Abstract

Searching for an effective and economical sand stabilization measure has an important significance in wind erosion control. Wind tunnel experiments were conducted to evaluate the sand-fixing effect of fly ash (FA) at three different application rates (10, 20, and 30 % (w/w) soil). The additional effect of polyacrylamide (PAM) was also studied under two different application rates (0.05 and 0.1 % (w/w) soil) on the basis of the optimum FA usage. The results indicated that the utilization of FA increased the threshold wind speed of the treated soil significantly, which was further increased by the addition of PAM. The soil treated with 20 % FA could most effectively withstand the pure wind with a wind speed of 8 m s−1 for 10 min, while only the slightest wind erosion occurred after exposure to the sand-carrying wind with a wind speed of 8 m s−1 for 10 min. However, moderate wind erosion occurred after exposure to both the pure wind and the sand-carrying wind with a wind speed of 14 m s−1 for 10 min, respectively, and there was a decline in the wind erosion rate with the increase of FA application rate. The soil treated with 20 % FA and 0.05 or 0.1 % PAM could effectively withstand the pure wind with a wind speed of 14 m s−1 for 30 min, while only the slightest wind erosion occurred after exposure to the sand-carrying wind with a wind speed of 14 m s−1 for 30 min. The combination of a 20 % FA and 0.05 % PAM application rate is recommended to give effective and economical wind erosion protection.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wind erosion is not only a basic geomorphic process of eroding and altering landforms but also one of the main causes of sandy desertification in arid and semiarid areas (Chepil 1945; Nordstrom and Hotta 2004). China is currently facing the harsh situation of sandy desertification that is mostly caused by wind erosion, with a total sandified land area of 1,731,100 km2, making up 18 % of the national territory, among which the area of shifting and semifixed sand dunes (lands) is 583,300 km2. Inner Mongolia as one of the most serious provinces of sandy desertification has a sandified land area of 414,700 km2, with 177,900 km2 of the land most vulnerable to sandy desertification, comprising 57 % of the total area of land most vulnerable to sandy desertification of the whole country which is 311,000 km2 (State Forestry Administration, People’s Republic of China 2011). Sandy desertification persists as a serious threat to national ecological security and a severe restriction to socioeconomic sustainable development. Therefore, vigorous efforts and accelerated treatments to sandy desertification await urgent actions and measures. The wind-sands’ fixation engineering mainly includes mechanical sand barriers, vegetal sand fixation, and chemical sand fixation (Chepil and Woodruff 1963; Skidmore 1986). The ecological response of mechanical sand barriers and vegetal sand fixation as traditional measures is relatively slow, while chemical sand fixation has the advantages of a quick sand-fixing effect, high mechanization, and easy implementation as an auxiliary and transitional measure for the traditional ones. At present, because of its prohibitive material cost, chemical sand fixation has been limited to certain special locations, such as airports and railways, which are susceptible to significant loss caused by wind erosion (Wu et al. 2003). Thus, one of the key problems in the large scale application of chemical sand fixation is to reduce the cost of chemical sand-fixing materials.

Fly ash (FA), a coal combustion residue produced from thermal power plants, has an external appearance resembling cement. It consists of fine and glass-like particles which range in particle size from 0.01 to 100 μm. The particles are predominantly spherical in shape, either solid or hollow, and mostly glossy in nature (Haynes 2009; Pandey and Singh 2010). FA has a low bulk density, high surface area, and light texture (Asokan et al. 2005; Jala and Goyal 2006). The major matrix elements in FA are Si, Al, and Fe together with significant percentages of Ca, Mg, S, and unburned C, while the concentrations of Na and K are low (Rees and Sidrak 1956; Adriano et al. 1980). The FA generated from the thermal power plants of China in 2009, alone, amounted to 375 million tons and less than one third of which had been utilized. The remainder was disposed of in landfills, not only wasting land resources but also polluting the environment (Yang et al. 2010). For example, the catastrophic dust storm of March 2010 in China swept through 16 provinces with huge masses of FA which contained large quantities of pollutants such as heavy metals and radioactive substances, resulting in serious effects on air quality and public health. Nowadays, the comprehensive utilization of FA has drawn considerable attention. Most of the physical and chemical characteristics of FA are very similar to those of soil (Jala and Goyal 2006). Dry disposed FA with high calcium oxide content has strong pozzolanic action (Wen et al. 2000). FA significantly decreases the sandy particle content in sandy soil (Mittra et al. 2005) and increases the available P and Si contents in soil, which are advantageous to crop growth (Pathan et al. 2003). Taking into account those features of FA mentioned above, FA can be a potential source of inexpensive chemical sand-fixing material.

Polyacrylamide (PAM) has been widely used as a soil amendment due to its ability to stabilize soil structure (Terry and Nelson 1986; Sojka and Lentz 1997), preserve moisture and fertility (Woodhouse and Johnson 1991; Sojka et al. 2007), and hence increase crop production (Levy et al. 1991; Stern et al. 1992). Many studies show that PAM improves soil’s resistance to wind erosion by enhancing the cohesive force between soil particles and binding them together to form a stable soil structure. Armbrust (1999) observed that the application of PAM formulations to the soil surface of a soil from Haynie in Kansas, USA, reduced the amount of loose erodible material by 38–98 % and protected the soil surface from wind erosion if the treated area could be protected from incoming saltation particles. Chen et al. (2006) reported that PAM applied to a sandy soil surface could increase the threshold wind speed of the treated soil. When the loose soil was treated with more than 1 g m−2 PAM and there were no cracks or disturbances on its surface, soil’s resistance to wind erosion was significantly improved. He et al. (2007) found that 2 g m−2 PAM applied to the surface of a sandy loam and loam soils could control the wind erosion effectively and economically. Therefore, the possibility exists for PAM to be used in combination with FA to improve the sand-fixing effect on soils.

The Inner Mongolia reach of the Yellow River was chosen as the study area due to the occurrence of widespread shifting and semifixed sand dunes, numerous large scale thermal power plants, and rich FA resources. Wind tunnel experiments were conducted to evaluate the sand-fixing effects of FA and PAM and to determine the optimum application rates of FA and PAM in order to provide a viable option to form consolidated layers on the surfaces of the shifting and semifixed sand dunes. Such consolidation would protect them from wind erosion, preserve moisture and fertility, improve the physical and chemical properties of the treated sand dunes, and promote plant growth in the treated area.

2 Materials and Methods

2.1 Soil, FA, and PAM Characteristics

The experimental soil was taken from a shifting sand dune near Shenmuyingzi in Dalate County, Inner Mongolia; it had an initial water content of 0.64 % (w/w). The experimental FA, with a high calcium oxide content of 21.77 % (w/w), was taken from the FA dry disposal sites of Dalate Thermal Power Plant. The experimental soil was passed through a 2-mm sieve to remove plant roots and other extraneous materials. The grain-size distributions of the experimental soil and FA, as determined by the laser diffraction method, are presented in Table 1. The experimental PAM was a white powder with a polyacrylamide content of ≥85 % (w/w) and a molecular weight of ≥3 million.

2.2 Experimental Design

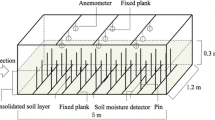

The wind erosion experiments were conducted in the wind tunnel laboratory of the College of Water Conservancy and Civil Engineering, China Agricultural University. A straight line forces wind tunnel with a test section which had a length of 9 m and a cross-section of 0.75 × 1 m2 was used. The wind speed could be controlled successively from 0.2 to 25 m s−1. Samples were packed in trays which had a length of 0.45 m, a width of 0.24 m, and a height of 0.045 m. The sample tray was placed on the floor of the test section, 7.5 m in the downwind direction from the air source (Fig. 1).

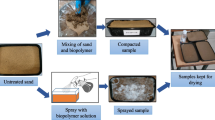

There were two experiments in this study. Experiment I was designed to test the sand-fixing effect of FA. FA at three different application rates (10, 20, and 30 % (w/w) soil) was homogeneously mixed with the experimental soil before being packed in trays according to the soil bulk density of the study area, which was 1.6 Mg m−3. After leveling the surface of the sample tray by drawing an iron bar over it, an appropriate amount of water was spayed uniformly on the surface of the sample tray to ensure that it could penetrate to the bottom of the sample tray. The sample tray was then covered with plastic films for 24 h to allow the soil moisture to distribute homogeneously. Finally, the plastic films were removed, and the sample tray was air dried until the final water content of the sample was less than 0.8 % (w/w), which was usually referred to as a dry state (Hu et al. 1991; Liu et al. 1992). To prepare a control, the experimental soil without FA was treated as per the same procedures as above. Experiment II was designed to test the additional effect of PAM on the sand-fixing effect of FA. PAM at two different application rates (0.05 and 0.1 % (w/w) soil), together with FA at the optimum application rate, was homogeneously mixed with the experimental soil. The subsequent procedures were the same as those mentioned in experiment I.

The threshold wind speed was determined by exposing the sample trays to a series of successive increasing wind speeds. Starting at 4 m s−1, the speed was increased until it was observed through the organic glass sheet on the top of the test section that sand particles began to be blown away by wind; at this stage, the wind speed was recorded. For each treatment, two replications were made. The amount of wind erosion was determined by exposing the sample trays to different types of wind conditions and measuring the mass of sand lost from each sample tray. The wind erosion rate, as used by Chepil (1956) to study the wind erodibility of soil, was then calculated and expressed in grams per minute. For each treatment, two replications were again made. In order to simulate the sand-carrying wind, the untreated and air-dried soil tray was placed 1.5 m in front of the test sample tray as the sand source. Soils treated with FA were then exposed to either the pure winds or the sand-carrying winds. Two wind speeds of 8 and 14 m s−1 for 10 min were studied. Soils treated with both FA and PAM were also exposed to the pure winds and the sand-carrying winds. A wind speed of 14 m s−1 for three successive 10 min intervals was used.

3 Results and Discussion

3.1 Sand-Fixing Effect of FA

Figure 2 shows the effect of FA on the threshold wind speed. The threshold wind speed of the untreated soil was 5.6 m s−1, while the threshold wind speed of the soil treated with FA was increased by 30–50 %. The threshold wind speeds of the soil treated with 10, 20, and 30 % FA were 8.0, 8.4, and 7.4 m s−1, respectively. Figure 3 shows the effect of FA on the wind erosion rate. After exposure to the pure wind with a wind speed of 8 m s−1 for 10 min, the wind erosion rate of the untreated soil was 157.5 g min−1, while there was no wind erosion occurring on the surfaces of the soil treated with 10 and 20 % FA. However, the wind erosion rate of the soil treated with 30 % FA was 84.5 g min−1, which was approximately 55 % of the untreated soil. After exposure to the sand-carrying wind with a wind speed of 8 m s−1 for 10 min, the wind erosion rate of the untreated soil was 210.8 g min−1, while the wind erosion rates of the soil treated with 10, 20, and 30 % FA were 60.0, 48.3, and 88.7 g min−1, respectively. After exposure to the pure wind and the sand-carrying wind with a wind speed of 14 m s−1 for 10 min, respectively, the wind erosion rates of the untreated soil were 506.8 and 592.3 g min−1, respectively. For the soils treated with FA, there was a gradual decline in the wind erosion rate with an increase in the FA application rate. This effect occurred with both the pure wind and the sand-carrying wind. The results demonstrated that the experimental soil’s resistance to both the pure wind erosion and the sand-carrying wind erosion was improved by about 15 % after 30 % FA was applied to it.

There are two probable reasons why the threshold wind speed of the soil treated with FA was significantly increased. On the one hand, the addition of FA would cause the relative amounts of sandy particles in the soil to decrease and silt particles to increase. Fine FA particles are able to enhance the cohesive forces among soil particles and bind them together, resulting in the reinforcement of the integrity of the soil. On the other hand, fine FA particles fill the pores of the coarse soil particles and decrease the point-and-point contact among soil particles, as well as the soil particles’ vibrations caused by the periodic action of gas pulsation. Both these effects improve the structural stability of the soil. The two reasons mentioned above are in agreement with the conclusions drawn by Wu et al. (2003). According to the data they observed in the field, the resistance to wind erosion of sand with an unstable soil structure was much lower than that of sandy loam with a relatively stable soil structure, under the conditions of a similar wind speed. The threshold wind speed of both soils treated with 30 % FA was lower than those of the soils treated with 10 and 20 % FA. This is probably because the content of large FA aggregates in the range of 0.6–2 mm increased with FA application rate. There were relatively few large FA aggregates in the soil treated with 10 and 20 % FA, while the content of large FA aggregates in the soil treated with 30 % FA was about 9.1 %. Excessively, large FA aggregates can have a negative effect on the structural stability of the soil and the action of binding soil particles together, resulting in a decrease in the threshold wind speed.

The stable structure of the soil treated with 20 % FA could withstand the pure wind with a wind speed of 8 m s−1 for 10 min, while only the slightest wind erosion occurred after exposure to the sand-carrying wind with a wind speed of 8 m s−1 for 10 min, which has the potential to cause stronger wind erosion. After exposure to the sand-carrying wind with a wind speed of 8 m s−1 for 10 min, the wind erosion rates of the soil treated with FA were in sequence of 20 % FA, <10 % FA, <30 % FA, and less than that of the control, which indicated that the resistance to wind erosion of the soil treated with FA was mainly based on the enhancement of the cohesive forces among soil particles by fine FA particles. The 20 % FA application rate was the most efficient at promoting the structural stability of the soil, as well as most effectively at reducing the negative effect of the large FA aggregates. After exposure to the pure wind and the sand-carrying wind with a wind speed of 14 m s−1 for 10 min, there was a decline in the wind erosion rate with the increase of FA application rate. The grain-size distribution result of the particles remaining on the surface of the soil treated with 30 % FA after the exposure showed that the content of large FA aggregates was nearly 60 %. Soil particles with a diameter larger than 0.7 mm were classified as difficult to erode (Dong and Li 1998), according to which large FA aggregates were also difficult to erode. The results indicated that the resistance to wind erosion of the soil treated with FA was mainly a result of the inertia of large FA aggregates ranging in size from 0.6 to 2 mm. These FA aggregates were difficult to erode and had a blocking effect against wind erosion of the fine FA and soil particles. It was this effect, instead of the cohesive forces among soil particles enhanced by fine FA particles, which caused the resistance.

3.2 Sand-Fixing Effect of FA and PAM

Chen et al. (2006) used the same wind tunnel in their research and found that PAM applied as a liquid to a sandy soil surface through spraying could significantly increase the threshold wind speed of the treated soil (Fig. 4). He et al. (2007) also used the same wind tunnel and observed that PAM applied to the soil surface of a sandy loam and loam could significantly reduce the rate of wind erosion on both soils (Fig. 5). In this study, PAM was applied to the experimental soil on the basis of 20 % as the optimum FA application rate. Figure 6 shows the additional effect of PAM on the threshold wind speed of a soil treated with 20 % FA. The threshold wind speeds of the soil treated with 20 % FA and PAM up to 0.1 % were slightly higher than that of the control soil treated with 20 % FA. The threshold wind speeds of the soils treated with 20 % FA and 20 % FA and 0.05 % PAM were both 8.4 m s−1, and the threshold wind speed of the soil treated with 20 % FA and 0.1 % PAM was 8.7 m s−1. Figure 7 shows the additional effect of PAM on the wind erosion rate. After exposure to the pure wind with a wind speed of 14 m s−1 for 10 min, the wind erosion rate of the soil treated with 20 % FA was 441.3 g min−1, while there was no wind erosion occurring on the surfaces of the soil treated with 20 % FA and PAM at rates of 0.05 and 0.1 %. After exposure to the sand-carrying wind with a wind speed of 14 m s−1 for 10 min, the wind erosion rate of the soil treated with 20 % FA was 548.5 g min−1, while the wind erosion rate of the soil treated with 20 % FA and 0.05 % PAM was 23.8 g min−1, and the wind erosion rate of the soil treated with 20 % FA and 0.1 % PAM was 7.0 g min−1. Thus, it can be seen that the experimental soil’s resistance to both the pure wind erosion and the sand-carrying wind erosion was improved significantly after 20 % FA together with 0.05 or 0.1 % PAM was applied to it. Figure 8 shows that under the condition of three successive 10 min exposures to the pure wind and the sand-carrying wind with a wind speed of 14 m s−1, respectively, the wind erosion rate of the soil treated with 20 % FA and PAM increased rapidly with the wind erosion time from 10 min to 20 min. For both types of wind, the rate of increase of the wind erosion rate of the soil treated with 20 % FA and 0.05 % PAM was higher than that of the soil treated with 20 % FA and 0.1 % PAM. For all treatments, the rate of increase of the wind erosion rate of the soil treated with 20 % FA and PAM decreased significantly when the wind erosion time went from 20 to 30 min, except for the soil treated with 20 % FA and 0.05 % PAM and pure wind, where there was a slight decline in the wind erosion rate.

Effect of PAM on the threshold wind speed of a sandy soil (Chen et al. 2006)

Effect of PAM on the wind erosion rate of a sandy loam and loam (He et al. 2007). The wind was maintained for 20 min

As Fig. 6 indicates, the threshold wind speed of the soil treated with 20 % FA and PAM at rates up to 0.1 % was increased slightly. This is because PAM enhanced the cohesive forces among the soil and FA particles, effectively resulting in the reinforcement of the stable soil structure formed by the application of FA. Meanwhile, PAM reduced the content of loose particles on the surface of the soil treated with 20 % FA and PAM, lowering the risk of the surface particles being blown away by wind. Figure 7 indicates that the soil treated with 20 % FA and PAM could withstand the pure wind with a wind speed of 14 m s−1 for 10 min, while only the slightest wind erosion occurred after exposure to the sand-carrying wind with a wind speed of 14 m s−1 for 10 min. The resistance to wind erosion of the soil treated with 20 % FA and 0.1 % PAM was slightly better than that of the soil treated with 20 % FA and 0.05 % PAM (Fig. 8). There are two reasons why the resistance to wind erosion of the soil treated with 20 % FA and PAM was improved significantly. On the one hand, PAM bound soil and FA particles together to form larger and less erodible aggregates, thus enhancing the integrity and stability of the soil structure. This is extremely similar to the effect of clay which has a cementation action on the unstable aggregates in soil. Chen (1991) found that soil with higher clay particle (<0.01 mm) content had more stable aggregates, resulting in better soil resistance to wind erosion. On the other hand, PAM reinforced the adhesion strength between the 0.1-mm crusts formed by spraying water on the surface of the treated soil and the soil layer below the crusts. This formed a relatively smooth surface with lower friction resistance which could reduce the influence of high speed airflow on the surface of the treated soil, thus preventing wind erosion to the soil layer below the crusts. However, the crusts formed on the surface of the soil treated with FA were not well anchored to the soil layer below the crusts and were easily destroyed by pure wind with a wind speed of 8 m s−1; FA thus has little effect on the formation of the crusts to improve soil’s resistance to wind erosion. Figure 9 shows surface morphology changes of the untreated soil after exposure to the sand-carrying wind with a wind speed of 14 m s−1 for 10 min. Surface morphology changes of the soil treated with 20 % FA and 0.1 % PAM under the condition of three successive 10 min exposures to the pure wind and the sand-carrying wind with a wind speed of 14 m s−1 are shown in Figs. 10 and 11, respectively. The results indicated that in relation to the former condition, the crusts remained intact with no abrasion after 30 min exposure, while with the latter condition, the crusts remained intact with only the slightest abrasion occurring after the first 10 min exposure. A very small part of the crusts was blown away, and a light hollowed-out morphology occurred below the crusts after the second exposure of a total of 20 min. Most of the crusts still existed after 30 min exposure, but with an obvious hollowed-out morphology occurring below the crusts. In addition, the rate of increase of wind erosion (from both pure wind and sand-carrying wind) of the FA and PAM-treated soil from 20 to 30 min was generally lower than that of the treated soil from 10 to 20 min. This is because the content of the erodible particles decreased with the increase of the wind erosion time, improving soil’s resistance to wind erosion.

4 Conclusions

The utilization of FA increased the threshold wind speed of the treated soil significantly, which was further increased by the addition of PAM. FA and PAM could enhance the cohesive forces among particles, promote the formation of stable soil structure, and reduce the content of loose particles on the surface of the treated soil.

The stable structure of the soil treated with 10 % FA could withstand the pure wind with a wind speed of 8 m s−1 for 10 min, while with the soil treated with 20 % FA after exposure to the sand-carrying wind with a wind speed of 8 m s−1 for 10 min, only the slightest wind erosion occurred. The resistance to wind erosion of the soil treated with FA was mainly based on the enhancement of the cohesive forces among soil particles by fine FA particles, so as at low wind speeds, no wind erosion or only the slightest amount of wind erosion occurred.

However, the resistance to wind erosion of the soil treated with FA was limited. Moderate wind erosion occurred after exposure to the pure wind and the sand-carrying wind with a wind speed of 14 m s−1 for 10 min, and there was a gradual decline in the wind erosion rate with the increase of FA application rate. The resistance to wind erosion of the soil treated with FA at higher wind speeds was mainly based on the inertia of large FA aggregates ranging in size from 0.6 to 2 mm. Under these conditions, moderate wind erosion occurred.

The soil treated with FA and PAM could effectively withstand the pure wind with a wind speed of 14 m s−1 for 30 min, while only the slightest wind erosion occurred after exposure to the sand-carrying wind with a wind speed of 14 m s−1 for 30 min. PAM improved the resistance to wind erosion by further enhancing the cohesive forces among particles and reinforcing the adhesion strength between the crusts and the soil layer below the crusts.

Because 97–99 % of the winds which cause wind erosion are in the range of 4–8 m s−1 in nature (Wu et al. 2003), the combination of a 20 % FA and 0.05 % PAM application rate is recommended to give effective and economical wind erosion protection.

References

Adriano, D. C., Page, A. L., Elseewi, A. A., Chang, A. C., & Straughan, I. (1980). Utilization and disposal of fly ash and other coal residues in terrestrial ecosystems: a review. Journal of Environmental Quality, 9, 333–344.

Armbrust, D. V. (1999). Effectiveness of polyacrylamide (PAM) for wind erosion control. Journal of Soil and Water Conservation, 54, 557–559.

Asokan, P., Saxena, M., & Asolekar, S. R. (2005). Coal combustion residues—environmental implications and recycling potentials. Resource, Conservation and Recycling, 43, 239–262.

Chen, G. T. (1991). Analyses of mechanical composition and resistance to wind erosion of soil in Beijing Plain. Journal of Arid Land Resources and Environment, 5, 103–113.

Chen, Q. C., Jiang, P. F., Lei, T. W., Li, R. P., & Tang, Z. J. (2006). Wind tunnel experiment on the impacts of polyacrylamide on wind erosion of loosen soil materials. Transactions of the CSAE, 22, 7–11 (in Chinese with English Abstract).

Chepil, W. S. (1945). Dynamics of wind erosion: I. Nature of movement of soil by wind. Soil Science, 60, 305–320.

Chepil, W. S. (1956). Wind erodibility of farmlands. Journal of Soil and Water Conservation, 14, 214–219.

Chepil, W. S., & Woodruff, N. P. (1963). The physics of wind erosion and its control. Advances in Agronomy, 15, 270–291.

Dong, Z. B., & Li, Z. S. (1998). Wind erodibility of Aeolian sand as influenced by grain-size parameters. Journal of Soil Erosion and Soil and Water Conservation, 4, 1–5 (in Chinese with English Abstract).

Haynes, R. J. (2009). Reclamation and revegetation of fly ash disposal sites—challenges and research needs. Journal of Environmental Management, 90, 43–53.

He, J. J., Cai, G. Q., & Tang, Z. J. (2007). Wind tunnel experimental study on the effect of PAM on soil wind erosion control. Environmental Monitoring and Assessment, 145, 185–193.

Hu, M. C., Liu, Y. Z., Wu, L., Yang, Z. T., Wu, D., & Wang, G. C. (1991). An experimental study in wind tunnel on wind erosion of soil in Korqin Sandy Land. Journal of Desert Research, 11, 22–29 (in Chinese with English Abstract).

Jala, S., & Goyal, D. (2006). Fly ash as a soil ameliorant for improving crop production—a review. Bioresource Technology, 97, 1136–1147.

Levy, G. J., Ben-Hur, M., & Agassi, M. (1991). The effect of polyacrylamide on runoff, erosion and cotton yield from fields irrigated with moving sprinkler systems. Irrigation Science, 12, 55–60.

Liu, Y. Z., Dong, G. R., & Li, C. Z. (1992). Study on some factors influencing soil erosion by wind tunnel experiment. Journal of Desert Research, 12, 41–49 (in Chinese with English Abstract).

Mittra, B. N., Karmakar, S., Swain, D. K., & Ghosh, B. C. (2005). Fly ash—a potential source of soil amendment and a component of integrated plant nutrient supply system. Fuel, 84, 1447–1451.

Nordstrom, K. F., & Hotta, S. (2004). Wind erosion from cropland in the USA: a review of problems, solutions and prospects. Geoderma, 121, 157–167.

Pandey, V. C., & Singh, N. (2010). Impact of fly ash incorporation in soil systems. Agriculture, Ecosystems and Environment, 136, 16–27.

Pathan, S. M., Aylmore, L. A. G., & Colmer, T. D. (2003). Soil properties and turf growth on a sandy soil amended with fly ash. Plant and Soil, 256, 103–114.

Rees, W. I., & Sidrak, G. H. (1956). Plant nutrition on fly ash. Plant and Soil, 8, 141–159.

Skidmore, E. L. (1986). Wind erosion control. Climatic Change, 9, 209–218.

Sojka, R. E., Bjorneberg, D. L., Entry, J. A., Lentz, R. D., & Orts, W. J. (2007). Polyacrylamide in agriculture and environmental land management. Advances in Agronomy, 92, 75–162.

Sojka, R. E., & Lentz, R. D. (1997). Reducing furrow irrigation erosion with polyacrylamide (PAM). Journal of Production Agriculture, 10, 47–52.

State Forestry Administration, P. R. China (2011). A bulletin of status quo of desertification and sandification in China. China Green Times.

Stern, R., Van Der Merwe, A. J., Laker, M. C., & Shainberg, I. (1992). Effect of soil surface treatments on runoff and wheat yields under irrigation. Agronomy Journal, 84, 114–119.

Terry, R. E., & Nelson, S. D. (1986). Effect of polyacrylamide and irrigation method on soil physical properties. Soil Science, 141, 317–320.

Wen, Y. F., Bian, J. H., & Cai, H. (2000). The effect of pozzolanic action and frost and thaw cycles on the mechanical characteristics of dry disposed fly ash. Chinese Journal of Geotechnical Engineering, 22, 275–278 (in Chinese with English Abstract).

Woodhouse, J., & Johnson, M. S. (1991). Effect of superabsorbent polymers on survival and growth of crop seedlings. Agricultural Water Management, 20, 63–70.

Wu, Z., et al. (2003). Geomorphology of wind-drift sands and their controlled engineering. Beijing: Science Press.

Yang, A. L., Jiang, Y. N., Zhao, X. M., Huang, X., Zhou, H. H., Su, M. H., Tang, H. Y., & Li, F. (2010). The true cost coal: an investigation into coal ash in China. Beijing: Greenpeace.

Acknowledgments

This study was financially supported by the Ministry of Land and Resources, People’s Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, K., Tang, Z. Effectiveness of Fly Ash and Polyacrylamide as a Sand-Fixing Agent for Wind Erosion Control. Water Air Soil Pollut 223, 4065–4074 (2012). https://doi.org/10.1007/s11270-012-1173-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-012-1173-x