Abstract

The feasibility of a sequentially enhanced process for the remediation of soils contaminated by mixed contaminants, specifically multiple polycyclic aromatic hydrocarbons (PAHs) and heavy metals, was investigated. This process consists of sequential flushing using two chemical agents: a surfactant and a chelate. A series of laboratory column experiments was conducted with three different sequential schemes, designated as SEQ1, SEQ2, and SEQ3, in two distinct flushing stages, to remove PAHs and heavy metals from a field-contaminated soil. The SEQ1 scheme involved flushing 0.2 M ethylenediaminetetraacetic acid (EDTA) followed by flushing 5 % Igepal. The SEQ2 scheme involved flushing 5 % Igepal followed by flushing 0.2 M EDTA. SEQ1 was investigated under a constant hydraulic gradient of 1.2, while the SEQ2 scheme was investigated under hydraulic gradients that increased from 1.2 to 4.0. The SEQ3 scheme consisted of sequential flushing of 5 % Igepal (first stage) and 0.2 M EDTA (second stage) under a constant low hydraulic gradient of 0.2. The selected sequential schemes allowed an assessment of the efficacy of sequencing the surfactant and chelating flushing for the removal of multiple heavy metals and PAHs under various hydraulic gradients. The hydraulic conductivity (or flow) was found to vary depending on the flushing agent and the sequence scheme. Under the high hydraulic gradient, the hydraulic conductivity was lower during chelant flushing stage as compared with surfactant flushing stage in both SEQ1 and SEQ2. However, under a low gradient condition (SEQ3), the hydraulic conductivity was approximately the same during both chelant and surfactant flushing stages. The contaminant removal was also significantly affected by the flushing agent and sequence and the applied hydraulic gradient. Heavy metals were removed during chelant flushing, while PAHs were removed during surfactant flushing. The total removal efficiencies of Pb, Zn, and Cu were 76 %, 63 %, and 11 % in SEQ1 and 42 %, 40 %, and 7 % in SEQ2, respectively, while the total removal efficiencies of phenanthrene, anthracene, benz(a)anthracene, and pyrene were 51 %, 35 %, 58 %, and 39 % in SEQ1 and 69 %, 50 %, 65 %, and 69 % in SEQ2, respectively. Overall, the total mass removal of heavy metals and PAHs was higher in SEQ1 as compared with SEQ2, demonstrating that SEQ1 is the effective sequence scheme. Comparison of the results of high and low gradient conditions (SEQ2 and SEQ3) reveals that the removal of contaminants, especially heavy metals, is rate-limited. Overall, this study showed that the removal of co-existing heavy metals and PAHs from soils is possible through the careful selection of the sequence under which the flushing of chelant and surfactant occurs and depends on the site-specific soil and contaminant conditions. Additional research is needed to establish the most optimal flushing scheme (sequence duration and flow velocity) to remove the mixed contaminants effectively and efficiently.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Numerous industrial sites, such as former manufactured gas plants (MGP), have been contaminated with a mixture of known, undesirable toxic heavy metals and polycyclic aromatic hydrocarbons (PAHs) (Sharma and Reddy 2004). The remediation of such sites is urgently required to protect public health and the environment. The common technologies used to remediate contaminated soils include chemical oxidation, biodegradation, thermal desorption, and incineration (Lee et al. 1999; Bonten et al. 1999; Bogan and Trbovic 2003; Antizar-Ladislao et al. 2004). However, most of these technologies are ineffective or expensive, especially when applied to soils tainted by mixed organic–inorganic contaminants. Research studies have investigated the remediation of soils contaminated by either heavy metals or organic contaminants, but only a limited number of studies address the soils containing mixed contaminants (National Research Council NRC 1994; Brusseau et al. 1997; Bernnett 2001). The urgent need for the development of remediation technologies for mixed contaminants has been recognized for a long time (Roote 1997; United States Environmental Protection Agency USEPA 2000).

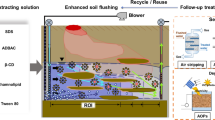

Ex situ soil washing or in situ soil flushing has been shown to have great potential to remove a wide range of contaminants from soils (Sharma and Reddy 2004). Principally, a suitable chemical agent is flushed through the soil to enhance the apparent solubilization of the contaminant. Under optimized conditions, this results in an increased mass removal rate with reduced remediation time and the concurrent reduction in the cost of remediation. However, it is critical to select an effective flushing agent that can enhance the solubilization of the contaminants and allow for their subsequent removal from the soils (Yeom et al. 1995). Many studies have investigated the use of cyclodextrins, surfactants, organic acids, and chelating agents for the solubilization and removal of a wide range of contaminants in soils (Szejtli 1982; Kamiya and Nakamura 1995; Wang and Brusseau 1995; Abumaizar and Smith 1999; Peters 1999; Reddy and Chinthamreddy 2000; Mulligan et al. 2001; Nowack 2002; Abu-Zreig et al. 2003; Chu and Kwan 2003; Reddy and Saichek 2003). Most of these studies focused on the solubilization or extraction of either heavy metals or PAHs in spiked soil systems, not on actual field contaminated soils.

Yeom et al. (1995) reported that enhanced soil flushing has a potential to remediate soils polluted with mixed contaminants. Maturi and Reddy (2008) and Reddy et al. (2011) investigated solubilizing agents, such as surfactants, chelants, and cyclodextrins, to enhance the dissolution of mixed contaminants in both spiked and field soils. These studies involved a series of batch and column tests that used different soil and flushing agent combinations and showed that surfactants, such as Igepal, and cyclodextrins, such as hydroxypropyl-β-cyclodextrin, are effective for the removal of PAHs from the soil, while ethylenediaminetetraacetic acid (EDTA) and acetic acid are effective for the removal of heavy metals from the soil. However, none of the flushing agents investigated completely removed both heavy metals and PAHs, simultaneously. Thus, sequential flushing schemes were deemed necessary to remediate mixed contaminants, such as co-existing multiple heavy metals and PAHs, in the soil.

This study investigates the feasibility of sequential flushing of a chelant (EDTA) and a non-ionic surfactant (Igepal) for the effective removal of mixed contaminants, specifically heavy metals and PAHs, from a soil from an industrial site (a former manufactured gas plant located in Chicago, IL, USA) under different hydraulic gradient conditions. The sequencing of flushing agents was investigated by conducting a series of bench-scale column experiments, and these results helped to assess the best sequence for the remediation of the soil contaminated with multiple contaminants.

2 Experimental Methodology

2.1 Soil Characterization

A bulk sample of contaminated soil was obtained from an industrial site (a former MGP site in Chicago, IL) known to be contaminated with toxic metals as well as PAHs. The soil was homogenized and analyzed for different physical properties as well as its contaminant concentrations. All of the soil properties were determined according to the ASTM standard procedures and are presented in Table 1. Figure 1a shows the grain size distribution of the contaminated soil. The contaminant concentrations were determined according to the standard EPA method SW 6020 for metals and EPA method SW 8170 (SIM) for PAHs (United States Environmental Protection Agency USEPA 2007) and the results are shown in Table 2.

The presence of calcium carbonate and other compounds, such as magnesium carbonate or sodium carbonate, causes the soil to have a high acid buffering capacity, which can significantly affect the removal of heavy metals from the soil. Therefore, the buffering capacity of the contaminated soil was determined by titration analysis using 0.1 N nitric acid as the titrant solution. A soil slurry sample was prepared by mixing 20 g of soil in 200 mL of water. The acid was added incrementally to the slurry while it was mixed with a magnetic stirrer. The equilibrium pH of the slurry was measured with a pH meter (Thermo Orion model 720 A). The equilibrium pH of the slurry was the pH of the slurry when it no longer changed over time. A deionized water sample was also used as a control sample. Figure 1b shows that, at the inflection point of the titration curve (pH = 6.2), the buffering capacity of the aqueous soil slurry with a solids concentration of 8.5 % is approximately 3.7 eq kg−1 (dry soil), indicating that the soil possesses a high acid buffering capacity.

2.2 Flushing Agents

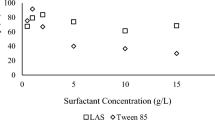

A non-ionic surfactant, 5 % Igepal CA-720, and a chelant, 0.2 M EDTA, were selected as the flushing agents for this study. These two flushing agents and their concentrations were selected based on the results of several series of batch and column tests conducted previously by Maturi and Reddy (2008) and Reddy et al. (2011). Based on the high acid buffering capacity of the soil, the use of weak acids for the removal of heavy metals was found to be ineffective. In high acid buffering soils, chelants are found to be effective in forming soluble chelant–metal complexes. Surfactants were found to be effective as compared with cosolvents and cyclodextrins for the solubilization of PAHs. The preparation and properties of the flushing agents are provided by Saicheck and Reddy (2005), Maturi and Reddy (2008) and Reddy et al. (2011).

2.3 Testing Setup and Variables

Figure 2 shows the schematic of the flushing test setup used in this study. The soil cell was made of Plexiglas® and had an inside diameter of 3.8 cm and a total length of 13.2 cm. A reservoir was connected to inlet end of the cell using screws. The 2.0 cm inner diameter reservoir was made of Plexiglas® and connected to the cell using Tygon tubing. The outlet was connected to a glass bottle to collect the flow (effluent) from the cell.

Table 3 shows the details of the three sequential flushing experiments conducted for this study. The initial soil conditions for all the column experiments were the same: moisture content = 14 %; dry density = 1.34 g cm−3; porosity = 49 %; degree of saturation = 38 %; and pore volume = 74.6 cm3. Three sequential schemes, SEQ1, SEQ2, and SEQ3, were selected to assess the efficacy of the sequential process for the removal of multiple contaminants (specifically, the combination of PAHs and heavy metals) from the soil. Each sequential scheme involved two distinct flushing stages under selected hydraulic gradient conditions. For SEQ1, 0.2 M EDTA was flushed first followed by flushing 5 % Igepal CA-720 under constant hydraulic gradient of 1.2. For SEQ2, the first stage involved flushing 5 % Igepal CA-720 at constant hydraulic gradient of 1.2 and the second stage comprised flushing 0.2 M EDTA at increased hydraulic gradients ranging from 1.2 to 4.0. While SEQ1 and SEQ2 were conducted with a high hydraulic gradient of 1.2, SEQ3 investigated the sequential flushing of 5 % Igepal CA-720 (first stage) and 0.2 M EDTA (second stage) at a low hydraulic gradient of 0.2. SEQ3 was essentially the same as SEQ2 but with low hydraulic gradient (flow). SEQ3 provided the ability to assess the rate-limited solubilization and removal of contaminants when those results were compared with the SEQ2 results.

2.4 Testing Procedure

Approximately 250 g of wet field soil was used for each test. The soil was placed in the cell in layers and compacted uniformly with a hand compactor. The exact weight of soil in the cell was determined. Filter paper (Whatman Grade 1) and porous stone (made of alundum) were placed at each end of the soil sample and end caps were attached. The cell was connected to the inlet reservoir using Tygon tubing. The inlet reservoir was filled with the selected flushing agent. The fluid level in the inlet reservoir was kept at a constant level using a Marriott tube at the inlet. When the first stage of testing was completed, the solution in the Marriott tube was replaced (from Igepal to EDTA or vice versa), and the test was continued. During the both stages of testing, the outflow from the cell (effluent) was collected and measured at different time periods.

The hydraulic gradient and duration of each stage of testing was decided based on the observed flow behavior, contaminant concentrations in the effluent, and total treatment time. Both stages of the SEQ1 and SEQ2 tests were planned to be conducted under a constant hydraulic gradient of 1.2. However, due to low flow conditions during the stage 2 of SEQ2 test, the hydraulic gradient was gradually increased from 1.2 to 4.0. A total of about 20–22 pore volumes of flow were allowed during each stage of SEQ1 and SEQ2. The pore volume is the volume of the soil occupied by the fluid and is equal to the bulk volume of the soil times the water-filled porosity (total porosity as the soil was fully saturated). The SEQ3 test was conducted under a low hydraulic gradient of 0.2, and each stage was terminated when about 6–7 pore volumes of flow was achieved. The total duration of stages 1 and 2 was 193 h; 24 h for SEQ1 and 73 and 226 h for SEQ2, respectively. The duration of stage 1 and stage 2 for SEQ3 was 258 and 247 h, respectively. It should be recognized that additional experiments are needed with real-time monitoring of the contaminant removal in the effluent to optimize the duration of each flushing stage based on the extent or rate of contaminant removal.

At the end of each test, the inlet reservoir was disconnected, and the soil specimen was extruded from the cell using a mechanical extruder. The extruded soil was weighed and preserved in a glass bottle.

2.5 Chemical Analyses

Representative samples of the effluent, treated soil, and initial contaminated soil for each test were analyzed for total metals and PAHs using the USEPA Methods SW8270 and SW8270C, respectively (United States Environmental Protection Agency USEPA 2007). To ensure the integrity and accuracy of the test results, new cells and tubing were used for each experiment. The cell and reservoir were washed thoroughly and then rinsed first with tap water and finally with deionized water to avoid cross contamination between the experiments. All analytical tests were conducted in duplicate.

3 Results and Analysis

3.1 Cumulative Flow

Figure 3 summarizes the cumulative flow data for the SEQ1, SEQ2, and SEQ3 tests. Results of the SEQ1 test show that, in stage1, when EDTA was flushed under a high hydraulic gradient of 1.2, the flow rate was initially higher for the first 24 h then decreased slightly between 24 and 100 h. Finally, the flow rate increased to approximately the same level as its initial value after 100 h and remained constant through the first stage. Based on these results, the calculated hydraulic conductivity of the soil was 3.4 × 10-4 cm s−1 initially, then decreased to 1.2 × 10−4 cm s−1 and then increased again to 2.0 × 10−4 cm s−1. A total of 22 pore volumes of flow were collected over a period of 193 h of EDTA flushing. In general, soil hydraulic conductivity depends on several factors including the soil void ratio, degree of soil saturation, soil structure, soil organic content, and flowing fluid viscosity. The influence of inorganic ions on hydraulic conductivity is consistent with their effect on the double-layer and interparticle forces in relation to flocculation/dispersion and shrinkage/swelling as well as their effect on surface charges of particles and the influence of these charges on flocculation and deflocculation (Mitchell and Soga 2005). Within the first 24 h, the initial ionic strength of the pore fluid was high due to the soluble ions present, which resulted in a smaller thickness diffuse double layer, thus causing the higher initial outflow rate (hydraulic conductivity). Once the initial pore fluid was flushed out of the soil over 24 h, a low ionic strength pore fluid existed, which promoted a thicker diffusive double layer and, consequently, a low outflow rate (hydraulic conductivity). After 100 h, the desorption of the metals from soil surfaces due to the chelating effects of the EDTA flushing by ligand exchange reactions increased the pore water ionic strength, promoting a return to a thinner diffuse double layer again and thereby inducing a higher outflow rate (hydraulic conductivity).

It should be noted that the soil contained about 11 % organic matter, which also played a role in the observed flow behavior. Organic (humic) substances contain a variety of functional organic groups such as carboxyl (COOH), hydroxyl (OH), and carbonyl (C = O) and humic molecules that are commonly negatively charged due to proton dissociation from these functional groups (Saichek and Reddy 2005). Humic substances may also be adaptable, and the molecular structure may change in response to pH and electrolyte concentration changes (Evangelou 1998). In addition, the molecular structure of organic matter is complicated, and different organic functional groups can bind with hydrophobic organic compounds (such as PAHs) as well as with clay mineral surfaces through a variety of chemical mechanisms (Sposito 1989; Evangelou 1998). These soil–organic matter–contaminant interactions may have affected the flow behavior. In addition, the presence of multiple interrelated factors (i.e., soil, contaminant, and flushing agent) makes it difficult to identify specific dominant factors that affect the flow variations in the tested soil systems.

After 193 h duration in SEQ1, the Igepal solution was flushed during the second stage, which sharply increased the flow rate that remained constant until the termination of the testing. Nearly 20 pore volumes flow were collected over 24 h, resulting in a hydraulic conductivity value of 1.4 × 10-3 cm s−1, an order magnitude higher than that of the first stage. The high and constant flow rate behavior is attributed to the changes in viscosity and pore solution chemistry due to the presence of Igepal.

The SEQ2 test was identical to SEQ1 except that the sequence of flushing agents was reversed. In the SEQ2 test, Igepal solution was initially flushed under the same high hydraulic gradient of 1.2 for 73 h to collect about 21 pore volumes of flow. The flow rate was constant (with a hydraulic conductivity value of 4.5 × 10−4 cm s−1) and slightly lower than that of flow rate observed in SEQ1 stage 2, which also represents Igepal flushing. The second stage flushing was initiated after 73 h. The EDTA solution was flushed initially under hydraulic gradient of 1.2, and it was observed that the flow rate was low (with a hydraulic conductivity of 7.5 × 10−5 cm s−1). After an elapsed time of 177 h, the hydraulic gradient for EDTA flushing was increased to 4.0, which resulted in a gradual increase in the flow rate (with an average hydraulic conductivity of 9.4 × 10−5 cm s−1). It is possible that the residual surfactant may have adsorbed to the surface of the soil and organic matter. In addition, EDTA may also have adsorbed to the adsorbed surfactant, soil, and organic content, resulting in low ionic strength. Higher gradient (flow velocity) was required to overcome the influence of the residual surfactant present in the test sample. When the hydraulic gradient was increased to 4.0, the hydraulic conductivity of the soil increased gradually. This led to the gradual increase in EDTA and EDTA complexes, which in turn resulted in higher ionic strength. A total of about 21 pore volumes of flow were collected during the entire second stage of EDTA flushing over 226 h duration.

The SEQ3 test was the same as SEQ2 with Igepal flushing occurring first followed by EDTA flushing, except that a low hydraulic gradient of 0.2 was used in SEQ3 as compared with 1.2 in SEQ2. Results show that the flow rate was low but constant during both the Igepal and EDTA flushing stages. Approximately 6 pore volumes of flow were accumulated during each stage: flushing with Igepal over a period of 258 h and flushing with EDTA for 247 h. These results show that an average hydraulic conductivity of 2.3 × 10−4 cm s−1 was achieved during the entire testing duration. Obviously, the low hydraulic gradient is expected to result in low flow rate, giving more time for a contaminant-flushing agent interaction in SEQ3 than that in SEQ2. As a result, more Igepal–solubilized organics and EDTA–metal complexes were produced gradually in the system, with a net effect of lower hydraulic conductivity in SEQ3 (2.3 × 10−4 cm s−1) compared with that in SEQ2 (4.5 × 10−4 cm s−1). Additional research is needed to determine the fundamental interactions between the flushing agent–contaminant–soil that influence the hydraulic conductivity of the soil.

3.2 Contaminant Removal

Figure 4 shows the cumulative mass removal of the total metals, total toxic metals (all metals except Al, Ca, Fe, Mg, K, and Na as shown in Table 2), and total PAHs from the soil sample with the cumulative pore volumes for all three SEQ tests performed. These results clearly show that the removal of heavy metals occurred only due to the EDTA flushing during stage 1 of the SEQ1 test and stage 2 in the SEQ2 and SEQ3 tests (Fig. 4a). The maximum removal of metals occurred when EDTA was flushed first (in SEQ1). Surfactant (Igepal) flushing prior to EDTA flushing in SEQ2 and SEQ3 hindered the metal removal, possibly due to sorption of metals to the surfactant or surfactant-laden soil surfaces (i.e., the surfactant physically blocked metal desorption).

Figure 4b shows that total toxic metals were also removed during the EDTA flushing stages in all three tests. Figure 5 shows the removal behavior of selected toxic metals in all three tests and demonstrates that contaminant removal would have continued if the duration of the EDTA flushing stages was increased. Under the tested conditions, the removal of Pb, Zn, and Cu was 76 %, 63 %, and 11 % in SEQ1, 42 %, 40 %, and 7 % in SEQ2 and 63 %, 42 %, and 8 % in SEQ3, respectively. The removal of heavy metals is the highest in SEQ1, followed by SEQ2 and then SEQ3. Though such a removal trend was not observed for some metals, the removal of most heavy metals generally followed the trend: SEQ1 > SEQ2 > SEQ3. The total outflow in SEQ3 was about 3.5 times less than SEQ1 and SEQ2, yet the heavy metal removal was significant. It appears that the low hydraulic gradient (flow) conditions in SEQ3 caused higher residence time in the soil for the flushing agents, improving the removal efficiency. It may be concluded that the removal of heavy metals is controlled by the rate-limited desorption/solubilization of heavy metals in the soil tested.

The PAHs were removed during the surfactant (Igepal) flushing stage in all three tests (Figs. 4c and 6). The removal of PAHs during the EDTA flushing stage was negligible. Figure 4c shows that the maximum removal of total PAHs occurred in the SEQ2 test during the first stage involving about 20 pore volumes of Igepal flushing. The SEQ1 test, which involved about 20 pore volumes of Igepal flushing following 20 pore volumes of EDTA flushing, resulted in lower total PAHs removal of about 45 %. The total PAHs removal in SEQ3 during about 6.6 pore volumes of Igepal resulted in about 35 % removal. Figure 6 shows the removal efficiencies of selected PAHs (phenanthrene, pyrene, and benzo(a)pyrene) in the three tests. These results show that the removal of phenanthrene, pyrene, and benzo(a)pyrene was 51 %, 39 %, and 45 % in SEQ1, 69 %, 69 %, and 25 % in SEQ2, and 58 %, 54 %, and 16 % in SEQ3, respectively. In general, the removal of PAHs in SEQ2 was higher, but the removal efficiencies in SEQ1 are comparable to those found in SEQ1 except in the case of some of the large-ring compounds, such as pyrene and chrysene. Furthermore, the SEQ3 results show that the removal of PAHs is significant despite the fact that only about 6.6 pore volumes of Igepal is flushed in this test as compared with about 20 pore volumes of Igepal flushing in SEQ1 and SEQ2. The low gradient condition leading to higher residence time enhanced the dissolution of PAHs and resulted in the substantial removal of PAHs. These results show that, instead of high hydraulic gradient (flow) conditions, the use of lower hydraulic gradient and longer duration should be explored for optimizing the flushing agent and sequence duration. The dissolved humic substances may also have enhanced the solubilization of compounds that are more hydrophobic than pyrene. Otherwise, the high benzo[a]pyrene removal in SEQ1 as compared with SEQ2 and SEQ3 could be attributed to some synergistic effects with any residual EDTA and/or inhomogeneous distribution within the soil samples used.

Thus, the three test results confirm that the removal efficiency depends upon the sequence of flushing agents and applied hydraulic gradient. Figures 7 and 8 compare the removal efficiency of SEQ1, SEQ2, and SEQ3 for all the metals and PAHs. It can be seen in Fig. 7 that heavy metals can be effectively removed following the SEQ1 system during EDTA flushing and, at the same time, as seen in Fig. 8, that significant amounts of PAHs can also be removed in SEQ1 during the second stage of Igepal flushing. Overall, SEQ1 resulted in the maximum total contaminant mass removal of heavy metals and PAHs.

In general, the removal of PAHs during the first stage Igepal flushing in SEQ2 was higher than that of SEQ3. About 21 pore volumes of Igepal flushing was implemented in SEQ2, but, despite about 6.6 pore volumes of Igepal flushing in SEQ3, significant amounts of PAHs were removed. The low hydraulic gradient (flow) in SEQ3 may have helped the dissolution of PAHs into solution and their subsequent removal. The desorption of PAHs may be rate-limited; therefore, further investigation of the optimal hydraulic gradient (flow) and flow volume to result in the higher removal of PAHs from the soils should be undertaken. The removal of metals during the second stage EDTA flushing was lower than that of SEQ1. The lower removal of metals was mainly attributed to potential surfactant adsorption to soil particles, which may have caused removal of metals difficult. Once the substantial amount of EDTA was injected, the residual and surface-coated Igepal may have been removed, facilitating the removal of metals. The 5.8 pore volume of EDTA flushing under low hydraulic gradient (flow) resulted in the removal of heavy metals comparable to 21.2 pore volumes of EDTA flushing under high gradient of 1.2 to 4.0, indicating that the formation of soluble EDTA–metal complexes may be rate-limited process. As the flow data (Fig. 3) indicated, the high hydraulic conductivity of the soil was maintained during the flushing of Igepal, but the hydraulic conductivity was reduced during the EDTA flushing at least during the initial stages of flushing. The effects of flushing agent on the hydraulic conductivity should also be carefully assessed to sustain the flow and contaminant removal.

The observed removal of heavy metals can be explained on the basis of the fact that polyaminocarboxylate chelates such as ethylenediaminetetraacetic acid (EDTA) form soluble complexes with free metal ions in the soil pore solution. In addition, they dissociate exchangeable cations attached to mineral surfaces and dissolve soil minerals. Thus, the EDTA-enhanced system relies on the availability and the interaction of the EDTA ions with the soil matrix and the stability of the EDTA–metal complexes. Therefore, the high removal of metals indicates that EDTA–metal complexes attain maximum stability at a low hydraulic gradients condition. It can also be concluded that the desorption/dissolution of the PAHs may be highest under low hydraulic gradients, leading to their mobilization and removal from the soil.

On the other hand, the removal of PAHs using a surfactant such as Igepal can also be attributed to micellar-enhanced contaminant solubility in the pore fluid (Reddy and Saichek 2003). Surfactants monomers aggregate to form micelles that exhibit unique properties with the hydrophobic portion of the molecules located in the center and the hydrophilic portions at the exterior of the micelle. The hydrophilic polar exterior makes micelles highly soluble in water, while the non-polar interior provides a hydrophobic sink for PAHs, which effectively increases the solubility of PAHs. The CMC is the surfactant concentration level above which micelles form. The concentration of Igepal used in this study is 5 %, which significantly exceeds its CMC of 2.3 × 10−4 mol L−. As a result, the removal of PAHs from the soil during the Igepal flushing depends upon the number and stability of micelles formed (Mulligan et al. 2001; Chu and Kwan 2003; Reddy and Saichek 2003). In all three tests conducted, micelles formed during the Igepal flushing, resulting in micelle solubilization and the subsequent removal of PAHs.

The assessment of the relative effectiveness of flushing sequences in this study was based on the extent of contaminant removal under the pre-selected flushing sequence, duration of each stage flushing, and hydraulic gradient (flow). The steady-state removal conditions may not have been reached for all of the contaminants during the duration of each flushing stage. Therefore, additional research is needed to optimize the duration and hydraulic gradient of each flushing stage based on the extent or rate of the contaminant removal.

4 Conclusions

The following conclusions can be drawn based on this study:

-

1.

The removal of mixed PAHs and heavy metals from the field soil required the use of sequential flushing of a surfactant (Igepal) and a chelant (EDTA). PAHs were removed during the flushing of Igepal, while heavy metals were removed during the flushing of EDTA. The sequence of flushing agents affected the removal of PAHs and heavy metals. Surfactant-enhanced solubilization of PAHs occurred through the forming micelles that provided hydrophobic sinks for PAHs, while chelant-enhanced desorption and solubilization of heavy metals occurred through the formation of metal complexes.

-

2.

Hydraulic conductivity of the soil and, consequently, flow behavior, was dependent on the transient changes in viscosity, density, and soil–contaminant interactions of the flushing agent used. Hydraulic conductivity was higher with Igepal and lower with EDTA.

-

3.

The higher hydraulic gradient conditions appeared to help the mobilization and removal of the contaminants. The low hydraulic gradient conditions helped to desorb/solubilize the contaminants due to the greater time allowed for the contaminant and flushing agent interaction. Due to aging, contaminants may be strongly held in the soil under which circumstances desorption and solubilization appears to be rate-limited processes.

-

4.

Depending on the flushing sequence used, the removal of individual heavy metals ranged from 0 to 100 %, while the removal of individual PAHs ranged from 2 to 69 %. Sequential flushing of EDTA followed by Igepal (SEQ1) resulted in the removal of maximum combined mass of heavy metals and PAHs from the soil. Further optimization of flushing stage duration and hydraulic gradient is needed to maximize the contaminant removal from the soil.

References

Abumaizar, R. J., & Smith, E. H. (1999). Heavy metal contaminants removal by soil washing. Journal of Hazardous Materials, 70, 71–86.

Abu-Zreig, M., Rudra, R. P., & Dickinson, W. T. (2003). Effect of surfactants on hydraulic properties of soils. Biosystems Engineering, 84, 363–372.

Antizar-Ladislao, B., Lopez-Real, J. M., & Beck, A. J. (2004). Bioremediation of polycyclic aromatic hydrocarbon (PAH)-contaminated waste using composting approaches. Critical Reviews in Environmental Science and Technology, 34, 249–289.

Bernnett, G. F. (2001). Fundamentals of site remediation for metal and hydrocarbon contaminated soils. Journal of Hazardous Materials, 83, 281–282.

Bogan, B. W., & Trbovic, V. (2003). Effect of sequestration on PAH degradability with Fenton's reagent: Roles of total organic carbon, humin, and soil porosity. Journal of Hazardous Materials, 100, 285–300.

Bonten, L. T. C., Grotenhuis, T. C., & Rulkens, W. H. (1999). Enhancement of PAH degradation in soil by physicochemical pre-treatment. Chemosphere, 38, 3627–3636.

Brusseau, M. L., Wang, X., & Wang, W. Z. (1997). Simultaneous elution of heavy metals and organic compounds from soil by cyclodextrin. Environmental Science & Technology, 31, 1087–1092.

Chu, W., & Kwan, C. Y. (2003). Remediation of contaminated soil by a solvent/surfactant system. Chemosphere, 53, 9–15.

Evangelou, V. P. (1998). Environmental soil and water chemistry: Principles and applications. New York: John Wiley & Sons.

Kamiya, M., & Nakamura, K. (1995). Cyclodextrin inclusion effects on photodegradation rates of phosphorous pesticides. Environment International, 21, 299–304.

Lee, J. K., Park, D., & Kim, B. U. (1999). Remediation of petroleum contaminated soils by fluidized thermal desorption. Waste Management, 18, 503–507.

Maturi, K., & Reddy, K. R. (2008). Extraction of mixed contaminants from different soil types. Soil and Sediment Contamination: An International Journal, 17(6), 586–608.

Mitchell, J. K., & Soga, K. (2005). Fundamentals of soil behavior (3rd ed.). New Jersey: John Wiley & Sons.

Mulligan, C. N., Yong, R. N., & Gibbs, B. F. (2001). Surfactant-enhanced remediation of contaminated soil: A review. Engineering Geology, 60, 371–380.

National Research Council (NRC). (1994). Alternatives for ground water cleanup. Washington: National Academy Press.

Nowack, B. (2002). Environmental chemistry of aminocarboxylate chelating agents. Environmental Science & Technology, 19, 4009–4016.

Peters, R. W. (1999). Chelant extraction of heavy metals from contaminated soils. Journal of Hazardous Materials, 66, 151–210.

Reddy, K. R., & Chinthamreddy, S. (2000). Comparison of different extractants for removing heavy metals from contaminated clayey soils. Journal of Soil and Sediment Contamination, 9(5), 449–462.

Reddy, K. R., & Saichek, R. E. (2003). Effect of soil type on electrokinetic removal of phenanthrene using surfactants and cosolvents. Journal of Environmental Engineering, 129, 336–346.

Reddy, K. R., Al-Hamdan, A. Z., & Ala, P. (2011). Enhanced soil flushing for simultaneous removal of PAHs and heavy metals from industrial contaminated soil. Journal of Hazardous Toxic and Radioactive Waste, 15(3), 166–174.

Roote, D. S. (1997). In-situ flushing. Technology Overview Report, TO-97-02. Pittsburgh: Groundwater Remediation Technologies Analysis Center.

Saichek, R. E., & Reddy, K. R. (2005). Electrokinetically enhanced remediation of hydrophobic organic compounds in soils: A review. Critical Reviews in Environmental Science and Technology, 35, 115–192.

Sharma, H. D., & Reddy, K. R. (2004). Geoenvironmental engineering: Site remediation, waste containment, and emerging waste management technologies. Hoboken: John Wiley & Sons, Inc.

Sposito, G. (1989). The chemistry of soils. New York: Oxford University Press.

Szejtli, L. (1982). Cyclodextrins and their inclusion complexes. Budapest: Akademiai Kiado.

United States Environmental Protection Agency (USEPA) (2000). A resource for MGP site characterization and remediation. EPA/542-R-00-005, Washington, DC.

United States Environmental Protection Agency (USEPA) (2007). Test methods for evaluating solid waste, physical/chemical methods. EPA Method SW 846, Washington, DC: U.S. Government Printing Office.

Wang, X., & Brusseau, M. L. (1995). Simultaneous complexation of organic compounds and heavy metals by a modified cyclodextrin. Environmental Science & Technology, 29, 2632–2635.

Yeom, I. T., Ghosh, M. M., Cox, C. D., & Robinson, K. G. (1995). Micellar solubilization of polynuclear aromatic hydrocarbons in coal tar-contaminated soils. Environmental Science & Technology, 29, 3015–3021.

Author information

Authors and Affiliations

Corresponding author

Additional information

Guest Editors: R Naidu, Euan Smith, MH Wong, Megharaj Mallavarapu, Nanthi Bolan, Albert Juhasz, and Enzo Lombi

This article is part of the Topical Collection on Remediation of Site Contamination

Rights and permissions

About this article

Cite this article

Reddy, K.R., Al-Hamdan, A.Z. Enhanced Sequential Flushing Process for Removal of Mixed Contaminants from Soils. Water Air Soil Pollut 224, 1709 (2013). https://doi.org/10.1007/s11270-013-1709-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1709-8