Abstract

The xylanase gene xyn II from Aspergillus usamii E001 was placed under the control of an alcohol oxidase promoter (AOX1) in the plasmid pPIC9K and integrated into the genome of a methylotrophic yeast, P. pastoris GS115, by electroporation. His+ transformants were screened for on the basis of their resistance to G418 and activity assay. A transformant, P. pastoris GSC12, which showed resistance to over 6 mg G418/ml and highest xylanase activity was selected. Recombinant xylanase was secreted by P. pastoris GSC12 24 h after methanol induction of shake-flask cultures, and reached a final yield of 3139. About 68 U/mg 120 h after the induction. The molecular mass of this xylanase was estimated to be 21 kDa by SDS-PAGE. The optimum pH and temperature were 4.2 and 50 °C, respectively. Xylanase was stable below 50 °C and within pH 3.0–7.0. Its activity was increased by EDTA and Co2+ ion and strongly inhibited by Mn2+, Li+ and Ag+ ions. The K m and V max values with birchwood xylan as the substrate were found to be 5.56 mg/ml and 216 μmol/mg/min, respectively. This is the first report on expression and characterization of xylanase from A. usamii in P. pastoris. The hydrolysis products consisted of xylooligosaccharides together with a small amount of xylose. This property made the enzyme attractive for industrial purposes, as relatively pure xylooligosaccharides could be obtained.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Xylan, a major structural component of plant cell walls and the most abundant renewable hemicellulose, constitutes 20–40% of total plant biomass. Complete degradation of these compounds could generate various forms of cellulosic biomass and thus allow utilization of these low-cost raw materials for industrial applications (Beg et al. 2001; Polizeli et al. 2005). Due to the structural heterogeneity of xylan, complete degradation requires the synergistic action of different xylanolytic enzymes such as endo-xylanase, β-xylosidase, α-glucuronidase, α-arabinofuranosidase and esterase. Among these, the most important one is endo-1,4-β-xylanase (EC 3.2.1.8), which cleaves internal glycosidic bonds at random or specific positions of the xylan backbone and thus hydrolyses xylan into xylooligosaccharide and xylose (Biely 1985; Collin et al. 2005). Xylanases have attracted considerable research interest because of their potential industrial applications. Xylanases with different properties are suited for use in different applications, e.g., alkaline xylanases for the pulp industry and acidic xylanases for the food and feed industry (Wong and Saddler 1993; Viikari et al. 1994; Subramaniyan and Prema 2002; Techapun et al. 2003; Polizeli et al. 2005). In recent years, many kinds of xylanases have been isolated from various microorganisms (Nicolas et al. 1996; Ruiz-Arribas et al. 1997; Xu et al. 2005; Sapre et al. 2005; Farooq et al. 2006). Up to now, many kinds of xylanases have been cloned, and expressed in heterologous hosts (Rose and Van Zyl 2002; Damaso et al. 2003; Gorgenes et al. 2005; Wang et al. 2007).

Our previous work reported the production and purification of a xylanase (Xyn II) from Aspergillus usamii E001 (Fu et al. 2005; Wu et al. 2005). This enzyme belongs to family 11 of xylanases. This gene (xyn II) was cloned and has been successfully expressed in E. coli as soluble form of intracellular protein (Zhou et al. 2008). However, the low expression level of this recombinant protein and the extra cost of downstream processing make it unsuitable for industrial application. Pichia pastoris is a methylotrophic yeast that has been shown to be an outstanding host for high-level heterologous gene expression because of its potential for high expression levels, efficient secretion of extracellular protein, posttranslational modifications and growth to high cell densities on defined minimal medium (Akira and Yumiko 2001; Delroisse et al. 2005; Manuel et al. 2005). Thus, heterologous gene expression by P. pastoris is a useful alternative when scaling up to industrial process (Baumgartner et al. 2002). Several proteins of bacterial, fungal or mammalian origin have been successfully expressed in P. pastoris (Jesus et al. 2002; Laetitia et al. 2004; Sue et al. 2005; Layla et al. 2006; Vasimon et al. 2007; Zhijian et al. 2007). However, to the best of our knowledge, no study on the expression of a xylanase gene from A. usamii in P. pastoris has been reported. In this paper, the high-expression of this xylanase Xyn II from A. usamii in P. pastoris and some properties of the purified recombinant xylanase are reported.

Materials and methods

Strains, plasmids and media

E. coli DH5α (Invitrogen, USA) was used for the cloning of the plasmid and P. pastoris GS115 (Invitrogen, USA) for xylanase expression. Plasmid pET-28a-xyn II containing the cDNA of Xyn II cloned in vector pET-28a(+) has been described elsewhere (Zhou et al. 2008) and was stored in this laboratory. The vector pPIC9K was supplied from Invitrogen. E. coli was grown at 37 °C in Luria-Bertani (LB) medium containing 100 μg kanamycin/ml for selection of clones transformed with the vector pPIC9K. P. pastoris was routinely grown in shaking flasks at 30 °C, in a rich medium containing 1% (w/v) yeast extract, 2% (w/v) peptone, 0.1 M potassium phosphate buffer, pH 6.0, 1.34% (w/v) yeast nitrogen base, 4 × 10−5% (w/v) biotin and 1% (v/v) glycerol (BMGY) before induction, or 0.5% (v/v) methanol (BMMY) for induction. For maintaining cultures and plates, 1% (w/v) yeast extract, 2% (w/v) peptone, 2% (w/v) dextrose (YPD) medium was used, and for selection of transformants, YPD plates containing geneticin (G418) were used.

Reagents

DNA Gel Extraction Kit, Taq polymerase and restriction enzymes were purchased from the TaKaRa Biotechnology (Dalian, China) Co. Ltd. Culture media were obtained from Invitrogen and Shanghai Sangon Co. Ltd, respectively. All other chemicals were of analytical grade.

DNA manipulation

DNA manipulations were performed according to the standard methodology (Sambrook et al. 1989). The general methodology for manipulation of P. pastoris was in accord with the method described in the Manual Version A of the Pichia Multi-Copy Expression Kit (Invitrogen).

Construction of expression plasmids

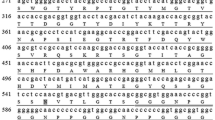

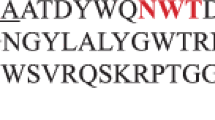

An E. coli/P. pastoris shuttle vector, pPIC9K, was used to achieve secreted expression of xylanase. pPIC9K contains the tightly regulated AOX1 promoter and the Saccharomyces cerevisiae α-factor secretion signal located immediately upstream of the multiple cloning site (Higgins et al. 1998). The xylanase gene xyn II was derived by PCR using a recombinant plasmid pET-28a-xyn II as a template. The two PCR primers were designed as follows: JN (5′-CGGAATTCAGTGCCGGTATCAACTATG-3′) with the EcoRI site (italics) and JZ (5′-ATTTGCGGCCGCTTAAGAAGATATCGTGAC-3′) with NotI site (italics). The thermal program used to amplify the sequence induced 1 cycle at 94 °C (2 min), 30 cycles of [94 °C (30 s), 55 °C (30 s), and 72 °C (45 s)], and 1 cycle at 72 °C (10 min). The PCR reaction mixture contained 30 pmol of each primer, two units of Taq DNA polymerase, 20 mM Tris/HCl (pH 8.4), 50 mM KCl, 2.5 mM MgCl2, and 100 μΜ each dNTPs in 50 μl total volume. PCR reaction was carried out in a Gene Amp PCR system 2400 (Perkin-Elmer, Norwalk, CT). The PCR product was gel-purified and digested with EcoRI and NotI before cloning into the plasmid pPIC9K at restriction sites EcoRI and NotI resulting in the recombinant plasmid pPIC9K-xyn II and amplified in E. coli DH5α. After transformation into E. coli DH5α, one recombinant plasmid designated as pPIC9K-xyn II was selected on an LB agar plate containing 100 μg/ml kanamycin. The insertion was checked by restriction analysis and sequenced by Invitrogen (Shanghai, China) Co. Ltd.

Construction of yeast transformants

For P. pastoris integration, 10 μg of recombinant plasmid was linearized with SacI and transformed into P. pastoris GS115 by electroporation using Eppendorf electroporator at 1,500 V. The parent pPIC9K without insert, linearized with SacI was also transformed as negative control. The selected integrants were seeded on plates with YPD medium containing G418 at 0.25, 0.5, 1, 1.5, 2, 3, 4, 5, 6 mg/ml. The integration of the xylanase gene into the genome of P. pastoris was confirmed by PCR using 5′AOX1 and 3′AOX1 primers.

Optimization of xylanase expression in P. pastoris

Various physical and nutritional parameters for xylanase production were optimized by maintaining all factors as a constant level except the one being studied. Recombinant P. pastoris was inoculated into 20-ml BMGY medium in 250 ml conical flask along with negative control (P. pastoris GS115 transformed with pPIC9K without insert) and were incubated on a rotary shaker at 30 °C and 250 rev/min until the culture reached an OD600 of 2–4. The cells were harvested by centrifugation at 3,000 rev/min for 5 min at room temperature and the cell pellet was suspended in BMMY medium (pH 4.5–7.0) so as to get an OD600 of 1.0 in a conical flask for induction. Incubation was continued on a rotary shaker at 30 °C and 50–350 rev/min with the addition of methanol to achieve concentrations ranging from 0.5% to 2.5% at every 24 h to sustain the expression conditions and the induction. Different induction periods ranging from 24 to 192 h were also tested, along with different methanol concentrations as above to find the optimal expression conditions.

SDS-PAGE

The protein in the culture supernatants was collected and subjected to 15% SDS-PAGE according to a standard protocol (Laemmli 1970). The gels were stained with Coomassie brilliant blue G250. The standard protein markers used were: phosphorylase b (97,400), bovine serum albumin (66,200), ovalbumin (43,000), carbonic anhydrase (31,000), soybean trypsin inhibitor (20,100), lysozyme (14,400).

Determination of protein concentration

Protein was determined by the Bradford assay using bovine serum albumin as a standard.

Assay of recombinant xylanase activity

Xylanase activity was measured using 0.5% (w/v) birchwood xylan (Sigma, USA) as a substrate in 50 mM Na2HPO4–citric acid buffer, pH 4.2, incubated at 50 °C for 15 min with constant shaking. The liberation of reducing sugars was estimated by the dinitrosalicylic acid (DNS) method (Miller 1959) using xylose as a standard. Reducing sugars were determined by measuring the absorption at 540 nm relative to a d-xylose standard. One unit of enzyme activity was defined as the quantity of enzyme required to liberate 1 μmol of xylose equivalent per minute at 50 °C, and specific activity was defined as units per mg protein (Shao and Wiegel 1992). The results were means of duplicate determination on triple independent measurements.

Purification

After 120 h growth, cultures were centrifuged at 10,000 rev/min for 10 min and the supernatant was used as enzyme source. The crude xylanase was precipitated with ammonium sulfate (60% saturation) followed by centrifugation at 10,000 rev/min for 15 min at 4 °C. The precipitated proteins were then resuspended in Na2HPO4–citric acid buffer (0.2 M Na2HPO4, 0.1 M citric acid; pH 6.0). Desalting was performed on a Sephadex G-25 column. The fractions containing xylanase were applied onto a Sephadex G-100 column and eluted with the same buffer, and then fractions containing the enzyme were pooled, concentrated. No significant loss of activity was seen even after 6 months′ storage.

pH optimum and stability

The effect of pH on xylanase activity was evaluated at 50 °C over a pH range of 3.0–9.0, using appropriate buffers (50 mM): Na2HPO4–citric acid buffer (pH 3.0–7.0), KH2PO4–NaOH buffer (pH 8.0) and glycine–NaOH buffer (pH 9.0) under xylanase activity assay conditions. Further study on the pH stability of the recombinant xylanase was carried out at 50 °C by pre-incubation of the enzyme solutions in the aforementioned buffer systems in the absence of substrate at 40 °C for 1 h. The pH values of various reaction solutions were adjusted to pH 4.2. Then they were subjected to xylanase activity assay.

Temperature optimum and thermostability

The temperature optimum was measured by performing the xylanase activity assay for 15 min at temperatures ranging from 35 to 60 °C under the optimal pH of 4.2. The thermostability of xylanase was investigated at temperatures 40, 45, 50 and 55 °C after incubation of the enzyme solutions in absence of substrate for 5, 10, 15, 20, 40 or 60 min, respectively. Residual activities were determined under xylanase activity assay conditions.

Effects of metal ions on xylanase activity

Metal ions are generally considered as important factors affecting microbial enzyme activity. Each metal ion (5 mM) was added in 5 ml of diluted enzyme to a final concentration of 1 mM. The effects of these metals were investigated after 1 h of incubation.

Kinetic parameters

The purified enzyme was used for studying kinetic parameters (K m and V max). For determining the reaction rate, different substrate (birchwood xylan) concentrations were used, ranging from 1.25 to 20.0 mg/ml. The reaction rate versus substrate concentration was plotted to determine whether the enzyme obeys Michaelis–Menten kinetics, and K m and V max were determined from the Lineweaver–Burk plot.

Analysis of the birchwood xylan hydrolysis products

The products from birchwood xylan hydrolysed by purified xylanase were analysed by TLC. The hydrolysis was carried out with 200 U of purified xylanase and 1% birchwood xylan as described above. Aliquotes were removed periodically and 5 μl of each sample was spotted on to the TLC plate (Silica gel G). The end products were separated by the solvent system (butyl alcohol/acetic acid/water: 2:1:1, by vol), and xylo-oligosaccharides were located using aniline–diphenylamine–phosphoric acid reagent. Xylose and xylobiose were used as standards.

Results and discussion

Construction of expression vector

The fragment of xyn II gene was obtained and cloned into the yeast expression vector pPIC9K, resulting in the recombinant expression plasmid pPIC9K-xyn II (Fig. 1) which was used in the transformation of P. pastoris GS115.

Schematic representation of the pPIC9K-xyn II vector. The vector contains the following elements or encoding sequences: 5′AOX1 promoter region, α-factor secretion signal, xyn II, 3′AOX1 transcription termination region (TT), His4 ORF, kanamycin resistance gene, 3′AOX1 fragment, and the ampicillin resistance gene

Construction of yeast transformants

The recombinant expression plasmid pPIC9K-xyn II was introduced into P. pastoris GS115. The colonies that were found positive with PCR (data not shown) and showed resistance to over 6 mg G418/ml were selected for induction. The α-factor signal peptide from S. cerevisiae functioned well in leading the secretion of the expressed xylanase into the culture media. One recombinant strain, designated as P. pastoris GSC12, expressing the highest xylanase activity was chosen for optimizing expression conditions.

Optimization of xylanase expression in P. pastoris

There will be a great potential to increase the expression levels. In order to enhance the yield of xylanase, the gene dosage can be further increased by integrating more copies of the foreign gene, and we have used high concentrations of antibiotic to select transfected P. pastoris strains which could lead to the selected strain having multiple copies of the transgene. To optimize the conditions of fermentation is another method that can increase the quantity of recombinant protein (Villatte et al. 2001; Gorgenes et al. 2005).

Agitation and aeration are generally used to meet the oxygen demands, uniform mixing and distribution of nutrients during fermentation process. The flasks were shaken at different agitation speeds (50–350 rev/min) for assessing the effect of agitation. P. pastoris GSC12, grown in 250-ml shake flasks, was incubated at different agitation velocities. Figure 2a shows that agitation at 250 rev/min supported maximum xylanase secretion. Under stationary conditions, at 50 rev/min and at more than 350 rev/min, xylanase production was very low as observed in Geobacillus thermoleovorans (Sharma et al. 2007).

The effect of pH on enzyme production was assessed by cultivating the strain in media of varied pH. Maximum xylanase activity was reported when the fermentation was carried out in a medium with pH 6.5, and xylanase activity decreased on both sides of this pH (Fig. 2b).

At 250 rev/min and in BMMY media (pH 6.5), P. pastoris GSC12 was induced by different concentration methanol for 72 h. As can be seen from Fig. 3a, the highest xylanase level appeared after 1.5% methanol induction.

Figure 3b shows the time-dependent changes in the cell growth and accumulation of xylanase activity in the culture. Xylanase activity was detected in the culture supernatant of the transformants every 24 h during induction. The activity increased steadily up to 120 h after the induction, to a final value of 3139.68 U/mg.

SDS-PAGE

The supernatants were analysed by SDS-PAGE and a distinctive band, with a molecular weight of approximately 21 kDa, was found in the transformants but not in the control at the corresponding position (Fig. 4). The molecular weight of the recombinant xylanase is greater than that expressed in E. coli, but consistent with the native form. This could suggest that the recombinant enzyme was O-glycosylated, since there was no putative N-glycosylation site in the deduced amino acid sequence of A. usamii Xyn II (Zhou et al. 2008). Yeast-expressed xylanase has a higher activity than bacterially expressed xylanase. This indicated that yeast-expressed xylanase may hold a structural configuration closer to the native form compared with the bacterially expressed xylanase.

Characterization of xylanase

Purified xylanase was used to evaluate its biochemical properties. From the pH profile (Fig. 5a), we can see that under the assay conditions used, the pH for optimal activity of xylanase was pH 4.2, which is slightly lower than the pH optimum of the bacteria-expressed xylanase and the native xylanase, which were confirmed to be pH 4.6 (Wu et al. 2005; Zhou et al. 2008). At 40 °C, in the absence of substrate, the enzyme was stable for 1 h over a pH range of 3.0–7.0 which is wider than that of the bacteria-expressed xylanase (pH 4.5–5.5), but in agreement with that of the native xylanase (Wu et al. 2005; Zhou et al. 2008). The apparent optimal temperature for enzyme activity at pH 4.2 was 50 °C (Fig. 5b) which is exactly the same as the optimal temperature reported for the bacteria-expressed xylanase and the native xylanase (Wu et al. 2005; Zhou et al. 2008). At pH 4.2, in the absence of substrate, the enzyme was stable under 50 °C (Fig. 5c), which was 5 °C higher than that of the bacteria-expressed xylanase and 5 °C lower than that of the native xylanase (Wu et al. 2005; Zhou et al. 2008). The differences in the biochemical characteristics among yeast-expressed xylanase, bacteria-expressed xylanase and the native xylanase from A. usamii E001 are probably due to the differences of posttranslational modifications of the three expression hosts. Now, the discrepancies of the posttranslational modifications are not very clear, but the definite mechanism analysis will be taken into account in further study.

Compared with xylanases from other microorganisms (Table 1), the recombinant xylanase secreted by Pichia pastoris GSC12 could be more suitable for application in the animal feed industry because it was active over pH range from 3 to 7 and stable below 50 °C which are close to the digestion circumstances of animals. Furthermore, considering that most industrial enzymatic operations are carried out at high temperatures (Wang and Xia 2007) and the thermostability of xylanases could be enhanced by protein engineering (Xiong et al. 2004), researches on enhancing the thermostability of this enzyme are being carried out in our laboratory.

Effects of cations and chelating agents on xylanase activity

It was found that several ions, such as EDTA, Co2+, Cu2+ could activate the enzyme, while others (i.e. Mn2+, Li+, Ag+) inhibited xylanase activity significantly. Compared to those, the enzyme was relatively unaffected by Pb2+, Mg2+ and Sn2+ (Table 2).

Kinetic study

Substrate (birchwood xylan) concentration was varied from 1.25 to 20.00 mg/ml in the reaction mixture. Initial reaction rates versus substrate concentration showed that the enzyme obeyed Michealis–Menten kinetics and had K m of 5.56 mg/ml and V max of 216 μmol/mg/min.

Analysis of the birchwood xylan hydrolysis products

TLC analysis (Fig. 6) showed the action of purified xylanase on birchwood xylan was characterized by an initial release of xylooligosaccharides (Xoligo > X2). The mode of action of xylanase was found to be endo-type as it produced xylobiose (X2) as the predominant end product from birchwood xylan along with higher xylo-oligosaccharides as intermediates. This property makes the enzyme attractive as relatively pure xylooligosaccharides can be obtained.

Conclusions

Currently, heterologous expression is the main tool for the production of industrial enzymes. P. pastoris is one of the favorite expression hosts because of many advantages over other hosts. In this study, the A. usamii E001 xylanase was expressed and secreted by P. pastoris in an inducible system. Using this expression system, acceptable yields of recombinant xylanase have been obtained upon optimization of growth and expression conditions. To our knowledge, this is the first report describing expression of a xylanase gene from A. usamii in P. pastoris.

Yeast-expressed xylanase had a higher biological activity than bacterially expressed xylanase. In addition, the secreted xylanase was active over the pH range from 3.0 to 7.0, which could be suitable for application in the animal feed industry. In addition, this xylanase was found to be able to degrade xylan into xylooligosaccharides effectively. As xylan can be prepared cost-effectively from agricultural by-products (i.e. wheat bran, bagasse, corn core) only by alkaline hydrolysis, this xylanase also displays a potential to be used in the production of nutraceuticals, for example, oligosaccharides.

References

Akira M, Yumiko TA (2001) Comparison of three signals for secretory expression of recombinant human midkine in Pichia pastoris. Biosci Biotechnol Biochem 65:2291–2293

Baumgartner P, Raemaekers RJ, Durieux A, Gatehouse A, Davies H, Taylor M (2002) Large-scale production, purification, and characterization of recombinant Phaseolus vulgaris phytohemagglutinin E-form expressed in the methylotrophic yeast Pichia pastoris. Protein Expr Purif 26:394–405

Beg QK, Kapoor M, Mahajan L, Hoondal GS (2001) Microbial xylanases and their industrial applications: a review. Appl Microbiol Biotechnol 56:326–338

Belancic A, Scarpa J, Peirano A, Diaz R, Steiner J, Eyzayuirre J (1995) Penicillium purpurogenum produces several xylanases:purification and properties of two of the enzymes. J Biotechnol 41:71–79

Biely P (1985) Microbial xylanolytic enzymes. Trends Biotechnol 11:286–290

Collin T, Gerday C, Feller G (2005) Xylanase, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

Damaso MC, Almedia MS, Kurtenbach E, Martins OB, Pereira NJ, Andrade CM (2003) Optimized expression of a thermostable xylanase from Thermomyces lanuginosus in Pichia pastoris. Appl Environ Microbiol 69:6064–6072

Delroisse JM, Marie D, Gilsoul JJ, Thami EM, Jacqueline D, Daniel P, Philippe T, Eric H, Micheline V (2005) Expression of a synthetic gene encoding a Tribolium castaneum carbosylesterase in Pichia pastoris. Protein Expr Purif 42:286–294

Farooq L, Muhammad A, Rabia S, Ahmed A, Legge RL (2006) Purification and characterization of a xylanase produced by Chaetomium thermophile NIBGE. World J Microbiol Biotechnol 22:45–50

Fu DD, Xie H, Wu MC (2005) Solid fermentation for xylanase production by Aspergillus usamii. Food Ferment Indus (Chin J) 31:50–53

Gorgenes JF, Van Zye WH, Kuoetze JH, Han-Hageral B (2005) Amino acid supplementation improves heterologous protein production by Saccharomyces cerevisiae in defined medium. Appl Microbiol Biotechnol 67:684–69l

Higgins DR, Busser K, Comiskey J, Whittier PS, Purcell TJ, Hoeffler JP (1998) Small vectors for expression based on dominant drug resistance with direct multicopy selection. In: Higgins DR, Cregg JM (eds) Methods in molecular biology: Pichia protocols. Humana Press, New Jersey, pp 28–41

Inagaki K, Nakahira K, Mukai K, Tamura T, Tanaka H (1998) Gene cloning and characterization of an acidic xylanase from Acidobacterium capsulatum. Biosci Biotechnol Biochem 62:1061–1067

Jesus MP, Maria JB, Xin GL (2002) Functional expression of keratinase (kerA) gene from Bacillus licheniformis in Pichia pastoris. Biotechnol Lett 24:631–636

Kimura I, Sasahar H, Tajima S (1995) Purification and characterization of two xylanases and an arabinofuranosidase from Aspergillus sojae. J Ferment Bioeng 80:334–339

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Laetitia B, Virginie N, Laure L, Helene B, Guy M, Frederic B, Eric D (2004) High-level expression of Candida parapsilosis lipase/acyltransferase in Pichia pastoris. J Biotechnol 111:41–50

Layla F, Ignacio PV, Alberto Z, Pedro LB, Juan CM, Javier V, Jose LA (2006) High-level expression and characterization of Galactomyces geotrichum (BT107) lipase I in Pichia pastoris. Protein Expr Purif 49:256–264

Manuel M, Cecilia C, Lester H, Jose P, Laura V, Jorge V, Yanet T, Abdel H, Liuba P, Vladimir B, Liudys G, Emilio L, Lila C, Eduardo M (2005) Multiple gene copy number enhances insulin precursor secretion in the yeast Pichia pastoris. Biotechnol Lett 27:339–345

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Nicolas P, Dieter K, Francois S, Rolf M (1996) Increased xylanase yield in Streptomyces lividans:dependence on number of ribosome-binding sites. Nat Biotechnol 14:756–759

Polizeli MLTM, Rizzattim ACS, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Radionova NA, Dubovaya NV, Eneiskaya EV, Matrinovich LI, Gracheva IM, Bezborodov AM (2000) Purification and characterization of endo-1,4-β-xylanase from Geotrichum candidum 3C. Appl Biochem Microbiol 36:460–465

Raj KC, Chandra TS (1996) Purification and characterization of xylanase from alkalitolerant Aspergillus fischeri Fxn 1. FEMS Microbiol Lett 145:457–461

Rose SH, Van Zyl W (2002) Constitutive expression of the Trichoderma reesei beta-1,4-xylanase gene (xyn2) and the beta-1,4-entoglucanase gene (egl) in Aspergillus niger in molasses and definded glucose media. Appl Microbiol Biotechnol 58:461–468

Ruiz-Arribas A, Fernandez-Abalos JM, Sanchez P, Garda AL, Santamaria RI (1997) Overproduction, purification, and biochemical characterization of a xylanase (Xysl) from Streptomyces halstedii JM8. Appl Environ Microbiol 61:2414–2419

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual, 2 edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Sapre MP, Jha H, Patil MB (2005) Purification and characterization of a thermoalkaliphilic xylanase from Bacillus sp. World J Microbiol Biotechnol 21:649–654

Shah AR, Madamwar D (2005) Xylanase production by a newly isolated Aspergillus foetidus strain and its characterization. Process Biochem 40:1763–1771

Shao W, Wiegel J (1992) Purification and characterization of a thermostable β-xylosidase from Thermoanaerobacter ethanolicus. J Bacteriol 174:5848–5853

Sharma A, Adhikari S, Satyanarayana T (2007) Alkali-thermostable and cellulase-free xylanase production by an extreme thermophile Geobacillus thermoleovorans. World J Microbiol Biotechnol 23:483–490

Subramaniyan S, Prema P (2002) Biotechnology of microbial xylanases: enzymology, molecular biology, and application. Crit Rev Biotechnol 22:33–64

Sue MP, Mariana LF, Brian M, Linda MH (2005) Heterologous protein production using the Pichia pastoris expression system. Yeast 22:249–270

Techapun C, Poosaran N, Watanabe M, Sasaki K (2003) Thermostable and alkaline-tolerant microbial cellulose-free xylanases produced from agricultural wastes and the properties required for use in pulp bleaching bioprocesses: a review. Process Biochem 38:1327–1340

Vasimon R, Rutchadaporn S, Nakul R, Pacawadee T, Duriya C, Sutipa T, Kusol P, Lily E (2007) Cloning, expression, characterization, and high cell-density production of recombinant endo-1,4-β-xylanase from Aspergillus niger in Pichia pastoris. Enzyme Microb Technol 41:19–25

Viikari L, Kantelinen A, Sundquist J, Linko M (1994) Xylanases in bleaching: from an idea to the industry. FEMS Microbiol Rev 13:335–350

Villatte F, Hussein AS, Bachmann TT (2001) Expression level of heterologous protein in Pichia pastoris is influenced by flask design. Appl Microbiol Biotechnol 55:463–465

Wang Q, Xia T (2007) Enhancement of the thermostability and hydrolytic activity of GH10 xylanase by module shuffling between Cellulomonas fimi Cex and Thermomonospora alba XylA. World J Microbiol Biotechnol 23:1047–1055

Wang YR, Zhang HL, He YZ, Luo HY, Yao B (2007) Characterization, gene cloning, and expression of a novel xylanase XYNB from Streptomyces olivaceoviridis Al. Aquaculture 267:328–334

Wong KKY, Saddler JN (1993) Applications of hemicellulases in the food, feed and pulp and paper industries. In: Coughlan MP, Hazlewood GP (eds) Hemicellulose and hemicellulases. Portland Press, London, pp 127–143

Wu MC, Fu DD, Zhu J, Xia MF (2005) Purification and some properties of two xylanases from Aspergillus usamii. J Food Sci Biotechnol (Chin J) 24:29–33

Xiong H, Weymarn N, Leisola M, Turunen O (2004) Influence of pH on the production of xylanase by Trichoderma reesei C-30. Process Biochem 39:731–736

Xu ZH, Bai YL, Xu X, Shi JS, Tao WY (2005) Production of alkali-tolerant cellulase-free xylanase by Pseudomonas sp. WLUN024 with wheat bran as the main substrate. World J Microbiol Biotechnol 21:575–581

Zhijian S, Xiaoping W, Ya F, Changcai D, Yechen X, Lu C, Wenke F, Xiaokun L (2007) High level expression of human endostatin in Pichia pastoris using a synthetic gene construct. Appl Microbiol Biotechnol 73:1355–1362

Zhou CY, Bai JY, Deng SS, Wang J, Zhu J, Wu MC, Wang W (2008) Cloning of a xylanase gene from Aspergillus usamii and its expression in Escherichia coli. Bioresour Technol 99:831–838

Acknowledgements

This work was supported by a grant from the State High Technology R&D Project (863) of China (No. 2006AA10Z305). We are grateful to Prof Wei Shen (The Key Laboratory of Industrial Biotechnology, Ministry of Education, Jiangnan University) for providing technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, C., Li, D., Wu, M. et al. Optimized expression of an acid xylanase from Aspergillus usamii in Pichia pastoris and its biochemical characterization. World J Microbiol Biotechnol 24, 1393–1401 (2008). https://doi.org/10.1007/s11274-007-9622-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-007-9622-1