Abstract

Agroindustrial residues are materials often rich in cellulose and hemicellulose. The use of these substrates for the microbial production of enzymes of industrial interest is mainly due to their high availability associated with their low cost. In this work, corncob (CCs) particles decomposed to soluble compounds (liquor) were incorporated in the microbial growth medium through autohydrolysis, as a strategy to increase and undervalue xylanase and β-xylosidase production by Aspergillus terricola and Aspergillus ochraceus. The CCs autohydrolysis liquor produced at 200 °C for 5, 15, 30 or 50 min was used as the sole carbon source or associated with untreated CC. The best condition for enzyme synthesis was observed with CCs submitted to 30 min of autohydrolysis. The enzymatic production with untreated CCs plus CC liquor was higher than with birchwood xylan for both microorganisms. A. terricola produced 750 total U of xylanase (144 h cultivation) and 30 total U of β-xylosidase (96–168 h) with 0.75% untreated CCs and 6% CCs liquor, against 650 total U of xylanase and 2 total U of β-xylosidase in xylan; A. ochraceus produced 605 total U of xylanase and 56 total U of β-xylosidase (168 h cultivation) with 1% untreated CCs and 10% CCs liquor against 400 total U of xylanase and 38 total U of β-xylosidase in xylan. These results indicate that the treatment of agroindustrial wastes through autohydrolysis can be a viable strategy in the production of high levels of xylanolytic enzymes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Xylanases (EC 3.2.1.8) are xylan-degrading enzymes that, over recent years, have attracted attention for several potential industrial applications, such as (1) beer and juice clarification; (2) improving digestibility of animal feed; (3) accelerating the baking of cookies, cakes, crackers; (4) pharmaceutical and chemical applications; (5) prebleaching of kraft pulp by improving the liberation of lignin through hydrolysis of hemicellulose; (6) an alternative to the sulfuric acid treatment of textile polyester-cellulose wastes. β-xylosidase (EC 3.2.1.37) is a xylanolytic enzyme that hydrolyzes the non-reducing end of xylo-oligosaccharides to release xylose and to catalyze the cleavage of xylobiose. Moreover, the xylanases in synergistic action with β-xylosidase have the potential to achieve the complete saccharification of lignocellulosic biomass for ethanol production as an alternative fuel [1–6]. Xylanases have an annual worldwide market of around US $ 200 million and the widespread use of xylanase in commercialized industrial applications requires extensive studies to optimize their production [7].

Microbial xylanase production can be performed by submerged fermentation (SmF). Substrates are dissolved or suspended in an aqueous medium and mixed so that fermentation takes place in a homogeneous environment. Corncobs (CCs), an agroindustrial residue rich in hemicelluloses and that acts as an inducer for xylanases production can be used as a substrate for the production of these enzymes in submerged fermentation.

The utilization of agroindustrial residues for enzymes production minimizes pollution and allows obtaining high added-value products using an economical technology. Over 300 million tons of agroindustrial residues are produced annually worldwide [8]. CCs are important by-products of the sweet corn processing industry. They contain approx. 391 g cellulose, 421 g hemicellulose, 91 g lignin, 17 g protein, and 12 g ash per kg of dry matter. For every 100 kg of corn grain, approx. 18 kg of CCs are produced. A large quantity of CCs thus generated remains unused as lignocellulosic wastes in fields and factories or is used as animal feed [9]. Xylans, the main component of hemicelluloses in CCs, are composed of β-d-xylopyranosyl units (xylose) linked by β-(1-4) glycosidic bonds with different substituent groups in the side-chain [10, 11].

The chemical fractionation of CCs in their structural components (cellulose, hemicellulose and lignin) is an attractive possibility leading to an integral benefit of this agricultural residue. From the several fractionation processes, autohydrolysis is one of the most interesting. Autohydrolysis is an environmentally friendly process based on the selective depolymerization of hemicellulose present in CCs, which is catalyzed by hydronium ions (coming initially from water autoionization and later from in situ generated acids, mainly acetic acid from acetyl groups hydrolysis). The hemicelluloses are decomposed into soluble products, including xylooligomers (XOS) and xylose that can be used as substrate for xylanases production, whereas the spent solids from autohydrolysis are enriched into cellulose and lignin [12–15]. The present work aims to improve the xylanolytic enzymes production by using CC autohydrolysis liquor to obtain a viable substrate for xylanase and β-xylosidase production by Aspergillus terricola and Aspergillus ochraceus.

Materials and methods

Raw material

Corncobs (CCs) were kindly supplied by a local farmer (Portugal). The CCs, after being dried at 40 °C for 12 h, were cut into small chips (1–3 cm), milled using a knives mill to pass through a 0.5 or 1.0 mm screen, and stored at room temperature. All chemicals used were analytical grade reagents.

Chemical characterization of the raw material

The chemical characterization was performed following the procedure reported by Ruiz et al. [16]. Aliquots from the homogenized CCs (milled to pass a 0.5 mm screen) were subjected to moisture determination (drying at 105 °C to constant weight). Approximately, 0.5 g of CCs was treated with 5 ml of 72% (w/w) H2SO4 for 1 h at 30 °C, followed by a quantitative posthydrolysis with 4% sulfuric acid (adding water until 148.67 g) at 121 °C during 60 min. Before HPLC analysis, the solid residue from the posthydrolysis process was recovered by filtration and considered as Klason lignin. For the determination of ash, the solid retained after filtration was taken in a crucible and kept in a muffle furnace at 750 °C for 8 h. The monosaccharide sugars and acetic acid contained in the hydrolysates were determined by HPLC (see below), in order to estimate the contents of the samples in glucan, xylan, arabinan and acetyl groups.

Autohydrolysis process

The autohydrolysis process was carried out in 160 ml total volume stainless steel cylinder reactors. Milled CCs samples with a particle size of 1.0 mm and water were mixed in a closed and pressurized vessel in order to obtain a solid/liquid ratio of 1:10 (w/v). The system was submerged in an oil bath with an open heating circulator (Julabo Labortechnik GmbH, Seelbath, Germany) with PID temperature control at 200 °C during 5, 15, 30 or 50 min. At the end of the desired reaction time, the reactor was removed from the oil bath and immediately immersed in an ice bath for 5 min to quench the reaction. The liquid phase or liquor (hemicelluloses rich fraction) was separated from the solids by vacuum filtration, and then used as liquid substrate.

Characterization of the liquor from the autohydrolysis process

A sample of the liquor from the autohydrolysis process at 200 °C for 30 min was filtrated through 0.45 µm membranes and analysed by HPLC (see below) for determination of monosaccharides (glucose, xylose and arabinose) and acetic acid. A second aliquot of the liquor (1 ml) was subjected to quantitative posthydrolysis (with 4% H2SO4 at 121 °C, during 60 min) before HPLC analysis. The increase in the concentrations of monosaccharides and acetic acid caused by posthydrolysis is a measure of the concentrations of oligomers and acetyl groups bound to oligosaccharides. Furfural and hydroxymethylfurfural (HMF) concentrations were determined following the procedure reported by Ruiz et al. [17]. The quantification was performed using HPLC with a Nucleosil 120–5 C18 column at room temperature, using acetonitrile–water in a ratio 1:8 (v/v) containing 10 g/l acetic acid as the mobile phase, at a flow rate of 0.9 ml/min, being the detection performed with a UV intelligent UV–VIS detector at 276 nm.

HPLC analysis

The chemical characterization and quantification of the sugars and acetic acid present in the raw material (corncob) and in the autohydrolysis liquor mentioned above was performed with a refractive index (RI) detector in a Jasco chromatograph equipped with a Metacarb 87H column (300 × 7.8 mm, Varian, USA) under the following conditions: mobile phase 0.005 M H2SO4, flow rate 0.7 ml/min, and column temperature 60 °C.

Microorganisms

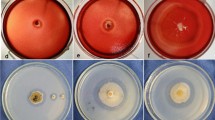

The microorganisms used in this work were the fungal strains Aspergillus terricola and Aspergillus ochraceus. These were isolated from nature, in São Paulo State, Brazil, and classified by Mycology Culture Collection URM at the Federal University of Pernambuco. Stock cultures were maintained on PDA medium slants (Difco), at 4 °C.

Cultivation conditions

Conidia from 7-day-old cultures, with cell concentration of 2 × 108 cells/ml, were inoculated into 250 ml Erlenmeyer flasks containing 50 ml of the liquid medium described by Vogel [18] and Adams [19], pH 6.0, for A. terricola and A. ochraceus cultures, respectively. The design of each experiment with relation to carbon sources are specified in Tables 1 and 2. The cultures were incubated at 30 °C, at 100 rpm, for up to 7 days. During fermentations, samples were taken every 24 h and the mycelia and residues were removed by centrifugation at 10,000g for 15 min. The filtrates were used as sources of crude extracellular xylanase and β-xylosidase.

Enzymatic assays

Xylanase activity was assayed using birchwood xylan as substrate. Reaction mixtures contained 0.2 ml enzyme and 0.2 ml 1% (w/v) birchwood xylan solution in citrate–phosphate buffer, pH 6.0. The mixture was incubated at 60 °C, and after predetermined periods the released reducing sugars were quantified by DNS method [20], using xylose as standard. One unit of xylanase activity was defined as the amount of enzyme that released 1 µmol product per min under the assay conditions.

β-Xylosidase activity was assayed using p-nitrophenyl-β-d-xylopyranoside (PNP-xyl) as substrate. Reaction mixtures contained 0.2 ml enzyme, 0.15 ml citrate–phosphate buffer, pH 4.5, and 0.05 ml 0.25% (w/v) PNP-xyl in distilled water. The mixture was incubated at 70 °C, and after predetermined periods the released p-nitrophenolate were estimated with saturated sodium tetraborate solution, using p-nitrophenol as standard [21]. One unit of β-xylosidase was defined as the amount of enzyme that released 1 µmol of product per min under the assay conditions.

Results and discussion

Chemical composition of raw material

The composition of CCs samples used as a raw material (as the average of three replicates) is shown in Table 3. The raw materials are defined by their contents of glucan (corresponding to cellulose), xylan (measured as xylose equivalent, which forms the main polymer backbone), xylan substituents (arabinose units, reported as arabinan expressed in sugar equivalent, and acetyl groups), lignin, ashes, and other components [12]. CC is an agricultural waste that contains around 35% cellulose, 30% hemicellulose and 15% lignin. Xylan content in CCs accounted for about 30% of the dry weight of the raw material. This chemical composition is in good agreement with other values found in the literature for this material [22, 23]. Glucan and xylan are the main polysaccharides present.

Characterization of liquors from autohydrolysis process

The hemicellulosic fraction was the most important for the objectives of this study. Autohydrolysis caused a substantial solubilization of the feedstock, and the liquid phase contained a mixture of xylo-oligosaccharides (XOS), arabino-oligosaccharides (ArOS), gluco-oligosaccharides (GOS) and acetyl groups-oligosaccharides (AcOS), monosaccharides (xylose, arabinose and glucose), acetic acid, furfural and hydroxymethylfurfural (HMF), the main decomposition product of pentoses and hexoses. The operational conditions were selected in order to achieve high xylan solubilization with little decomposition. The concentrations (g/l) of the liquid phase components obtained after autohydrolysis at 200 °C/30 min, the conditions that allowed for a higher enzyme production, are shown in Table 4.

The CCs liquor obtained after autohydrolysis is rich in XOS that acts as an inducer and can be used as substrate for xylanase and β-xylosidase production. Furthermore, it is important that low amounts of furfural and HMF are formed, once concentrations higher than 1 g/l HMF are reported as inhibitory to microbial metabolism [24, 25]. Taherzadeh et al. [26] reported that Saccharomyces cerevisiae growth in synthetic medium was 70% inhibited on 4 g/l HMF and 89% on 4 g/l furfural. In the presence of both furfural (2 g/l) and HMF (2 g/l), the growth of this organism was completely inhibited. Szengyel and Zacchi investigated the effects of acetic acid, furfural and combinations of the two on the cellulase production by filamentous fungus H. jecorina RUT C30. They concluded that furfural inhibits enzyme production and that addition of acetic acid increased the production of β-glucosidase but had no effect on cellulase production [27]. Therefore, the bioconversion of hydrolysates derived from hemicellulosic fraction in hemicellulases is dependent not only on the productive capacity of the microorganism, but also on its tolerance to inhibitory effects caused by several toxic compounds present in these hydrolysates [28].

Xylanase and β-xylosidase production from the autohydrolysis liquor of corncob

The high xylan content in some wastes such as CC makes it an accessible and cheap source of inducer for xylanase and β-xylosidase production, making the inclusion of these components in the nutrient medium composition the main strategy in microbial xylanase biosynthesis [28]. However, it is important to consider that these residues are complex and, therefore, can induce different types of proteins, including cellulases, which makes difficult the application of this extract on paper and cellulose industry, for example. Sometimes, the separation of different fractions contained in these lignocellulosic materials is necessary. Having this in mind, it is of the utmost importance to evaluate the use of the hemicellulolytic fraction (obtained from CC autohydrolysis) as inducer source of xylan-degrading enzymes, a subject that has not been much considered.

Pretreatment has often been useful to improve the digestibility of lignocellulosic materials and to facilitate access for microbial attack. The pretreatment results in the enlargement of the inner surface area of substrate particles, accomplished by partial solubilization and/or degradation of hemicellulose and lignin. This leads to the fractionation of the three main components and to the opening of cellulose structure [29].

Thus, in order to improve the production of xylanolytic enzymes, CCs were submitted to an autohydrolysis process to produce XOS for further use as substrate. According to Fig. 1, the best condition for xylanase production was observed when the microorganisms were cultivated with 1% (w/v) CCs added to 10% (v/v) of CC autohydrolysis liquor obtained after 30 min of autohydrolysis process; and the highest xylanase production (720 total U—A. terricola and 660 total U—A. ochraceus) was observed in the period between 120 and 168 h of cultivation.

Xylanase and β-xylosidase production by A. terricola (a, c) and A. ochraceus (b, d) using the CC autohydrolysis liquor after different times of autohydrolysis treatment as carbon source. Symbols: 1% (w/v) CC plus 10% (v/v) CC autohydrolysis liquor after autohydrolysis treatment of 5 min (filled squares), 15 min (filled circles), 30 min (filled triangles) and 50 min (filled diamonds); and 100% (v/v) CC autohydrolysis liquor after autohydrolysis treatment of 5 min (open squares), 15 min (open circles), 30 min (open triangles) and 50 min (open diamonds). Microorganisms were cultivated in Vogel and Adams media, respectively, at 30 °C, 100 rpm, for up to 7 days

The mixtures of 1% (w/v) CCs and 10% (v/v) CCs liquor obtained after 15 and 50 min of autohydrolysis treatment were also excellent xylanase inducers for both microorganisms, corresponding to 91–93% of the activity observed with the first option (mixture of 1% (w/v) CCs added to 10% (v/v) of CCs autohydrolysis liquor obtained after 30 min of autohydrolysis pretreatment) for A. terricola (120–144 h cultivation) and 80–93% for A. ochraceus (120–168 h cultivation). The mixture obtained with a 5 min treatment was the least favorable. The liquor obtained after 15 min of autohydrolysis treatment, when used alone, corresponded to 70% of the enzyme production observed with the mixture of 1% CC and 10% CC liquor—30 min autohydrolysis, being the most favorable among the liquors. Similar results for enzyme production were obtained with the liquor obtained after 5 min treatment and its mixture with CCs. Regarding the liquors with 30 and 50 min of autohydrolysis, these were not favorable to xylanolytic synthesis, probably due to an high xylan decomposition (Fig. 1a, b).

In relation to β-xylosidase activity from A. terricola, the mixture containing 1% (w/v) CC plus 10% (v/v) CC liquor obtained after 30 min of autohydrolysis treatment (14 total U; 144–168 h cultivation), and the use of 100% (v/v) of the liquor obtained with 30 min pretreatment (13 total U; 72 h cultivation) were the best inducers (Fig. 1c). The mixture of 1% (w/v) CC and 10% (v/v) liquor obtained with 50 min autohydrolysis treatment was also a good source of β-xylosidase inducer, with 168 h of cultivation. For A. ochraceus, mixtures of 1% (w/v) CC with the 10% (v/v) liquors obtained after 30 min (51–54 total U; 96–168 h cultivation) and 50 min (52 total U; 144–168 h cultivation) of autohydrolysis treatment were the best inducers of β-xylosidase synthesis (Fig. 1d). The substrate obtained after 5 min of thermal treatment was not favorable to β-xylosidase production for both microorganisms.

Therefore, the autohydrolysis pretreatment of CCs at 200 °C for 30 min was considered, within the evaluated conditions, the best condition to obtain a liquor rich in hemicellulose for further use in xylanase and β-xylosidase production by A. terricola and A. ochraceus in submerged fermentation.

Effect of the concentration of CCs autohydrolysis liquor on xylanase and β-xylosidase production: a comparison with birchwood xylan and untreated corncob

Xylan is an excellent option for xylanases production and this has been done often at small scale. However, for production at large scale, the use of these high cost materials makes the process uneconomical. To solve this, the use of agroindustrial or agricultural residues, such as sugar cane bagasse [29], corncob [30, 31] and wheat bran [32] among others, has been the most used solution.

In order to compare the effects of xylanase and β-xylosidase production from autohydrolysis liquors of CCs, different fermentations were done using different carbon sources: 1% (w/v) xylan (as control), 1% (w/v) raw CCs, different concentrations of the mixture of raw CC and CC autohydrolysis liquor after 30 min of autohydrolysis treatment (pre-standardized condition), and 100% (v/v) CC autohydrolysis liquor.

Xylanase production (A. terricola) obtained with a mixture composed of 0.75% (w/v) CCs and 6% (v/v) CCs liquor (760 total U) was 15% higher than with birchwood xylan, after 144 h of cultivation. Similar results were observed with the mixtures: 1% (w/v) CC plus 10% (v/v) CC liquor and 0.5% (w/v) CC plus 10% (v/v) liquor, respectively. These results are very attractive, mainly when considering its application on industrial scale, because of the high cost of the xylan. The xylanase production with 1% (w/v) raw CCs only was smaller than with xylan, showing the importance of the association of the residue with the liquor (Fig. 2a).

Xylanase and β-xylosidase production by A. terricola (a, c) and A. ochraceus (b, d) using the carbon sources: 1% (w/v) birchwood xylan (filled squares); 1% (w/v) CC (open squares); mixture of 0.5% (w/v) CC plus 2% (v/v) CC liquor (filled circles); mixture of 0.5% (w/v) CC plus 10% (v/v) CC liquor (open circles); mixture of 1% (w/v) CC plus 2% (v/v) CC liquor (filled triangles); mixture of 1% (w/v) CC plus 10% (v/v) CC liquor (open triangles); mixture of 0.75% (w/v) CC plus 6% (v/v) CC liquor (filled diamonds); and 100% (v/v) CC liquor (open diamonds). In all cases, the CC autohydrolysis liquor was obtained after 30 min of autohydrolysis treatment. Microorganisms were cultivated in Vogel and Adams media, respectively, at 30 °C, 100 rpm, for up to 7 days

For A. ochraceus, xylanase production with 1% (w/v) CCs in addition to 10% (v/v) CCs liquor was 35% higher than with birchwood xylan, at the end of both fermentation processes. The mixtures of 0.5% (w/v) residue added to 10% (v/v) liquor and 0.75% (w/v) residue added to 6% (v/v) liquor are also excellent inducing sources of xylanase activity. The use of 1% (w/v) raw CCs as carbon source was not very effective in xylanase synthesis, corresponding to 60–75% of the production with xylan and 40–45% of the production achieved with the best inducer [1% (w/v) CCs plus 10% (v/v) CCs liquor], in the period from 96 to 168 h (Fig. 2b). The cultivation with autohydrolysis liquor as the only carbon source (100%; v/v) was not suitable for xylanase production for both microorganisms, as previously observed (Fig. 2a, b).

In relation to β-xylosidase production from A. terricola, the best inducer was a mixture of 0.75% (w/v) CCs and 6% (v/v) CCs liquor (as observed to xylanase activity). The enzymatic production (around 30 total U) was about 15-times higher than when birchwood xylan was used (96–168 h cultivation). The enzymatic production observed with all mixtures of CCs and liquor was higher than with xylan, even when the liquor was used at a level of 100% (v/v). However, the cultivation with raw CCs as the only carbon source was not suitable for β-xylosidase production (Fig. 2c). Regarding A. ochraceus β-xylosidase, the highest productions (around 56 total U) were obtained with 0.5% (w/v) CCs plus 10% (v/v) CCs liquor, 0.75% (w/v) CCs plus 6% (v/v) of the liquor, and 1% (w/v) CCs plus 10% (v/v) liquor, corresponding to productions around 30–35% higher than with birchwood xylan, for 168 h of cultivation. CC was not favorable for β-xylosidase synthesis by A. ochraceus (Fig. 2d).

Thus, the obtained results indicate a practical application of these hemicelluloses as inducer substrates of enzymatic synthesis, since xylanase levels were higher than when birchwood xylan was used. The increase on xylanase activity was about 20%, while for β-xylosidase activity the increase was around 30% for A. ochraceus, and 50–90% for A. terricola (a microorganism that secretes low β-xylosidase levels when grown on xylan [see Fig. 2c)].

Conclusions

Agroindustrial wastes can be added to cultivation media for the production of biomass-degrading enzymes. However, as the untreated lignocellulosic material is degraded at a very slow rate by microorganisms, a pretreatment step may be useful for improved substrate utilization. CC liquor obtained after 30 min of autohydrolysis process at 200 °C was a good adjunct for the production of xylanase and β-xylosidase by Aspergillus terricola and Aspergillus ochraceus. For A. terricola, a 15% higher xylanase production and a 15 times higher β-xylosidase production were obtained when using 0.75% untreated CC and 6% CC liquor as carbon source in comparison with the use of birchwood xylan; for A. ochraceus, xylanase and β-xylosidase productions 35% higher were observed using 1% untreated CC and 10% CC liquor used as substrate as compared to birchwood xylan. These results clearly demonstrate the importance of the CCs pre-treatment for its use as a substrate for the productions of xylanase and β-xylosidase. However, further work is required in order to increase components yield and cellulose/hemicellulose digestibility to an extent, which makes its use economically viable.

References

Rojas-Rejón OA, Poggi-Varaldo HM, Ramos-Valdivia AC, Martínez-Jiménez A, Cristiani-Urbina E, Martínez MT, Ponce-Noyola T (2011) Production of cellulases and xylanases under catabolic repression conditions from mutant PR-22 of Cellulomonas flavigena. J Ind Microbiol Biotechnol 38:257–264. doi:10.1007/s10295-010-0821-7

Cavka A, Alriksson B, Rose SH, van Zyl WH, Jonsson LJ (2011) Biorefining of wood: combined production of ethanol and xylanase from waste fiber sludge. J Ind Microbiol Biotechnol 38:891–899. doi:10.1007/s10295-010-0856-9

López G, Bañares-Hidalgo A, Estrada P (2011) Xylanase II from Trichoderma reesei QM 9414: conformational and catalytic stability to chaotropes, trifluoroethanol, and pH changes. J Ind Microbiol Biotechnol 38:113–125. doi:10.1007/s10295-010-0836-0

Abdeshahian P, Samat N, Wan Yusoff WM (2010) Production of β-xylosidase by Aspergillus niger FTCC 5003 using palm kernel cake in a packed-bed bioreactor. J Appl Sci 10:419–424. doi:10.3923/jas.2010.419.424

Rajoka MI, Riaz S (2005) Hyper-production of a thermotolerant β-xylosidase by a deoxy-d-glucose and cycloheximide resistant mutant derivate of Kluyveromyces marxianus PPY 125. Electron J Biotechnol 8:177–184. doi:10.2225/vol8-issue2-fulltext-9

Tengerdy RP, Szakacs G (2003) Bioconversion of lignocellulose in solid substrate fermentation. Biochem Eng J 13:169–179. doi:10.1016/S1369-703X(02)00129-8

Mullai P, Fathima NSA, Rene ER (2010) Statistical analysis of main and interaction effects to optimize xylanase production under submerged cultivation conditions. J Agric Sci 2:144–153

Nigam PS, Gupta N, Anthwal A (2009) Pretreatment of agro-industrial residues. In: Nigam PS, Pandey A (eds) Biotechnology for agro-industrial residues, 1st edn. Springer-Verlag, New York, pp 13–33

Topakas E, Kalogeris E, Kekos D, Macris BJ, Christakopoulos P (2004) Production of phenolics from corn cobs by coupling enzymatic treatment and solid state fermentation. Eng Life Sci 4:283–286. doi:10.1002/elsc.200420025

Saha BC (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291. doi:10.1007/s10295-003-0049-x

Polizeli MLTM (2009) Properties and commercial applications of xylanases from fungi. In: Rai M (ed) Advances in fungal biotechnology, 1st edn. International Publisher, New Delhi, pp 82–108

Garrote G, Falqué E, Domínguez H, Parajó JC (2007) Autohydrolysis of agricultural residues: study of reaction byproducts. Bioresour Technol 98:1951–1957. doi:10.1016/j.biortech.2006.07.049

Montané D, Farriol X, Salvadó J, Jollez P, Chornet E (1998) Fractionation of wheat straw by steam-explosion pretreatment and alkali delignification. Cellulose pulp and byproducts from hemicellulose and lignin. J Wood Chem Technol 18:171–191

Shimizu K, Sudo K, Ono H, Ishihara M, Fujii T, Hishiyama S (1998) Integrated process for total utilization of wood components by steam explosion pretreatment. Biomass Bioenergy 14:195–203. doi:10.1016/S0961-9534(97)10044-7

Nabarlatz D, Ebringerová A, Montané D (2007) Autohydrolysis of agricultural by-products for the production of xylo-oligosaccharides. Carbohydr Polym 69:20–28. doi:10.1016/j.carbpol.2006.08.020

Ruiz HA, Ruzene DS, Silva DP, Silva FFM, Vicente AA, Teixeira JA (2011) Development and characterization of an environmentally friendly process sequence (autohydrolysis and organosolv) for wheat straw delignification. Appl Biochem Biotechnol 164:629–641. doi:10.1007/s12010-011-9163-9

Ruiz HA, Ruzene DS, Silva DP, Quintas MAC, Vicente AA, Teixeira JA (2011) Evaluation of a hydrothermal process for pretreatment of wheat straw-effect of particle size and process conditions. J Chem Technol Biotechnol 86:88–94. doi:10.1002/jctb.2518

Vogel HF (1964) Distribution of lysine pathways among fungi: evolutionary implications. Am Nat 98:435–446

Adams PR (1990) Mycelial amylase activities of thermophilic species of Rhizomucor, Humicola and Papulaspora. Mycopathologia 112:35–37. doi:10.1007/BF01795178

Miller GH (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–429

Kersters-Hilderson H, Claeyssens M, Doorslaer EV, Saman E, Bruyne CK (1982) β-d xylosidase from Bacillus pumilus. Meth Enzymol 83:631–639

Garrote G, Domínguez H, Parajó JC (2002) Autohydrolysis of corncob: study of non-isothermal operation for xylooligosaccharide production. J Food Eng 52:211–218

Parajó JC, Garrote G, Cruz JM, Dominguez H (2004) Production of xylooligosaccharides by autohydrolysis of lignocellulosic materials. Trends Food Sci Technol 15:115–120. doi:10.1016/j.tifs.2003.09.009

Felipe MGA, Mancilha IM, Vitolo M, Roberto IC, Silva SS, Rosa SAM (1993) Preparation of xylitol by fermentation of a hydrolysate of hemicellulose obtained from sugarcane bagasse. Arq Biol Technol 36:103–114

Olsson L, Hahn-Hagerdal B (1996) Fermentation of lignocellulosic hydrolysates for ethanol production. Enzyme Microb Technol 18:312–331. doi:10.1016/0141-0229(95)00157-3

Taherzadeh MJ, Gustafsson L, Niklasson C, Lidén G (2000) Physiological effects of 5-hydroxymethylfurfural on Saccharomyces cerevisiae. Appl Microbiol Biotechnol 53:701–708. doi:10.1007/s002530000328

Szengyel Z, Zacchi G (2000) Effect of acetic acid and furfural on cellulase production of Trichoderma reesei RUT C30. Appl Biochem Biotechnol 89:31–42

Dobrev GT, Pishtiyski IG, Stanchev VS, Mircheva R (2007) Optimization of nutrient medium containing agricultural wastes for xylanase production by Aspergillus niger B03 using optimal composite experimental design. Bioresour Technol 98:2671–2678. doi:10.1016/j.biortech.2006.09.022

Pandey A, Soccol CR, Mitchell D (2000) New developments in solid-state fermentation: I-bioprocesses and products. Process Biochem 35:1153–1169. doi:10.1016/S0032-9592(00)00152-7

Damaso MCT, Andrade CMM, Pereira N Jr (2000) Use of corncob for endoxylanase production by Thermomyces lanuginosus IOC—4145. Appl Biochem Biotechnol 84–86:821–834

Betini JHA, Michelin M, Peixoto-Nogueira SC, Jorge JA, Terenzi HF, Polizeli MLTM (2009) Xylanases from Aspergillus niger, Aspergillus niveus and Aspergillus ochraceus produced by solid state fermentation and its application on cellulose pulp bleaching. Bioprocess Biosystem Eng 32(6):819–824. doi:10.1007/s00449-009-0308-y

Ridder ER, Nokes SE, Knutson BL (1999) Optimization of solid-state fermentation parameters for the production of xylanase by Trichoderma longibrachiatum on wheat bran in a forced aeration system. Am Soc Agric Eng 42(6):1785–1790. doi:10.1016/j.enzmictec.2006.06.013

Acknowledgments

This work was supported by State of Sao Paulo Research Foundation (FAPESP/Brazil), National Counsel of Technological and Scientific Development (CNPq/Brazil), National System for Research on Biodiversity (SISBIOTA-Brazil, CNPq 563260/2010-6/FAPESP 2010/52322-3), and Portuguese Foundation for Science and Technology (FCT/Portugal). Héctor A. Ruiz thanks to Mexican Science and Technology Council (CONACYT, Mexico) for PhD fellowship support (CONACYT grant number: 213592/308679).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Michelin, M., Polizeli, M.d.L.T.M., Ruzene, D.S. et al. Production of xylanase and β-xylosidase from autohydrolysis liquor of corncob using two fungal strains. Bioprocess Biosyst Eng 35, 1185–1192 (2012). https://doi.org/10.1007/s00449-012-0705-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0705-5