Abstract

The main goal of this study was to explore the suitability and performance of bicomponent polymer membranes based on acrylonitrile copolymers-polyvinyl alcohol (PVA) mixtures and small quantities of anion (Purolite A100) or cation exchange resin (Purolite C150), prepared by phase inversion. Membranes were used for copper removal from synthetic wastewater solutions. A three detachable cylindrical compartment electrodialysis cell without recirculation of the electrolytes and synthetic solutions of various concentrations, similar to a copper electrowinning electrolyte, were used. The electrodialysis unit operates under galvanostatic control. The effect of pH on electrodialysis separation of Cu2+ and on the solution conductivity has been also investigated. The laboratory electrodialysis cell performance was evaluated in terms of percent of extraction (pe) and current efficiency (ce). Experimental results showed that the ionic transfer in electrodialysis cell was especially affected by concentration. The highest values for the pe (>81 %) and the ce (>25 %) of copper ions were obtained at maximum concentration in copper ions (3 g/L), indicating a better performance of the ion extraction. The transport of copper ions was also correlated with flux data. The ion exchange membranes were characterized using FT-IR spectroscopy, ESEM, and electrochemical impedance spectroscopy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Removal of various toxic heavy metal ions such as copper, nickel, lead, cadmium, zinc, chromium, and mercury from anthropogenic sources such as metallurgical, galvanizing, metal finishing, electroplating, mining, power regeneration, electronic device manufacturing, and tannery industries is highly important for environmental remediation. These heavy metals are persistent, bioaccumulative and toxic (Mosa et al. 2011; Lito et al. 2012).

The use of copper baths in the electroplating industry generates a strong concern related to environmental impacts due to the copper toxicity. Although some minute amounts of copper are necessary, (copper being an oligoelement that is essential for human health), the excessive ingestion of copper brings about serious toxicological concerns, such as stomach-aches, dizziness, vomiting, and diarrhea. Intentionally high uptakes of copper may cause liver and kidney damage and even death (Mohammadi et al. 2004; Caprarescu et al. 2012a, b).

Removal of heavy metal ions is currently carried out using various technologies, including reverse osmosis, electrodialysis, precipitation, solvent extraction, filtration, adsorption, and ion exchange.

Reverse osmosis and ion-exchange can be effectively used to reduce the metal ions, but are limited due to a number of disadvantages such as the requirement of high amount of water, wastage of water a bit high, and high initial and operational costs, in addition to the limited pH range for the ion-exchange resin (Strathmann 2010; Dalla Costa et al. 2002; Shi et al. 2010; Lee et al. 2008).

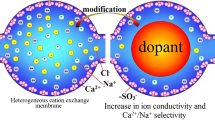

Electrodialysis with ion-exchange membranes represents one of the most important membrane separation technologies in which ionized species in solution are transported, through anion and cation-exchange membranes, under the influence of an electric field. Depending on their charge, ions pass through one membrane and are restricted by the other, resulting in formation of diluted and concentrated compartments. The transport for ion depends, especially, on its charge, mobility, solution conductivity, relative concentrations, and applied voltage.

Electrodialysis exhibits several advantages, such as the possibility to repair and disassembly the stack, easiness to manually clean the membranes or replace them, low chemical usage, long life of membranes, selective removal of target species, flexibility in removal rate (through voltage control), good water recovery rate, multiple contaminant removal, and low energy consumption.

Electrodialysis can be used in the wastewater treatment of industries with galvanic production because it allows the reuse of the diluted solution as rinse-water and of the concentrated solution in the electroplating bath (Mohammadi et al. 2004; Caprarescu et al. 2012a, b; Strathmann 2010; Dalla Costa et al. 2002; Shi et al. 2010; Lee et al. 2008; Park et al. 2006).

The aim of the present study was to investigate the copper removal from synthetic wastewater solutions by electrodialysis process using bicomponent acrylic-PVA ion-exchange membranes. PVA was used to increase the hydrophilicity and so to enhance the ion transport. The effects of solution conductivity and solution pH, under the constant applied cell current, were investigated.

Electrodialysis experiments were evaluated in terms of percent of extraction (pe) and current efficiency (ce).

2 Experimental

2.1 Reagents

Copper sulphate pentahydrate (CuSO4 5H2O) and sulphuric acid (98 %), purchased from Chimopar Bucharest and Merck Millipore, respectively, were used without further purification.

Acrylonitrile, vinyl acetate, and dimethyl sulfoxide (DMSO) were purchased from Fluka. All chemicals were of analytical grade. Polyvinyl alcohol 90–98 was prepared in the laboratory by solution polymerization of vinyl acetate (azoisobutyronitrile initiation) in methanol, followed by methanolysis conducted using NaOH as catalyst.

2.2 Membrane Sample Preparation

There were used two different types of bicomponent acrylic-PVA ion-exchange membranes. These membranes were obtained by phase inversion using a mixture composed of 80 % acrylic copolymer (90 % acrylonitrile: 10 % vinyl acetate) and 20 % polyvinyl alcohol with the global concentration of 8 % in dimethyl sulfoxide (DMSO) by dissolving both components at 90 °C for 2 h, in the presence of 5 % ion exchange resin (Purolite A100 or Purolite C150) (Purolite Company), calculated to the polymer mixture.

The acrylic copolymer had a relative viscosity (0.3 % in dimethylformamide at 30 °C) of 1.58 and PVA presented an acetalization degree of 99.12 % and an average numerical polymerization degree of 900.

The polymer solution was cast at room temperature onto a glass plate (70, 110, and 4 mm). The draw-down technique was used in order to obtain wet films with thickness in range of 180 to 200 μm. Afterwards, the plate was immersed in a coagulation bath containing 80 % isopropanol: 20 % water and kept for 30 min. Then these membranes were intensively washed with distilled water at room temperature.

Purolite A100 is a macroporous polystyrenic weak base anion exchange resin having tertiary amine functionality and Purolite C150 is a macroporous poly(styrene sulfonate) strong acid cation exchange resin having sulfonic acid functionality (Badawy et al. 2009; Caprarescu et al. 2012a, b).

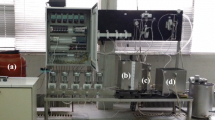

2.3 Experimental Apparatus

The original electrodialysis cell, consisting of three PVC detachable cylindrical compartments, between which the two acrylic ion-exchange membranes were introduced, is presented in Fig. 1. Each compartment has a volume of 29.85 mL and the effective area of the membranes was 23.32 cm2. The working electrodes, both of pure lead and with effective area of 23.32 cm2, were arranged in the electrodialysis cell at the extremities.

The distance between anode and cathode electrodes was 3.6 cm. The thickness of each compartment was 0.92 cm. The distance between the membranes was 1.2 cm.

All the experiment studies were carried out at room temperature (25 ± 3 °C) and without recirculation, in batch-mode operation. The time of the experiments was of 1.5 h.

A synthetic solution containing copper ions was prepared by dissolving copper sulphate pentahydrate (CuSO4 .5H2O) and sulphuric acid (98 %) (molar ratio 1:1) in distilled water to obtain two copper ions concentration: 1.5 or 3 g/L. Electrodialysis cell compartments were filled with the same solution, in order to reduce the effect of diffusive transport between compartments.

A constant anode–cathode current of 0.2 A (current density 8.58 mA/cm2) was applied between two lead electrodes by a power supply (Protek, Germany). The experimental current density was based on the actual surface area of the membranes. During the experimental studies, the imposed current promotes the motion of different ions due to the electric field created within the electrodialytic cell. The SO4 2− ions, with electronegative sign, move from the central compartment toward the anodic compartment crossing the anion exchange membrane. At the same time, the anion exchange membrane impedes the passage of the protons generated in the anode as a consequence of water oxidation. SO4 2− ions take part at the composition of the plating baths as catalyst. On the other hand, copper is present in the cationic Cu2+ form at the acidic pH of the solutions. The released H+ ions are also transported through the cation exchange membrane. Therefore, H+ and Cu2+ ions, with positive charge, compete for the transport toward the cathodic compartment, where the deposition of metallic copper on the cathode surface occurs.

The conductivity of solutions was measured using a conductivity meter type PIERRON (France) equipped with a bell type conductivity electrode system. It contains two plan-parallel platinum disk electrodes.

The pH of the solutions was measured by a pH meter type HI 8915 (HANNA Instruments, Germany) that contains a temperature sensor. Copper concentration was determined by titration method (Caprarescu et al. 2012a, b).

2.4 Membrane Characterization

2.4.1 Fourier Transform Infrared Spectroscopy

Morphology structure of the membranes was measured in attenuated total reflectance (ATR) mode on a Tensor 37, Bruker instrument using the Golden Gate unites in the spectral range of 400–4,000 cm−1.

2.4.2 Environmental Scanning Electron Microscopy

Morphology and structure surface of the membranes were observed with a FEI-Quanta 200 microscope. The environmental scanning electron microscopy (ESEM) images were obtained in low vacuum mode.

2.4.3 Electrochemical Impedance Spectroscopy

The impedance measurements were carried out using a VoltaLab 40 Dynamic Electrochemical System in the frequency range from 100 kHz to 1 Hz and a potential amplitude perturbation of 10 mV.

Electrochemical experiments were performed at ambient temperatures using a dedicated electrochemical cell consisting of two plan-parallel platinum disk electrodes. The obtained membranes were clamped between these electrodes. This cell, the associated system and the evaluation procedure, was presented elsewhere (Vaireanu et al. 2008).

3 Results and Discussion

3.1 Effect of pH and Solution Conductivity on Cu2+ Separation

Table 1 presents the pH and the conductivity values for the untreated and treated waters, from all three cell compartments, measured after 1.5 h, at room temperature for two copper ions concentration.

The low pH values are due to the acidic electrolyte solutions. At low pH, the high H+ concentrations compete with Cu2+ at the cathode plate surface. Moreover, the electrodeposition process was influenced by H2 evolution, leading to dendrite formation.

In the central cell compartment, the value of pH decreases which could be associated to the OH− consumption. The electrical resistance of the solution decreases (Caprarescu et al. 2012a, b; Abou-Shady et al. 2012; Peng et al. 2011; Ergun et al. 2008; Rodrigues et al. 2008; Vallois et al. 2003; Raissouni et al. 2007; Amado et al. 2004).

The values of solution conductivities measured in the anodic, central, and cathodic compartment were also determinated in comparison to untreated wastewater.

In the central compartment for both values of concentration of copper ions, the conductivity decreases in comparison to untreated wastewater. This indicates that the Cu2+ and SO4 2− ions were removed. The values of conductivity increase in the anodic compartment in comparison to untreated wastewater and can be due to the H+ ion produced in this compartment.

In the cathodic compartment, the values of conductivity decrease in comparison to untreated wastewater. This may be attributed to Cu2+ transport from the central compartment to cathodic compartment that conducted to copper electrodeposition reaction on the cathode lead (Caprarescu et al. 2012a, b).

The cell voltage increase can be attributed to the decrease in the conductivity of the central cell compartment solution as a consequence of the ionic species removal, increasing the solution electrical resistance (Caprarescu et al. 2012a, b; Peng et al. 2011; Rodrigues et al. 2008; Vallois et al. 2003; Raissouni et al. 2007).

3.2 Transport Numbers of Cu2+ and SO4 2−

Transport numbers for Cu2+ and SO4 2− were determinated by Eqs. (1) and (3) (Rodrigues et al. 2008; Vallois et al. 2003) as follows:

where t i is the transport number of the i species, z is the valence of the i species, J i is the flux of the i species (mol/cm2 s), F is the Faraday constant, and i is the current density (mA/cm2).

Table 2 presents the values of transport numbers determined for Cu2+ (\( {t}_{C{ u}^{2+}} \)) and SO4 2− (\( {t}_{S{ O}_4^{2-}} \)), for different solutions, after 1.5 h of experiment.

The transport number of a counter-ion in the ion-exchange membrane is generally close to 1 and that of the co-ion close to 0 while in the solution the transport numbers of anions and cations are not very different. The transport number of the cations is lower in the solution in comparison with the transport number of the cations in the membrane because at the surface of a cation-exchange membrane facing the dilute solution, the concentration of ions in the dilute solution is reduced. The number of anions is reduced in the boundary layer due to the electroneutrality by migration in the opposite direction (Strathmann 2010).

From Table 2, one may notice the decrease of the SO4 2− transport number as the initial concentration increased, which involves an increase of the H+ transport number through the anion exchange membranes.

In literature, the phenomena of H+ leakage were explained by studying the kinetics of transport of anions and protons through anion exchange membranes placed in an acid medium. It was suggested that the apparent rate constant of H+ transport remains practically constant whatever the acid concentration of the solution. Because the over-voltage interfacial transfers protons, the current efficiency becomes independent of the acid concentration (Rodrigues et al. 2008; Vallois et al. 2003; Raissouni et al. 2007; Amado et al. 2004).

The Cu2+ transport number increases with an increase in the initial concentration and may be due to the cation exchange membranes that have a higher specific permselective property and to the fact that the intrinsic mobility of H+ in the presence of water is larger than that of OH−.

The low values for transport number of Cu2+ ions demonstrated an excellent selectivity and good separation properties of the studied membranes.

A decrease in SO4 2− ions transfer with the increasing in concentration is essentially due to the decrease in the membrane selectivity (Rodrigues et al. 2008; Vallois et al. 2003; Raissouni et al. 2007; Amado et al. 2004; Boucher et al. 1997; Yamauchi et al. 1991; Hirata et al. 1992).

3.3 The Flux of Cu2+, Percent Extraction, and Current Efficiency

The flux values were evaluated for all experimental conditions. The flux of Cu2+ (J) was determined by using the following Eq. (3) (Ergun et al. 2008; Rodrigues et al. 2008):

where J is flux of copper ion, (g/cm2 s), V is the cathodic compartment volume (L), C f is the final concentration of the copper ion (g/L), C i is the initial concentration of the copper ions (g/L), A is the effective working area of the membrane (cm2), and t is the working time (s).

The laboratory electrodialysis cell efficiency was evaluated in terms of percent of extraction (pe) and current efficiency (ce), defined by Eqs. (4) and (5), respectively (Caprarescu et al. 2012a, b; Hirata et al. 1992; Marder et al. 2004; Abou-Shady et al. 2012):

where C i is the initial concentration of the copper ion and C f is the final concentration of the copper ion.

where z is the valence of the ion, V is the total volume of the aqueous solution in all compartments (dm3), C is the concentration of copper ions in the feed solution (mol/dm3), F is the Faraday’s constant (96485 A s/mol), I is the electric current applied (A), and t the time (s).

From Table 3, one may notice that for an electrodialysis process, duration of 1.5 h, the flux of copper ions increased with increasing the copper ion concentration. This is probably due to the transported amount of copper which increased with increasing the concentration of copper ions (Ergun et al. 2008; Rodrigues et al. 2008). The flux of copper ions was maximum at concentration of 3 g/L.

It was observed that the extraction percent of copper ions increases with an increase in solution concentration and the highest value of extraction percentage of copper ions was obtained at a maximum current of 0.20 A. The formation of copper ions increases at higher value of concentration.

It was observed that the extraction percent of copper increased when the initial concentration of copper in the feed solution increased due to the enhanced flux of copper. The lower Cu2+ recovery at lower pH is due to a decrease of conductivity values (Caprarescu et al. 2012a, b; Dalla Costa et al. 2002).

The results suggest that the pe of the ionic species is higher (>81 %) when higher concentrations are applied (3 g/L). The formation and evolution of the H2 and O2 reduce the current efficiency. The Faradic process at the anode (oxygen evolution) results in the regeneration of free protons in the feed compartment. This leads to a reduction in current efficiency for electrodialysis due to the competing transport of hydrogen ions across the membrane, especially as the free protons are more mobile than the metal ions (Caprarescu et al. 2012a, b; Amado et al. 2004; Boucher et al. 1997; Yamauchi et al. 1991; Hirata et al. 1992).

The current efficiency was low at low concentration, possible due to the high concentration of active H+, which retarded permeation of Cu2+ through the cation exchange membranes (Marder et al. 2004; Abou-Shady et al. 2012).

A very low extraction percent demonstrated that there was low transport through the membrane, in accordance with the calculation of the transport number.

3.4 Membrane Characterization

3.4.1 FT-IR Spectroscopy

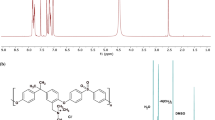

The chemical structure of bicomponent acrylic-PVA anion- and cation-exchange membranes (non-used membranes and used membranes at constant value of current and different values of concentration) was investigated by the Fourier transform infrared (FT-IR) spectroscopy (see Figs. 2 and 3). The samples were examined before and after exposure to electrodialysis process.

FT-IR spectra of acryl-PVA anion exchange membranes (Purolite A100) for different values of Cu2+ concentration: a Purolite A100 powder, b membrane without Purolite A100, c membrane with Purolite A100 blank, d membrane with Purolite A100, concentration 1.5 g/L, e membrane with Purolite A100, concentration 3 g/L

FT-IR spectra of acryl-PVA cation exchange membranes (Purolite C150) for different values of Cu2+ concentration: a Purolite C150 powder, b membrane without Purolite C150, c membrane with Purolite C150 blank, d membrane with Purolite C150, concentration 1.5 g/L, e membrane with Purolite C150, concentration 3 g/L

Bicomponent polymer membranes based on mixtures of acrylonitrile copolymers and PVA, obtained by phase inversion, in which small quantities of anion (Purolite A100) or cation exchange resin (Purolite C150) were introduced, were characterized by FT-IR in order to study the composition and chemical structure of the membranes.

From Fig. 2, it was observed that a peak appears at 2,770 cm−1 in the spectra of the loaded anion exchangers (Purolite A100), which may be due to O-H and N-H stretching vibrations. At the same time, the peak at 2,925–2,937 cm−1 interval is related to the stretching vibrations of the ring C–H bands of the resin (cross-linked polystyrene) (Purolite C150; Fig. 3).

In Figs. 2 and 3, the large band at around 3,500 cm−1 are assigned to OH groups in PVA. The specific absorption band of polyacrylonitrile from copolymer occurs at 2,244 cm−1, which may be assigned to the stretching vibrations of cyan group (−C ≡ N).

The peak that appears at 1,735 cm−1 can be ascribed to C = O (stretching vibration), confirming the presence of OCOCH3 group from vinyl acetate. The presence of C = C in the cation exchanger (Purolite C150) was noticed at 1,636 cm−1.

The ring C–C stretching and the scissoring of the methylene groups (δ-CH2) appeared at about 1,453 cm−1 (Purolite C150). The peak that appears at 1,370 cm−1 may be due to C-N stretching vibrations. C-O-C asymmetric vibration from vinyl acetate appears at 1,235–1,238 cm−1 (stretching vibration). The peak that appears at 1,371 cm−1 may be due to CH3 symmetric deformation vibration.

It was stated that symmetric and asymmetric vibrations of –SO3– groups appeared at 1,039 and 1,176 cm−1, respectively, and is due to the sulfonic acid group (Purolite C150).

The peak occurring in 1,024–1,031 cm−1 range is assigned to C-O (stretching vibration) and O-H (deformation vibration; ion exchange was carried out) (Purolite A100) (Tzanetakis et al. 2003; Dizge et al. 2009; Osaki and Tanioka 2002).

3.4.2 ESEM

The ESEM images for prepared membranes are shown in Fig. 4. The ESEM pictures for the membrane with and without ion exchange resins present macro- and micropores which indicate the occurrence of phase-separation in the polymer solution. The pores also indicate that the evaporation occurred fastly and confirm the uniformity of the membranes. For the ion exchange membranes, the pores offered a large surface area. As it can be observed, the pronounced heterogeneity of the ion exchange membranes was conducted by both ion exchange particle polarities. This fact explains also the good ion mobility and extraction values obtained on such a low amount of ion exchanger resin in the obtained membranes (Arthanareeswaran and Starov 2011; Chakrabarty et al. 2011; Boricha and Murthy 2009).

3.4.3 Electrochemical Impedance Spectroscopy Tests

The impedance data are depicted using the Nyquist plots (see Figs. 5 and 6). Figures 5 and 6 are two samples of a Nyquist plots using as coordinates, for OX the real part of impedance Zr, while for OY the imaginary part, Zi, of the impedance Z, for the acrylic-PVA anion exchange membranes and, respectively, for acrylic-PVA cation exchange membranes, tested after they have been subjected to two different values of copper ions concentrations comparing to its original state (the blank sample).

As one may see, the slope is lower for the membranes subjected to the ionic exchange (copper ions concentrations) indicating that these membranes may be used for their intended purpose. Moreover, the similarity of the two slopes indicated that the saturation concentration was not reached yet, these membranes being able to stand a higher concentration than the 3 g/L. The absence of the semicircular portion in the high-frequency region of plot indicated that the conduction is mainly due to the bulk ionic conduction.

The capacitive loop in low-frequency range starts linearly, but presents a finite limit at very low frequencies, (anomalous diffusion) depicting the electrical responses to interface phenomena originating from the ion-exchange membrane and the transport ions (Park et al. 2006; Benavente et al. 2001; Martinhon et al. 2006; Sistat et al. 2008; Hurwitz and Dibiani 2004; Moya 2010).

The dispersions of the capacitance with frequency for each concentration were essentially linear. Figures 7 and 8 show that the capacitance increases with the decrease in frequency and may be due to the contribution of increase in the interfacial layer resistance to total impedance. Moreover, the decrease in the capacitance values of the membranes subjected to the ionic exchange processes in comparison with the blank sample indicated that the ionic process takes place, the membranes becoming loaded in time with copper ions and act as loose capacitors with a value lower than that of the blank sample.

It was observed that the capacitance dispersions are very small, depending on the concentration of the electrolyte; if the concentration of Cu2+ in the electrolyte is higher, the capacitance is larger and the charge transfer resistance is lower. This capacitance is considered as being associated to the ionic changes coupled with the double layer at the interface membrane/metal (Park et al. 2006; Benavente et al. 2001; Martinhon et al. 2006; Sistat et al. 2008; Hurwitz and Dibiani 2004; Moya 2010; López-García et al. 2009).

4 Conclusion

Bicomponent polymer membranes with anion (Purolite A100) or cation exchange resin (Purolite C150) were used for the removal of Cu2+ from simulated wastewaters by applying electrodialysis.

The Cu2+ percent extraction and current efficiency depend on the concentration of the solution to be treated. At the constant current density of 8.58 mA/cm2, the percent extraction of the ionic species is higher (>81 %) and current efficiency is higher (>25 %) when higher concentrations are applied (3 g/L); this fact demonstrated an excellent separation properties of the studied membranes.

Infrared spectroscopy showed characteristic bands of ion exchanger resin from bicomponent polymer membranes. It was found that the occurrence of symmetric and asymmetric vibrations of –SO3– groups are due to the sulfonic acid group (Purolite C150). It was observed that a peak appears at 2,770 cm−1 in the spectra of the loaded anion exchangers (Purolite A100), which may be due to O-H and N-H stretching vibrations.

The impedance spectroscopy can provide useful information on the interfacial phenomena of bicomponent polymer membranes. It is found that the impedance spectra (Nyquist plots) present a finite limit at very low frequencies; the straight lines could be associated with the diffusion effect of the transport ions; the capacitance increases with decreasing in the frequency and may be due to the contribution of increasing the resistance of interfacial layers to total impedance.

The removal of copper ions using electrodialysis has more advantages such as not using chemicals or causing sludge problems; the operation cost of this method can be reduced because of the recovery of copper, this deposited on the cathode lead.

References

Abou-Shady, A., Peng, C., Almeria, O. J., & Xu, H. (2012). Effect of pH on separation of Pb (II) and NO3 2− from aqueous solutions using electrodialysis. Desalination, 285, 46–53.

Amado, F. D. R., Gondran, E., Ferreira, J. Z., Rodrigues, M. A. S., & Ferreira, C. A. (2004). Synthesis and characterisation of high impact polystyrene/polyaniline composite membranes for electrodialysis. Journal of Membrane Science, 234(1–2), 139–145.

Arthanareeswaran, G., & Starov, V. M. (2011). Effect of solvents on performance of polyethersulfone ultrafiltration membranes: investigation of metal ion separations. Desalination, 267, 57–63.

Badawy, N. A., El-Bayaa, A. A., Abdel-Aal, A. Y., & Garamon, S. E. (2009). Chromatographic separations and recovery of lead ions from a synthetic binary mixtures of some heavy metal using cation exchange resin. Journal of Hazardous Materials, 166(2–3), 1266–1271.

Benavente, J., Cañas, A., Ariza, M. J., Lozano, A. E., & de Abajo, J. (2001). Electrochemical parameters of sulfonated poly(ether ether sulfone) membranes in HCl solutions determined by impedance spectroscopy and membrane potential measurements. Solid State Ionics, 145(1–4), 53–60.

Boricha, A. G., & Murthy, Z. V. P. (2009). Acrylonitrile butadiene styrene/chitosan blend membranes: preparation, characterization and performance for the separation of heavy metals. Journal of Membrane Science, 339, 239–249.

Boucher, M., Turcotte, N., Guillemette, V., Lantagne, G., Chapotot, A., Pourcelly, G., Sandeaux, R., & Gavach, C. (1997). Recovery of spent acid by electrodialysis in the zinc hydrometallurgy industry: performance study of different cation-exchange membranes. Hydrometallurgy, 45(1–2), 137–160.

Caprarescu, S., Purcar, V., Sarbu, A., Ciripoiu, A. L., & Maior, I. (2012a). Copper ions removal from electroplating wastewater using new type of ion exchange membranes. Journal of Science and Arts, 3(20), 323–330.

Caprarescu, S., Purcar, V., & Vaireanu, D.-I. (2012b). Separation of copper ions from synthetically prepared electroplating wastewater at different operating conditions using electrodialysis. Separation Science and Technology, 47, 2273–2280.

Chakrabarty, T., Rajesh, A. M., Jasti, A., Thakur, A. K., Singh, A. K., Prakash, S., Kulshrestha, V., & Shahi, V. K. (2011). Stable ion-exchange membranes for water desalination by electrodialysis. Desalination, 282, 2–8.

Dalla Costa, R. F., Klein, C. W., Bernardes, A. M., & Ferreira, J. Z. (2002). Evaluation of the electrodialysis process for the treatment of metal finishing wastewater. Journal of the Brazilian Chemical Society, 13, 540–547.

Dizge, N., Keskinler, B., & Barlas, H. (2009). Sorption of Ni(II) ions from aqueous solution by Lewatit cation-exchange resin. Journal of Hazardous Materials, 167(1–3), 915–926.

Ergun, E., Tor, A., Cengeloglub, Y., & Kocak, I. (2008). Electrodialytic removal of fluoride from water: effects of process parameters and accompanying anions. Separation and Purification Technology, 64(2), 147–153.

Hirata, Y., Sugihara, G., & Kimizuka, H. (1992). Transport number of an ion across an amphoteric ion-exchange membrane in CaCl2/NaCl system. Journal of Membrane Science, 66(2–3), 235–240.

Hurwitz, H. D., & Dibiani, R. (2004). Experimental and theoretical investigations of steady and transient states in systems of ion exchange bipolar membranes. Journal of Membrane Science, 228(1), 17–43.

Lee, H.-J., Hong, M.-K., Han, S.-D., Shim, J., & Moon, S.-H. (2008). Analysis of fouling potential in the electrodialysis process in the presence of an anionic surfactant foulant. Journal of Membrane Science, 325(2), 719–726.

Lito, P. F., Aniceto, J. P. S., & Silva, C. M. (2012). Removal of anionic pollutants from waters and wastewaters and materials perspective for their selective sorption. Water, Air, & Soil Pollution, 223, 6133–6155.

López-García, U., Antaño-López, R., Orozco, G., Chapman, T., & Castaneda, F. (2009). Characterization of electrodialysis membranes by electrochemical impedance spectroscopy at low polarization and by Raman spectroscopy. Separation and Purification Technology, 68, 375–381.

Marder, L., Bernardes, A. M., & Ferreira, J. Z. (2004). Cadmium electroplating wastewater treatment using a laboratory-scale electrodialysis system. Separation and Purification Technology, 37(3), 247–255.

Martinhon, P. T., Carreño, J., Sousa, C. R., Barcia, O. E., & Mattos, O. R. (2006). Electrochemical impedance spectroscopy of lead(II) ion-selective solid-state membranes. Electrochimica Acta, 51(15), 3022–3028.

Mohammadi, T., Moheb, A., Sadrzadeh, M., & Razmi, A. (2004). Separation of copper ions by electrodialysis using Taguchi experimental design. Desalination, 169, 21–31.

Mosa, A. A., El-Ghamry, A., & Trüby, P. (2011). Chemically modified crop residues as a low-cost technique for the removal of heavy metal ions from wastewater. Water, Air, & Soil Pollution, 217, 637–647.

Moya, A. A. (2010). Study of the electrochemical impedance and the linearity of the current–voltage relationship in inhomogeneous ion-exchange membranes. Electrochimica Acta, 55(6), 2087–2092.

Osaki, T., & Tanioka, A. (2002). Dielectric relaxation on the intermediate layer in a bipolar membrane under the water splitting phenomenon: II. Double dielectric relaxation and identification of phase parameters. Journal of Colloid and Interface Science, 253(1), 94–102.

Park, J.-S., Choi, J.-H., Woo, J.-J., & Moon, S.-H. (2006). An electrical impedance spectroscopic (EIS) study on transport characteristics of ion-exchange membrane systems. Journal of Colloid and Interface Science, 300(2), 655–662.

Peng, C., Liu, Y., Bi, J., Xu, H., & Abou-Shady, A. (2011). Recovery of copper and water from copper-electroplating wastewater by the combination process of electrolysis and electrodialysis. Journal of Hazardous Materials, 189(3), 814–820.

Raissouni, I., Marraha, M., & Azmani, A. (2007). Effect of some parameters on the improvement of the bipolar membrane electrodialysis process. Desalination, 208(1–3), 62–72.

Rodrigues, M. A. S., Amado, F. D. R., Bischoff, M. R., Ferreira, C. A., Bernardes, A. M., & Ferreira, J. Z. (2008). Transport of zinc complexes through an anion exchange membrane. Desalination, 227(1–3), 241–252.

Shi, S., Lee, Y.-H., Yun, S.-H., Xuan Hung, P. V., & Moon, S.-H. (2010). Comparisons of fish meat extract desalination by electrodialysis using different configurations of membrane stack. Journal of Food Engineering, 101(4), 417–423.

Sistat, P., Kozmai, A., Pismenskaya, N., Larchet, C., Pourcelly, G., & Nikonenko, V. (2008). Low-frequency impedance of an ion-exchange membrane system. Electrochimica Acta, 53(22), 6380–6390.

Strathmann, H. (2010). Electrodialysis, a mature technology with a multitude of new applications. Desalination, 264(3), 268–288.

Tzanetakis, N., Taama, W. M., Scott, K., Jachuck, R. J. J., Slade, R. S., & Varcoe, J. (2003). Comparative performance of ion exchange membranes for electrodialysis of nickel and cobalt. Separation and Purification Technology, 30(2), 113–127.

Vaireanu, D. I., Cojocaru, A., Maior, I., & Caprarescu, S. (2008). Practical considerations regarding the measurement of ionic conductivity by EIS in conductive polymers. Chemical Bulletin “POLITEHNICA” University (Timisoara), 53, 258–261.

Vallois, C., Sistat, P., Roualdès, S., & Pourcelly, G. (2003). Separation of H+/Cu2+ cations by electrodialysis using modified proton conducting membranes. Journal of Membrane Science, 216(1–2), 13–25.

Yamauchi, A., Hirata, Y., & Shinoda, M. (1991). Relation between transport number and concentration of Donnan salt in membranes. Desalination, 80(1), 61–70.

Acknowledgments

Simona Caprarescu acknowledges the financial support of strategic grant Grant CNCSIS, TD CH410806, code 26, co-financed by The National Authority for Scientific Research (CNCSIS, Romania). Violeta Purcar acknowledges the financial support of strategic grant POSDRU/89/ 1.5/S/58852, Project Postdoctoral programme for training scientific researchers “co-financed by the European Social Found within the Sectorial Operational Program Human Resources Development 2007-2013.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Caprarescu, S., Radu, AL., Purcar, V. et al. Removal of Copper Ions from Simulated Wastewaters Using Different Bicomponent Polymer Membranes. Water Air Soil Pollut 225, 2079 (2014). https://doi.org/10.1007/s11270-014-2079-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-014-2079-6