal fungal primers ITS5 (5′- GGAAGTAAAAGTCGTAACAAGG-3′) and LR6 (5′- CGCCAGTTCTGCTTACC-3′) (http://www.biology.duke.edu/fungi/mycolab/primers.htm). The ITS-1–5.8S–ITS-2 sequence (412 bp) was analyzed using TrichoBLAST (http://www.isth.info/tools/blast/index.php). The nucleotide sequence used in this study was submitted to the DDBJ/EMBL/GenBank database under accession number LC132713.

HPLC analysis

Sugars were analyzed using an HPLC system equipped with a refractive index detector (RI-2031 Plus, JASCO). Glucose, xylose, galactose, arabinose, and xylobiose were analyzed using an Aminex HPX-87P column (7.8 mm I.D. × 30 cm, Bio-Rad, Hercules, CA, USA) with a Carbo-P Micro-Guard cartridge. The mobile phase used was doubly deionized water, and the flow rate was 1.0 mL/min at 80 °C column temperature. Xylose was also analyzed using a Dionex ICS 3000 chromatograph system equipped with CarboPac PA1 column (4 mm I.D. × 25 cm, Dionex) with a CarboPac PA1 guard column. A pulsed amperometric detector with an Au electrode operating in the integrated amperometric mode (Dionex) was used for the detection of xylose which was eluted with a 4.0–0 mM NaOH gradient. The flow rate was 1.0 mL/min at 35 °C column temperature.

Results

Screening and identification of a β-xylosidase-producing fungal strain

Fungal β-xylosidases are induced by xylan and xylose (Knob et al. 2010). In this study, 4 % (w/v) WDM-RS, corresponding to 1.31 % glucan and 0.78 % xylan in the medium, was used as a cheap carbon source and an inducer of β-xylosidase to prepare culture supernatants of 132 KIF strains. The supernatants were screened for extracellular β-xylosidase activity using PNP-X, and the screening was repeated for 8 candidate strains exhibiting high β-xylosidase activity (data not shown). Through these screenings, KIF125 was identified as the best β-xylosidase producer in the screening medium, and was therefore selected as the strain for further characterization. Since KIF125 has been originally isolated on an agar plate containing birch xylan from a soil sample as carbon source, it seems reasonable that this strain was found as a β-xylosidase producer. The sequence analysis of the partial ITS 1-5.8S-ITS 2 region (412 bp) for KIF125 showed 100 % sequence identity to T. asperellum CBS433.97 in the TrichoBLAST database (GenBank accession number AY380912), and thus, KIF125 was identified as a strain of T. asperellum.

Compositional characteristics of KIF125 hemicellulase

The enzymatic profile of KIF125 crude enzyme was compared to those of A. aculeatus KIF78, A. niger KIF109, and T. cellulolyticus CF-2612, which were prepared using WDM-RS, and the commercial hemicellulolytic enzyme Optimash BG. KIF78 and Optimash BG had been utilized as supplemental hemicellulases to increase sugar yield in xylan hydrolysis during the enzymatic hydrolysis of lignocellulosic biomass by T. cellulolyticus cellulase in our previous work (Hideno et al. 2009; Yano et al. 2009). KIF109 was used as a reference strain for β-xylosidase production, since A. niger has been reported as a high xylanase and β-xylosidase producer in RS (Kang et al. 2004). The crude enzymes of KIF strains were prepared in screening medium containing 6 % (w/v) WDM-RS using Erlenmeyer flasks for 7 days. They exhibited higher β-xylosidase activity than the cultures with 4 % (w/v) WDM-RS (data not shown). A comparison on the basis of specific activities is presented in Table 1. Multiple cellulolytic and hemicellulolytic enzymes were observed in the KIF125 enzyme. The KIF125 enzyme contained the highest β-xylosidase specific activity (2.04 U/mg), 7.6-, 2.7-, 10 -, and 51-fold higher than KIF78, KIF109, Optimash BG and CF-2612 enzymes, respectively. The unit ratio of β-xylosidase to xylanase in the KIF125 enzyme (0.18) was 8.1- to 111-times the ratio in the other sources. The KIF125 crude enzyme also contained higher α-l-arabinofuranosidase specific activity, 7.4-, 3.7-, and 6.7-fold higher compared to KIF78, KIF109, and CF-2612 enzymes, respectively. In contrast, xylanase and CMCase specific activities in KIF125 were significantly lower than those of Optimash BG (11- and 9.1-fold, respectively).

Effect of hemicellulase supplementation with T. cellulolyticus cellulase on DBM-RS hydrolysis

DBM treatment improves the enzymatic hydrolysis of lignocellulosic biomass by disrupting the cellulose-hemicellulose-lignin network in the cell wall by mechanochemical milling energy (Hideno et al. 2009; Inoue et al. 2015b). Although the cellulose crystallinity of the biomass is reduced during the pretreatment, the hemicellulose component is retained in the pretreated sample without chemical modification. Thus, we used DBM-RS as a model substrate to evaluate xylan digestibility in this study. The enzymatic hydrolysis of DBM-RS using T. cellulolyticus CF-2612 cellulase alone (1–20 FPU/g-substrate) resulted in relatively high xylobiose accumulation (15.8–31.3 %) in the hydrolysate (Fig. 1a). The results are consistent with the observation that CF-2612 cellulase has little β-xylosidase activity (Table 1). To evaluate the effect of hemicellulase supplementation, the hydrolysis of DBM-RS was fixed at a cellulase loading of 5 FPU/g-substrate (corresponding to 8.93 mg/g-DBM-RS): the glucose and xylose yields were 77 and 38 %, respectively, and the theoretical yield of xylose and xylobiose in the hydrolysate was estimated as 67 % at this cellulase loading (Fig. 1a).

Enzymatic hydrolysis of DBM-RS by T. cellulolyticus cellulase alone a and T. cellulolyticus cellulase (5 FPU/g of-DBM-RS) supplemented with hemicellulase b. The yields of sugars released from the hydrolysate were determined after 72 h. Dashed horizontal line in panel b shows the theoretical xylose yield (67 %) produced by T. cellulolyticus cellulase loading of 5 FPU/g-DBM-RS

The addition of hemicellulase from KIF strains and Optimash BG to CF-2612 cellulase improved the xylose yield with a decrease in the xylobiose accumulation, without a significant effect on the sugar yield in glucan hydrolysis of DBM-RS (Fig. S1: see electronic supplementary material). The theoretical xylose yield (67 %) produced by a cellulase loading of 5 FPU/g-substrate was achieved by a loading of 0.48, 0.83, 1.69, and 1.81 mg/g-DBM-RS for KIF125, KIF109, Optimash BG, and KIF78 hemicellulases, respectively (Fig. 1b). These results indicate that KIF125 hemicellulase was more effective in reducing the total enzyme loading for the improvement of xylose yield in combination with CF-2612 cellulase. In contrast, the β-xylosidase activity of supplemented KIF125 enzyme, which was estimated as 0.98 U/g-DBM-RS, was 2.9-fold higher than that of Optimash BG. The β-xylosidase loading required for CF-2612 cellulase may be affected by the enzyme composition in the hemicellulases, such as xylanase activity (Table 1). However, xylose yields by hemicellulase addition were kept at approximately 70 % (Fig. 1b). The glucose and theoretical xylose yields increased to 85 and 78 %, respectively, when cellulase loading increased to 20 FPU/g-substrate (Fig. 1a). These results suggest that the amount of cellulolytic enzymes was rate-limiting for further increase of glucose and xylose yields.

Characterization of β-xylosidase from KIF125

To identify the major β-xylosidase in KIF125 enzyme, we purified the enzyme from the culture supernatant prepared using WDM-RS (Table 2). The apparent molecular weight for β-xylosidase was estimated as 80.2 kDa on an SDS-PAGE gel (Fig. 2). The gene encoding β-xylosidase was identified by searching the T. asperellum CBS 433.97 genomic sequence on the Joint Genome Institute (JGI) database (http://genome.jgi.doe.gov/Trias1/Trias1.home.html) for the amino acid sequences RAPAGRLV and FXASQVLGAAHP, which were obtained from two internal peptide fragments. The identified gene was located on scaffold_16:398760–401402 on the CBS 433.97 genome, and the deduced 795 amino acid residues revealed homology to a glycosyl hydrolase (GH) family 3 β-xylosidase with 95 % identity to Trichoderma atroviride (XP_01340821) and 89 % identity to Trichoderma reesei (XP_006964075). Based on these analyses, the purified KIF125 enzyme was identified as GH3 β-xylosidase.

SDS-PAGE analysis of β-xylosidase from KIF125. The β-xylosidase fractions from all purification steps (Table 2) were analyzed. Lanes: M, protein marker; 1, culture supernatant (20 μg); 2, HiPrep desalting fraction (20 μg); 3, HiTrap Q HP fraction (5 μg); 4, Source 15Q fraction (5 μg); 5, Source 15Phe fraction (5 μg)

β-Xylosidase activity of the purified enzyme was optimal at pH 4.0, and more than 90 % between pH 3.5 and 4.5 (data not shown). The enzyme retained greater than 90 % of its original activity between pH 4.2 and 6.8 when incubated at 25 °C for 24 h. The enzyme had a temperature optimum of 60 °C and remained stable up to 60 °C at pH 5.0 for 30 min, but the activity was significantly reduced during incubation at 70 °C. The substrate specificities of the purified enzyme are summarized in Table 3. These activities were measured at 45 °C and pH 5.0 in consideration of the enzymatic hydrolysis conditions for lignocellulose using T. cellulolyticus cellulase. T. asperellum β-xylosidase showed high activities towards both PNP-X and xylobiose. The apparent K m for PNP-X and xylobiose were estimated as 0.10 and 0.14 mM, respectively. The k cat values, which were calculated for the theoretical molecular mass of 85 kDa of the mature enzyme, were 31.7 and 32.3 s−1, respectively. Similarly to other GH3 fungal β-xylosidases, the enzyme hydrolyzed PNP-A. In contrast, PNP-G was hydrolyzed only slightly, and no activity was detected when cellobiose was used as substrate. The relative activity for xylotriose decreased to 46 % compared to that for xylobiose, suggesting that the enzyme prefers shorter xylo-oligosaccharide as substrates. The enzyme also released xylose from birchwood xylan, although β-xylosidases generally exhibit little or no activity against polymeric xylans (Knob et al. 2010).

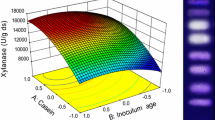

β-Xylosidase production of KIF125 using a bench-scale fermentor

The applicability of KIF125 for industrial β-xylosidase production on RS was evaluated using a bench-scale fermentor. The composition of nitrogen sources and inorganic salts in the medium was preliminarily examined based on β-xylosidase production using 6 % RS in flasks, and the optimal content of RS in the improved medium was determined in the fermentor. The removal of yeast extract, corn steep liquor, and tartrate salt in the screening medium did not affect β-xylosidase production, whereas the addition of urea increased its production (data not shown). Urea as nitrogen source had also been reported for the improvement of β-xylosidase production from Aspergillus awamori (Gottschalk et al. 2013). Medium (1 L) containing 20 g WDM-RS and 0.4 g urea was used for β-xylosidase production using a fermentor as described in Materials and Methods.

The fermentation course for ATP reflecting fungal growth (Cochet et al. 1984; Fang et al. 2009), urea, protein concentration, and β-xylosidase activity in the fermentor culture are shown in Fig. 3. The ATP concentration significantly increased and reached its maximum value at 48 h together with the consumption of urea (Fig. 3a). The time-dependent increase in protein concentration and β-xylosidase activity showed a similar trend (Fig. 3b). These values significantly increased between 24 and 42 h, and were closely related to the increase in fungal growth (Fig. 3). The enzyme activity in the culture hardly increased until 96 h. The production of KIF125 β-xylosidase in the fermentor was estimated as 118 U/g-WDM-RS (2350 U/L culture) at 48 h (Fig. 3b). In addition, a similar production profile of xylanase was also observed in this culture (data not shown). The addition of urea (0.2 g) at 48 h of fermentation had no beneficial effect on further enzyme production, although the ATP concentration was maintained at around 15 μmol/L until 96 h (Fig. 3). These results indicate that KIF125 produces hemicellulases only in the early to middle stages of cell growth.

The enzymatic profile in the fermentor culture at 96 h is shown in Table 1. Both the protein concentration and xylanase specific activity were 1.8- and 2.0-fold higher, respectively, than in the flask KIF125 culture. Although β-xylosidase specific activity in the fermentor culture was 2.1-fold lower than that in the KIF125 flask culture, the activity was still high compared to those of the other fungal cultures and Optimash BG. In addition, the unit ratio of xylanase to β-xylosidase (0.042) in the fermentor culture was also higher than those in the other sources, suggesting that the fermentor culture had similar properties as the flask culture regarding the relatively high abundance of β-xylosidase in the xylanolytic enzyme system.

Discussion

In this study, we revealed that T. asperellum KIF125 selected from 132 fungal cultures prepared using WDM-RS is a promising candidate for on-site hemicellulase production, especially production of GH3 β-xylosidase that possesses high substrate specificity for xylobiose. T. asperellum, a mycoparasitic fungus isolated from soil, plant roots and tissues, fungal biomass, and dead wood, is an effective biocontrol agent against many soil-borne plant pathogenic fungi (Liu et al. 2010; Marx et al. 2013), and has attracted attention as isolates for on-site enzyme production using lignocellulosic materials in recent years. For example, cellulolytic enzymes, including high activities of β-glucosidase, have been produced from oil palm empty fruit bunch using T. asperellum UPM1 (Ibrahim et al. 2013). T. asperellum S4F8 cultured on sugarcane bagasse has produced a wide range of lignocellulolytic enzymes with significantly higher hemicellulase and β-glucosidase activities, exceeding those of T. reesei (Marx et al. 2013). T. asperellum T-1 has been used as the main fermentation strain for cellulolytic enzyme production by a fungal consortium using wheat straw in the medium (Lin et al. 2011). Our results suggest that T. asperellum KIF124 is preferable for production of hemicellulase rather than cellulase when RS was used as carbon source.

KIF125 hemicellulase produced using RS was unique in the high abundance of β-xylosidase in the xylanolytic enzyme system compared to other fungal hemicellulase preparations (Table 1). It should be noted that KIF125 hemicellulase was more effective as a supplement for the β-xylosidase-deficient T. cellulolyticus CF-2612 cellulase than the hemicellulases from other fungal sources. This successful combination is due to high β-xylosidase dominance in KIF125 hemicellulase. The ability of KIF125 β-xylosidase to rapidly hydrolyze low molecular weight oligomers should be effective in the prevention of xylobiose accumulation in the enzymatic hydrolysis of pretreated biomass. These results indicate that T. asperellum hemicellulase would be useful as a supplemental enzyme for the hydrolysis of lignocellulosic biomass. T. asperellum had been reported to produce a high diversity of hemicellulases in culture using sugarcane bagasse and wheat bran (Marx et al. 2013; Bech et al. 2015 ). However, these unknown hemicellulases in KIF125 combined with T. cellulolyticus enzyme did not seem to be beneficial in the hydrolysis of DBM-RS, This is probably due to appropriate xylanase and accessory enzymes activities in T. cellulolyticus cellulase system produced using RS (Hideno et al. 2011).

Marx et al. (2013) have reported two putative β-xylosidases (GH3 and GH43) in a secretome analysis of T. asperellum S4F8 cultured on sugarcane bagasse. The major β-xylosidase purified from KIF125 was consistent with the GH3 protein in a secretome analysis of S4F8, suggesting that this enzyme plays an important role in the hydrolysis of lignocellulosic biomass by T. asperellum. The pH and temperature properties of KIF125 β-xylosidase were close to those reported for T. reesei β-xylosidase (Poutanen and Puls 1988; Semenova et al. 2009). The significant exo-β-xylanase activity of KIF125 β-xylosidase may be characteristic of Trichoderma β-xylosidase (Margolles-Clark et al. 1996; Herrmann et al. 1997).

The production of fungal β-xylosidase has been examined under various conditions including solid-state and submerged fermentation techniques (Table 4). The KIF125 fermentor culture at 48 h seemed to produce a higher activity of β-xylosidase in comparison to Aspergillus cultures in submerged fermentation (Chipeta et al. 2008; Michelin et al. 2012; Gottschalk et al. 2013). On the other hand, β-xylosidase production of A. aculeatas and Colletotrichum graminicola under solid-state fermentation were similar to that of KIF125 (Zimbardi et al. 2013; Suwannarangsee et al. 2014). Higher production levels were observed for Aspergillus tamarii and A. niger under solid-state fermentation (Ferreira et al. 1999; Kang et al. 2004). These comparisons suggest that the β-xylosidase production of KIF125 is comparable to those of other promising hemicellulase producers. It should be noted that KIF125 produced hemicellulases in the early to middle stages of cell growth that ATP concentration increased. These observations are in contrast to our previous results of cellulase production using T. cellulolyticus: its enzyme production continuously increased after ATP concentration decreased (Fang et al. 2009; Hideno et al. 2011). The rapid cellulase secretion of T. asperellum has also been observed in solid-state fermentation and flask cultures using wheat bran and wheat straw, respectively (Raghuwanshi et al. 2014; Wang et al. 2015). The relatively shorter fermentation time for T. asperellum enzyme production would give an advantage in the industrial process using KIF125 as a new on-site hemicellulase source.

References

Banerjee G, Scott-Craig JS, Walton JD (2010) Improving enzymes for biomass conversion: a basic research perspective. Bioenerg Res 3:82–92

Bech L, Busk PK, Lange L (2015) Cell wall degrading enzymes in Trichoderma asperellum grown on wheat bran. Fungal Genom Biol 4:116

Chipeta ZA, du Preez JC, Christopher L (2008) Effect of cultivation pH and agitation rate on growth and xylanase production by Aspergillus oryzae in spent sulphite liquor. J Ind Microbiol Biotechnol 35:587–594

Cochet N, Tyagi RD, Ghose TK, Lebeault JM (1984) ATP measurement for cellulase production control. Biotechnol Lett 6:155–160

Fang X, Yano S, Inoue H, Sawayama S (2009) Strain improvement of Acremonium cellulolyticus for cellulase production by mutation. J Biosci Bioeng 107(3):256–261

Ferreira GL, Boer CG, Peralta RM (1999) Production of xylanolytic enzymes by Aspergillus tamarii in solid state fermentation. FEMS Microbiol Lett 173:335–339

Fujii T, Fang X, Inoue H, Murakami K, Sawayama S (2009) Enzymatic hydrolyzing performance of Acremonium cellulolyticus and Trichoderma reesei against three lignocellulosic materials. Biotechnol Biofuels 2:24

Gao D, Uppugundla N, Chundawat SP, Yu X, Hermanson S, Gowda K, Brumm P, Mead D, Balan V, Dale BE (2011) Hemicellulases and auxiliary enzymes for improved conversion of lignocellulosic biomass to monosaccharides. Biotechnol Biofuels 4:5

Gottschalk LM, de Sousa Paredes R, Teixeira RS, da Silva AS, da Silva Bon EP (2013) Efficient production of lignocellulolytic enzymes xylanase, β-xylosidase, ferulic acid esterase and β-glucosidase by the mutant strain Aspergillus awamori 2B.361 U2/1. Braz J Microbiol 44:569–576

Gusakov AV (2011) Alternatives to Trichoderma reesei in biofuel production. Trends Biotechnol 29:419–425

Herrmann MC, Vrsanska M, Jurickova M, Hirsch J, Biely P, Kubicek CP (1997) The β-d-xylosidase of Trichoderma reesei is a multifunctional β-d-xylan xylohydrolase. Biochem J 321(Pt 2):375–381

Hideno A, Inoue H, Tsukahara K, Fujimoto S, Minowa T, Inoue S, Endo T, Sawayama S (2009) Wet disk milling pretreatment without sulfuric acid for enzymatic hydrolysis of rice straw. Bioresour Technol 100(10):2706–2711

Hideno A, Inoue H, Tsukahara K, Yano S, Fang X, Endo T, Sawayama S (2011) Production and characterization of cellulases and hemicellulases by Acremonium cellulolyticus using rice straw subjected to various pretreatments as the carbon source. Enzyme Microb Technol 48(2):162–168

Hong Y, Nizami AS, Bafrani MP, Saville BA, MacLean HL (2013) Impact of cellulase production on environmental and financial metrics for lignocellulosic ethanol. Biofuel Bioprod Bior 7:303–313

Hu J, Arantes V, Saddler JN (2011) The enhancement of enzymatic hydrolysis of lignocellulosic substrates by the addition of accessory enzymes such as xylanase: is it an additive or synergistic effect? Biotechnol Biofuels 4:36

Hu J, Arantes V, Pribowo A, Saddler JN (2013) The synergistic action of accessory enzymes enhances the hydrolytic potential of a “cellulase mixture” but is highly substrate specific. Biotechnol Biofuels 6:112

Ibrahim MF, Razak MN, Phang LY, Hassan MA, Abd-Aziz S (2013) Crude cellulase from oil palm empty fruit bunch by Trichoderma asperellum UPM1 and Aspergillus fumigatus UPM2 for fermentable sugars production. Appl Biochem Biotechnol 170:1320–1335

Inoue H, Decker SR, Taylor LE II, Yano S, Sawayama S (2014) Identification and characterization of core cellulolytic enzymes from Talaromyces cellulolyticus (formerly Acremonium cellulolyticus) critical for hydrolysis of lignocellulosic biomass. Biotechnol Biofuels 7:151

Inoue H, Kishishita S, Kumagai A, Kataoka M, Fujii T, Ishikawa K (2015a) Contribution of a family 1 carbohydrate-binding module in thermostable glycoside hydrolase 10 xylanase from Talaromyces cellulolyticus toward synergistic enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 8:77

Inoue H, Yano S, Sawayama S (2015b) Effect of β-mannanase and β-mannosidase supplementation on the total hydrolysis of softwood polysaccharides by the Talaromyces cellulolyticus cellulase system. Appl Biochem Biotech 176:1673–1686

Kang SW, Park YS, Lee JS, Hong SI, Kim SW (2004) Production of cellulases and hemicellulases by Aspergillus niger KK2 from lignocellulosic biomass. Bioresour Technol 91:153–156

Kanna M, Yano S, Inoue H, Fujii T, Sawayama S (2011) Enhancement of β-xylosidase productivity in cellulase producing fungus Acremonium cellulolyticus. AMB Express 1:15

Klein-Marcuschamer D, Oleskowicz-Popiel P, Simmons BA, Blanch HW (2012) The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol Bioeng 109:1083–1087

Knob A, Terrasan CRF, Carmona EC (2010) β-Xylosidases from filamentous fungi: an overview. World J Microb Biot 26:389–407

Knob A, Fortkamp D, Prolo T, Izidoro SC, Almeida JM (2014) Agro-residues as alternative for xylanase production by filamentous fungi. Bioresources 9:5738–5773

Lin H, Wang B, Zhuang R, Zhou Q, Zhao Y (2011) Artificial construction and characterization of a fungal consortium that produces cellulolytic enzyme system with strong wheat straw saccharification. Bioresour Technol 102:10569–10576

Liu Z, Yang X, Sun D, Song J, Chen G, Juba O, Yang Q (2010) Expressed sequence tags-based identification of genes in a biocontrol strain Trichoderma asperellum. Mol Biol Rep 37:3673–3681

Liu G, Zhang J, Bao J (2016) Cost evaluation of cellulase enzyme for industrial-scale cellulosic ethanol production based on rigorous aspen plus modeling. Bioprocess Biosyst Eng 39:133–140

Margolles-Clark E, Tenkanen M, Nakari-Setälä T, Penttilä M (1996) Cloning of genes encoding α-l-arabinofuranosidase and β-xylosidase from Trichoderma reesei by expression in Saccharomyces cerevisiae. Appl Environ Microbiol 62:3840–3846

Marx IJ, van Wyk N, Smit S, Jacobson D, Viljoen-Bloom M, Volschenk H (2013) Comparative secretome analysis of Trichoderma asperellum S4F8 and Trichoderma reesei Rut C30 during solid-state fermentation on sugarcane bagasse. Biotechnol Biofuels 6:172

Merino ST, Cherry J (2007) Progress and challenges in enzyme development for biomass utilization. Adv Biochem Eng Biotechnol 108:95–120

Michelin M, Polizeli Mde L, Ruzene DS, Silva DP, Ruiz HA, Vicente AA, Jorge JA, Terenzi HF, Teixeira JA (2012) Production of xylanase and β-xylosidase from autohydrolysis liquor of corncob using two fungal strains. Bioprocess Biosyst Eng 35:1185–1192

Poutanen K, Puls J (1988) Characteristics of Trichoderma reesei β-xylosidase and its use in the hydrolysis of solubilized xylans. Appl Microbiol Biotechnol 28:425–432

Qing Q, Wyman CE (2011) Supplementation with xylanase and β-xylosidase to reduce xylo-oligomer and xylan inhibition of enzymatic hydrolysis of cellulose and pretreated corn stover. Biotechnol Biofuels 4:18

Raghuwanshi S, Deswal D, Karp M, Kuhad RC (2014) Bioprocessing of enhanced cellulase production from a mutant of Trichoderma asperellum RCK2011 and its application in hydrolysis of cellulose. Fuel 124:183–189

Selig MJ, Knoshaug EP, Adney WS, Himmel ME, Decker SR (2008) Synergistic enhancement of cellobiohydrolase performance on pretreated corn stover by addition of xylanase and esterase activities. Bioresour Technol 99:4997–5005

Semenova MV, Drachevskaya MI, Sinitsyna OA, Gusakov AV, Sinitsyn AP (2009) Isolation and properties of extracellular β-xylosidases from fungi Aspergillus japonicus and Trichoderma reesei. Biochemistry (Mosc) 74:1002–1008

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure NREL technical report TP-510-42618. National renewable energy laboratory (NREL). http://www.nrel.gov/biomass/pdfs/42618.pdf

Suwannarangsee S, Arnthong J, Eurwilaichitr L, Champreda V (2014) Production and characterization of multi-polysaccharide degrading enzymes from Aspergillus aculeatus BCC199 for saccharification of agricultural residues. J Microbiol Biotechnol 24:1427–1437

Van Dyk JS, Pletschke BI (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes—factors affecting enzymes, conversion and synergy. Biotechnol Adv 30:1458–1480

Wang Q, Lin H, Shen Q, Fan X, Bai N, Zhao Y (2015) Characterization of cellulase secretion and Cre1-mediated carbon source repression in the potential lignocellulose-degrading strain Trichoderma asperellum T-1. PLoS ONE 10:e0119237

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities. Methods Enzymol 160:87–117

Xin D, Ge X, Sun Z, Viikari L, Zhang J (2015) Competitive inhibition of cellobiohydrolase I by manno-oligosaccharides. Enzyme Microb Technol 68:62–68

Yano S, Kitao C, Inoue H, Sawayama S, Imou K, Yokoyama S (2009) A newly isolated hemicellulase-producing fungus for second-generation ethanol production, Aspergillus aculeatus KIF 78. J Environ Biotechnol 9(2):81–87

Zhu H, Qu F, Zhu LH (1993) Isolation of genomic DNAs from plants, fungi and bacteria using benzyl-chloride. Nucleic Acids Res 21(22):5279–5280

Zimbardi AL, Sehn C, Meleiro LP, Souza FH, Masui DC, Nozawa MS, Guimarães LH, Jorge JA, Furriel RP (2013) Optimization of β-glucosidase, β-xylosidase and xylanase production by Colletotrichum graminicola under solid-state fermentation and application in raw sugarcane trash saccharification. Int J Mol Sci 14:2875–2902

Acknowledgments

This work was partially supported by the Regional Biomass Energy Project of the Ministry of Agriculture, Forestry, and Fisheries of Japan. The authors are grateful to Dr. Akihiro Hideno for useful discussion. The authors would like to thank Ms. Reiko Yoshii for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Inoue, H., Kitao, C., Yano, S. et al. Production of β-xylosidase from Trichoderma asperellum KIF125 and its application in efficient hydrolysis of pretreated rice straw with fungal cellulase. World J Microbiol Biotechnol 32, 186 (2016). https://doi.org/10.1007/s11274-016-2145-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-016-2145-x