Abstract

The effect of Fe(III) on Cr(VI) reduction by organic reducing substances in sugarcane molasses was investigated under different conditions [i.e., Fe(III) concentration, pH, and temperature] using batch experiments. Results indicated that Fe(III) can accelerate Cr(VI) reduction by sugarcane molasses over a wide pH range. The catalytic mechanism of the reaction involved the formation of organic reducing substance complexes with both Fe(III) and Cr(VI) that decrease the reaction activation energy of Cr(VI) reduction and accelerate electron transfer between Cr(VI) and organic reducing substances. The reaction could be described by a pseudo-first-order kinetic model with respect to Cr(VI) concentration. Increasing the Fe(III) concentration could promote Cr(VI) reduction. At pH 2.5, 3.0, 3.5, 4.0, 5.6, and 8.0, the initial reaction rates (vinitial) increased by 0.68, 0.84, 1.38, 1.39, 0.89, and 0.29 times, respectively, in the presence of Fe(III) compared with those obtained without Fe(III). The vinitial increased by 0.87 times in the presence of Fe(III) compared with that without Fe(III) at 10 °C (pH 2.5).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Chromium, the 22nd most abundant element in the Earth’s crust, is used in a wide variety of industrial and commercial applications, such as in electroplating, leather tanning, and the chemical industry. A large amount of industrial waste containing chromium compounds has been released to the environment because of improper disposal and leakage (Hashim et al. 2011). Depending on the pH and redox conditions, chromium, a redox active element, most frequently exists as trivalent chromium [Cr(III)] or hexavalent chromium [Cr(VI)] in the environment. However, these two oxidation states exhibit very different mobilities and toxicities. Cr(III) either forms the precipitate Cr(OH)3 or is easily adsorbed by inorganic mineral and organic colloids in the underground environment. Cr(III) is much less toxic than Cr(VI); the 3+ oxidation state element is an essential trace element for sugar and lipid metabolism in humans. By contrast, Cr(VI) is extremely toxic and carcinogenic when present even at very low concentrations. Moreover, as a soluble anion of chromate and dichromate, Cr(VI) is highly mobile; this compound migrates from the soil profile to aquifer systems and poses a serious threat to the environment (Han et al. 2014; Yalçın Tepe 2014). Hence, the reduction of Cr(VI) to Cr(III) is considered an important remediation strategy targeted at contaminant immobilization.

Many inorganic and organic compounds used to transform Cr(VI) to Cr(III) have been widely studied. Inorganic compounds that have been successfully tested for treating Cr(VI) in the environment are mainly divided into three classes: zero valent iron-based reagents (Qiu et al. 2013; Fu et al. 2014), ferrous-based mixed reagents (Qin et al. 2005; Su and Ludwig 2005; Henderson and Demond 2013), and sulfur-based reagents (Ludwig et al. 2007; Chrysochoou and Ting 2011; Chrysochoou et al. 2012). Compared with inorganic reductants, organic compounds are inexpensive and environmentally harmless. Depending on the reaction mechanism and their physicochemical properties, organic compounds can be classified as organic reductants or microbial carbon sources. Organic reductants that are effective in Cr(VI) reduction include naturally occurring organic compounds (e.g., citrate, oxalate, and humic substances) and bacterial exopolymeric substances (Hosseini 2009; Sarkar et al. 2013; Chauhan et al. 2014; Lee et al. 2008). Microbial carbon sources that can strengthen biological metabolism to promote Cr(VI) reduction include emulsified vegetable oil and molasses (Krishna and Philip 2005; Somasundaram et al. 2011; Michailides et al. 2014).

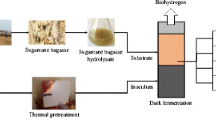

As a commonly used microbial carbon source, sugarcane molasses have been successfully used for remediating Cr(VI) contamination in groundwater, such as in the Selma Superfund site and Department of Energy’s site at Savannah River (US EPA 2011, 2003; Michailides et al. 2014). In Cr(VI)-contaminated groundwater, bioremediation microorganisms can be divided into three classes: chromium-reducing bacteria, sulfate-reducing bacteria, and iron-reducing bacteria (Somasundaram et al. 2009; Brodie et al. 2011; Pagnanelli et al. 2012; Sugiyama et al. 2012; Field et al. 2013). Our previous work has demonstrated that sugarcane molasses can reduce Cr(VI) to Cr(III) by chemical reduction under acid conditions without effective microorganisms and that Cr(VI) acts as an electrophile that readily accepts electrons from the hydroxyl and carbonyl groups of organic reducing substances (such as flavonoids), subsequently reducing to Cr(III) (Okello et al. 2012; Guan et al. 2014; Chen et al. 2015b). Promoting the use of sugarcane molasses in the remediation of Cr(VI)-contaminated soil and groundwater is a significant endeavor.

Iron is one of the most common transition metals and a high redox active element in the underground environment; iron can effectively promote the reduction of Cr(VI) to Cr(III) by direct or indirect processes. Zero and ferrous ion from ion-bearing minerals or hydroxysalt green rusts can directly reduce Cr(VI) to Cr(III) quickly in an underground environment (Patterson et al. 1997; Loyaux-Lawniczak et al. 2000; Bond and Fendorf 2003). Fe(III) can effectively catalyze the photochemical reduction of Cr(VI) by oxalic and citric acids, reducing 95 % of the initial Cr(VI) concentration into Cr(III) within 20–40 min (Hug et al. 1997). Sun et al. (2009) further demonstrated that the α-OH group in organic acids is an important factor for rapid Fe(III) photocatalytic reduction of Cr(VI). In addition, the phenolic hydroxyl group in organic reducing substances is more active than the α-OH group in organic acids. Hynes et al. (2001) reported that low molecular weight polyphenol (gallic acid, gallic acid methyl ester, and catechin) complexes of Fe(III) subsequently decompose to form Fe(II) and the corresponding quinone without photocatalysis.

Little information on the effect of Fe(III) on Cr(VI) reduction by sugarcane molasses is available. We hypothesize that Fe(III) can catalyze Cr(VI) reduction through organic reducing substances from sugarcane molasses. The present study aims to explore the mechanisms of the catalytic effect of Fe(III) on Cr(VI) reduction by organic reducing substances from sugarcane molasses with high-temperature sterilization and evaluate the effects of Fe(III) on the kinetics of Cr(VI) reduction under different influencing factors [i.e., Fe(III) concentration, pH, temperature, and initial molasses concentration]. The results of this paper will be significant in promoting the use of sugarcane molasses for the remediation of Cr(VI)-contaminated groundwater.

2 Materials and Methods

2.1 Reagents

Sugarcane molasses produced in accordance with the Chinese national standard (QB/T2684-2005) was purchased from Jinan Honghao Chemical Reagent Co., Ltd. The main ingredients of organic reducing substances include a small amount of organic acids and considerable amounts of polyphenols (38.4–48.8 g/L), which are a structural class of mainly natural compounds characterized by the presence of large multiples of phenol structural units.

All of the chemicals were of analytical pure grade and used as received without any further pretreatment. Potassium dichromate, ferric nitrate, sulfuric acid (98 %), phosphorus acid (85 %), sodium hydroxide, glacial acetic acid, and anhydrous sodium carbonate were supplied by Sinopharm Chemical Reagents Co., Ltd or Beijing Chemical Plant (Beijing, China). Folin–Ciocalteu reagent was purchased from Beijing Dingguo Changsheng Biotechnology Co., Ltd. Reverse osmosis–Milli-Q water (18 M) was used to prepare all solutions and dilutions.

The diluted molasses solution was prepared by high-temperature sterilization; here, 0.50, 1.00, and 2.00 mL of sugarcane molasses was dissolved into deionized water and then diluted to 1 L; that is, the concentrations of the sugarcane molasses solutions were 0.308, 0.617, and 1.234 g/L, respectively. The stock solution was prepared by dissolving a certain amount of potassium dichromate and Fe(NO3)3 in deionized water and then diluting it to 1000 mL to obtain 20 mg/L of Cr(VI) solution, 20 mg/L Cr(VI), and 10 mg/L Fe(III) mixed solution, respectively.

2.2 Experimental Methods

The reactions were conducted in 250 mL brown reaction bottles. Reaction mixtures were obtained by taking 100 mL of stock solutions, adjusting the pH values, and adding 100 mL of diluted molasses solutions. The initial pH of a solution was adjusted with the sulfur (0.5 M) and sodium hydroxide (1.0 M) solutions. The following conditions were applied as standard conditions in the reaction system: 5 mg/L Fe(III), 10 mg/L initial Cr(VI), 0.308 g/L sugarcane molasses, pH 2.5 ± 0.1, and temperature-controlled room at 20 ± 1 °C unless otherwise specified below.

Four groups of experiments were conducted to determine the effects of Fe(III) on Cr(VI) reduction with organic reducing substances from sugarcane molasses under different conditions. To evaluate the effect of Fe(III) concentration on the reduction by sugarcane molasses, the concentrations of Fe(III) were set to 0, 0.1, 0.5, 1.0, 2.0 5.0, and 10.0 mg/L. To study the effect of Fe(III) on Cr(VI) reduction at different pH values, the pH values were set to 2.0, 2.5, 3.0, 3.5, 4.0, and 5.6 (±0.1). To study the effect of Fe(III) at different temperatures, several experiments were performed at different temperatures of 10, 20, and 30 °C (±1 °C). To study the effect of Fe(III) on Cr(VI) reduction at different initial sugarcane molasses concentrations, the initial molasses concentrations were set to 0.308, 0.617, and 1.234 g/L. Control experiments without Fe(III) were also carried out. At regular time intervals, 10 mL of the mixed solution was withdrawn to determine the Cr(VI), total Cr concentration, and organic reducing substances. Each experiment was repeated three times in sterilized conditions.

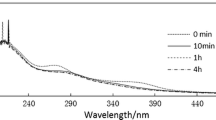

2.3 Analytical Methods

Total Cr, Cr(VI), and Fe(II) concentrations, pH, and temperature were measured in all of the experiments. Cr(VI) concentration was determined by the diphenylcarbazide spectrophotometric method according to the “Standard Methods for the Examination of Water and Wastewater” (1998) at 540 nm, using a UNIC 7200 UV-visible spectrophotometer. Total chromium was determined by flame atomic absorption spectrometry according to the “Standard Methods for the Examination of Water and Wastewater” using a Shimadzu AA-6300 atomic absorption spectrophotometer. Polyphenol content was quantified by the Folin–Ciocalteu method at 765 nm using a WFZUV-2802H UV spectrophotometer as described in the literature (Singleton et al. 1999). pH and temperature were determined by using a Hach DR900 portable multiparameter device.

3 Results and Discussion

3.1 Effect of Fe(III) Concentration on Cr(VI) Reduction

Figure 1 shows the relationship between Fe(III) concentration and removal efficiency of Cr(VI) reduction. Cr(VI) reduction was faster with 10 mg/L Fe(III) (100 % reduction in 24 h) than with 5.0 or 0 mg/L Fe(III) (100 % reduction in over 24 and 36 h, respectively). These results indicate that Fe(III) could effectively promote Cr(VI) reduction reaction by sugarcane molasses and that Cr(VI) reduction was enhanced with increasing Fe(III) concentration. This observation may be due to the fact that Fe(III) can promote electron transfer between the reducing organic matter and Cr(VI) (Chen et al. 2015b; Hynes and Coinceanainn 2001). This result is similar to that obtained using organic acid containing α-OH with photocatalysis (Sun et al. 2009).

The initial reaction rate (vinitial) was evaluated by a kinetic model with respect to the Cr(VI) concentration; this kinetic model may be expressed as follows:

where v is the reaction rate, c (mg/L) is the Cr(VI) concentration, k obs(h−1) is the rate constant, and n is the reaction order. Thus, the initial reaction rate of Cr(VI) reduction (vinitial) is calculated via Eq. (2):

where c 0 is the Cr(VI) initial concentration.

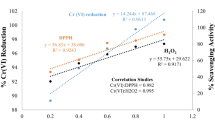

Cr(VI) reduction in sugarcane molasses can be described by a pseudo-first-order kinetic model with respect to Cr(VI) concentration. The initial reaction rate (vinitial) increased with increasing Fe(III) concentration (Table 1). The vinitial increased by 0.68, or about 1.19 times compared with the control, as the Fe(III) concentration increased from 0 to 5.0 and 10 mg/L. When the Fe(III) concentration was no more than 10 mg/L, the initial reaction rates plotted versus Fe(III) concentration produced a nearly straight line (Fig. 2), thereby indicating that vinitial has a linear positive correlation with Fe(III) concentration.

3.2 Effect of Fe(III) on Cr(VI) Reduction at Different pH Values

Figure 3 shows the effect of Fe(III) on Cr(VI) reduction by sugarcane molasses at different pH values. When the Fe(III) concentration was 5.0 mg/L, marked enhancement of Cr(VI) reduction was observed in different pH values. When pH ≤ 4.0, the contact time required for complete Cr(VI) removal was shortened in the presence of Fe(III) compared with the time required for reduction without Fe(III). At pH 4.0, enhancement of Cr(VI) reduction by sugarcane molasses was more remarkable in the presence of Fe(III) (97 % reduction in 120 h) than without Fe(III) (97 % reduction in over 312 h). At pH 5.6 and 8.0, the removal efficiencies of Cr(VI) increased by 23.68 and 10.05 % with increasing Fe(III) concentration from 0 to 5.0 mg/L. These results illustrate that Fe(III) could not only improve the reaction rate of Cr(VI) reduction but also increase the removal efficiency of Cr(VI) reduction with sugarcane molasses. This finding may be explained as follows: (1) Fe(III) could promote electron transfer between the reducing organic matter and Cr(VI), thereby improving Cr(VI) reduction rates; and (2) Fe(III) could catalyze the chemical reduction of Cr(VI) via reducing organic matter, thereby increasing Cr(VI) reduction removal efficiency (Chen et al. 2015a; Sun et al. 2009; Hynes and Coinceanainn 2001).

Table 2 presents the rate constants and initial reaction rates (vinitial) of the pseudo-first-order model with and without Fe(III). The initial reaction rates increased by 0.68, 0.84, 1.38, 1.39, 0.89, and 0.29 times in the presence of Fe(III) from 0 to 5.0 mg/L at different pH values of 2.5, 3.0, 3.5, 4.0, 5.6, and 8.0, respectively. These results suggest that Fe(III) catalyzes Cr(VI) reduction strongly within the pH range of 3.5–4.0 and that Fe(III) catalysis decreases under strongly acid (pH < 3.5) or increasing pH (pH > 5.6).

3.3 Effect of Fe(III) on Cr(VI) Reduction at Different Temperatures

Temperature can play an important role in the reduction of Cr(VI) to Cr(III) with sugarcane molasses by chemical reduction. Figure 4 presents the effect of Fe(III) on Cr(VI) reduction at different temperatures (i.e., 10, 20, and 30 °C). The contact times required for complete removal of Cr(VI) were 14, 24, and 84 h in the presence of Fe(III), which was less compared with that in the absence of Fe(III) more than 24, 36, and 110 h at different temperatures. The results illustrate that Fe(III) catalysis of Cr(VI) reduction is more obvious at lower temperatures than at higher ones.

Table 3 shows the effect of Fe(III) on the kinetics of Cr(VI) reduction using the pseudo-first-order model at different temperatures. The initial reaction rates at 10, 20, and 30 °C increased by 0.87, 0.68, and 0.43 times, respectively, in the presence of Fe(III) from 0 to 5.0 mg/L. Based on the k obs obtained at different temperatures, Fig. 5 was plotted on the basis of the Arrhenius equation as follows:

The relationship between lg(k obs) and 1/T showed a straight line (Fig. 5). The activation energy (E а) was estimated to be 61.9 and 70.1 kJ/mol with and without Fe(III), respectively. Hence, Fe(III) can reduce the activation energy of Cr(VI) reduction by sugarcane molasses and promote the rate of the redox reaction.

3.4 Effect of Fe(III) on Cr(VI) Reduction at Different Molasses Concentrations

Figure 6 shows the time-dependent removal efficiency of Cr(VI) with and without Fe(III) at various molasses concentration. The marked enhancement of Cr(VI) reduction was observed in the presence of Fe(III) compared with that without Fe(III). The reaction could be described by a pseudo-first-order kinetic model with respect to Cr(VI) concentration at different molasses concentrations. The initial reaction rates increased by 0.24, 0.50, and 0.68 times with or without Fe(III) when the sugarcane molasses concentrations were 0.154, 0.308, and 0.617 g/L, respectively. These results illustrate that increasing the molasses concentration could strengthen Fe(III) catalysis of Cr(VI) reduction.

3.5 Reaction Mechanism

Fe(III) could improve the reaction rate of Cr(VI) reduction and increase the removal efficiency of Cr(VI) by organic reducing substances in sugarcane molasses under various environmental conditions. To ascertain the mechanism through which Fe(III) facilitates the Cr(VI) reduction by sugarcane molasses, we summarize and analyze our findings below.

First, we measured the Fe(II) concentration during the experiment. Only a small amount of ferrous iron (<0.2 mg/L) was observed after complete Cr(VI) reduction. This observation may be attributed to the fact that Fe(II) generated in the reaction system reduced Cr(VI) to Cr(III) quickly and itself into Fe(III); thus, Fe(II) was detected after complete Cr(VI) removal (Chen et al. 2015a; Lin and Huang 2008). Hynes and Coinceanainn (2001) reported that the Fe(III) complexes of gallic acid (containing phenol hydroxyl groups) subsequently decomposed to form Fe(II) and the corresponding semiquinone (the product of the phenolic hydroxyl group loses electron). This observation shows that the redox activity of phenolic hydroxyl group from polyphenols is stronger than that of α-hydroxyl group from organic acid. Second, α-hydroxyl group is a key factor both in the reduction of Cr(VI) and the catalytic effect of Al(III), Mn(II), and Fe(III) (Chen et al. 2013; Hug et al. 1997; Khan et al. 1998; Babu et al. 2004; Li et al. 2007). Organic acids with more α-hydroxyl groups exhibit stronger reduction capabilities (Sun et al. 2009). The relevant mechanism here involves formation of a complex between organic acids and metal ions [e.g., Al(III), Mn(II), and Fe(III)] which significantly enhances the reductivity of α-hydroxy acids and further leads to the more complicated Cr(VI)-tartaric acid-Al(III) cyclic ester, which significantly accelerates the reduction rate.

Considering these results, we hypothesized that Fe(III) can facilitate Cr(VI) reduction by organic reducing matter (such as polyphenols) from sugarcane molasses through mechanisms I and II. Mechanism I consists of two steps: first, organic reducing substances in sugarcane molasses can complex with Fe(III) and subsequently decompose to form Fe(II); second, the generated Fe(II) rapidly reduces Cr(VI) to Cr(III) and is itself oxidized to Fe(III) during the experiment. In mechanism II, organic reducing matter complexes with both Fe(III) and Cr(VI) can reduce the reaction activation energy and accelerate electron transfer between Cr(VI) and organic reducing substances compared with that of organic reducing matter complexes with Cr(VI), decomposing to form Cr(III). Based on the Fe(II) concentrations observed, mechanism II appears to be the major route for Fe(III) catalysis of Cr(VI) reduction by sugarcane molasses. These results are significant for promoting the use of sugarcane molasses in the remediation of Cr(VI)-contaminated groundwater because iron is abundant in groundwater.

4 Conclusions

Fe(III) can catalyze Cr(VI) reduction by organic reducing matter in sugarcane molasses. The reaction can be described by a pseudo-first-order kinetic model with respect to Cr(VI) concentration under different conditions. The catalytic effect of Fe(III) shows a linear positive correlation with Fe(III) concentration when the Fe(III) concentration is no more than 10 mg/L. Fe(III) catalysis of Cr(VI) reduction occurs more strongly within the pH range 3.5–4.0 and at lower temperatures. The main mechanism involves organic reducing matter complexes with both Fe(III) and Cr(VI) reducing the reaction activation energy, facilitating Cr(VI) reduction by organic reducing matter in the presence of Fe(III). These findings are significant for promoting the application of sugarcane molasses to the remediation of Cr(VI)-contaminated groundwater.

References

Babu, P. S. S., Khan, Z., & Kabir-ud-Din. (2004). Electron transfer reaction in the chromium(VI)-manganese(II) system in the presence of ethylenediaminetetraacetic acid (EDTA). Transition Metal Chemistry, 29(8), 885–892.

Bond, D. L., & Fendorf, S. (2003). Kinetics and structural constraints of chromate reduction by green rusts. Environmental Science & Technology, 37(12), 2750–2757.

Brodie, E. L., Joyner, D. C., Faybishenko, B., Conrad, M. E., Rios-Velazquez, C., Malave, J., Martinez, R., Mork, B., Willett, A., Koenigsberg, S., Herman, D. J., Firestone, M. K., & Hazen, T. C. (2011). Microbial community response to addition of polylactate compounds to stimulate hexavalent chromium reduction in groundwater. Chemosphere, 85(4), 660–665.

Chauhan, D., Dwivedi, J., & Sankararamakrishnan, N. (2014). Facile synthesis of smart biopolymeric nanofibers towards toxic ion removal and disinfection control. RSC Advances, 4(97), 54694–54702.

Chen, N., Lan, Y., Wang, B., & Mao, J. (2013). Reduction of Cr (VI) by organic acids in the presence of Al (III). Journal of Hazardous Materials, 260, 150–156.

Chen, J., Chen, R., & Hong, M. (2015a). Influence of pH on hexavalent chromium reduction by Fe(II) and sulfide compounds. Water Science and Technology, 72, 22–28.

Chen, Z. F., Zhao, Y. S., Zhang, J. W., & Bai, J. (2015b). Mechanism and kinetics of hexavalent chromium chemical reduction with sugarcane molasses. Water, Air, and Soil Pollution, 226, 363.

Chrysochoou, M., & Ting, A. (2011). A kinetic study of Cr(VI) reduction by calcium polysulfide. Science of the Total Environment, 409(19), 4072–4077.

Chrysochoou, M., Johnston, C. P., & Dahal, G. (2012). A comparative evaluation of hexavalent chromium treatment in contaminated soil by calcium polysulfide and green-tea nanoscale zero-valent iron. Journal of Hazardous Materials, 201–202, 33–42.

Field, E. K., Gerlach, R., Viamajala, S., Jennings, L. K., Peyton, B. M., & Apel, W. A. (2013). Hexavalent chromium reduction by Cellulomonas sp strain ES6: the influence of carbon source, iron minerals, and electron shuttling compounds. Biodegradation, 24(3), 437–450.

Fu, F., Dionysiou, D. D., & Liu, H. (2014). The use of zero-valent iron for groundwater remediation and wastewater treatment: a review. Journal of Hazardous Materials, 267C, 194–205.

Guan, Y., Tang, Q., Fu, X., Yu, S., Wu, S., & Chen, M. (2014). Preparation of antioxidants from sugarcane molasses. Food Chemistry, 152, 552–557.

Han, J., Bu, X., Zhou, D., Zhang, H., & Yang, B. (2014). Discriminating Cr(III) and Cr(VI) using aqueous CdTe quantum dots with various surface ligands. RSC Advances, 4(62), 32946–32952.

Hashim, M. A., Mukhopadhyay, S., Sahu, J. N., & Sengupta, B. (2011). Remediation technologies for heavy metal contaminated groundwater. Journal of Environmental Management, 92(10), 2355–2388.

Henderson, A. D., & Demond, A. H. (2013). Permeability of iron sulfide (FeS)-based materials for groundwater remediation. Water Research, 47(3), 1267–1276.

Hosseini, M. S., & Belador, F. (2009). Cr(III)/Cr(VI) speciation determination of chromium in water samples by luminescence quenching of quercetin. Journal of Hazardous Materials, 165(1–3), 1062–1067.

Hug, S. J., Laubscher, H. U., & James, B. R. (1997). Iron(III) catalyzed photochemical reduction of chromium(VI) by oxalate and citrate in aqueous solutions. Environmental Science and Technology, 37, 160–170.

Hynes, M. J., & Coinceanainn, M. O. (2001). The kinetics and mechanisms of the reaction of iron(III) with gallic acid, gallic acid methyl ester and catechin. Journal of Inorganic Biochemistry, 85, 131–142.

Khan, Z., Hashmi, A. A., Ahmed, L., & Hao, M. M. (1998). Kinetics and mechanism of chromic acid oxidation of oxalic acid in absence and presence of different acid media. A kinetic study. International Journal of Chemical Kinetics, 30, 335–340.

Krishna, K. R., & Philip, L. (2005). Bioremediation of Cr(VI) in contaminated soils. Journal of Hazardous Materials, 121(1–3), 109–117.

Lee, S. E., Lee, J. U., Chon, H. T., & Lee, J. S. (2008). Reduction of Cr(VI) by indigenous bacteria in Cr-contaminated sediment under aerobic condition. Journal of Geochemical Exploration, 96, 144–147.

Li, C., Lan, Y. Q., & Deng, B. L. (2007). Catalysis of manganese(II) on chromium(VI) reduction by citrate. Pedosphere, 17(3), 318–323.

Lin, Y. T., & Huang, C. P. (2008). Reduction of chromium(VI) by pyrite in dilute aqueous solutions. Separation and Purification Technology, 63, 191–199.

Loyaux-Lawniczak, S., Refait, P., Ehrhardt, J. J., Lecomte, P., & Genin, J. M. R. (2000). Trapping of Cr by formation of ferrihydrite during the reduction of chromate ions by Fe(II)-Fe(III) hydroxysalt green rusts. Environmental Science & Technology, 34(3), 438–443.

Ludwig, R. D., Su, C. M., Lee, T. R., Wilkin, R. T., Acree, S. D., Ross, R. R., & Keeley, A. (2007). In situ chemical reduction of Cr(VI) in groundwater using a combination of ferrous sulfate and sodium dithionite: a field investigation. Environmental Science & Technology, 41(15), 5299–5305.

Michael, J., & Hynes, M. O. C. (2001). The kinetics and mechanisms of the reaction of iron(III) with gallic acid, gallic acid methyl ester and catechin. Journal of Inorganic Biochemistry, 85, 131–142.

Michailides, M. K., Tekerlekopoulou, A. G., Akratos, C. S., Coles, S., Pavlou, S., & Vayenas, D. V. (2014). Molasses as an efficient low-cost carbon source for biological Cr(VI) removal. Journal of Hazardous Materials, 281, 95–105.

Okello, V. A., Mwilu, S., Noah, N., Zhou, A., Chong, J., Knipfing, M. T., Doetschman, D., & Sadik, O. A. (2012). Reduction of hexavalent chromium using naturally-derived flavonoids. Environmental Science & Technology, 46(19), 10743–10751.

Pagnanelli, F., Viggi, C. C., Cibati, A., Uccelletti, D., Toro, L., & Palleschi, C. (2012). Biotreatment of Cr(VI) contaminated waters by sulphate reducing bacteria fed with ethanol. Journal of Hazardous Materials, 199–200, 186–192.

Patterson, R. R., Fendorf, S., & Fendorf, M. (1997). Reduction of hexavalent chromium by amorphous iron sulfide. Environmental Science & Technology, 31(7), 2039–2044.

Qin, G., Mcguire, M. J., Blute, N. K., Seidel, C., & Fong, L. (2005). Hexavalent chromium removal by reduction with ferrous sulfate coagulation, and filtration: a pilot-scale study. Environmental Science and Technology, 39, 6321–6327.

Qiu, X., Fang, Z., Yan, X., Cheng, W., & Lin, K. (2013). Chemical stability and toxicity of nanoscale zero-valent iron in the remediation of chromium-contaminated watershed. Chemical Engineering Journal, 220, 61–66.

Sarkar, B., Naidu, R., Krishnamurti, G. S. R., & Megharaj, M. (2013). Manganese(II)-catalyzed and clay-minerals-mediated reduction of chromium(VI) by citrate. Environmental Science & Technology, 47(23), 13629–13636.

Singleton, V. L., Orthofer, R., & Lamuela-Raventos, R. M. (1999). Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Oxidants and Antioxidants, Part A, 299, 152–178.

Somasundaram, V., Philip, L., & Bhallamudi, S. M. (2009). Experimental and mathematical modeling studies on Cr(VI) reduction by CRB, SRB and IRB, individually and in combination. Journal of Hazardous Materials, 172(2–3), 606–617.

Somasundaram, V., Philip, L., & Bhallamudi, S. M. (2011). Laboratory scale column studies on transport and biotransformation of Cr(VI) through porous media in presence of CRB, SRB and IRB. Chemical Engineering Journal, 171(2), 572–581.

Standard Methods for the Examination of Water and Wastewater, 20th ed., (1998). American Water Works Association and Water Pollution Control Federation, Washington D.C.

Su, C. M., & Ludwig, R. D. (2005). Treatment of hexavalent chromium in chromite ore processing solid waste using a mixed reductant solution of ferrous sulfate and sodium dithionite. Environmental Science & Technology, 39(16), 6208–6216.

Sugiyama, T., Sugito, H., Mamiya, K., Suzuki, Y., Ando, K., & Ohnuki, T. (2012). Hexavalent chromium reduction by an actinobacterium Flexivirga alba ST13(T) in the family Dermacoccaceae. Journal of Bioscience and Bioengineering, 113(3), 367–371.

Sun, J., Mao, J. D., Gong, H., & Lan, Y. (2009). Fe(III) photocatalytic reduction of Cr(VI) by low-molecular-weight organic acids with α-OH. Journal of Hazardous Materials, 168(2–3), 1569–1574.

US EPA (2011). Molasses Injections at Selma Superfund Site Result in Multiple Environmental and Economic Benefits. http://www.epa.gov/region9/cleanup-clean-air/selma.html.

US EPA (2003). Molasses-Based Microbial Precipitation Used Successfully for Chromium Reduction. http://www.epa.gov/tio/download/newsltrs/tnandt0703.pdf.

Yalçın Tepe, A. (2014). Toxic Metals: Trace Metals – Chromium, Nickel, Copper, and Aluminum. Encyclopedia of Food Safety. Y. Motarjemi (pp. 356–362). Waltham: Academic.

Acknowledgments

This research project was supported by College Innovation Ability Promotion Projects of Beijing Municipal Education Commission (Grant No. TJSHG201310772028). The authors are grateful to the Analysis and Testing Foundation of the Key Laboratory of Groundwater Resources and Environment, Ministry of Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, ZF., Zhao, YS. & Li, Q. Influence of Fe(III) on Cr(VI) Reduction by Organic Reducing Substances from Sugarcane Molasses. Water Air Soil Pollut 227, 19 (2016). https://doi.org/10.1007/s11270-015-2678-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-015-2678-x