Abstract

The electrochemical elimination of the herbicide diquat dibromide (DQ) in an undivided electrochemical cell (Condiacell®-type cell) and an H-type cell (a divided electrochemical cell) using boron-doped diamond (BDD) electrodes is reported for the first time. The degradation of essentially 100% of the DQ present was achieved in the undivided electrochemical cell and ca. 92% in the H-type cell. Nearly 80% of the total organic carbon (TOC) and of the chemical oxygen demand (COD) were removed after 5 h of treatment at different current densities (i.e., 0.5, 1.0, and 1.5 mA/cm2 for the undivided cell, and 2.5, 5.0, and 7.5 mA/cm2 for the H-type cell) with a maximum specific energy consumption of approximately 150 kWh kg−1 of COD degraded in the undivided cell, and 300 kWh kg−1 of COD in the H-type cell. Energy consumption of about 0.30 kWh g−1 of TOC occurred in the undivided electrochemical cell and 2.0 in the H-type cell. In spite of obtaining similar percentages of DQ degradation and of COD and TOC removal, a smaller energy usage was required in the undivided cell since smaller current densities were employed. Best results were obtained with the undivided cell, since it required a smaller current density to obtain virtually the same percentage of DQ degradation and removal of COD and TOC. The results obtained herein show that the use of electrochemical advanced oxidation processes may be a good alternative for DQ degradation in polluted water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Since the discovery of their herbicidal potential in the mid-1950s, dipyridylium compounds such as paraquat (PQ; C12H14Cl2N2, 1′-dimethyl-4,4′-bipyridinium dichloride hydrate) and diquat (DQ; C12H12N2Br2, 6,7-dihydrodipyrido[1,2-a:2′,1′-c]pyrazinediium dibromide, see Fig. 1) have been used extensively for the control and management of terrestrial and aquatic vegetation (Pateiro-Moure et al. 2008; EFEDO 2010; Karuppagounder et al. 2012; Bouétard et al. 2013; Prosser et al. 2016). These herbicides are usually formulated as dusts, aqueous solutions containing non-ionic surface-active agents, or as water-soluble granules containing DQ (ca. 2.5%) and PQ (ca. 2.5%). DQ is a member of a group of herbicides known as cell membrane destroyers. Exposure to such compounds results in a rapid disruption of cell membranes and a very rapid kill of plant material (Karuppagounder et al. 2012; Bouétard et al. 2013; EFEDO 2010). DQ (LD50 = 231 mg kg−1 in rats) is considered to be less toxic than PQ (LD50 = 150 mg kg−1 in rats). However, exposure to DQ may damage tissues and gastrointestinal tracts or produce kidney failure and central nervous affectations (Fortenberry et al. 2016). DQ does not accumulate in the lungs; nevertheless, its presence has been observed in the livers, kidneys, plasma, and adrenal glands (Fortenberry et al. 2016). DQ is very persistent in the solid phase (i.e., it binds irreversibly in the soil) and degrades very slowly (half-life from 1.2 to 41 years) (Pateiro-Moure et al. 2008, 2013; Fortenberry et al. 2016). In surface waters, DQ is removed by photolysis (1–3 weeks) or by adsorption to plants and particulate matter. However, traces of DQ have been found in ground waters and surface waters, some of which are sources of drinking water (Núñez et al. 2002; Pateiro-Moure et al. 2013; Gao et al. 2015). Herbicide use has increased the risk to human health and to the conservation of the ecological equilibrium of fragile ecosystems like wetland zones (NCFAP 1997; Núñez et al. 2002; Gupta 2014; Gao et al. 2015). Several methods have been proposed to remediate contaminated water with PQ and DQ including adsorption on biopolymer membranes (Cocenza et al. 2012; de Moraes et al. 2013), activated carbons (Khorram et al. 2016), biochar (Khorram et al. 2016), constructed wetlands (Vymazal and Brezinova 2015), and soils and clays (Weber and Coble 1968). These processes may require regeneration of the adsorbent and an additional post-treatment step to reduce waste management issues which may reduce their applicability from the environmental point of view. Heterogeneous photocatalytic oxidation (Florencio et al. 2004; Devipriya and Yesodharan 2005; Shibin et al. 2015), microbial degradation (Cork and Krueger 1991), and homogeneous advanced oxidation processes have been applied to mineralize herbicides (Ikehata and El-Din 2006; Ribeiro et al. 2015). In the case of PQ and DQ, removal rate and mineralization were highly dependent on pH, herbicide concentration, type of catalyst, light source, and catalyst concentration. In photocatalytic processes, oxidants (i.e., oxygen, hydrogen peroxide, persulfate) and/or doped and modified catalysts are essential during treatments to suppress electron/hole recombination in the semiconductor particle; unfortunately, recombination reactions reduce the effectiveness of redox processes and represent a major energy-wasting step because they limit the achievement of high quantum yields (Florencio et al. 2004; Devipriya and Yesodharan 2005). Previous studies have shown major variations in terms of operational cost, removal efficiency, and robustness because process performance is highly affected by chemical auxiliaries, shock loads, and the recalcitrant nature of the herbicides.

Electrochemical advanced oxidation processes (EAOPs) have recently received much attention in environmental science and technology (Brillas and Martínez-Huitle 2014; Subba-Rao and Venkatarangaiah 2014; Wu et al. 2014; Martínez-Huitle et al. 2015; Martínez-Huitle and Ferro 2006; Särkkä et al. 2015). The most popular EAOP is anodic oxidation (AO) or electrochemical oxidation (EO) that is based on the destruction of organics in an electrolytic cell by indirect reaction with physisorbed hydroxyl radicals (M[·OH], Eq. (1)) or chemisorbed active oxygen (MO, Eq. (2)) (Brillas and Martínez-Huitle 2014; Martínez-Huitle et al. 2015).

EO allows the partial transformation of recalcitrant substances into highly biodegradable compounds or else the electrochemical incineration (mineralization) of the parent compounds. The mineralization of organic matter takes place at non-active anodes (PbO2, SnO2, and boron-doped diamond (BDD)) where physisorbed active oxygen (in the form of M·OH) is accumulated on the surface allowing the formation of carbon dioxide and inorganic ions (Eq. (3)). A partial transformation occurs in active anodes (C, Pt, IrO2, and RuO2) where chemisorbed oxygen acts as an active site for the selective oxidation of organic matter (Eq. (4)).

The anode material, cell configuration, pollutant structure, temperature, pH, and supporting electrolyte strongly affect the selectivity and the efficiency of EO (Brillas and Martínez-Huitle 2014; Subba-Rao and Venkatarangaiah 2014; Wu et al. 2014; Martínez-Huitle et al. 2015; Särkkä et al. 2015). The anodic material can be considered as the most important factor during the degradation of recalcitrant compounds because it largely determines the mineralization degree and energy consumption. Doped and undoped metal oxides (SnO2, PbO2, RuO2, and IrO2) (Maharana et al. 2015; Pereira et al. 2015), mixed metal oxides (MMO) (Santos et al. 2015), carbonaceous electrodes (Martínez-Huitle et al. 2015; Saidi et al. 2016), MMO with nanostructured deposits (Guo et al. 2015), MMO with deposited polymer composites (Wu et al. 2014), and boron-doped diamond electrodes (García et al. 2014; Pereira et al. 2015; Souza et al. 2017) have been extensively used for the EO of wastewaters (Brillas and Martínez-Huitle 2014; Subba-Rao and Venkatarangaiah 2014; Wu et al. 2014; Martínez-Huitle et al. 2015; Särkkä et al. 2015; Moreira et al. 2017).

BDD films are recognized as highly efficient anodes for the degradation of recalcitrant compounds. They provide superior chemical and dimensional stability, resistance to fouling, low background currents, and a wide potential window in aqueous and non-aqueous electrolytes (Panizza and Cerisola 2009; Martínez-Huitle et al. 2015; Särkkä et al. 2015; Moreira et al. 2017). This facilitates the production of large quantities of ·OH radicals that are weakly adsorbed on their surfaces, with the consequent high reactivity for the oxidation of organics (Martínez-Huitle et al. 2015). Depending on electrolyte composition, additional oxidant species (e.g., S2O8 2−, C2O6 2−, and P2O8 4−) can be formed on BDD by anodic oxidation of sulfate, carbonate, or phosphate ions present in solution, respectively (Panizza and Cerisola 2009; Brillas and Martínez-Huitle 2014; Martínez-Huitle et al. 2015). These additional oxidants (e.g., S2O8 2− with E 0 = 2.05 V) are highly reactive towards organic matter. In the case of S2O8 2−, such reactions are typically slow at ordinary temperatures unless they are catalyzed by ions such as Fe2+ (Yu et al. 2016).

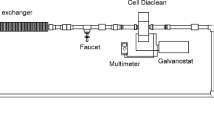

Electrochemical-based processes with diamond electrodes are considered a promising alternative for the removal of toxic and/or recalcitrant compounds because very few chemicals are required during water treatment, they are easy to automate, and the oxidants are produced in situ (either directly or indirectly) and only during the treatment. In general, anodic oxidation in undivided cells is more efficient than in divided cells since the presence of an ionic exchange membrane increases energy consumption. Nevertheless, in some cases, a divided cell provides a higher oxidation ability than its corresponding undivided counterpart like during the oxidation of sulfanilamide and Orange G with a BDD anode (El-Ghenymy et al. 2013, 2014). Therefore, it is important to clarify the comparative oxidation ability of BDD in both kinds of electrochemical cells. This work reports for the first time the anodic oxidation with BDD of aqueous solutions containing the herbicide diquat. The influence of applied current density, cell configuration, and DQ concentration on the degradation rate, carbon removal, and current efficiency are studied. From previous experience (Espinoza-Montero et al. 2013; Campos-Gonzalez et al. 2014), two types of electrolytic cells were selected: (a) a typical two-electrode H-type cell and (b) an undivided electrochemical cell (Condiacell®-type cell) with three BDD electrodes (Figs. 2 and 3, respectively). The main difference between them is the arrangement of the BDD electrodes and the geometry of the cell, as discussed next.

2 Experimental

2.1 Reagents and Materials

Diquat dibromide monohydrate Pestanal® (analytical standard, 99% pure, Sigma-Aldrich) was used at 25, 50, and 100 mg L−1. In order to maintain an acidic medium (i.e., a pH in the vicinity of 2) during the entire electrolysis time (5 h), the supporting electrolyte used in all experiments was a buffer with the following concentrations: 0.04 M Na2SO4 (Sigma-Aldrich, 99%) and 0.05 M NaHSO4 (Sigma-Aldrich, 99%). High-purity water (Milli-Q®, ρ ≥ 18.2 MΩ cm) was used to prepare all the solutions. HgSO4 (Baker Analyzed®, 99.5% pure), Ag2SO4 (Baker Analyzed, 99.5% pure), H2SO4 (Meyer 95–98%, A.C.S certified), and H2O2 (Meyer 29–32%, A.C.S certified) were used in a modified chemical oxygen demand (COD) test, as described below. K2S2O8 (Baker Analyzed, 100.1%) was used for the persulfate evaluation.

2.2 Experimental Setup

The experiments were conducted at room temperature (ca. 25 °C) in the two electrochemical systems mentioned earlier: a divided H-type cell (250 mL) and an undivided cell (Condiacell®-type cell, 300 mL). For the H-type cell, two BDDs (total geometrical area = 20 cm2 each) were used as anode and cathode, with a 12-cm gap. A Nafion® 424 cationic membrane was used in order to allow proton exchange. The undivided electrochemical cell with a three BDD electrode arrangement was used in order to compare both processes (total anodic area = 100 cm2, total cathodic area = 200 cm2, gap between electrodes = 0.5 cm). Identical applied currents, i appl, were used in both cells (50, 100, and 150 mA). In view of the geometrical area of each set, these entail different current densities, j appl (i.e., undivided cell 0.5, 1.0, and 1.5 mA cm−2; H-type cell 2.5, 5.0, and 7.5 mA cm−2). DQ concentrations were 25, 50, and 100 mg L−1. For the undivided cell, three different volumetric flows (250, 500, and 750 mL min−1) were studied in order to find the most adequate one. In the case of H-type cell, a flow of 500 mL min−1 is operated because the anodic compartment of the said cell uses a magnetic stirrer (see Fig. 2). Current was imposed with an AMEL potentiostat-galvanostat, model 2051 (AMEL, Italy). Prior to each electrochemical assay, the BDD electrodes were washed thoroughly with high-purity water in order to remove impurities from their surfaces. The same procedure was applied to the cell bodies both before and after assembly. The BDD DiaChem® electrodes (1–10 μm conducting diamond layer, a 500–8000-ppm boron concentration, and 0.1 Ω cm resistivity) were purchased from Condias GmbH (Germany) (Tröster et al. 2002). In this work, the DQ concentration, COD and total organic carbon (TOC) removal, average oxidation state (AOS), instantaneous current efficiency (ICE), specific energy consumption (E sp ), electrochemical oxidability index (EOI), and energy consumption per gram of TOC removed (EC TOC ) were used as figures of merit to evaluate the performance of the cells as a function of electrolysis time.

2.3 Analytical Methods

DQ concentration was monitored spectrophotometrically with a UV–visible spectrophotometer (Varian Cary 50-C spectrophotometer, 10-mm quartz cuvettes, bandwidth = 1 nm; 4800 nm min−1, Japan). DQ removal was assessed on the basis of changes in absorbance at λ = 309 nm (i.e., its wavelength of maximum absorbance). Additionally, a spectral scan between 200 and 450 nm was used to evaluate the removal of aromatic structures in the 250–300-nm region. A linear calibration plot was obtained in the concentration range between 0 and 40 mgDQ L−1 (Fig. 4). Samples were taken every 30 min during the degradation time (5 h) and diluted 1:4 with the buffer solution in order to attain suitable optical densities. TOC was measured in 15-mL aliquots to monitor the amount of organic matter remaining at each time with a Shimadzu VCPH TOC Analyzer (Japan). COD could not be monitored using the standard method (APHA 1999) since erratic results were obtained. This is very likely due to the presence of pyridinic intermediates (Florencio et al. 2004). This method uses a strong oxidizer K2Cr7O2 (E 0 = 1.36 V) in the presence of Ag2SO4 as catalyst for the oxidation of organics under acidic conditions (H2SO4) but it is not enough to oxidize pyridine compounds. Therefore, an alternative method developed in our laboratories (Carbajal-Palacios et al. 2012) was used as a greener alternative, which uses a stronger oxidizer such as H2O2 (E 0 = 1.8 V) instead of K2Cr7O2 in the presence of Ag2SO4 as catalyst and HgSO4 as halide inhibitor. H2O2 is less harmful to humans and to the environment than toxic dichromate. A great advantage of using this method is that it does not require a 2-h digestion at 150 °C since it can be performed at room temperature. In order to find the COD at each stage of electrolysis, samples were prepared in the same way as in the APHA international standard method by placing 3.5 mL of the catalyst solution, 1.5 mL of the digesting solution, and 2.5 mL of the sample solution in a vial. After 2 h at room temperature, the resulting absorbance was read at 280 nm. A more detailed description of this modified method can be found elsewhere (Carbajal-Palacios et al. 2012).

2.4 Parameters Analyzed and Figures of Merit for the Electrochemical Process

The percent of DQ removal (DQ REM ) is calculated from Eq. (5) where A 0 and A t are the DQ absorbances at t = 0 and at a given time, t, respectively.

The ICE is calculated using the following relationship (Rajeshwar and Ibanez 1997; Kapalka et al. 2010):

where (COD) t and (COD) t + Δt are the chemical oxygen demands (in mg O2 L−1) at times t and t + Δt (in s), respectively; F is Faraday’s constant (96,487 C mole −1), i is the applied current (in A), and V is the volume of the electrolyte (in L).

The mineralization of organic pollutants in EAOPs is usually monitored by TOC removal, calculated as follows (Brillas 2014):

where ΔTOC is the experimental TOC decay (in mg L−1) at the electrolysis time t, and TOC 0 is the initial TOC value.

The AOS can be calculated from Eq. (8), where TOC and COD are expressed in moles of carbon per liter (molC L−1) and moles of dioxygen per liter (molO2 L−1), respectively (Blanco and Malato 2003).

One of the most important parameters to determine the efficiency of EAOP processes is the specific energy consumption (E sp ) that relates the energy consumed per kilogram of COD removed. This can be estimated as follows (Kapalka et al. 2010; Panizza et al. 2001):

where E sp is the specific energy consumption (kWh kgCOD −1); F is Faraday’s constant (96,487 C mole −1); E c is the cell potential (V); and EOI is the electrochemical oxidability index calculated as follows (Rajeshwar and Ibanez 1997; Kapalka et al. 2010):

where τ is the total electrolysis time.

The energy consumption (kWh) per gram of TOC removed (ΔTOC) during the degradation time is given by (Brillas 2014) the following:

where E C is the cell potential (V), i is the applied current (A), t is the electrolysis time (h), and V S is the solution volume (L).

Lastly, the diffusion coefficient (D) was calculated from the rotating disk electrode technique using Levich’s equation (Bard and Faulkner 2001):

where i l is the limiting current (A), F is Faraday’s constant (96,487 C mole −1), A is the electrode area (cm2), v is the kinematic viscosity (cm2 s−1), ω is the angular velocity (rad s−1), C is the analyte concentration (mol cm−3), and n is the average number of electrons transferred in the reaction (mole mol−1). For this, a Teflon-embedded BDD disk electrode (A = 0.19 cm2) was fabricated with the same diamond material as described above. Different angular velocities (i.e., 1250, 1500, 1750, 2000, 2250, and 2500 rpm) were applied to it with a Pine Analytical Rotator and its ASR Speed Control (both from Pine Instruments, USA), and a Bioanalytical Systems Epsilon potentiostat (BAS Company, USA) was used for potential control.

3 Results and Discussion

Experiments were performed at room temperature (ca. 25 °C) and all the solutions were analyzed immediately after preparation. The DQ diffusion coefficient D was determined to be 0.8 × 10−5 cm2 s−1 which is in the range of previously reported values for analogous compounds (Delgado 2007; Compton et al. 2014). According to the boundary-layer theory (Cussler 2007), the mass transfer coefficient (k L ) represents the relationship between the diffusion coefficient and the diffusion layer thickness (concentration boundary layer: δ). Due to the difficulty to measure the diffusion layer thickness in this type of systems, different volumetric flow rates were fed into the undivided system instead. It was found that from 500 mL min−1 and upward, the percent degradation did not change significantly (see Fig. 5) which means that the system is under mass transfer control (Kapalka et al. 2010). For this reason, this volumetric flow was selected for all the subsequent experiments. In the case of the divided H-type cell, due to the use of a magnetic stirrer in the anodic compartment, the flow profile became constant from the solution bulk to the electrode surface.

The degradation of DQ was studied using the two types of cells described earlier with the aid of the following analytical determinations.

3.1 UV–Visible Spectrophotometry

The initial concentration of organic compounds and the energy consumption are key parameters in wastewater treatment by electrochemical processes. Thus, the influence of current density on the decrease in DQ concentration was followed spectrophotometrically by monitoring its absorbance at 309 nm. Figure 6 shows the normalized DQ concentration as a function of time at different current densities for the undivided cell (0.5, 1.5, and 1.5 mA cm−2) and the H-type cell (2.5, 5.0, and 7.5 mA cm−2), respectively. The two cells were highly efficient and removed over 90% of the DQ after 300 min of electrolysis (Table 1). For the undivided and divided cells, DQ degradation rate was accelerated with increasing j, as expected by the associated generation of more physisorbed hydroxyl radicals (see Fig. 6).

DQ degradation and COD removal are known to increase with increasing applied current density up to 150 mA cm−2 by using a C/PbO2 electrode (NaCl = 2 g L−1, pH = 2.2, electrolysis time = 210 min) (Abu-Ghalwa et al. 2012). Total removal and complete mineralization can be achieved with samples containing up to 50 mg L−1 of the DQ herbicide. Nevertheless, a further increase of DQ concentration resulted in a significant decrease in degradation rates.

In the present study, different kinetic reaction models (i.e., zeroth-, first-, and second-order reactions) were used to represent the absorbance reduction of DQ in the two types of electrochemical cells. As indicated in Eq. (13), a pseudo-first-order model results adequate (R 2 > 0.99) to represent the DQ absorbance decrease (a behavior typical of processes essentially controlled by mass transfer). In Eq. (13), r is the reaction rate, A is the electrode area (cm2), V is the electrolyte volume (cm3), k m is the average mass transfer coefficient (cm s−1), and k app is the pseudo-first-order rate constant (s−1).

As shown in Fig. 7a, b, the values of k app for the DQ removal increase with current density. For the undivided electrochemical cell at the selected concentrations, the pseudo-first-order rate constant increases 28% (for 25 mg L−1), 32% (for 50 mg L−1), and 59% (for 100 mg L−1), while the current density increases threefold. For the H-type cell at the same concentrations, the pseudo-first-order rate constant increases 31% (for 25 mg L−1), 28% (for 50 mg L−1), and 23% (for 100 mg L−1), while the current density increases threefold. The kinetic analysis suggests that the operating regimes of the electrochemical processes are under mass transport control taking into account that DQ removal follows an exponential trend. The decrease in the removal rate responds to the adsorption of insulating organic matter (polymeric substances) on the surface of the electrode that prevents the transfer of electrons between the DQ and the anode.

As shown, the DQ removal rate significantly increases with current density; this is related to the consequent higher production of ·OH radicals, see Eqs. (1) and (3). At the end of the process, the removal rates decrease and the process performance is strongly affected by the presence of competitive and non-oxidizing processes (i.e., undesirable reactions) which promote the decomposition of ·OH radicals and the concomitant production of less powerful oxidants (e.g., O2, H2O2, ·OOH, and S2O8 2−). The absorbance reduction does not imply that DQ has been fully mineralized. Therefore, in order to examine the mineralization ability of the studied systems, additional assays were performed.

3.2 Electrochemical Oxidation of DQ

Table 2 shows the influence of current density on the organic content degradation (expressed as COD) during the electrochemical treatment of DQ in the undivided- and H-type cells. Experimental data indicate that COD removal is significantly enhanced when increasing the applied current density. At low current densities (0.5 and 1.0 mA cm−2), the undivided electrochemical cell is more efficient at removing COD, although at 1.5 mA cm−2, the COD removal slightly increased. This behavior is likely related to the production of additional weaker oxidants like those described above and may suggest a modification in the DQ degradation mechanism. Under the conditions analyzed, the undivided electrochemical cell was favorably efficient and removed 42–68% of the COD in the herbicide solution during 300 min of electrolysis. With the H-type cell, an increase in current density from 2.5 to 7.5 mA cm−2 caused an increase in COD removal from 32 to 47%. The faster COD removal in the undivided electrochemical cell with j appl can be related to the consequent greater production of ·OH radicals (see Eq. (1)). Furthermore, the performance of the mineralization process can be significantly increased with higher initial COD contents. This can be attributed to the enhancement of the mass transport of DQ and of its intermediate degradation products to the anode surface whereby the organics can be oxidized by the ·OH radicals. There is a residual COD at the end of the electrolytic process that reveals remaining organic matter present in the electrolyte, although the DQ molecule is no longer observed in the UV–vis scans.

For the present purposes, two boundary operation regimes can be considered: (a) j appl < j lim , where the process is under charge transfer control and the ICE is nearly 100%, and (b) j appl > j lim , where the electrochemical system is under mass transport control and undesirable reactions (e.g., dioxygen evolution) become more important. Under mass transport control, ICE decreases along the process and the COD decays exponentially. For intermediate current density values, the process is under a mixed regime; therefore, higher j appl values can cause an increase in the pollutant removal rate and a reduction in the ICE. See Fig. 8 and Table 2.

Although DQ concentration decreases nearly 100% in some cases (see for example, the results with the Condiacell®-type cell of Fig. 6), this does not necessarily reflect a total mineralization of the organic material, which can be better analyzed in Fig. 9 for the Condiacell®- and H-type cells, respectively (complementary information for TOC removal can be found in Table 1). These graphs represent the decrease in TOC as a function of time. Opposite to the results obtained for COD, TOC abatement is affected by j appl. Current density commonly delineates the efficiency of a process which also depends on the formation of additional oxidants at the anode surface (like those described above), the anode’s properties, the operating mode, and mass transfer limitations. In fact, there is still a remnant of about 20% of organic matter (for the highest current density case) that can be attributed to intermediates still present at the end of the electrolysis whose nature and toxicity are currently under study.

Although COD and TOC removal suggest a partial mineralization of DQ, their evolution does not reveal the oxidation degree of the treated solutions. The AOS of the carbon atoms (which is a function of the electrolysis time) is a better indicator of the oxidation degree of the DQ products that remained in the solution. AOS has been used to signpost when to switch from an electrochemical process to a biological treatment because it gives information about the extent of biodegradability of the treated wastewater (Blanco and Malato 2003). AOS varies between +4 for carbon dioxide (i.e., the most oxidized state of carbon) to −4 for methane (i.e., the most reduced state of carbon). Preliminary results by applying Eq. (8) for example in the undivided electrochemical cell using an initial DQ concentration of 100 mg L−1 at 1.5 mA cm−2 reveal that the AOS changed from ca. −1.7 to −0.9. This indicates a greater degree of oxidation in the dissolved products. Nevertheless, this is not an indication of the degree of mineralization since the CO2 generated does not remain in the solution at the present pH. On the other hand, the specific energy consumption (E sp ) is a very important parameter when determining the feasibility of scaling up a process for wastewater treatment. Figures 10 and 11 show the behavior of E sp (in kWh per kg of COD consumed in the undivided electrochemical cell and H-type cell respectively) versus current density. With the highest current density (i.e., 1.5 mA cm−2 for the undivided electrochemical cell and 7.5 mA cm−2 for the H-type cell) and the highest DQ concentration (100 mg L−1), about 150 kWh is needed per kilogram of COD in the undivided electrochemical cell and about 300 kWh for the H-type cell. These are rather adequate values because mineralization reaches about 80% of TOC (especially considering that DQ is a very recalcitrant herbicide). These values are within acceptable parameters for scaling up wastewater remediation (Campos-Gonzalez et al. 2014).

Recent studies have reported a nearly 100% mineralization or complete TOC abatement of herbicides by means of a photoelectro-Fenton (PEF) process with BDD in the presence of iron (Fe2+ = 28 mg L−1), a hybrid electrochemical-photochemical process (using a DSA anode and UV-C light), or with photoelectro-Fenton and solar photoelectro-Fenton processes albeit with higher energy consumption than those in the present research (Montes et al. 2017; Moreira et al. 2017; Pipi et al. 2014). The exceptional removal of organics is attributed to the synergistic effect of electron transfer, ·OH radicals generated by Fenton’s reagent in the solution, and photodecarboxylation reactions assisted by artificial and natural solar radiation (Moreira et al. 2017).

In a different study, photoelectrocatalysis with TiO2-based anodes and an anodic Fenton treatment was applied for the removal of chloroacetanilide herbicides (i.e., acetochlor, alachlor, butachlor, metolachlor, and propachlor). Photoelectrocatalysis can be considered a suitable and environmentally friendly technology for the mineralization or biocompatibilization of herbicides (Brillas et al. 2009; Garcia Bessegato et al. 2015); nevertheless, it evidences mass transport limitations and requires the continuous supply of hydrogen peroxide (Friedman et al. 2006). The need of an added oxidant not only increases the process costs but also decreases process efficiency owing to the fact that an increase in H2O2 concentration promotes the transformation of ·OH radicals into HO2 · (i.e., a less powerful oxidant). Therefore, its practical applications are severely restricted by undesirable reactions and operational costs.

Herbicides and recalcitrant compounds are partially removed (60–80%) in active anodes whereas in non-active anodes, a wide range of pollutants (e.g., picloram, paraquat, atrazine, dyes) can be satisfactorily degraded (95–99%) or mineralized (TOC or COD removal >90%). In fact, BDD anodes favor the complete oxidation (mineralization) of organics to CO2 (Cartaxo et al. 2015; Maharana et al. 2015; Moreira et al. 2017; Pereira et al. 2015). Figures 10 and 11 also show the energy consumption per unit of TOC versus current density for the two cells used in the present work. At the same applied current (i.e., 50, 100, and 150 mA), one can observe that for the undivided electrochemical cell, the highest EC is almost 0.3 kWh per gram of TOC for a DQ0 = 25 ppm whereas for the H-type cell under the same conditions, about 1.8 kWh is needed per gram of TOC.

Lastly, the formation of the strong oxidizer peroxodisulfate, S2O8 2−, during the oxidation process and its possible influence on DQ degradation were considered. From literature reports (Serrano et al. 2002; Michaud et al. 2000) peroxodisulfate formation is unlikely to be significant under our experimental conditions (i.e., 0.04 M sulfate, 0.05 M bisulfate). A separate report indicates that sulfate concentration should be higher than 2 M to have a high current efficiency for sulfate oxidation (Davis et al. 2014). In addition, during the degradation of another herbicide (i.e., diuron), Yu et al. used sodium persulfate to evaluate its influence on the herbicide’s degradation; results indicate that the presence of peroxodisulfate in the absence of a transition metal catalyst (e.g., Fe2+) or of an external energy input (e.g., heat, UV-light) has a very low impact on the degradation of said herbicide. Nevertheless, we conducted an exploratory experiment using peroxodisulfate in their reported concentration range (i.e., 0.25 mM) in a 25 mg L−1 DQ solution and monitored its degradation by UV–vis. Our preliminary results suggest that this influence is not significant (i.e., less than 0.2% change) under such conditions.

4 Conclusions

In this work, the recalcitrant DQ herbicide was efficiently mineralized for the first time with an EAOP using BDD anodes, reaching a high TOC removal (around 80%) and almost 70% of COD removal. COD values were continuously monitored with a modified analytical test since the standard method with K2Cr2O7 is not able to oxidize pyridinic-type compounds. All of the DQ is essentially removed from a water sample in the case of the undivided electrochemical cell (Condiacell®-type cell), while in the case of the H-type cell, this value reaches around 92% (and the final waste can be treated biologically). The ICE is higher for the lowest current density used (i.e., 0.5 mA/cm2) since a value of ca. 80% is achieved. Lastly, the EC values obtained (undivided cell, 0.3 kWh gTOC −1; H-type cell, 1.8 kWh gTOC −1) and E SP values (undivided cell, 150 kWh kgCOD −1; H-type cell, 300 kWh kgCOD −1) show that this method presents a worthy option for the treatment of water contaminated with DQ.

References

Abu-Ghalwa, N., Abu-Shawish, H. M., Hamada, M., Hartani, K., & Hakem-Basheer, A. A. (2012). Studies on degradation of diquat pesticide in aqueous solutions using electrochemical method. American Journal of Analytical Chemistry, 3, 99–105.

APHA, AWWA, WPCF, in: A.D. Eaton, A.E. Clesceri, E.W. Rice, A.E. Greenberg (Eds.) (1999) Standard methods for the examination of water and wastewater, 20st ed., American Public Health Association, American Water Works Association and Water Environment Federation, Washington, D.C.

Bard, A. J., & Faulkner, L. R. (2001). Electrochemical methods fundamentals and applications (Second editionth ed., p. 339). New York: John Wiley & Sons, Inc.

Blanco, J., & Malato, S. S. (2003). Solar detoxification. France: UNESCO Publishing.

Bouétard, A., Besnard, A. L., Vassaux, D., Lagadic, L., & Coutellec, M. A. (2013). Impact of the redox-cycling herbicide diquat on transcript expression and antioxidant enzymatic activities of the freshwater snail Lymnaea stagnalis. Aquatic Toxicology, 126, 256–265.

Brillas, E. (2014). Electro-Fenton, UVA photoelectro-Fenton and solar photoelectro-Fenton treatments of organics in waters using a boron-doped diamond anode: a review. Journal of the Mexican Chemical Society, 58, 239–255.

Brillas, E., & Martínez-Huitle, C. A. (2014). Decontamination of wastewaters containing synthetic organic dyes by electrochemical methods. An updated review, Applied Catalysis B, 166–167, 603–643.

Brillas, E., Sirés, I., & Oturan, M. A. (2009). Electro-Fenton process and related electrochemical technologies based on Fenton’s reaction chemistry. Chemical Reviews, 109, 6570–6631.

Campos-Gonzalez, E., Frontana-Uribe, B. A., Vasquez-Medrano, R., Macias-Bravo, S., & Ibanez, J. G. (2014). Advanced electrochemical oxidation of methyl parathion at boron doped diamond electrodes. Journal of the Mexican Chemical Society, 58, 315–321.

Carbajal-Palacios, P., Balderas-Hernández, P., Ibanez, J. G., & Roa-Morales, G. (2012). Replacing dichromate with hydrogen peroxide in the chemical oxygen demand (COD) test. Water Science & Technology, 66, 1069–1073.

Cartaxo, M. A. M., Borges, C. M., Pereira, M. I. S., & Mendonca, M. H. (2015). Electrochemical oxidation of paraquat in neutral medium. Electrochimica Acta, 176, 1010–1018.

Cocenza, D. S., de Moraes, M. A., Beppu, M. M., & Fraceto, L. F. (2012). Use of biopolymeric membranes for adsorption of paraquat herbicide from water. Water Air Soil Pollution, 223, 3093–3104.

Compton, R. G., Laborda, E., & Ward, K. R. (2014). Understanding voltammetry: simulation of electrode processes (p. 30). London: Imperial College Press.

Cork, D. J., & Krueger, J. P. (1991). Microbial transformations of herbicides and pesticides. Advances in Applied Microbiology, 36, 1–66.

Cussler, E. L. (2007). Diffusion mass transfer in fluid systems (3rd ed., pp. 284–297). Cambridge: Cambridge University Press.

Davis, J., Baygents, C., & Farrell, J. (2014). Understanding persulfate production at boron doped diamond film anodes. Electrochimica Acta, 150, 68–74.

de Moraes, A. M., Sgarbi-Cocenza, D., Vasconcellos, F., Fernandes-Fraceto, L., & Masumi-Beppu, M. (2013). Chitosan and alginate biopolymer membranes for remediation of contaminated water with herbicides. Journal of Environmental Management, 131, 222–227.

Delgado, J. (2007). Molecular diffusion coefficients of organic compounds in water at different temperatures. Journal of Phase Equilibria and Diffusion, 28, 427–432.

Devipriya, S., & Yesodharan, S. (2005). Photocatalytic degradation of pesticide contaminants in water. Solar Energy Materials and Solar Cells, 86, 309–348.

EFEDO, Risks of diquat dibromide use to the federally threatened delta smelt (Hypomesus transpacificus), Environmental Fate and Effects Division Officer of Pesticide Programs. http://citeseerx.ist.psu.edu/viewdoc/download?doi = 10.1.1.185.1235&rep = rep1&type = pdf, 2010 (accessed Jul. 4, 2016).

El-Ghenymy, A., Garrido, J. A., Rodríguez, R. M., Cabotm, P. L., Centellas, F., Arias, C., & Brillas, E. (2013). Degradation of sulfanilamide in acidic medium by anodic oxidation with a boron-doped diamond anode. Journal of Electroanalytical Chemistry, 689, 149–157.

El-Ghenymy, A., Centellas, F., Garrido, J. A., Rodríguez, R. M., Sirés, I., Cabot, P. L., & Brillas, E. (2014). Decolorization and mineralization of Orange G azo dye solutions by anodic oxidation with a boron-doped diamond anode in divided and undivided tank reactors. Electrochimica Acta, 130, 568–576.

Espinoza-Montero, P. J., Vasquez-Medrano, R., Ibanez, J. G., & Frontana-Uribe, B. A. (2013). Efficient anodic degradation of phenol paired to improve cathodic production of H2O2 at BDD electrodes. Journal of Electrochemical Society, 160, G3171–G3177.

Florencio, M. H., Pires, E., Castro, A. L., Nunes, M. R., Borges, C., & Costa, F. M. (2004). Photodegradation of diquat and paraquat in aqueous solutions by titanium dioxide: evolution of degradation reactions and characterisation of intermediates. Chemosphere, 55, 345–355.

Fortenberry, G. Z., Beckman, J., Schwartz, A., Prado, J. B., Graham, L. S., Higgins, S., Lackovic, M., Mulay, P., Bojes, H., Waltz, J., Mitchell, Y., Leinenkugel, K., Oriel, M. S., Evans, E., & Calvert, G. M. (2016). Magnitude and characteristics of acute paraquat- and diquat-related illnesses in the US: 1998–2013. Environmental Research, 146, 191–199.

Friedman, C. L., Templey, A. T., & Hay, A. (2006). Degradation of chloroacetanilide herbicides by anodic Fenton treatment. Journal of Agricultural and Food Chemistry, 54, 2640–2651.

Gao, L., Liu, G., Zhu, J., Wang, C., & Liu, J. (2015). Solid phase microextraction combined with gas chromatography–mass spectrometry for the determination of diquat residues in water. Journal of Analytical Chemistry, 70, 552–557.

Garcia Bessegato, G., Tasso-Guaraldo, T., Ferreira de Brito, J., Brugnera, M. F., & Boldrin-Zanoni, M. V. (2015). Achievements and trends in photoelectrocatalysis: from environmental to energy applications. Electrocatalysis, 6, 415–441.

García, O., Isarain, E., El-Ghenymy, A., Brillas, E., & Peralta, J. M. (2014). Degradation of 2,4-D herbicide in a recirculation flow plant with a Pt/air-diffusion and a BDD/BDD cell by electrochemical oxidation and electro-Fenton process. Journal of Electroanalytical Chemistry, 728, 1–9.

Guo, X., Li, D., Wan, J., & Yu, X. (2015). Preparation and electrochemical property of TiO2/nano-graphite composite anode for electro-catalytic degradation of ceftriaxone sodium. Electrochimica Acta, 180, 957–964.

Gupta, P.K. Herbicides and fungicides, in P.K. Gupta (Ed.) (2014). Biomarkers in toxicology, (pp. 409–431). Academic Press.

Ikehata, K., & El-Din, G. M. (2006). Aqueous pesticide degradation by hydrogen peroxide/ultraviolet irradiation and Fenton-type advanced oxidation processes: a review. Journal of Environmental Engineering and Science, 5, 81–135.

Kapalka, A., Fóti, G., & Comninellis, C. (2010). Basic principles of the electrochemical mineralization of organic pollutants for wastewater treatment. In C. Comninellis & G. Chen (Eds.), Electrochemistry for the environment (pp. 1–23). New York: Springer.

Karuppagounder, S. S., Ahuja, M., Buabeid, M., Parameshwaran, K., Abdel-Rehman, E., Suppiramaniam, V., & Dhanasekaran, M. (2012). Investigate the chronic neurotoxic effects of diquat. Neurochemical Research, 37, 1102–1111.

Khorram, M. S., Zhang, Q., Lin, D., Zheng, Y., Fang, H., & Yu, Y. (2016). Biochar: a review of its impact on pesticide behavior in soil 3 environments and its potential applications. Journal of Environmental Sciences, 44, 269–279.

Maharana, D., Xu, D., Niu, J., & Rao, N. N. (2015). Electrochemical oxidation of 2,4,5-trichlorophenoxyacetic acid by metal-oxide-coated Ti electrodes. Chemosphere, 136, 145–152.

Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35, 1324–1340.

Martínez-Huitle, C. A., Rodrigo, M. A., Sirés, I., & Scialdone, O. (2015). Single and coupled electrochemical processes and reactors for the abatement of organic water pollutants: a critical review. Chemical Reviews, 115, 13362–13407.

Michaud, P. A., Mahé, E., Haenni, W., Perret, A., & Comninellis, C. (2000). Preparation of peroxodisulfuric acid using boron-doped diamond thin film electrode. Electrochemical and Solid-State Letters, 3(2), 77–79.

Montes, I. J. S., Silva, B. F., & Aquino, J. M. (2017). On the performance of a hybrid process to mineralize the herbicide tebuthiuron using a DSA® anode and UVC light: a mechanistic study. Applied Catalysis B: Environmental, 200, 237–245.

Moreira, F. C., Boaventura, R. A. R., Brillas, E., & Vilar, V. J. P. (2017). Electrochemical advanced oxidation processes: a review on their application to synthetic and real wastewaters. Applied Catalysis B: Environmental, 202, 217–261.

NCFAP, Pesticide use in U.S. crop production: 1997, National Center for Food and Agricultural Policy. http://www.ncfap.org/documents/nationalsummary1997.pdf, 2000 (accessed Jul. 4, 2016).

Núñez, O., Kima, J. B., Moyano, E., Galceran, M. T., & Terabe, S. (2002). Analysis of the herbicides paraquat, diquat and difenzoquat in drinking water by micellar electrokinetic chromatography using sweeping and cation selective exhaustive injection. Journal of Chromatography A, 961, 65–75.

Panizza, M., & Cerisola, G. (2009). Direct and mediated anodic oxidation of organic pollutants. Chemical Reviews, 109, 6541–6569.

Panizza, M., Michaud, P. A., Cerisola, G., & Comninellis, C. (2001). Electrochemical treatment of wastewaters containing organic pollutants on boron-doped diamond electrodes: prediction of specific energy consumption and required electrode area. Electrochemistry Communications, 3, 336–339.

Pateiro-Moure, M., Martínez-Carballo, E., Arias-Estévez, M., & Simal-Gándara, J. (2008). Determination of quaternary ammonium herbicides in soils: comparison of digestion, shaking and microwave-assisted extractions. Journal of Chromatography A, 1196–1197, 110–116.

Pateiro-Moure, M., Arias-Estévez, M., & Simal-Gándara, J. (2013). Critical review on the environmental fate of quaternary ammonium herbicides in soils devoted to vineyards. Environmental Science & Technology, 47, 4984–4998.

Pereira, G. F., Rocha, R. C., Bocchi, N., & Biaggio, S. R. (2015). Electrochemical degradation of the herbicide picloram using a filter-press flow reactor with a boron-doped diamond or β-PbO2 anode. Electrochimica Acta, 179, 588–598.

Pipi, A. R. F., de Andrade, A. R., Brillas, E., & Sirés, I. (2014). Total removal of alachlor from water by electrochemical processes. Separation and Purification Technology, 132, 674–683.

Prosser, R. S., Anderson, J. C., Hanson, M. L., Solomon, K. R., & Sibley, P. K. (2016). Indirect effects of herbicides on biota in terrestrial edge-of-field habitats: a critical review of the literature. Agriculture, Ecosystems and Environment, 232, 59–72.

Rajeshwar, K., & Ibanez, J. G. (1997). Environmental electrochemistry: fundamentals and applications in pollution abatement (p. 364). New York: Academic.

Ribeiro, A. R., Nunes, O. C., Pereira, M. F. R., & Silva, A. M. T. (2015). An overview on the advanced oxidation processes applied for the treatment of water pollutants defined in the recently launched Directive 2013/39/EU. Environment International, 75, 33–51.

Saidi, I., Soutrel, I., Fourcade, F., Amrane, A., Bellakhal, N., & Geneste, F. (2016). Electrocatalytic reduction of metronidazole using titanocene/Nafion 1-modified graphite felt electrode. Electrochimica Acta, 191, 821–831.

Santos, T. E. S., Solva, R. S., Eguiluz, K. I. B., & Salazar, G. R. (2015). Development of Ti/(RuO2)0.8(MO2)0.2(M = Ce, Sn or Ir) anodes for atrazine electro-oxidation. Influence of the synthesis method. Materials Letters, 146, 4–8.

Särkkä, H., Bhatnagar, A., & Sillanpää, M. (2015). Recent developments of electro-oxidation in water treatment—a review. Journal of Electroanalytical Chemistry, 754, 46–56.

Serrano, K., Michaud, P. A., Comninellis, C., & Savall, A. (2002). Electrochemical preparation of peroxodisulfuric acid using boron doped diamond thin film electrodes. Electrochimica Acta, 48, 431–436.

Shibin, O. M., Yesodharan, S., & Yesodharan, E. P. (2015). Sunlight induced photocatalytic degradation of herbicide diquat in water in presence of ZnO. Journal of Environmental Chemical Engineering, 3, 1107–1116.

Souza, F., Quijorna, S., Lanza, M. R. V., Saez, C., Cañizares, P., & Rodrigo, M. A. (2017). Applicability of electrochemical oxidation using diamond anodes to the treatment of a sulfonylurea herbicide. Catalysis Today, 280, 192–198.

Subba-Rao, A. N., & Venkatarangaiah, V. T. (2014). Metal oxide-coated anodes in wastewater treatment. Environmental Science and Pollution Research, 21, 3197–3217.

Tröster, I., Fryda, M., Herrmann, D., Schäfer, L., Hänni, W., Perret, A., Blaschke, M., Kraft, A., & Stadelmann, M. (2002). Electrochemical advanced oxidation process for water treatment using DiaChem® electrodes. Diamond and Related Materials, 11, 640–645.

Vymazal, J., & Brezinova, T. (2015). The use of constructed wetlands for removal of pesticides from agricultural runoff and drainage: a review. Environment International, 75, 11–20.

Weber, J. B., & Coble, H. D. (1968). Microbial decomposition of diquat adsorbed on montmorillonite and kaolinite clays. Journal of Agricultural and Food Chemistry, 16, 475–478.

Wu, W., Huang, Z. H., & Lim, T. T. (2014). Recent development of mixed metal oxide anodes for electrochemical oxidation of organic pollutants in water. Applied Catalysis A: General, 480, 58–78.

Yu, Y., Zhou, S., Bu, L., Shi, Z., Zhu, S. (2016). Degradation of diuron by electrochemically activated persulfate. Water Air Soil Pollution, 227–279.

Acknowledgements

We acknowledge the financial support from the research office of the Universidad Iberoamericana Project No. 54. “Electrochemical and photochemical reactions for more efficient energy use, 2nd. Phase,” and the experimental assistance by Samuel Macias-Bravo.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valenzuela, A.L., Vasquez-Medrano, R., Ibanez, J.G. et al. Remediation of Diquat-Contaminated Water by Electrochemical Advanced Oxidation Processes Using Boron-Doped Diamond (BDD) Anodes. Water Air Soil Pollut 228, 67 (2017). https://doi.org/10.1007/s11270-017-3244-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-017-3244-5