Abstract

The present work evaluated a mercury adsorption from its aqueous solution through chemically enhanced kapok fiber with the self-polymerization of the dopamine (DA) on the surface of the kapok fiber. The adsorption capacity of mercury ions was greatly improved with the DA coated kapok fiber (235.7 mg/g), compared with the raw kapok fiber (39.9 mg/g). The kinetic and isotherm studies were established, and the most fitting pseudo-first-order reaction and the Langmuir model indicated that the homogenous chemisorption occurred on the surface of the chemically modified kapok fiber with the equilibrium time of 80 min. According to the FTIR and XPS spectra analyses, the bidentate adsorption of mercury ions was illustrated with hydroxyl groups induced by three-dimensional (3-D) polymerization of DA. The optimum pH was at 8 for the adsorption with the dopamine-coated kapok fiber and the high adsorption efficiency was still maintained after three recycle times, extending its application to treating a number of industrial wastewater streams.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mercury, classified as a toxic heavy metal, is a threat to human health and living organisms because of its neurological toxicity, volatility, persistence, and bioaccumulation through a food chain. Once entering human body system, it was known to be difficult to be metabolized and eliminated (Anirudhan et al. 2008; Ghodbane and Hamdaoui 2008; Miretzky and Cirelli 2009; Starvin and Rao 2004). Also, it was added that high levels of mercury and its complexes could cause an inhibition of enzyme activity, cell damage, impairment of pulmonary function and kidney performance, chest pain, and damage on a central nerve system (Han et al. 2014; Jeong et al. 2007; Kaneko 1988; Zahir et al. 2005). The main source of mercury pollution comes from industrial wastewater discharged by such a variety of industries as oil refinery, chloro-alkali chemical facility, pulp and paper, mining, electroplating, paint, pharmaceutical and battery manufacturing (Boening 2000; Donia et al. 2008; Krishnan and Anirudhan 2002). Therefore, the environmental remediation of the effluent containing mercury or its compound draws a great deal of attention from many environmental scientists and engineers, in terms of developing innovative methods to remove it (Li et al. 2018; Liu et al. 2018).

A number of chemical and physical methods have been developed for the removal of mercury from varied wastewater streams. A method of adsorption is one of the most effective techniques among numerous chemical and physical separation processes such as solvent extraction, ion-exchange, precipitation, membrane separation including reverse osmosis, coagulation and photo reduction (Chiarle et al. 2000; Dawlet et al. 2013; Nam et al. 2003). For the case of adsorption process, many adsorbents, like charcoal-immobilized papain (CIP), eucalyptus bark, guava bark, char, yellow stuff, pozzolana, clays, and ion-exchange resin, were used for treating aqueous mercury from wastewater streams (Cai et al. 2014; Dutta et al. 2009; Ghodbane and Hamdaoui 2008; Lohani et al. 2008; Di Natale et al. 2006; Velicu et al. 2007; Wang et al. 2019). When it comes to dealing with those, the use of adsorbents is quite advantageous because of such reasons as low operating cost, easy modification and adaptation to an existing system, and relatively short operation time. As far as an industrial application is concerned, a small footprint and capital costs are important decision-making factors for a system installation. With such consideration, the objectives of this study were to develop an efficient adsorbent using kapok fibers, derived from the fruit of Ceiba pentandra. Kapok fibers drift away in the wind after they reached maturity, which adds to the pollution issues and are considered a waste of potential bioresource. Moreover, only the minority of those are used as stuffing material for bedding, upholstery, life preservers, and other water-safety devices (Dong et al. 2015; Lim and Huang 2007; Wang et al. 2014, 2015). Therefore, any attempt to extend the utilization of kapok fiber will be worthwhile. Admittedly, some efforts were already made for using kapok fiber as precursors for the preparation of potential adsorbents in removing a mercury contamination. However, it is quite new and innovative to significantly increase the adsorption capacity of mercury via inducing functional groups to bind mercury ions because of a self-polymerization phenomenon of dopamine in a 3-D structure. The initial concentration of mercury ions, contact time, and initial pH, were systematically and carefully studied to evaluate their effects on the mercury adsorption process. In addition, to investigate the adsorption process of bioadsorbents, the pseudo-first order and pseudo-second order reactions were applied for a kinetic evaluation, and the Langmuir and the Freundlich models were used to describe an isotherm study. The mechanisms of adsorption of mercury onto the surface of kapok fiber were also explored based on the kinetics and thermodynamics of adsorption with the help of XPS and FTIR analyses of adsorbents. At last, the reusability of the adsorbents was also assessed for the purpose of practical applications. The poly(dopamine)-coated kapok fibers (D-KF) can be highly utilized as an attractive adsorbent for the mercury treatment from aqueous solution.

Materials and methods

The raw kapok fiber (R-KF) products were imported from Malaysia and were filtered, washed to remove some impurities, and dried at room temperature for a longer use. Dopamine (DA) was purchased from the Sigma-Aldrich, Germany, and mercury(II) chloride was purchased from the Daejung Chemicals and Metals Co., Ltd, Korea.

Surface modification of the adsorbent

The DA solution (2 g/L) was prepared by completely dissolving DA into tris–HCl buffer solution (0.1 mol/L) and the pH value was adjusted to approximately 8.0. Then, 100 mL of the DA solution containing 0.2 g of kapok fiber was stirred for 24 h. After that, the poly(dopamine)-coated kapok fibers (D-KF) were washed with deionized water and then dried at 60 °C in a vacuum condition.

For a comparison, another chemical modification process on the surface of the kapok fiber (M-KF) was carried out, using a NaClO2 solution. One hundred grams of kapok fiber were added to 500 mL of NaClO2 solution (0.1 N) and such oxidative treatment lasted for 30 m at room temperature. Then, the fibers were rinsed several times with deionized water. The M-KF was dried at room temperature.

Characterization

To identify the differences of the surface morphology of the kapok fiber (e.g., before and after modification), a field emission scanning electron microscope (FE-SEM) (Model S-5500, Hitachi, USA) was used and the measurements were carried out at an accelerating voltage of 10 kV. The IR spectra of raw kapok fibers, surface modified kapok fibers, and kapok fibers after adsorption were recorded with a FTIR Spectrophotometer (Model Bomen MB Series, Hartmann and Braun (ABB), Canada). Samples of 100 mg of potassium bromide containing 2% of finely ground powder were prepared for an analysis. An X-ray photoelectron spectrometer (Model Kratos AXIS Ultra DLD, Shimadzu, Japan) with an Al Kα X-ray source (1486.6 Ev photons) was used for the XPS measurements. Binding energies were calibrated with a containment carbon (C1s = 284.8 eV).

Adsorption study

Adsorption studies for mercury ions were developed with raw and chemically modified kapok fibers in mercury (II) aqueous solutions, in terms of various parameters, initial concentration of mercury ions, and the contact time during the adsorption process. For the adsorption process, a flask containing 0.1 g of the adsorbent and 100 mL of the mercury chloride solution (400 mg/L) was shaken at room temperature for 2 h, using a flask shaking incubator and the residual solution was analyzed for the estimation of the residual mercury ion concentration with an Atomic Absorption Spectrophotometer (Model AA-7000, Shimadzu, Japan) equipped with a Hydride Vapor Generator (Model HVG-1, Shimadzu, Japan). The standard solutions for the analysis were purchased from Kriat, Korea. All of the experiments were repeated and the average value was expressed as a mean value.

Effects of pH on adsorption

To find the optimum pH on the adsorption effectiveness of mercury (II) ions, mercury chloride solution was adjusted to various pH5 of 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, and 10.0, using hydrochloric acid (1 M) and sodium hydroxide (1 M), and the initial concentration of mercury ions was 70 mg/L in the aqueous solution before adsorption. One hundred milliliters of mercury chloride solution were shaken with 0.1 g of raw kapok fibers (R-KF), modified/oxidized kapok fibers (M-KF), and DA coated kapok fibers (D-KF) at a room temperature for 2 h and the residual concentration of mercury ions was analyzed.

Reusability of the adsorbents

After the adsorption process, the adsorbent of D-KF was thoroughly rinsed with deionized water and dried in vacuum. Then, one hundred milliliters of hydrochloric acid solution (1 M) were used to desorb the mercury ions from the adsorbent, and the flask containing hydrochloric acid solution and the adsorbent, was shaken for 2 h at a room temperature.

Results and discussion

Characteristics of the adsorbents

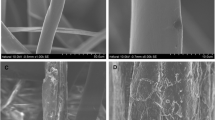

The surface morphological difference between R-KF and D-KF is viewed in Fig. 1. Figure 1a shows the smooth surface of R-KF because of the presence of a thick wax structure (Zahir et al. 2005). On the contrary, the relatively rough and uneven surface of D-KF was observed with some degrees of wrinkles and grooves, which was due to the 3-D polymerization of DA (Fig. 1b). Also, it was reported that the wax structure on the surface of kapok fiber could be removed then transformed to a hydrophilic surface when treated with NaClO2 solution (Wang et al. 2012).

According to the XPS spectra, the same peak components including carbon 1 s, nitrogen 1 s and oxygen 1 s were observed in Fig. 2. It could be assessed that the intensities of C1s, N1s and O1s of D-KF were increased, compared to the peaks of R-KF (Liao et al. 2010; Xu et al. 2011). It could indicate that the DA layer was formed on the surface of the kapok fiber through a self-polymerization of the DA along with chemical bonds of C, N, and O. The process mechanism for the DA 3-D polymerization was well described in a previous work (Wang et al. 2014, 2015), based on the oxidative self-polymerization of DA (2-(3, 4-dihydroxy-phenyl) ethylamine) onto the surfaces with an intermediate step forming 5, 6-dihydroxyindole right after chemical oxidation and structural rearrangement (Wang et al. 2015). In addition, chemical functional groups are involved in such structural change. A quinone structure was formed by oxidizing catechol groups from the redox activity of catechol groups in DA. These quinone structures could react further with amines and other catechol or quinone to form an adherent poly(dopamine) film, which will become an inter- and intra-polymer network (IPN) (Kim et al. 2005). This reorganized polymer network will play a fishnet in easily entrapping mercury ions (Kim et al. 2005).

As for one another possible evidence of change on kapok fibers, the color of kapok fiber gradually changed from bright white to dark gray. Figure 3 showed the FTIR spectra of the three kapok adsorbent samples. The strong and broad peak at 3341 cm−1 was assigned to non-free O–H stretching vibration and N–H stretching vibration, and another strong peak at 2917 cm−1 was corresponding to asymmetric and symmetric stretching vibration in –CH2 and –CH3 because of the presence of the wax structure on the surface of kapok fiber (Wang et al. 2012). The absorption peak at 1738 cm−1 was suggested to the C=O stretching vibration of ketones, carboxylic groups or esters, while another peak at 1594 cm−1 was corresponding to the aromatic ring of carbon skeletal stretching. In addition, the absorption peaks at 1238 cm−1 and 1035 cm−1 were assigned to the C-N bending vibration and C-O bending vibration, respectively. Notably, after DA coated onto the R-KF, the peaks in 3341 cm−1 and 1035 cm−1 became more intense in the D-KF, indicating that DA was successfully introduced onto the surface of kapok fiber with ample hydroxyl groups and amino groups. Additionally, because of the self-polymerization of DA, many functional groups and bonds such as carbonyl group, aromatic rings, C-N bonds and C-O bonds could be introduced onto the surface of kapok fiber, which caused the FTIR of D-KF, again representing the significant increase in other range of wavenumber, when it comes to comparing the raw and chemically enhanced fibers.

Kinetics and isotherm study of mercury adsorption

The adsorption kinetic study was conducted to estimate the adsorption rates and optimized reactions for the removal of mercury ions. Figure 4 exhibited the Hg2+ adsorption kinetics of mercury ions of three kapok fiber samples. The sorption displayed a quite high rate of mercury adsorption uptake for the first 5 min and gently slowed down after 10 min. Commonly, the pseudo-first-order (Eq. 1) and pseudo-second-order (Eq. 2) reactions (Zhang et al. 2014) can be applied in the formulas as follows:

where k stands for the rate constant (min−1), Qt is the adsorption capacity (mg/g) at a certain time t, and Qe is the adsorption capacity (mg/g) at an equilibrium time, respectively (Nam et al. 2003).

The experimental parameters and the correlation coefficients of reactions (R2) are presented in Table 1. The pseudo-second-order provided a better fit than the pseudo-first-order model according to the correlation value, which means that the chemisorption process might be a dominant step and the reaction rate could be increased by increasing the concentration of adsorbents and adsorbates, when chemically modifying fibers. On the contrary, the diffusion process appeared to be a rate limiting step for the adsorption process of mercury ions with R-KF. With such notion, the adsorption rate of D-KF was significantly enhanced through chemical modifications, as shown in Fig. 4.

In addition, Langmuir (Eq. 3) and Freundlich (Eq. 4) models were applied to estimate the adsorption capacity and reaction mechanisms. The equations are respectively represented as follows:

where Ce (mg/L) is the equilibrium concentration of Hg2+ and Qe (mg/g) is the equilibrium adsorption capacity. Qmax (mg/g) and K (L/mg) are the Langmuir constants relating to an adsorption capacity and the energy of an adsorption reaction, respectively. KF is the Freundlich constant relating to an adsorption capacity and n is the energy of an adsorption reaction.

Figure 5 presents the uptake of mercury ions from kapok fiber samples under various initial concentrations of mercury solution. The parameters and correlation coefficients (R2) are presented in Table 2, in conjunction with the Langmuir and the Freundlich models. The adsorption process ended for R-KF and M-KF because capacity was saturated with no significant increase after increasing the initial concentration of mercury ions up to 115.00 mg/L (Fig. 5). It can be speculated from the correlation coefficients (R2) that the Langmuir model is a better fit than the Freundlich model for all three kapok fibers. This can further suggest that a monolayer adsorption was carried out on a homogenous surface. Additionally, the maximum adsorption capacity of D-KF from the Langmuir model was found to 235.68 mg/g, a great enhancement made for the mercury adsorption using D-KF. This was due to functional groups induced by the layer of DA artificially built on the surface of kapok fiber, which can be identified by the FTIR spectra. Generally, as the KF increases adsorption capacity of an adsorbent increases. However, mercury uptake by M-KF was quite limited similarly to that of R-FK. Only bleaching with NaClO2 was not sufficient to build an IPN structure by chemically removing lignin and producing a matrix in fibers (Wang et al. 2014; Kim et al. 2005).

Sorption study of Hg2+ on D-KF

The kinetic and isotherm study of the mercury adsorption indicated that the chemisorption dominated the whole sorption process on the modified surface of D-KF. Figure 6 provides the FTIR spectra of R-KF, D-KF, and D-KF-400 (after adsorption at 400 mg/L of Hg2+). When compared to the unique FTIR spectra of R-KF and D-KF, the spectra of D-KF-400 had a significant reduction at 3341 cm−1. This identified the chemisorption of mercury ions happened owing to the DA coating process induced by dominating hydroxyl (-OH) groups. In Fig. 7, two peaks (4f7/2 and 4f5/2) at 99.9 eV and 103.8 eV, respectively, appeared. The difference of 4f7/2 and 4f5/2 peaks, 3.9 eV was obtained after deconvolving the experimental data with a software (XPS peak 4.1). It appeared that there were 57% of Hg0 (metallic state), and 43% of mercury atoms in the Hg2+ chemical state existing on the surface of D-KF-400 after the adsorption reaction ceased in mercury solution (Hutson et al. 2007).

Also, in Fig. 8, the mercury adsorption was graphically illustrated. Most of mercury ions were homogeneously adsorbed on the surface of the kapok fiber and had a bidentate reaction with a great number of hydroxyl groups, induced by the 3-D DA polymerization through chelating bonds. The catechol groups in the poly-dopamine film were spontaneously oxidized to quinone structures, allowing for the reduction of Hg2+ to Hg0 in situ along with a bond switch from covalent to chelating bond without the addition of a reducing agent (Liao et al. 2010). In addition, being compared to FTIR of R-KF, the increased peak area of D-KF-400 corresponded to the oxidized quinone structures ranging from 1738 to 1035 cm−1 (Fig. 6).

Effect of pH

Figure 9 shows how pH affected a mercury adsorption of kapok fibers. Sorption was strongly dependent on a specific pH range. Adsorption efficiency was greatly increased at pH of 5, and maximized through pH of 8 for D-KF, while efficiencies for R-KF and M-KF were relatively low at an acidic range, attributable to competition between H+ and Hg2+. Therefore, the adsorption study for kapok fiber was optimized at the pH range of 5-8. In other words, the highest adsorption efficiency was obtained at the pH of 8 because of the neutralization between hydroxyl groups and replaced hydrogen ions, while more alkali condition might age surface sites of kapok fibers, resulting in a decrease of adsorption efficiency (Ghodbane and Hamdaoui 2008).

Recyclability of D-KF

It has been reported that it was inappropriate for recovering metal ions from an absorbent in alkali solution, since the recovery could be maximized at a lower pH with the reduction of metal binding capacity (Dutta et al. 2009). Most of metals are more freely moving at an acidic environment. With such results of pH effect on adsorption, the experiment of recyclability was conducted at a low pH around 1.5, artificially adjusted with hydrochloric acid solution (1 M). In Fig. 10, after three times of recycling D-KF, the adsorption capacity decreased only 8.6%, from 224.8 to 205.4 mg/g. It was found that even strong acidity was not able to weaken functional groups and chemical bonds in crosslinked fishnet agglomeration of the 3-D structure.

Conclusions

The study dealt with the bidentate adsorption of mercury ions through artificially manufactured kapok fiber adsorbent. The kinetic and isotherm study indicated the adsorption capacity of mercury ion was greatly enhanced with the application of D-KF. The improvement in surface morphology was made with the help of the functional groups of D-KF through a 3-D DA functionalization. The equilibrium study for D-KF adsorption fitted with the Langmuir model. The oxidation of catechol groups and the reduction of Hg2+ to Hg0 were identified. The recyclability of fibers assessed a potential use for the metal recovery and industrial wastewater treatment.

References

Anirudhan TS, Divya L, Ramachandran M (2008) Mercury (II) removal from aqueous solutions and wastewaters using a novel cation exchanger derived from coconut coir pith and its recovery. J Hazard Mater 157:620–627

Boening DW (2000) Ecological effects, transport, and fate of mercury: a general review. Chemosphere 40:1335–1351

Cai J, Shen B, Li Z, Chen J, He C (2014) Removal of elemental mercury by clays impregnated with KI and KBr. Chem Eng J 241:19–27

Chiarle S, Ratto M, Rovatti M (2000) Mercury removal from water by ion exchange resins adsorption. Water Res 34:2971–2978

Dawlet A, Talip D, Mi HY, MaLiKeZhaTi M (2013) Removal of mercury from aqueous solution using sheep bone charcoal. Procedia Environ Sci 18:800–808

Di Natale F, Lancia A, Molino A, Di Natale M, Karatza D, Musmarra D (2006) Capture of mercury ions by natural and industrial materials. J Hazard Mater 132:220–225

Dong T, Xua G, Wanga F (2015) Adsorption and adhesiveness of kapok fiber to different oils. J Hazard Mater 196:101–111

Donia AM, Atia AA, Heniesh AM (2008) Efficient removal of Hg(II) using magnetic chelating resin derived from copolymerization of bisthiourea/thiourea/glutaraldehyde. Sep Purif Technol 60:46–53

Dutta S, Bhattacharyya A, De P, Ray P, Basu S (2009) Removal of mercury from its aqueous solution using charcoal-immobilized papain (CIP). J Hazard Mater 172:888–896

Ghodbane I, Hamdaoui O (2008) Removal of mercury (II) from aqueous media using eucalyptus bark: kinetic and equilibrium studies. J Hazard Mater 160:301–309

Han DS, Orillano M, Khodary A, Duan Y, Batchelor B, Abdel-Wahab A (2014) Reactive iron sulfide (FeS)-supported ultrafiltration for removal of mercury (Hg(II)) from water. Water Res 53:310–321

Hutson ND, Attwood BC, Scheckel KG (2007) XAS and XPS characterization of mercury binding on brominated activated carbon. Environ Sci Technol 41:1747–1752

Jeong HY, Klaue B, Blum JD, Hayes KF (2007) Sorption of mercuric ion by synthetic nanocrystalline mackinawite (FeS). Environ Sci Technol 41:7699–7705

Kaneko K (1988) Dynamic Hg(II) adsorption characterization of iron oxide-dispersed activated carbon-fibers. Carbon 26:903–905

Kim DI, Petrisor IG, Yen TF (2005) Evaluation of bio-polymer modified concrete systems for disposal of cathode ray tube glass. Air Waste Manag Assoc 55:961–969

Krishnan KA, Anirudhan TS (2002) Removal of mercury(II) from aqueous solutions and chlor-alkali industry effluent by steam activated and sulphurised activated carbons prepared from bagasse pith: kinetics and equilibrium studies. J Hazard Mater B92:161–183

Li Y, Wen L, Liu Q, Meng H, Ying L, Li C (2018) Alkynyl carbon materials as novel and efficient sorbents for the adsorption of mercury(II) from wastewater. J Environ Sci 68:169–176

Liao Y, Wang Y, Feng X, Wang W, Xu F, Zhang L (2010) Antibacterial surfaces through dopamine functionalization and silver nanoparticle immobilization. Mater Chem Phys 121:534–540

Lim TT, Huang X (2007) Evaluation of hydrophobicity/oleophilicity of kapok and its performance in oily water filtration: comparison of raw and solvent-treated fibers. Ind Crops Products 26:125–134

Liu C, Peng J, Zhang L, Wang S, Ju S, Liu C (2018) Mercury adsorption from aqueous solution by regenerated activated carbon produced from depleted mercury-containing catalyst by microwave-assisted decontamination. J Clean Prod 196:109–121

Lohani MB, Singh A, Rupainwar DC, Dhar DN (2008) Studies on efficiency of guava (Psidium guajava) bark as bioadsorbent for removal of Hg(II) from aqueous solutions. J Hazard Mater 159:626–629

Miretzky P, Cirelli AF (2009) Hg (II) removal from water by chitosan and chitosan derivatives: a review. J Hazard Mater 167:10–23

Nam KH, Gomez-Salazar S, Tavlarides LL (2003) Mercury(II) adsorption from wastewaters using a thiol functional. Ind Eng Chem Res 42:1955–1964

Starvin AM, Rao TP (2004) Removal and recovery of mercury(II) from hazardous wastes using 1-(2-thiazolylazo)-2-naphthol functionalized activated carbon as solid phase extractant. J Hazard Mater 113:75–79

Velicu M, Fu H, Suri RP, Woods K (2007) Use of adsorption process to remove organic mercury thimerosal from industrial process wastewater. J Hazard Mater 148:599–605

Wang J, Zheng Y, Wang A (2012) Effect of kapok fiber treated with various solvents on oil absorbency. Ind Crops Products 40:178–184

Wang R, Shin CH, Park SH, Park JS, Kim DI, Cui LZ, Ryu MH (2014) Removal of lead (II) from aqueous stream by chemically enhanced kapok fiber adsorption. Environ Earth Sci 72:5221–5227

Wang R, Shin CH, Park SH, Cui LZ, Kim DI, Park JS, Ryu MH (2015) Enhanced antibacterial activity of silver-coated kapok fibers through dopamine functionalization. Water Air Soil Pollut 226(2241):1–9

Wang J, Xing Y, Xie Y, Meng Y, Xia J, Feng X (2019) The use of calcium carbonate-enriched clay minerals and diammonium phosphate as novel immobilization agents for mercury remediation: spectral investigations and field applications. Sci Total Environ 646:1615–1623

Xu H, Shi X, Ma H, Lv Y, Zhang L, Mao Z (2011) The preparation and antibacterial effects of dopa-cotton/AgNPs. App Surface Sci 257:6799–6803

Zahir F, Rizwi SJ, Haq SK, Khan RH (2005) Low dose mercury toxicity and human health. Environ Toxicol Pharm 20:351–360

Zhang X, Jia X, Zhang G, Hu J, Sheng W, Ma Z, Lu J, Liu Z (2014) Efficient removal and highly selective adsorption of Hg2+ by polydopamine nanospheres with total recycle capacity. Appl Surf Sci 314:166–173

Funding

Shanghai sailing program, 17YF1407200. Capacity Building Project of Some Local Colleges and Universities in Shanghai, 17030501200. Foundation of Shanghai University of Engineering Science, 2016-22. Excellent Young Talents Fund Program of Higher Education Institutions of Anhui Province (CN), ZZGCD16018.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is a part of Topical Collection in Environmental Earth Sciences on Water Sustainability: A Spectrum of Innovative Technology and Remediation Methods, edited by Dr. Derek Kim, Dr. Kwang-Ho Choo, and Dr. Jeonghwan Kim.

Rights and permissions

About this article

Cite this article

Yang, N., Shin, CH., Kim, D. et al. Synthesis, characterization, and mercury removal application of surface modified kapok fibers with dopamine (DA): investigation of bidentate adsorption. Environ Earth Sci 79, 264 (2020). https://doi.org/10.1007/s12665-020-08980-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-020-08980-x