Abstract

The processes of wind erosion of fertile soil, dune movement in sand deserts, dust storms in arid and semi-arid regions, as well as the emission and dispersion of agricultural or industrial dusts create a lot of problems and dangers for human life, environment, and infrastructure. Conventional ways to suppress dust emission to the atmosphere are agricultural fixation in the case of fertile soil surface and application of chemical agents to immobilize dust particulates onto the surface of soil, desert sand, country roads, or mining areas. However, these methods are often too expensive to be applied for large-scale suppression of sand dust. Chemical methods of dust suppression are often environmentally unfriendly due to the release of toxic reagents in water, air, and soil. This paper examines, for the first time, the microbially mediated aggregation of fine sand particles to suppress the emission of sand dust and its chemical and bacteriological pollutants. The bioaggregation reagent was a solution of calcium chloride and urea sprayed over the sand surface, which was preliminarily treated with the suspension of urease-producing bacteria. Quantity of calcium used for sand dust suppression was 15.6 g of Ca/m2. After the biotreatment of fine sand, the release of sand dust and its artificial pollutants to the atmosphere decreased in comparison with control by 99.8 % for dust, 92.7 % for phenantherene, 94.4 % for led nitrate, and 99.8 % for bacterial cells of Bacillus megaterium. This immobilization of dust and dust pollutants was due to the bioaggregation of fine sand particles. The sizes of 90 % of the sand dust particles increased from 29 μm in control to 181 μm after bioaggregation. Bioaggregation treatment of the soil surface could be a useful method to prevent the dispersion of dust and dust-associated chemical and bacteriological pollutants in water, air, and soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Such processes as wind erosion of fertile soil, dune movement in sand deserts, dust storms in arid and semi-arid regions, as well as the emission and dispersion of agricultural, construction, transportation, or mining dusts create a lot of problems and dangers for human life, environment, and infrastructure. Dust is also a carrying agent for soil-associated pollutants such as chemicals, viruses, and microorganisms. So, the release of the polluted dust in the atmosphere can cause the deposition of these pollutants to ecosystems located downwind and negatively affect human health and environment (Boreson et al. 2004; Falkovich et al. 2004; Griffin et al. 2007; Raisi et al. 2010). Dust storms originating in desert areas effect many countries in Middle and East Asia and North Africa (Lee et al. 2006; Ci and Yang 2010).

There are many known biological, chemical, and mechanical technologies to prevent and control wind erosion of soil, wind dispersion of dust, desertification due to wind-blown sand movement, as well as the release of dust from agriculture, construction, or transportation on unpaved roads. One conventional way, but limited by agricultural conditions, is the use of vegetation as the land surface is covered to reduce wind erosion of soil (Ci and Yang 2010). Wind erosion of soil and dust formation could be prevented by the compaction of the soil surface layer using treatments with inorganic compounds such as sodium chloride, calcium chloride, magnesium chloride, lime, and fly ash (Petry and Little 2002; Santoni et al. 2005; Goodrich and Jacobi 2012). Many patents have been issued on the methods to control wind erosion of soil and dust suppression. However, application of binding reagents could negatively affect plants (Goodrich and Jacobi 2012) and quality of surface and underground waters due to the solubility of the reagents in water and their dispersion in environment with runoff.

Another approach to suppress dust dispersion is the use of organic compounds such as an asphalt emulsion (Santoni et al. 2005), lignin and lignosuphonates (Gargulak and Lebo 1999), surfactants (Copeland et al. 2009), fly ash and polyacrylamide (Yang and Tang 2012), starch ethers, polyacrylonitrile, polyvinyl alcohol, urea-formaldehyde and their co-polymers, polyacrylamide co-polymers, carboxymethyl cellulose, polyvinyl acetate, epoxyresins, and many others (Nij et al. 2003; Santoni et al. 2005; US Army, US Air Force 2005; Orts et al. 2007; Yang et al. 2007; Naemi and Ghorbanalizadeh 2010; Zandieh and Yasrobi 2010). These dust suppressors change the physical properties of the soil surface by wetting or binding the fine particles and are used in construction industry, mining, at the loading/unloading points, transportation on unpaved roads, and using of airfields. However, organic fixing reagents are usually relatively expensive for large scale application and could be environmentally harmful due to their toxicity or ability to cause eutrophication of water.

An alternative way for the dust suppression with chemical reagents can be an application of biomediated cementation/aggregation of the soil particles (Ivanov and Chu 2008; Bang et al. 2011; Chu et al. 2012a, b; DeJong et al. 2010, 2011, 2013). Biocementation is based on the precipitation or crystallization of insoluble compounds in porous soil using enzymatic activity of microorganisms (Ivanov and Chu 2008; Ivanov 2010). The most popular technology of biocementation is crystallization of calcite (CaCO3) from the solution of calcium chloride and urea mediated by enzyme urease or biomass of urease-producing bacteria (Ivanov 2010). Enzymatic hydrolysis of urea by urease increases the pH and releases a carbonate following calcium carbonate crystallization on the soil surface particles, and their binding according to the following biochemical reaction:

However, it is important to know that chemical precipitation of calcium carbonate in sand did not produce effect of sand cementation (Chu et al. 2012b).

Calcite crystals produced as the result of biocementation, are the naturally abundant, environmentally neutral substance and, depending on the content of precipitated calcium in soil, can significantly enhance soil strength and reduce its water permeability. Therefore, biocementation of sandy soil can be used in geotechnical engineering to enhance stability of the slopes and dams (van Paassen et al. 2010), for road construction and prevention of soil erosion (Mitchell and Santamarina 2005; Ivanov and Chu 2008; Ivanov 2010), for the construction of the channels, aquaculture ponds, or reservoirs in sandy soil (Chu et al. 2012b; Stabnikov et al. 2011).

The major hypothesis of this study was that even very small levels of sand dust biocementation can prevent its dispersion.There is known experimental attempt to study the effects of biocementation on sand immobilization (Bang et al. 2011), but the published results are not applicable for sand dust suppression because of the following reasons: (1) the object of study was not fine sand or sand dust but big sand particles with the sizes from 0.075 mm to 4.76 mm; (2) the effect of biocementation on the sand dust formation in the wind tunnel was studied only by the mass losses of sand; (3) the content of precipitated calcium in sand was not measured; (4) the effects of some biotreatments were measured after simultaneous application of urease-producing bacteria, calcium chloride, and urea to sand, which can cause chemical precipitation of calcium carbonate due to the high pH of medium after cultivation of urease-producing bacteria. Meanwhile, only crystallization of calcite on the sand surface mediated by urease activity is important for the sand grain binding (Chu et al. 2012b).

The research described in this paper examines the effects of small dosage, calcium-based biomediated aggregation of fine sand on the airborne movement of sand dust and dust-associated chemical and bacteriological pollutants.

2 Materials and Methods

2.1 Materials for Biomediated Aggregation of Sand Dust

Urease-producing alkalophilic bacteria Bacillus sp. VS1, isolated from tropical sand beach in Singapore (Chu et al. 2012b), were used as the bioagent for dust particle aggregation. The bacterial biomass was grown for 2 days in a non-sterile liquid medium of the following composition: Tryptic Soy Broth Bacto™ (DIFCO, Lawrence, USA), 30 g/L; urea, 20 g/L; MnSO4 · H2O, 12 mg/L; NiCl2 · 6H20, 24 mg/L, phenol red, 10 mg/L. Final concentration of bacterial biomass was 8.3 g of dry biomass/L. Bacterial biomass was separated by centrifugation at 4 °C and 10,000 rpm for 15 min using a Micro Cooling Centrifuge 5922 (Kubota, Japan), suspended to concentration about 8 mg of dry biomass per 1 mL of water, and stored at 4 °C before experiments. Two components of liquid biocement, applied sequentially, were this suspension and solution of calcium chloride, 0.375 M (41.2 g/L) and urea, 0.75 M (45 g/L).

2.2 Characteristics of the Fine Sand

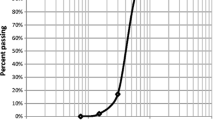

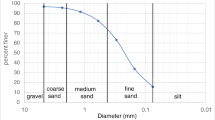

Particles size distribution of initial sand and fine sand, which was used to produce sand dust, was measured using the Mastersizer 2000 particle size analyzer (Malvern Instruments Ltd, UK). The particle size distributions, volume-weighted mean sizes of the particles, and the maximum size of 90 % of the particles (d90) have been used to characterize the changes of the dust particles sizes during biocementation. Graded Ottawa sand with specific gravity 2.65 and silica content 98.9 % was used in this study. Size of these sand particles varied from 150 μm to 1,180 μm. For the fine sand preparation, 200 g of sand was placed in the Pulverisette 5/2 type laboratory planetary ball mill (FRITSCH GmbH, Germany) and was ground at a rotation rate of 200 rpm for 3.5 hours. Mean (volume weighted) size of the fine sand, which was used to form sand dust, was 12 μm and the sizes of 90 % of these particles (d90) were lower than 29 μm.

2.3 Artificial Pollution of the Fine Sand

Sand dust is often polluted with microbiological materials (Ichinose et al. 2008; Lee et al. 2009), heavy metals like Fe, Mn, Zn, and Pb, especially at the heavy traffic flow sites (Funasaka et al. 2003; Gat et al. 2011) and organic substances, for example, polyaromatic hydrocarbons (Zhang et al. 2010). The artificial chemical and microbial pollutants of fine sand have been used in our experiments in the contents, which are significantly higher than the contents of the real pollutants of sand dust, just to simplify analytical procedures to study two research tasks: (1) evaluate movement of sand dust with adsorbed pollutants in controls and experiments; (2) to demonstrate the fate of typical soil pollutants after soil biocementation treatment. The following biological and chemical agents were used for artificial sand dust pollutions: (1) vegetative cells and spores of typical soil bacteria Bacillus megaterium that were used as a surrogate modeling pollution of soil with pathogens; (2) phenanthrene (Sigma-Aldrich, St. Louis, MO, USA) solution, 6 g/L, in glacial acetic acid, modeling pollution of soil with hydrophobic petrochemicals; (3) lead nitrate solution in water with concentration 9.6 g/L, modeling pollution of soil with heavy metals.

Bacterial strain Bacillus megaterium de Bary 1884, DSM No. 90, is from Risk Group 1, i.e., “unlikely to cause human disease” according to the classification of the German Technical Rules for Biological Agents. The vegetative cells and spores of this strain were used as a surrogate of the bacteriological pollutant. The strain was cultivated aseptically and aerobically in Tryptic Soy Broth Bacto™ (DIFCO, Lawrence, USA) at 30 °C on the rotary shaker at 150 rpm for 48 hours.

For artificial pollution of sand, 20 mL of phenantrene solution in glacial acetic acid was added to 50 g of fine sand and the sample was dried at 30 °C for 1 day. After that, this sample of fine sand was mixed with 20 mL of lead nitrate solution and dried at 30 °C for 1 day. At the next day, this sample was mixed with 20 mL of bacterial suspension of Bacillus megaterium DSM 90 with about 3.5 g/L concentration of dry biomass and dried at 30 °C for 1 day. Finally, the sample was shaken at 100 rpm with 500 mL of distilled water for 1 hour to remove not adsorbed pollutants from fine sand, the solution was decanted after precipitation of fine sand, and the polluted fine sand was dried at 30 °C for 1 day.

2.4 Experimental Set Up

The laboratory facility to study the effects of biocementation on sand dust suppression consisted of the air pump, the air flow velocity controller, the dust releasing chamber, and the cyclone collecting the dust (Fig. 1). The dust chamber was the 13-mm diameter holder of cellulose membrane with the 50-μm diameter of pores and the layer of 1-mm depth of 200 mg of fine sand on this membrane. There were two controls and two experimental dust chambers. Nothing except the fine sand was added in control 1. Water, 100 μL, was added to the fine sand in control 2. An aliquote of bacterial suspension of Bacillus sp. VS1 in water, 50 μL, was added to the fine sand, and after 1 hour, an aliquote of the solution of calcium chloride and urea, 50 μL, was added to the fine sand. The test of dust formation was started at the next day. In experiment 1, concentrations of calcium chloride and urea were reduced by five times, i.e., to 0.075 M and 0.15 M, respectively. Dosage of added calcium in experiment 2 was 0.31 mg of Ca/cm2 (3.12 g of Ca/m2). Calculated addition of calcium to the fine sand in experiment 2 with concentrations of calcium chloride and urea 0.375 M (41.2 g/L) and 0.75 M (45 g/L), respectively, was 1.56 mg of Ca/cm2 (15.6 g of Ca/m2).

Air was supplied into the dust chambers with the flow rates 1, 2, and 3 L/min ensuring linear velocities in the dust chamber 0.13, 0.26, and 0.39 m/s, respectively, for 10 min. These velocities were sufficient to move the particles of the fine sand in our experiments and are within the range of real air velocities in deserts (Bagnold 2005)

Dust suppression was assessed using change of air flow rate through the laboratory facilities. Every air flow rate was used in triplicates. The sand dust was collected in the cyclones and was washed out from there with 10 mL of deionized water.

2.5 Measurements

Relative reduction of air conductivity through the filter with the fine sand in experiments was calculated as a drop of air flow in control 2 or experiment to air flow in control 1 at the same pressure before the dust chamber (Fig. 2). Air flow for control 1 was installed by the air flow meter at 1, 2, or 3 L/min, then dust chamber from control 1 was replaced for the dust chamber from control 2 or experiment, and air flow was measured.

Concentrations of phenanthrene, Pb, and bacterial cells were determined for all controls and experiment 1. The enumeration of colony-forming units (c.f.u.) was done after spread-plate inoculation of Petri plates by 0.1 mL of the serial tenfold dilutions of the bacterial suspension produced by the vortexing of 0.1 g of the fine sand or the sand dust in 10 mL of phosphate-buffered saline solution with pH 7.2. Before inoculation, the Petri plates were aseptically filled with Tryptic Soy Broth Bacto™ (DIFCO, Lawrence, USA). The enumeration of c.f.u. was made after incubation of inoculated Petri plates at 30 °C for 2 days.

An aliquote of 5 mL of glacial acetic acid was used for extraction of phenanthrene from 50 mg of the sand dust. UV light absorption measurements of phenanthrene in extracts were performed at fixed wavelength 252 nm using a quartz cell with the length of optical way 1 cm. Concentration of phenanthrene in solution was determined by the reference to the calibration curve.

To determine content of Pb in the sand dust 20 mg of sample was dried in a 15 mL quartz vessel at 103 °C for 24 hours, then mixed with 3 mL of 69.9 % (w/v) solution of nitric acid. The mixture was digested under 300 °C and 90 bars in a high pressure asher (Model HPA-S, Anton Paar, Graz, Austria) for 160 min. The solution was diluted 50 times with water and then filtered using a 45-μm pore size Whatman membrane filter. The filtrate was analyzed for Pb using the inductively coupled plasma (ICP OES) emission spectrometer Optima 2000 DV (Perkin-Elmer, Inc., Shelton, USA). Two replicates were analyzed for each sample and the average value was reported.

2.6 Microscopic Observations

The structure of sand and the sand dust was observed using the scanning electron microscope (SEM) V050 (Carl Zeiss Microscopy, LLC, Germany). The sand sample was fixed in 2 % glutaraldehyde for 2 hours, washed three times with 0.1 M sodium cacodylate buffer for 20 min, dehydrated step-wise in 50, 70, 85, and 95 % (v/v) solutions of ethanol for 10 min, kept in 100 % ethanol, dried in Polavon E3100 critical point dryer (Quorum Technologies Ltd, UK), and then sputter coated with Au-Pd using Emitech SC7620 (Quorum Technologies Ltd, UK).

3 Results and Discussion

Drops of air flow for the treated fine sand in comparison with control 1 was 14 ± 3, 42 ± 3, and 90 ± 7 % after addition of water (control 2) or bioaggregation with the dosages of added calcium 0.31 and 1.56 mg of Ca/cm2, respectively (Fig. 2). All other experiments on the dust formation were done with bioaggregation at the dosage of added calcium 1.56 mg of Ca/cm2 (15.6 g of Ca/m2) because it produced sufficient bioaggregation of the fine sand. Treatment with water or bioaggregation of the fine sand in the dosage 1.56 mg of Ca/cm2 increased mean (volume weighted) size of the superfine sand particles from 12 to 33 or 47 μm (Fig. 3). The sizes of 90 % of the particles (d90) in superfine sand increased from 29 to 92 or to 181 μm after treatment with water or after bioaggregation (Fig. 3). Under SEM, the fine sand after water treatment became aggregated and cracked, while the fine sand after biocementation looks as not-cracked surface with inclusions of calcite (Fig. 4). It was shown previously that the mechanism of biocementation includes adsorption of bacterial cells on the surface of sand, calcilte crystal formation around bacterial cells which occurs preferentially at particle contacts (DeJong et al. 2013). Probably, sand bioaggregation with low quantity of added reagents in our experiments was due to the formation of the mechanical bonds at sand particle contacts.

Either addition of water or bioaggregation of the fine sand reduced the release of sand dust by 96.2 % or 99.8 %, respectively. Average concentrations of dust in air at the flow rate 3 L/min were 6.13, 0.87, and 0.01 mg/L for non-treated fine sand, fine sand treated with water, and fine sand after bioaggregation, respectively. Addition of water reduced the release of the dust-associated pollutants but not so effectively as bioaggregation of the fine sand (Table 1). Most effective was the reduction of the release of bacteriological pollutant in the atmosphere, 99.8 %, due to bioaggregation of the fine sand.

The dosage of applied dust suppressant was 44 g of CaCl2/m2, 48 g of urea/m2, and 9 g of bacterial biomass/m2, total of 101 g/m2. This value is significantly smaller than dosages of any other dust suppressants published in literature. For example, about 360 g/m2 of sulfolignin, 750 g/m2 of cement or 1200 g/m2 of bituminous materials have to be used for the dust control on the roads and airfields, as it was calculated from the related manual (US Army, US Air Force 2005). The cost of biocement as the dust suppressor is the lowest among other materials (Table 2). However, the initial cost of the dust palliative is not the governing factor in the making the selection of the method, because other economic factors such as equipment and labor, maintenance, shipping, and area preparation costs are also essential (Thompson and Visser 2007; US Army, US Air Force 2005).

Therefore, our study showed that bioaggregation of fine sand with low dosage of biocement, about 100 g/m2 of soil surface, could be used for dust suppression, for example: (1) during seasonal soil dust dispersion in arid and semi-arid areas; (2) during industrial or transportation activities accompanying dust formation, and (3) in chemical, biological, radiological, and nuclear (CBRN) defense (Cordesman 2002; Parra et al. 2009) after release of CBRN agents in soil and air. The treatment in actual field conditions should be performed by spraying dust suppressant solution at a not-sunny and not-hot day under the highest possible humidity of air so that there will be no fast drying of added solution and the bioreaction in the upper layer of sand will be performed effectively overnight.

4 Conclusion

Bioaggregation of the surface of fine sand in the dosage of 0.016 kg of Ca/m2 and total dosage of the reagents of 0.1 kg/m2 could diminish dispersion of sand dust and dust-associated chemicals or microorganisms to atmosphere by 99.8, 93, and 99 %, respectively.

References

Bagnold, R. A. (2005). The physics of blown sand and desert dunes. New York: Dover Publications. 320.

Bang, S., Min, S. H., & Bang, S. S. (2011). Application of microbiologically induced soil stabilization technique for dust suppression. International Journal of Geo-Engineering, 3, 27–37.

Boreson, J., Dillner, A. M., & Peccia, J. (2004). Correlating bioaerosol load with PM2.5 and PM10cf concentrations: a comparison between natural desert and urban-fringe aerosols. Atmospheric Environment, 38, 6029–6041.

Chu, J., Ivanov, V., Stabnikov, V., He, J., Li, B., & Naemi, M. (2012a). Biocement: green building- and energy-saving material. Advanced Materials Research, 347–353, 4051–4054.

Chu, J., Stabnikov, V., & Ivanov, V. (2012b). Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiology Journal, 29, 544–549.

Ci, L., & Yang, X. (2010). Desertification and its control in China (p. 500). China: Springer/Higher Education Press.

Copeland, C. R., Eisele, T. C., & Kawatra, S. K. (2009). Suppression of airborne particulates in iron ore processing facilities. International Journal of Mineral Processing, 93, 232–238.

Cordesman, A. H. (2002). Terrorism, asymmetric warfare, and weapons of mass destruction: Defending the U.S. homeland. Westport: Praeger Publishers.

DeJong, J. T., Mortensen, B. M., Martinez, B. C., & Nelson, D. C. (2010). Bio-mediated soil improvement. Ecological Engineering, 36, 197–210.

DeJong, J. T., Soga, K., Banwart, S. A., Whalley, W. R., Ginn, T. R., Nelson, D. C., et al. (2011). Soil engineering in vivo: harnessing natural biogeochemical systems for sustainable, multi-functional engineering solutions. Journal of the Royal Society, Interface, 8, 1–15.

DeJong, J. T., Soga, K., Kavazanjian, E., et al. (2013). Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Geotechnique, 63, 287–301.

Falkovich, A. H., Schkolnik, G., Ganor, E., & Rudich, Y. (2004). Adsorption of organic compounds pertinent to urban environments onto mineral dust particles. Journal of Geophysical Research, 109, D02208.

Funasaka, K., Sakai, M., Shinya, M., Miyazaki, T., Kamiura, T., Kaneco, S., et al. (2003). Size distributions and characteristics of atmospheric inorganic particles by regional comparative study in Urban Osaka, Japan. Atmospheric Environment, 37, 4597–4605.

Gargulak, J. D. & Lebo, S. E. (1999). Commercial use of lignin-based materials. In: Lignin: Historical, Biological, and Materials Perspectives, ACS Symposium Series, 742, 304–320.

Gat, D., Tsesarsky, M., & Shamir, D. (2011). Ureolytic CaCO3 precipitation in the presence of non-ureolytic competing bacteria. ASCE Geo-Frontiers 2011, Geotechnical Special Publication, 211, 3966–3964.

Goodrich, B. A., & Jacobi, W. R. (2012). Foliar damage, ion content, and mortality rate of five common roadside tree species treated with soil applications of magnesium chloride. Water, Air, and Soil Pollution, 223, 847–862.

Griffin, D. W., Kubilay, N., Koçak, M., Gray, M. A., Borden, T. C., & Shinn, E. A. (2007). Airborne desert dust and aeromicrobiology over the Turkish Mediterranean coastline. Atmospheric Environment, 1, 4050–4062.

Ichinose, T., Yoshida, S., Hiyoshi, K., Sadakane, K., Takano, H., Nishikawa, M., et al. (2008). The effects of microbial materials adhered to Asian sand dust on allergic lung inflammation. Archives of Environmental Contamination and Toxicology, 55, 348–357.

Ivanov, V. (2010). Environmental microbiology for engineers. CRC Press, pp. 402.

Ivanov, V., & Chu, J. (2008). Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Reviews in Environmental Science and Biotechnology, 7, 139–153.

Lee, H. N., Igarashi, Y., Chiba, M., Aoyama, M., Hirose, K., et al. (2006). Global model simulations of the transport of Asian and Sahara dust: total deposition of dust mass in Japan. Water, Air, and Soil Pollution, 169, 137–166.

Lee, S., Choi, B., Yi, S. M., & Ko, G. P. (2009). Characterization of microbial community during Asian dust events in Korea. Science of the Total Environment, 407, 5308–5314.

Mitchell, J. K., & Santamarina, J. C. (2005). Biological considerations in geotechnical engineering. Journal of Geotechnical and Geoenvironmental Engineering ASCE, 131, 1222–1233.

Naemi, S. A., & Ghorbanalizadeh, M. (2010). Effect of wet and dry conditions on strength of silty soil stabilized with epoxy resin polymer. Journal of Applied Sciences, 10, 2839–2846.

Nij, E. T., Hilhorst, S., Spee, T., Spierings, J., Steffens, F., Lumens, M., et al. (2003). Dust control measures in the construction industry. Annals of Occupational Hygiene, 47, 211–218.

Orts, W. J., Roa-Espinosa, A., Sojka, R. E., Glenn, G. M., Imam, S. H., Erlacher, K., et al. (2007). Use of synthetic polymers and biopolymers for soil stabilization in agricultural, construction, and military applications. Journal of Materials in Civil Engineering, 19, 58–66.

Parra, R. R., Medina, V. F., & Conca, J. L. (2009). The use of fixatives for response to a radiation dispersal devise attack – a review of the current (2009) state-of-the-art. Journal of Environmental Radioactivity, 100, 923–934.

Petry, T. M., & Little, D. N. (2002). Review of stabilization of clays and expansive soils in pavement and lightly loaded structures-history, practice and future. Journal of Materials in Civil Engineering, 14, 447–460.

Raisi, L., Lazaridis, M., & Katsivela, E. (2010). Relationship between airborne microbial and particulate matter concentrations in the ambient air at a Mediterranean site. Global NEST Journal, 12, 84–91.

Santoni, R. L., Tingle, J. S., & Nieves, M. (2005). Accelerated strength improvement of silty sand with nontraditional additives. Transportation Research Record: Journal of the Transportation Research Board, 1936, 34–42.

Stabnikov, V., Naemi, M., Ivanov, V., & Chu, J. (2011). Formation of water-impermeable crust on sand surface using biocement. Cement and Concrete Research, 41, 1143–1149.

Thompson, R. J., & Visser, A. T. (2007). Selection, performance and economic evaluation of dust palliatives on surface mine haul roads. Journal of South African Institute of Mining and Metallurgy, 107, 435–450.

US Army, US Air Force. (2005). Dust control for roads, airfields, and adjacent areas. Honolulu: University Press of the Pacific. 48.

van Paassen, L. A., Ghose, R., van der Linden, T. J. M., van der Star, W. R. L., & van Loosdrecht, M. C. M. (2010). Quantifying biomediated ground improvement by ureolysis: large-scale biogrout experiment. Journal of Geotechnical & Geoenvironmental Engineering ASCE, 136, 1721–1728.

Yang, K., & Tang, Z. (2012). Effectiveness of fly ash and polyacrylamide as a sand-fixing agent for wind erosion control. Water, Air, and Soil Pollution, 223, 4065–4074.

Yang, J., Cao, H., Wang, F., & Tan, T. (2007). Application and appreciation of chemical sand fixing (aspartic acid) and its composites. Environmental Pollution, 150, 381–384.

Zandieh, A. R., & Yasrobi, S. S. (2010). Study of factors affecting the compressive strength of sandy soil stabilized with polymer. Geotechnical and Geological Engineering, 28, 139–145.

Zhang, W., Zhuang, G., Huang, K., Li, J., Zhang, R., Wang, Q., et al. (2010). Mixing and transformation of Asian dust with pollution in the two dust storms over the northern China in 2006. Atmospheric Environment, 44, 3394–3403.

Acknowledgments

This research was supported in part by the grant from the Agency for Science, Technology and Research (A*STAR), Singapore.

Author information

Authors and Affiliations

Corresponding author

Additional information

Volodymyr Ivanov and Jian Chu are formerly associated with Nanyang Technological University, Singapore.

Rights and permissions

About this article

Cite this article

Stabnikov, V., Chu, J., Myo, A.N. et al. Immobilization of Sand Dust and Associated Pollutants Using Bioaggregation. Water Air Soil Pollut 224, 1631 (2013). https://doi.org/10.1007/s11270-013-1631-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1631-0