Abstract

This paper provides a short overview of the main oxidation processes more commonly applied for the remediation of contaminated sites, with specific reference to their application for the in situ remediation of contaminated sites, i.e. In Situ Chemical Oxidation (ISCO). A review of the main patents issued on this topic shows the relevant contribution to the development of this technology in the last 20 years, especially in the USA. The still limited deployment of ISCO in other geographical areas may be improved by the increased acceptance of the technology that may come from the development of proper application guidelines based on accepted design criteria. The latter ones are also discussed in this paper with reference to the application of Fenton’s treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The contamination of soil and groundwater by means of bio-recalcitrant organic compounds is a matter of concern for both scientific community and public opinion. The increasing number of contaminated sites is leading to gradually switching from the traditional remediation approaches to innovative technologies aimed to achieving the remediation goals, thus reducing the pollutant load to concentrations which are considered harmless for human health. The performance of traditional processes for the treatment of contaminated sites such as Air Sparging, Pump-and-Treat, Bioventing and Soil Vapour Extraction (SVE) are limited by resistance to mass transport, which makes them effective only during the first phase of the treatment, and gradually less effective when the remediation goals are approached (tailing phenomena). Besides, rebound phenomena may occur after the site closure, requiring further remediation efforts (Ciotti 2008). Alternative processes are hence required to overcome these limitations. Among these, Advanced Oxidation Processes (AOPs) are widely used for the treatment of water, wastewater and soils contaminated by a wide range of organic compounds. Their diffusion in the field of contaminated sites remediation has grown in the last 10 to 15 years due to the increasing number of applications of the so called In Situ Chemical Oxidation (ISCO). This class of technology consists in generating an underground reactive zone by injection of a proper oxidant for the treatment of organic contaminants. Different AOPs have been proposed so far, based on hydrogen peroxide (Fenton’s processes) (Kong et al. 1998; Watts and Stanton 1999; Watts et al. 2002; Watts and Teel 2005), permanganate (De Souza e Silva et al. 2009), persulfate (Liang et al. 2008a, b, c) and ozone (O’Mahony et al. 2006; Yu et al. 2007; Rivas et al. 2009).

This paper provides a short discussion of the main AOPs applied in the field of in situ remediation, i.e. Fenton’s, permanganate and persulfate (Ciotti 2008), a short review of the development of the ISCO technology in the last 25 years through the patents issued in this timeframe, whereas finally the main issues to be considered in the design of ISCO treatments are discussed making reference to a case study of In Situ Fenton’s Oxidation (ISFO).

2 Main ISCO Treatment Technologies

2.1 Fenton’s Reagent

Fenton’s reagent is commonly applied to oxidize organic pollutants in many applications, from the treatment of wastewaters to the remediation of contaminated aquifers (Kwan and Voelker 2002). Oxidant formulations based on hydrogen peroxide have been widely employed in the USA for the treatment of different contaminants (hydrocarbons, PAHs, PCBs, chlorinated solvents, explosives, etc.) by ISFO. Fenton’s reaction is widely used for the remediation of contaminated soil and groundwater, with a large number of in situ applications. The chemistry of the Fenton’s process is based upon the reaction of hydrogen peroxide with a proper catalyst, leading to the generation of a pool of radicals (Kiwi et al. 2000; Watts and Teel 2005), capable of non-selectively oxidizing a wide range of biorefractory organic pollutants such as chlorinated aliphatics, halogenated phenols, PAHs and PCBs. In the so-called classic Fenton process, hydrogen peroxide (H2O2) reacts with Fe(II) ((Huling et al. 2001; Teel and Watts 2002; Smith et al. 2006), yielding hydroxyl radicals and Fe(III) as reported in Eq. (1): Fe(III) is then reduced back to Fe(II) by reacting with hydrogen peroxide (Eq.(2)):

Hydroxyl radicals (OH•) are characterized by a very high Redox potential (2.7 V), and therefore, they are the main responsible for the oxidation of organic compounds taking place in Fenton’s systems, although together with a few other radical species. The main disadvantage of the application of classic Fenton’s reagent is that Fe(III) produced is only sparingly soluble, especially at circumneutral pH, so that high concentrations of ferric oxyhydroxides precipitates are generated when stoichiometric quantities of Fe(II) are used. A possible option to overcome this drawback is to acidify the soil to a pH value between 2 and 3, or to use a proper chelating agent capable of keeping Fe(III) in solution, allowing in both case the Fe(III) recycle to Fe(II) through reaction (2). It is worth pointing out that not all the hydroxyl radicals generated target the organic contaminants since non-target chemical species such as chloride, carbonates, other inorganic constituents and organic matter can react and “scavenge” hydroxyl radicals. Moreover, since hydrogen peroxide is generally used at high concentrations in remediation systems (1 ÷ 3 M) and has a moderate reaction rate constant with hydroxyl radicals, hydrogen peroxide scavenging may consume a considerable fraction of the hydroxyl radicals produced. Finally, it is also worth pointing out that an important fraction of hydrogen peroxide may also be decomposed through non-target reactions with natural constituents of soil and groundwater, such as background consumption of the oxidant by (natural) non-target reductants in the soil. The extent of this pathway, which depends on the potential reduction capacity of a soil (Descourvières et al. 2010), is typically assessed by measuring its Natural (NOD) or Total Oxidant Demand (TOD) in the presence of the soil (Haselow et al. 2003). Although NOD/TOD measurement provides a preliminary and simple indication of the suitability of ISCO for a given site, its evaluation may be poorly indicative of hydrogen peroxide stability, as this oxidant may also undergo disproportion reactions, catalyzed by metals (i.e. manganese and copper) or enzymes (i.e.catalase or peroxidase).These reactions, possibly leading to a loss of hydrogen peroxide through non-target reactions well above 50 % (Baciocchi et al. 2010), may affect Fenton’s process efficiency, and should be therefore minimized by properly selecting the operating conditions and amendments (Huling et al. 2001). For instance, the addition of phosphates has been proposed and tested as a useful way to overcome the main limitation of Fenton’s reaction due to H2O2 instability, so to increase H2O2 longevity, in order to improve the oxidant delivery and radius of influence in full scale applications (Baciocchi et al. 2003, 2005). Also, chelating agents, discussed above as amendment for increasing iron solubility, have been proposed as stabilizers of hydrogen peroxide. Although the stabilization effect of chelating agents is debated, recently Vicente et al. (2011) compared slurry phase H2O2 decomposition in the presence of KH2PO4 and different chelating agents, obtaining the highest H2O2 stabilization effect using citric acid. Nevertheless, this result was obtained on soils characterized by a fairly high soil organic carbon content (2.8–6.3 %) and thus cannot be generalized.

2.2 Persulfate

The technology based on persulfate oxidation chemistry is an emerging and promising approach for the In Situ Chemical Oxidation (ISCO) of chlorinated and non-chlorinated organic compounds. Persulfates are typically manufactured as sodium, potassium and ammonium salts. For ISCO applications, potassium persulfate has a low solubility, and the injection of ammonium persulfate may lead to the generation of ammonia, which is regulated in groundwater. Therefore, the most common salt used for environmental applications is sodium persulfate (ITRC 2005). The persulfate anion is the most powerful oxidant of the peroxygen family of compounds and one of the strongest oxidants among those usually employed. The standard oxidation–reduction potential of the reaction reported below [Eq. (3)] is 2.1 V, which is higher than the 1.8 V Redox potential of hydrogen peroxide:

In addition to direct oxidation, sodium persulfate may form sulfate radicals (SO4•−) [see Eq. (4)], thus providing a free radical reaction mechanism similar to the hydroxyl radical pathway generated in Fenton’s systems.

The sulfate radical is one of the strongest aqueous oxidizing species with a redox potential of 2.6 V, near to the hydroxyl radical one, equal to 2.7 V. Sulfate radical initiation can be achieved through the application of heat (Huang et al. 2006), UV radiation or transition metal catalysts (Liang et al. 2004a, b). The latter represents the most interesting and applied route for in situ remediation of contaminated site, where a transition metal, such as iron, reacts with persulfate as follows:

through the following steps:

The persulfate–ferrous ion reaction results in the rapid production of sulfate free radicals. A free radical half-life of 4 s was reported at a persulfate and ferrous ion concentration of 10−3 M and a temperature of 40 °C. Sulfate free radical converts ferrous ion to ferric ion through Eq. (7), with a diffusion control kinetics rate constant of 1 × 109 M−1 s−1 (Block et al. 2004a). The rate of reaction between persulfate and ferrous ion is dependent on the concentration of each reactant. According to Eq. (5), the reaction stoichiometry requires a Fe2+/S2O8 2− molar ratio of 2; however, the rate-determining step is the reaction between one S2O8 2− and one Fe2+ to form SO4 •− [Eq.(6)], which then rapidly reacts with a second Fe2+ [Eq. (7)]. When the reactions are completed, no sulfate free radical is available for further attack of target organic contaminants. Therefore, increasing the concentration of Fe2+ would speed up the reactions shown in Eqs. (6)–(7) and thus lead to completion of the reaction shown in Eq.(5). Conversion of Fe2+ to Fe3+ results in the production of SO4 •−, which immediately reacts with the target compound. However, the fast reaction between SO4 •− and excess Fe2+ could possibly result in the destruction of SO4 •− thus reducing the degradation efficiency of the target organic contaminant. In order to optimize the iron-activated persulfate oxidation of the target organic contaminant, it is necessary to slow down or control the reaction shown in Eq. (7). This result can possibly be achieved by gradually adding the Fe2+ activator to the reaction environment, thereby preventing the rapid conversion of Fe2+ to Fe3+ by the SO4 •− as shown in Eq. (7) (Liang et al. 2004a).

2.3 Permanganate

Permanganate is widely used for the oxidation of different organic compounds, such as chlorinated solvents, hydrocarbons, phenols and some PAHs in groundwater and soils (Woo et al. 2010; Silva et al. 2010). The stoichiometry and kinetics of permanganate oxidation may result quite complex, due to the different forms and valence states in which manganese may exist. Differently from hydrogen peroxide, where oxidation is driven by a radical mechanism, the degradation of organic compounds by permanganate takes place through direct electron transfer. The main reactions taking place in the application of permanganate are the following ones (Damm et al. 2002):

The reaction of permanganate at pH < 3.5 (Eq. 8) implies the transfer of five electrons, whereas three electrons are involved in Eq. (9), reporting the reaction taking place at pH between 3.5 and 12, and one electron only at pH > 12 (Eq. 10). In these reactions, Mn is reduced from the Mn+7 form to Mn+2, Mn+4, Mn+6, respectively. Equation (9), which is the predominant reaction at the pH values commonly met in environmental applications, leads to the formation of manganese oxides particles, that may deposit in the subsurface and impact the flow-regime in and around the zone of oxidant emplacement, thereby preventing effective oxidant distribution and contact with contaminants (Lee et al. 2003; Crimi et al. 2009).

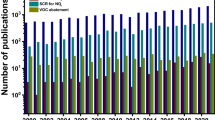

3 Development of ISCO Technologies

This section provides a short overview of the development of ISCO technologies during the last two decades, through the main relevant patents issued in this time frame. Apparently, the first ISCO patent is 25 years old, when Brown and Norris (1986) patented a method for decontaminating a permeable subterranean formation by oxidizing the contaminant therein, based on the injection of hydrogen peroxide. The patent includes information on the preferable H2O2 concentration to be applied (0.5 to 10 % by weight) and the possibility of using an aqueous solution of hydrogen peroxide or solid peroxy-compounds, capable of decomposing in the subsurface thus producing H2O2. The improvement of the oxidant distribution can be achieved by adding a mobility control agent (generally an hydratable polymeric material in order to increase the viscosity of the injected solution), an interface modifier (generally a surfactant to increase the wetting capacity of the injected solution) or a densifier ( typically a salt in order to improve the capacity of the injected solution to target the contaminant present in the bottom layer of an aquifer), in order to modify the flow of the aqueous treating material within the subterranean formation. The addition of a free radical activator (typically a transitional metal salt) to catalyze the Fenton’s process is also considered as well as that of a H2O2 stabilizer, such as different phosphate salts, for minimizing hydrogen peroxide decomposition in the subsurface. Although quite detailed in the description of the oxidant formulation, the early patent by Brown and Norris (1986) does not provide any insight on the methods and techniques for performing the in situ treatment. A first attempt to provide this insight is found in the patent by Vigneri (1994) that describes a method for remediating a hydrocarbon contaminated region of a subterranean waterbody; the invention consists in a plurality of mutually spaced wells through which the reactants used in the invention are injected. The patent is quite poor in providing details on the oxidant formulation, limiting the description to the oxidant used (hydrogen peroxide) and to the expected range of injection flows (4–24 l/min/well), injection pressure (0.5 to 3 bar) and H2O2 concentration (10 to 35 %). The possibility of using different amendments (catalyst, stabilizer, enhancer) is also considered, although few details on this are provided. Some more details on the oxidant formulation are provided in the patent by Watts et al. (1998), where the oxidant (preferably hydrogen peroxide, although permanganate or ozone is also considered) is stabilized with either phosphoric acid or an orthophosphate salt. H2O2 activation takes place via a catalyst (either an iron/copper salt or iron oxyhydroxide) chelated with a proper ligand (preferably phosphoric acid or monopotassium phosphate), also suggesting the typical dosage required. Lundy (2005) modified slightly this approach in his patent by proposing to use only one aqueous reagent containing both the oxidant (metal peroxides or hydrogen peroxide) and the chelating agent (preferably EDTA, DTPA or EDDHA), using the latter to extract the required divalent metals from the soil without any need to add an external source of iron or another metal, whereas pH is properly controlled. In another patent issued by Vigneri (1996), the use of a classic Fenton’s process with the same injection scheme previously outlined (Vigneri 1994) is also proposed, where acetic acid (to achieve a pH between 3 and 4), a ferrous iron solution and finally hydrogen peroxide are sequentially injected. Finally, some early methodologies are introduced to assess the effective overlapping of the H2O2 radius of influence (ROI) of neighboring wells, based either on pH or on temperature measurements, to be preliminary performed by a test flow of H2O2 from one of the wells. The delivery of the oxidant in this patent relies on the diffusive characteristics of the aquifer, thus obliging to use a quite large number of wells because of the small effective ROI. This limitation is discussed and possibly solved in the patent filed by Wilson (1996), where a pressurized injection system is proposed. Relevance is given to the characterization phase: this patent addresses specifically the importance of defining the extent of contamination and lists a long number of hydrogeological properties to be evaluated before starting the design of the clean-up process. Namely, these data are considered necessary in order to evaluate the absolute amount of oxidant to be used (once again hydrogen peroxide). A detailed sketch of the invention is also proposed, including that of the injection mixing head assembly. The feasibility of the proposed invention is then assessed by presenting the results of a case study, based on the use of an apparently classic Fenton’s scheme with pH shift to acidic values. The issue of oxidant delivery and mixing is also addressed by Cooper et al. (1999) that propose a two-step injection scheme where the catalyst (iron sulfate) is injected first and allowed to diffuse in the subsurface for at least 24 h, followed by injection of hydrogen peroxide. In one of the embodiments of the invention, gas injection is foreseen to allow for an improved mixing of the oxidant with the groundwater to be cleaned up. Besides, the issue of how handling the vapors produced by the Fenton-like reaction is also considered, proposing to couple the ISCO treatment with a vapor extraction system, collecting the vapor stream to an activated carbon treatment unit. It is worth pointing out that this issue is also discussed by Land et al. (1997) that propose a process based on Fenton’s reagent aimed to the transformation of the contaminants in smaller more volatile compounds to be recovered by vapor extraction wells; this patent also included potassium permanganate in the list of potential oxidants, but more specific reference to permanganate can be found in the patent by Siegrist and Murdoch (2000), which propose a process based on the injection of an Oxidative Particle Mixture, preferably made up of granular sodium permanganate (approximately 5 mm size), dispersed in a carrier fluid, i.e. a mixture of hydrated clay minerals and/or cement in water, thus resulting in a slurry phase characterized by a relatively high viscosity. In the same year, Hoag et al. (2000) developed a process for the chemical oxidation of volatile compounds based on the injection of either potassium or sodium permanganate. Specifically, in the preferred embodiment of the patent, permanganate is fed after pre-injecting a persulfate ion-bearing compound in order to reduce the oxidant demand of the soil, thus allowing to increase the reactivity of permanganate with the VOCs and to reduce the formation of MnO2 precipitate; in other embodiments of the invention, the possibility of mixing the two oxidants and/or of alternately injecting them is also accounted for, together with the possibility of activating the persulfate with a metal ion. The use of persulfate is also considered in more detail by Block et al. (2004b), where persulfate is injected preferably with sodium carbonate to keep the pH at basic values, whereas activation of persulfate is achieved either thermally or by the iron present in the soil or eventually from an external source. The same authors issued another patent (Sethi et al. 2005), where two oxidants, i.e. persulfate and hydrogen peroxide (with molar ratios between 1:20 and 20:1), are injected either in combination or sequentially, with the possible addition of metals and/or chelated metals as activators. More recently, Boulos et al. (2008) proposed the use of a solid metal peroxide, such as calcium or magnesium peroxide, for the chemical activation of persulfate, with a persulfate/percarbonate molar ratio preferably between 0.1 and 10. Activation may be enhanced either through pH shift (i.e. adding an acid), or by metal cations, eventually present in the soil matrix, or thermally. A different approach for activation of persulfate is found in the very recent patents by Block et al. (2010) and Hoag et al. (2011), both based on the use of Zero Valent Iron.

The use of multiple oxidants, already foreseen in some of the above discussed patents, is at the core of the patent developed by Whisman III (2007), where the injection of two oxidants is expected to take place through a borehole containing two nested conduits (in the case of hydrogen peroxide and ozone) or a single conduit (in the case of hydrogen peroxide and compressed air). As ISCO is recognized to be efficient in targeting the sources of contamination, but not as efficient in reducing concentrations down to the often very low target values set by some environmental legislation, it may become useful to couple ISCO with a biological in situ step, as proposed in the patent developed by Kukor et al. (2004) and Lessard (2005). Specifically, the latter makes reference to the in situ application of this combined approach, proposing a stepwise injection of hydrogen peroxide, monitoring the temperature increase, in order to positively affect the numbers of microorganisms responsible of further biodegradation of the contaminants left after the oxidation step. The possibility of adding amendments and eventually bacteria, if needed, is also considered. More recently, the focus of a few patents was on the integration of surfactant-enhanced remediation with ISCO, with the goal of increasing the (bio)-availability of the organic contaminants present in the site as NAPLs. A first example of this approach can be found in the patent by Shiau (2008), where ISCO (hydrogen peroxide/potassium permanganate) is used only as polishing step after applying a flushing process using surfactants with product recovery. The patent by Hoag and Collins (2011) is the first example of surfactant-enhanced ISCO, as it includes also a former world patent issued in 2007. This patent proposes a process based on the concept of injecting a proper surfactant-cosolvent to solubilize or desorb the contaminant, thus allowing the oxidant to react with the solubilized contaminant. In a preferred embodiment of this invention, activated sodium persulfate is used as oxidant, whereas a citrus terpene can be used as cosolvent together with a nonionic surfactant, such as an ethoxylated castor oil or coconut fatty acid. Dugan et al. (2010) also propose a similar approach, although the preferred oxidant is in this case permanganate, the surfactant is an anionic or a sulfonated one, thus making the process particularly fit in the case of DNAPLs.

4 Design Criteria of ISCO Technologies

As discussed in the previous section, ISCO has been the subject of several patents in the last 25 years, mostly originated in the USA, where this technology has been widely applied for the clean-up of contaminated sites. Although ISCO deployment is also growing outside of the USA, the number of full-scale ISFO application in Europe and particularly in some industrialized countries, such as Italy, is still limited. The development of this technology as a worldwide accepted and validated remediation technology cannot be achieved by simply transferring the state of knowledge gathered in the USA. ISFO diffusion is hindered by different constraints that can be grouped in two broad groups: technological and regulatory constraints. The former ones include the issue of hydrogen peroxide stability after injection in the subsurface, which has basically two main consequences: the entity of the radius of influence that affects the design of the injection scheme; the production of oxygen from decomposition of hydrogen peroxide, which needs to be properly evaluated and handled to avoid safety issues during site operation. Another technological constraint is represented by the site-specific hydro-geological conditions, namely the site permeability and heterogeneity that may limit the flow rate of the oxidant solution per injection well especially in shallow aquifers. The regulatory issues clearly depend on the attitude of the national or local regulator, depending for instance on whether the site belongs or not to the list of national priority sites. Typically regulatory requirements include the by-products evaluation in monitoring plans, the development of feasibility studies aimed to optimize the oxidant dosage and delivery, the control of oxidant and plume migration, eventually by imposing physical or hydraulic confinement of the site. For this reason, there is a strong need to develop guidelines for the application of ISCO treatments, based on strong and robust design criteria. This is the approach currently followed by the italian national environmental agency that has issued a first version of a protocol for ISCO application (APAT 2005), where ISCO is basically allowed provided that it is performed according to the guidelines reported in the protocol: these include, among the different requirements, the above discussed requirement to perform the ISCO treatment under controlled conditions, provided that the operating conditions (oxidant type, concentration, amendments, etc.) are selected based on a preliminary bench-scale tests and that a proper monitoring plan is prepared. This first protocol does not discuss the need or possibility to perform a pilot test on a representative, although limited, portion of the site, that should be a fundamental step in the design of an ISCO treatment This is the topic of this section, where the design criteria of ISFO treatments are discussed withreference to the development of a pilot scale In Situ Fenton’s Oxidation (ISFO) treatment The proposed design criteria are based on the integration of the results obtained from experimental and numerical modeling of the ISFO treatment, accounting for the technological and regulatory constraints existing in the site to be remediated. The main regulatory constraint considered here consists in the requirement to perform the injection under confined conditions, in order to avoid migration of the oxidant and/or of the contaminants outside the clean-up area. This constraint can be accounted for by including also pumping wells rather than injection wells only, as shown in Fig. 1, which reports the scheme of the pilot-scale ISFO treatment developed to meet this requirement. The technological constraints are mainly related to the hydro-geological conditions of the site, and therefore they are essentially site-specific and difficult to generalize. In the specific case study considered as a reference to develop the design criteria discussed here, the main constraint of this kind was the low depth of the groundwater table, which affected the choice of the injection and pumping flow rate to be applied in the pilot scale test and consequently the radius of influence of the oxidant. Both numerical and experimental design tools are summarized in the following, whereas more details on the specific case study used to develop the design criteria can be found in Baciocchi et al. (2010).

4.1 Experimental and Numerical Modeling

The first step of the experimental modeling consist in standard bench-scale batch tests, which allow to select the most effective oxidation process and the corresponding optimal operating conditions. The data collected are also used to evaluate the oxidant longevity and specifically the pseudo first-order decomposition rate constant of hydrogen peroxide that can then be used as input to the numerical modelling of the ISFO pilot-plant test, in order to estimate the radius of influence of the oxidant and thus the expected extension of the treatment area. The ISCO pilot-scale application can be simulated by means of a commercial software, such as Feflow or Modflow, based on the selected layout, as the one reported in Fig. 1 for the specific case study used as reference (Baciocchi et al. 2010). The modeling phase allows to optimize the choice in terms of number and position of the injection wells and of the pumping wells, if required as in the scheme reported in Fig. 1. Also, the maximum suitable injection and pumping flow rates for each well are selected, considering the technological constraint of the site. As a result, the distribution of the oxidant during the injection phase and therefore the effective area of influence of each well are calculated, as shown in Fig. 2 again with reference to a specific case study discussed in detail elsewhere (Baciocchi et al. 2010). Namely, Fig. 2 reports the calculated hydrogen peroxide concentration contour lines; since hydrogen peroxide concentration never achieves a constant value during the injection phase, the data calculated at the end of the injection phase, i.e. the maximum ones achieved, are reported. By looking at Fig. 2, it can be observed that the confinement of the hydrogen peroxide plume downstream the pumping wells looks quite effective since no appreciable H2O2 concentration is expected at the external monitoring wells row. Figure 2 also reports the groundwater velocity field which is another important outcome of the numerical modeling step. It is worth pointing out that the highest groundwater velocity and hydraulic gradient are clearly obtained near the injection and pumping wells, whereas the velocity gradient becomes quite flat in the central area between injection and pumping wells.

Simulation of the ISFO treatment: H2O2 iso-velocity (meters per day) and iso-concentration (milligrams per liter) curves at the end of the injection phase. Adapted with permission from Baciocchi et al. (2010)

The results of the modeling step can be already directly used for the design of the ISFO pilot plant, except for the section concerning the management of vapors produced during the treatment. It is well known that hydrogen peroxide may rapidly decompose in the subsurface leading to the production of oxygen gas. Besides, it is also well known that stripping of VOCs may also be enhanced by the ISCO treatment, due to the stripping effect caused by the oxygen flow plus local temperature increase due to the exothermic reactions taking place in the presence of H2O2. Therefore, it may be suggested in some situations to couple the ISCO treatment with a SVE section to collect the vapors produced and convey them to a proper external vapor treatment unit. The design of this unit requires to know in advance the expected gas flow rates produced during the ISCO treatments. As most of the gas produced is expected to be the oxygen produced by the H2O2 disproportion or Haber–Weiss decomposition, a conservative estimate may be obtained assuming that all injected hydrogen peroxide decompose to oxygen. In order to get a more realistic estimate, the proposed design criteria may include a further experimental step, based on a column-scale test, performed on a column set-up as the one shown in Fig. 3. The column can be fed with a hydrogen peroxide solution, adopting a flow rate and concentration that are representative of a given condition in the site, as obtained from the numerical modeling phase. Hydrogen peroxide concentration can be measured at the liquid inlet, outlet and monitoring ports, whereas the gas flow rate and oxygen concentration can be measured through on-line instruments installed at the gas outlet port. The hydrogen peroxide decomposition data can then be compared with the gas volume produced and measured on-line during the column experiments. The effective gas flow rate can then be determined through the following equation:

Scheme of a column-scale set-up. Adapted with permission from Baciocchi et al. (2010)

where \( \overset{\bullet }{n} \) is the gas molar flow rate in a given time interval, whereas \( \overset{\bullet }{V} \) is the average volumetric flow rate measured in the same time interval. The theoretical flow rate can instead be obtained through a mass balance performed on the column, which is readily obtained from the stoichiometry of the H2O2 decomposition reaction to oxygen and water, whichever decomposition route (disproportionation or Haber–Weiss) is followed:

where Q is the inlet flow rate of the liquid oxidant solution, \( {C}_{{\mathrm{H}}_2{\mathrm{O}}_2}^{\mathrm{IN}} \) is the inlet hydrogen peroxide concentration and \( {C}_{{\mathrm{H}}_2{\mathrm{O}}_2}^{\mathrm{O}\mathrm{UT}} \) is the outlet hydrogen peroxide concentration. The data obtained in this way may finally be used to design and size the SVE section, thus allowing to complete the design of the ISCO pilot plant.

5 Conclusions

The relevant number of patents issued in the last 20 years shows that In Situ Chemical Oxidation is an important option for the clean-up of soils and groundwater contaminated by a wide range of organic compounds. The recent developments on new methods for the activation of peroxides and for the mobilization of NAPLs in order to make the organic compounds available for being oxidized show also that ISCO is still an active field of research with opportunities for the extension of its field of application. Despite such a positive picture is obtained by looking at the patenting activity and at the status of deployment in the USA, an adequate penetration of ISCO outside the USA, and especially in some European countries, still requires an effort to convince some reluctant local authorities and regulators. The development of dedicated guidelines, based on a strong supporting evidence coming from feasibility studies based on bench-scale and pilot-scale experimental and numerical modeling, may be of help in increasing the confidence of regulators in approving remediation projects based on ISCO.

References

APAT (2005). Protocol for the application of in-situ chemical oxidation. Italian Agency for the Protetction of the Environment. (In Italian).

Baciocchi, R., Ciotti, C., Cleriti, G., Innocenti, I., & Nardella, A. (2010). Design of in-situ Fenton oxidation based on the integration of experimental and numerical modelling. Journal of Advanced Oxidation Technologies, 13(2), 153–163.

Baciocchi, R., Boni, M. R., & D'Aprile, L. (2003). Hydrogen peroxide lifetime as an indicator of the efficiency of 3-chlorophenol Fenton's and Fenton-like oxidation in soils. Journal of Hazardous Materials, 96(2–3), 305–329.

Baciocchi, R., Boni, M. R., & D'Aprile, L. (2005). Application of H2O2 lifetime as an indicator of TCE Fenton-like oxidation in soils. Journal of Hazardous Materials, 107(3), 97–102.

Block P.A., Brown R.A., Robinson D. (2004a). Novel activation technologies for sodium persulfate in situ chemical oxidation. Proceedings of the 4th International Conference on the Remediation of Chlorinated and Recalcitrant Compounds.

Block, P.A., Brown, R.A. (2010). Oxidation of organic compounds. US Patent 7785038.

Block, P.A., Sethi, D.S., Brown, R.A., Robinson, D.S. (2004b) Oxidation of organic compounds. Patent WO2004/002923.

Boulos, N., Carvel, D., Mucssig, J. (2008). Ex-situ and in-situ remediation with activated persulfate. US Patent application 2008/0272063.

Brown, R.A., Norris, R.D. (1986). Method for decontaminating a permeable subterranean formation. US Patent 4591443.

Ciotti C. (2008). Advanced oxidation processes as innovative technologies for the remediation of contaminated sites. Ph.D. Thesis (XX cycle). University of Rome Tor Vergata.

Cooper, K, Crim, R.J., Carey, J., Bowers, J. (1999). In situ water and soil remediation method and system. US Patent 5967230.

Crimi, M., Quickem, M., & Ko, S. (2009). Enhanced permanganate in situ chemical oxidation through MnO2 particle stabilization: evaluation in 1-D transport systems. Journal of Contaminant Hydrology, 105, 69–79.

Damm, J. H., Hardacre, C., Kalin, R. M., & Walsh, K. P. (2002). Kinetics of the oxidation of methyl tert-butyl ether (MTBE) by potassium permanganate. Water Research, 36(14), 3638–3646.

De Souza e Silva, P. T., da Silva, V., de Barros Neto, B., & Simonnot, M.-O. (2009). Potassium permanganate oxidation of phenanthrene and pyrene in contaminated soils. Journal of Hazardous Materials, 168(2–3), 1269–1273.

Descourvières, C., Hartog, N., Patterson, B. M., Oldham, C., & Prommer, H. (2010). Geochemical controls on sediment reactivity and buffering processes in a heterogeneous aquifer. Applied Geochemistry, 25(2), 261–275.

Dugan, P.J., Siegrist, R.L., Crimi, M.L. (2010). Method and compositions for treatment of subsurface contaminants. US Patent application 2010/0003082.

Haselow, J. S., Siegrist, R. L., Crimi, M., & Jarosch, T. (2003). Estimating the total oxidant demand for in situ chemical oxidation design. Remediation Journal, 13(4), 5–16.

Hoag, G.E. and Collins, J. (2011). Soil remediation method and composition. US Patent 7976241.

Hoag, G.E., Chheda, V., Woody, B.A., Dobbs, G.M. (2000) Chemical oxidation of volatile organic compounds. US Patent 6019548.

Hoag, G.E., Collins, J.B., Varma, R.S., Nadagouda, M.N. (2011). Polymer coated nanoparticle activation of oxidants for remediation and methods of use hereof. US Patent 7963720.

Huang, K.-C., Couttenye, R. A., & Hoag, G. E. (2006). Kinetics of heat-assisted persulfate oxidation of methyl-tert-butyl ether (MtBE). Chemosphere, 49, 413–420.

Huling, S. G., Arnold, R. G., Sierka, R. A., & Miller, M. R. (2001). Influence of peat on Fenton oxidation. Water Research, 35(7), 1687–1694.

ITRC (Interstate Technology & Regulatory Council). 2005. Technical and regulatory guidance for in situ chemical oxidation of contaminated soil and groundwater, 2nd ed. ISCO-2. Washington, D.C.: Interstate Technology & Regulatory Council, In Situ Chemical xidation Team. Available on the Internet at http://www.itrcweb.org.

Kiwi, J., Lopez, A., & Nadtochenko, V. (2000). Mechanism and kinetics of the OH-radical intervention during fenton oxidation in the presence of a significant amount of radical scavenger (Cl-). Environmental Science and Technology, 34, 2162–2168.

Kong, S. H., Watts, R. J., & Choi, J. H. (1998). Treatment of petroleum-contaminated soils using iron mineral catalyzed hydrogen peroxide. Chemosphere, 37(8), 1473–1482.

Kukor, J.J., Nam, K. (2004). Remediation of contaminates including low bioavailability hydrocarbons. US Patent 6746180.

Kwan, W. P., & Voelker, B. M. (2002). Decomposition of hydrogen peroxide and organic compounds in the presence of dissolved iron and ferrihydrite. Environmental Science and Technology, 36, 1467–1476.

Land, C.A., Pezzullo, J.A., Malot, J.J., Papa, L.C., Oberle, D. (1997). Process for soil decontamination by oxidation and vacuum extraction. US Patent 5615974.

Lee, E. S., Seol, Y., Fang, Y. C., & Schwartz, F. W. (2003). Destruction efficiencies and dynamics of reaction fronts associated with permanganate oxidation of trichloroethylene. Environmental Science and Technology, 37, 2540–2546.

Lessard, L.H. (2005). Method for the remediation of contaminated soil and/or groundwater via integrated chemical and biological treatment. US Patent 6923596.

Liang, C., Bruell, C. J., Marley, M. C., & Sperry, K. L. (2004a). Persulfate oxidation for in situ remediation of TCE. I. Activated by ferrous ion with and without a persulfate-thiosulfate redox couple. Chemosphere, 55, 1213–1223.

Liang, C., Bruell, C. J., Marley, M. C., & Sperry, K. L. (2004b). Persulfate oxidation for in situ remediation of TCE. II. Activated by chelated ferrous ion”. Chemosphere, 55, 1225–1233.

Liang, C., & Lee, I. (2008). In situ iron activated persulfate oxidative fluid sparging treatment of TCE contamination—a proof of concept study. Journal of Contaminant Hydrology, 100(3–4), 91–100.

Liang, C., Huang, C. F., & Chen, Y.-J. (2008a). Potential for activated persulfate degradation of BTEX contamination. Water Research, 42(15), 4091–4100.

Liang, C., Lee, I., Hsu, I.-Y., Liang, C.-P., & Lin, Y.-L. (2008b). Persulfate oxidation of trichloroethylene with and without iron activation in porous media. Chemosphere, 70(3), 426–435.

Lundy, W.L. (2005). In situ subsurface decontamination method. US Patent 6843618.

O’Mahony, M. M., Dobson, A. D. W., Barnes, J. D., & Singleton, I. (2006). The use of ozone in the remediation of polycyclic aromatic hydrocarbon contaminated soil. Chemosphere, 63(2), 307–314.

Rivas, J., Gimeno, O., de la Calle, R. G., & Beltràn, F. J. (2009). Ozone treatment of PAH contaminated soils: operating variables effect. Journal of Hazardous Materials, 169(1–3), 509–515.

Sethi, D.S., Sessa, F.C., Kinsman, L.J., Block, P.A. (2005). Treatment of environmental contaminants. Patent WO 2005/012181.

Shiau, B.J. (2008). In-situ surfactant and chemical oxidant flushing for complete remediation of contaminants and methods of using same. US Patent 7364386.

Siegrist, R.L., Murdoch, L.C. (2000). Oxidative particle mixtures for groundwater treatment. US Patent 6102621.

Silva, P. T. D. E., da Silva, V. L., Neto, B. D., & Simmonnot, M. O. (2010). Potassium permanganate oxidation of phenanthrene and pyrene in contaminated soils. Journal of Hazardous Materials, 168(2–3), 1269–1273.

Smith, B. A., Teel, A. L., & Watts, R. J. (2006). Mechanism for the destruction of carbon tetrachloride and chloroform DNAPLs by modified Fenton's reagent. Journal of Contaminant Hydrology, 85(3–4), 229–246.

Teel, A. L., & Watts, R. J. (2002). Degradation of carbon tetrachloride by modified Fenton's reagent. Journal of Hazardous Materials, 94(2), 179–189.

Vicente, F., Rosas, J. M., Santos, A., & Romero, A. (2011). Improvement soil remediation by using stabilizers and chelating agents in a Fenton-like process. Chemical Engineering Journal, 172, 689–697.

Vigneri, R.J. (1994). Method and system for remediation of groundwater contamination. US Patent 5286141.

Vigneri, R.J. (1996). Method and system for remediation of groundwater contamination. US Patent 5520483.

Watts, R. J., & Stanton, P. C. (1999). Mineralization of sorbed and NAPL-phase hexadecane by catalyzed hydrogen peroxide. Water Research, 33(6), 1405–1414.

Watts, R. J., & Teel, A. (2005). Chemistry of modified Fenton's reagent (catalyzed H2O2 propagations–CHP) for in situ soil and groundwater remediation. Journal of Environmental Engineering, 131(4), 612–622.

Watts, R.J., Greenberg, R.S. (1998). Soil and/or groundwater remediation process. US Patent 5741427.

Watts, R. J., Stanton, P. C., Howsawkeng, J., & Teel, A. L. (2002). Mineralization of a sorbed polycyclic aromatic hydrocarbon in two soils using catalyzed hydrogen peroxide. Water Research, 36(17), 4283–4292.

Whisman III, C.B. (2007). Methods and system for groundwater remediation. US Patent 7157770.

Wilson, J.T. (1996). Remediation apparatus and method for organic contamination in soil and groundwater. US Patent 5525008.

Woo, N. C., Hyun, S. G., Park, W. W., Lee, E. S., & Schwartz, F. W. (2010). Characteristics of permanganate oxidation of TCE at low reagent concentrations. Environmental Technology, 30(13), 1337–1342.

Yu, D. Y., Kang, N., Bae, W., & Banks, M. K. (2007). Characteristics in oxidative degradation by ozone for saturated hydrocarbons in soil contaminated with diesel fuel. Chemosphere, 66(5), 799–807.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: R Naidu, Euan Smith, MH Wong, Megharaj Mallavarapu, Nanthi Bolan, Albert Juhasz, and Enzo Lombi

This article is part of the Topical Collection on Remediation of Site Contamination

Rights and permissions

About this article

Cite this article

Baciocchi, R. Principles, Developments and Design Criteria of In Situ Chemical Oxidation. Water Air Soil Pollut 224, 1717 (2013). https://doi.org/10.1007/s11270-013-1717-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1717-8