Abstract

Biochars derived from the straws of rice, soybean, and peanut were prepared and modified with aluminum [Al(III)]. These modifications shifted zeta potential–pH curves of the biochars in a positive-value direction and changed surface charge of biochars from negative to positive under acidic conditions. The isoelectric points for 0.6 M Al(III)-modified rice, soybean, and peanut straw biochars were 8.0, 7.8, and 7.5, respectively. Electrostatic attraction of the positively charged surfaces on Al(III)-modified biochars to arsenate [As(V)] enhanced its sorption. The sorption of As(V) by these Al(III)-modified biochars was investigated in batch experiments. Al(III)-modified biochars had greater sorption capacity under acidic conditions compared with corresponding unmodified biochars. While unmodified biochars sorbed negligible amounts of As(V), their Al(III)-modified forms sorbed 445–667 mmol kg−1 at pH 5.0, which were predicted by the Langmuir equation. Modifications with 0.3 M Al3+ improved sorption capacity of As(V) on soybean straw biochar to 445 mmol kg−1, which was further increased by 50 % after modification with 0.6 M Al3+. These As(V) sorption capacities of biochars modified with 0.6 M Al3+ were larger than those of Fe/Al oxides determined at the same pH, which were < 500 mmol kg−1. Thus, biochars modified with 0.6 M Al3+ could substitute Fe/Al oxides used for water purification. However, the sorption of As(V) by the Al(III)-modified biochars increased with decreasing suspension pH. Thus, As(V) removal by Al(III)-modified biochars is suggested to be conducted under acidic conditions, but at pH > 4.0.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Arsenic (As) is a toxic element for humans, animals, and plants. Inorganic As is usually present as species of arsenate(V) and arsenite(III) in natural environments. Both forms are often present in either reduced or oxidized environments because of their relatively slow redox transformation (Sadiq 1997; Smith et al. 1998). Metal mining and smelting produce large amounts of As-containing wastewater that can pollute surface and ground water (Lu et al. 2005; Zhang et al. 2009; Wang et al. 2011). Many countries have stringent standards for As discharge in effluent. In China, the standard for As discharge in industrial effluent is 0.5 mg L−1 (GB 8978–1996). For drinking water, a lower limit of 0.01 mg L−1 is suggested by World Health Organization (WHO 2011) and the Chinese Ministry of Health (GB 5749–2006).

Therefore, it is necessary to remove As from wastewater prior to discharge into water bodies. Removal of As from aqueous solutions via sorption is a simple method known to be relatively low-cost and is thus used to purify water. The removal efficiency of As via sorption mainly depends on the choice of sorbents employed. Iron (Fe) and Al oxides such as amorphous Fe hydroxide, γ-Al2O3, goethite, hematite, and ferrihydrite are normally used as sorbents to remove As(V) from aqueous solutions (Fendorf et al. 1997; Arai et al. 2001; Catalano et al. 2007; Blanchard et al. 2012). In very recent times, synthetic magnesium (Mg)/Fe-layered double hydroxides, binary mixed oxides of Fe and silicon, and Fe(III)- and Al(III)-modified montmorillonite have been used as sorbents to remove As(V) (Luengo et al. 2011; Park and Kim 2011; Mahmood et al. 2012; Zhou et al. 2012). Biomass and natural red soil have been used as low-cost materials for As removal (Rajapaksha et al. 2011; Pontoni and Fabbricino 2012). However, recent attention has been given to biochars with sufficient suitability and selectivity for removal of toxic As from aqueous streams (Mohan et al. 2007).

Biochars have ample oxygen-containing functional groups on their surfaces and carry a large amount of negative charge (Yuan and Xu 2012). Hence, repulsion by negatively charged surfaces of biochars to As(V) anions may diminish As(V) sorption by biochars. Indeed increased concentrations of As in the pore water of a moderately contaminated urban soil were recorded after it had been amended with 30 % (v/v) hardwood-derived biochar (Beesley and Marmiroli 2011; Beesley et al. 2011), probably due to pH effects or competitive sorption processes (Beesley et al. 2011; Borchard et al. 2012).

To improve As(V) sorption surfaces of bamboo charcoal and activated carbon were modified with Fe (Liu et al. 2010, 2012), but not with Al. Similarly, Al oxides also have great sorption capacity for As(V) as mentioned above. To our knowledge, there are no reports of sorption of As(V) by Al(III)-modified biochars. The objectives of the present study were to prepare Al(III)-modified biochars and to examine their sorption capacity for As(V).

2 Materials and Methods

2.1 Biochar

Straws of rice, soybean, and peanut were collected from cropland in a suburb of Nanjing, China. These straws were air-dried at room temperature and ground to pass a 1-mm sieve. The ground straws were then placed in ceramic crucibles, each covered with a fitting lid, and pyrolyzed in a muffle furnace. The pyrolysis temperature was raised to the selected value of 350 °C at a rate of approximately 20 °C min−1 and held constant for 4 h (Yuan and Xu 2012), then the biochar was allowed to cool to room temperature and ground to pass a 1-mm sieve. The basic properties of the biochars are listed in Table 1. The biochar production rate was calculated using the following equation: Production rate (%) = (WeightBiochar/WeightPlant material) × 100. Ash contents of the biochars were determined by a modified ASTM method (D-1762-84) involving measurement of weight loss following combustion of about 10 g of each biochar in a ceramic crucible at 750 °C for 6 h (Peng et al. 2011).

The pH of the biochar was measured in deionized water at a 1:5 wt/wt ratio. The biochar samples were each thoroughly mixed and allowed to equilibrate for 1 h. The pH was then measured using an Orion 720 pH meter. The total C and N contents of the biochar were determined using a Leco CN-2000 analyzer (Leco Corp, St. Joseph, MI, USA) at 1,200 °C. The CEC for the biochars was measured by a modified ammonium acetate compulsory displacement method (Gaskin et al. 2008). The detailed procedures of the method were presented in a previous report (Yuan et al. 2011).

To modify soybean straw biochar, 20 g of the biochar was added into 200 mL of 0.3 M Al3+ (as AlCl3) solution with magnetic stirring, and then suspension pH was adjusted to 7.0 with 0.5 M NaOH and maintained for 2 h. After standing at 25 °C for 48 h, the solid was separated from solution by centrifugation at 3,880×g with a Sigma 3–16 centrifuge (SciQuip Ltd, Shrewsbury, UK). The Al(III) -modified soybean straw biochar was washed with deionized water once and then with ethanol until free of chloride ions (tested by 0.1 M AgNO3). The Al(III)-modified biochar was air-dried and ground to pass a 1-mm sieve. Similarly, the biochars generated from the straws of soybean, peanut, and rice were reacted with 0.6 M Al3+ (as AlCl3) to obtain 0.6 M Al(III)-modified biochars.

The surface area of biochars and Al(III)-modified biochars was determined using an analyzer model ASAP2020 (Micromeritics Instrument Corporation, Norcross, Georgia, USA). The BET surface areas were evaluated from the N2 adsorption isotherms by applying the BET equation in the relative pressure (P/P 0) range of 0.05–0.35, and taking the average area occupied by a molecule of N2 in the completed monolayer to be equal to 16.2 Å2.

2.2 Determination of Zeta Potential of Biochar

Samples of 0.045 g of biochars and Al(III)-modified biochars (0.054-mm sieve) were placed in separate 250-mL conical flasks, and 180 mL of 0.1 mM NaCl solution was then added to each flask. Aliquots were adjusted to pH values in the range of 4.0–9.0 (i.e., 4.0, 5.0, 6.0, 6.5, 7.5, 8.0, and 9.0) with NaOH or HCl. The suspensions were dispersed ultrasonically for 1 h at 25 ± 1 °C in a bath-type sonicator at a frequency of 40 kHz and a power of 300 W. After equilibration of 48 h, their zeta potentials were measured using Zetaplus 90 (Brookhaven Instruments, New York, USA). Final pH values were determined to plot the relationship between zeta potential and pH values.

To investigate effect of As(V) on zeta potential of Al(III)-modified biochars, these biochars were suspended in 0.1 mM NaH2AsO4 and treated as presented above.

2.3 Sorption Experiments

Various concentrations of NaH2AsO4 in the range of 0.3–1.2 mM (i.e., 0.3, 0.4, 0.5, 0.6, 0.8, 1.0, and 1.2 mM) were prepared in background solution of 0.01 M NaNO3 and adjusted to pH of 5.0 using HCl or NaOH. Samples of 100 mg of the biochar and Al(III)-modified biochar were weighed in duplicate into 250-mL polyethylene bottles. Then, 100 mL of NaH2AsO4 solutions of varying concentrations were added to each bottle. The suspension pH values were again adjusted to 5.0 with HCl or NaOH. For equilibration, suspensions were shaken with a reciprocating shaker in a constant-temperature water bath at 25 ± 1 °C for 2 h and stored for 12 h prior centrifugation at 3,880×g for 10 min with a Sigma 3–16 centrifuge (SciQuip Ltd, Shrewsbury, UK). The amount of As(V) sorbed by biochar was calculated from the difference between the concentration of As added and that remaining in the equilibrium solution.

To examine the effect of pH on sorption of As(V), 0.8 mM NaH2AsO4 solution was prepared and adjusted to pH in the range of 3.5–6.5 (i.e., 3.5, 4.0, 5.0, 5.5, 6.0, and 6.5). Then, 100 mg of Al(III)-modified biochar was added into 100 mL of the solution, and the same procedures were used to determine sorption of As(V). After centrifugation, final pH values of solutions were measured. The As(V) in the solution was determined, and the amount of As(V) sorbed was calculated using the methods mentioned above.

The concentration of As(V) in solutions was determinated by hydride generation–atomic fluorescence spectrometry with AFS 9700 (Beijing KCHG Instrument Ltd, Beijing, China). Fresh sodium borohydride solution (10 g L−1) was supplemented daily with 0.1 M NaOH, and 1.2 M HCl was used as the carrier.

2.4 Data Processing

The Langmuir equation is normally used to fit the sorption isotherms of ions by different sorbents, and was also used in this study:

Where C is the equilibrium concentration of As(V) in solution (in millimolar), Q is the amount of As(V) sorbed (in millimoles per kilogram), Q m is the maximum amount of As(V) sorbed (in millimoles per kilogram), and K is a constant related to binding strength.

3 Results and Discussion

3.1 Zeta potential of Al(III)-Modified Biochars

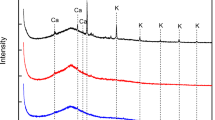

The zeta potential is the potential in the sliding plane of colloidal particles, and its value and sign are related to surface charge of the particles (Hunter 1981) that depends on solution pH. Zeta potential values were measured as a function of solution pH for the biochars from soybean, peanut, and rice straws and the corresponding Al(III)-modified biochars. The zeta potential values for non-modified biochars were negative in the pH range studied (Figs. 1 and 2), indicating that the biochar particles carried negative charges on their surfaces. The zeta potential of the biochars became more negative with increased pH, suggesting increased negative charge on the biochars with increasing pH. There are ample oxygen-containing functional groups on biochars (Yuan and Xu 2012), and deprotonation of these functional groups creates negative charge on biochar surfaces (Tong et al. 2011; Yuan et al. 2011).

When soybean straw biochar was modified with Al3+, its zeta potential changed to a positive value direction, which was more pronounced by 0.6 M Al3+ than by 0.3 M Al3+ (Fig. 1). However, the isoelectric points (IEPs; i.e., pH when zeta potential is zero) for all Al(III)-modified soybean straw biochars were >7. When peanut and rice straw biochars were modified by 0.6 M Al3+, their zeta potential shifted to positive values direction; hence, their surface charge changed from negative to positive below IEP that were >7 (Fig. 2). Thus, improved sorption of As(V) on both biochars modified with Al3+.

3.2 Sorption of As(V) by Biochars and Their Al(III)-Modified Forms

The sorption capacities of three 0.6 M Al(III)-modified biochars for As(V) were consistent with the order of their IEPs. The greater IEP of the Al(III)-modified rice straw biochar and subsequent greater positive charge on its surface led to greater sorption capacity for As(V) compared to 0.6 M Al(III)-modified peanut and soybean straw biochars.

The amount of As(V) sorbed by non-modified soybean straw biochar was negligible, in the range of 0.9–17.0 mmol kg−1 (Fig. 3). The repulsion by negatively charged surfaces of biochar to the anions of arsenate was one of main reasons for negligible sorption of As(V), probably due to competitive sorption processes or pH effects. Dissolved organic carbon or ash released by biochars may affect sorption of anions on biochars (Borchard et al. 2012; Oh et al. 2012). Surface modifications with Al3+ multiplied surface areas (Tables 1 and 2) and induced formation of positively charged surfaces that have electrostatic attraction to anions of arsenate. The larger surface area of the Al(III)-modified biochars provided more physical potential of sorption sites for As(V) and thus increased their sorption of As(V) compared with non-modified biochars. Moreover, increasing densities of Al3+ bonded to biochar surfaces enhanced sorption of As(V) (Fig. 3).

The Langmuir equation fitted the sorption data well, with all correlation coefficients (R 2) > 0.997, and thus could be used to describe sorption of As(V) by Al(III)-modified biochars. Compared to non-modified biochars, sorption capacity (Q m) and binding strength (K) of As(V) were larger for Al(III)-modified biochars (Table 2).

Sorption of As(V) on peanut and rice straw biochars modified with 0.6 M Al3+ were also examined (Fig. 3); both biochars sorbed similar amounts of As(V) as determined for soybean straw biochar modified with 0.6 M Al3+ (Fig. 3). Therefore, the three 0.6 M Al(III)-modified crop straw biochars could be used as adsorbents to remove As(V) from aqueous solutions.

As(V) sorption has been studied using a variety of sorbents; however, Fe(III) and Al(III) (hydr)oxides have been used in most studies. In the present study, the sorption capacity of As(V) on biochars modified with 0.6 M Al3+ was >645 mmol kg−1, which was larger than these of <500 mmol kg−1 on γ-Al2O3, goethite, gibbsite, and allophane at pH 5.0 (Arai et al. 2001; Violante and Pigna 2002). Therefore, Al(III)-modified crop straw biochars are more efficient to remove As(V) from aqueous solutions than pure Al(III) and Fe(III) (hydr)oxides.

3.3 Effect of pH on Sorption of As(V) and Sorption Mechanisms

Sorption capacities for As(V) of the three Al(III)-modified biochars decreased with rising pH (Fig. 4), which is in line with sorption of As(V) on Fe/Al oxides (Arai et al. 2001). The decrease in positive surface charge led to less electrostatic attraction of the biochars to As(V) and thus their decreased sorption of As(V). However, under acidic conditions, these Al(III)-modified biochars had relatively high sorption capacity. At pH < 4.0, some Al hydroxides can dissolve and release Al3+ into solution (Li et al. 2005). Therefore, As(V) removal by Al(III)-modified biochars was suggested to be conducted at pH > 4.0.

The effect of As(V) sorption on zeta potential of Al(III)-modified biochars was examined for investigation of sorption mechanisms of As(V) on Al(III)-modified biochars. The sorption of As(V) on the three Al(III)-modified biochars shifted their zeta potentials in a negative-value direction (Fig. 5), suggesting that specific sorption of As(V) occurred on the surfaces of the Al(III)-modified biochars. Thus, the change of zeta potential of Al(III)-modified biochars due to As(V) sorption indicated that As(V) formed chemical bonds with Al(III)-modified biochar surfaces and subsequently some negative charge of arsenate was transferred to the surface of the biochars. The shift of zeta potential of γ-Al2O3 due to sorption of As(V) was observed by Arai et al. (2001), and the reduction of positive surface charge on ferrihydrite caused by sorption of As(V) was also reported previously (Jain et al. 1999). These reports were consistent with the observations for Al(III)-modified biochars in the present study, which suggested that As(V) was sorbed by Al(III)-modified biochars through a similar mechanism to that in pure Fe/Al oxide systems. The formation of chemical bonds of arsenate on Fe and Al oxides has been confirmed through X-ray absorption in fine structure spectroscopic studies (Fendorf et al. 1997; Arai et al. 2001; Catalano et al. 2007). In the present study, the As(V) sorbed by Al(III)-modified biochars mainly reacted with Al hydroxides and formed inner-sphere complexes on the surfaces of the biochars.

4 Conclusions

Compared to non-modified biochars, their Al(III)-modified forms sorb larger amounts of As(V). Thus can be used as efficient sorbents to remove As(V) from aqueous solutions at pH < 7.0. The sorption of As(V) by Al(III)-modified biochars decreased with rising pH. As(V) removal by Al(III)-modified biochars was suggested to be conducted under acidic conditions, but at pH > 4.0.

References

Arai, Y., Elzinga, E. J., & Sparks, D. L. (2001). X-ray absorption spectroscopic investigation of arsenite and arsenate adsorption at the aluminum oxide-water interface. Journal of Colloid and Interface Science, 235, 80–88.

Beesley, L., & Marmiroli, M. (2011). The immobilization and retention of soluble arsenic, cadmium and zinc by biochar. Environmental Pollution, 159, 474–480.

Beesley, L., Moreno-Jiménez, E., Gomez-Eyles, J. L., Harris, E., Robinson, B., & Sizmur, T. (2011). A review of biochars’ potential role in the remediation, revegetation and restoration of contaminated soils. Environmental Pollution, 159, 3269–3282.

Blanchard, M., Morin, G., Lazzeri, M., Balan, E., & Dabo, I. (2012). First-principle simulation of arsenate adsorption on the (112) surface of hematite. Geochimica et Cosmochimica Acta, 86, 182–195.

Borchard, N., Prost, K., Kautz, T., Moeller, A., & Siemen, J. (2012). Sorption of cupper(II) and sulfate to different biochars before and after composting with farmyard manure. European Journal of Soil Science, 63, 399–409.

Catalano, J. G., Zhang, Z., Park, C., Fenter, P., & Bedzyk, M. J. (2007). Bridging arsenate surface complexes on the hematite (012) surface. Geochimica et Cosmochimica Acta, 71, 1883–1897.

Fendorf, S. E., Eick, M. J., Grossl, P., & Sparks, D. L. (1997). Arsenate and chromate retention mechanisms on goethite. 1. Surface structure. Environmental Science & Technology, 31, 315–320.

Gaskin, J. W., Steiner, C., Harris, K., Das, K. C., & Bibens, B. (2008). Effect of low-temperature pyrolysis conditions on biochar for agricultural use. Transactions of the ASABE, 51, 2061–2069.

Hunter, R. J. (1981). Zeta potential in colloid science—principles and applications. London: Academic.

Jain, A., Raven, K. P., & Loeppert, R. H. (1999). Arsenite and arsenate adsorption on ferrihydrite: surface charge reduction and net OH− release stoichiometry. Environmental Science & Technology, 33, 1179–1184.

Li, J. Y., Xu, R. K., & Ji, G. L. (2005). Dissolution of aluminum in variably charged soils as affected by low-molecular-weight organic acids. Pedosphere, 15, 484–490.

Liu, X., Ao, H. Y., Xiong, X., Xiao, J. G., & Liu, J. T. (2012). Arsenic removal from water by iron-modified bamboo charcoal. Water, Air, and Soil Pollution, 223, 1033–1044.

Liu, Z. G., Zhang, F. S., & Sasai, R. (2010). Arsenate removal from water using Fe3O4-loaded activated carbon prepared from waste biomass. Chemical Engineering Journal, 160, 57–62.

Lu, X. W., & Zhang, X. L. (2005). Environmental geochemistry study of arsenic in western Hunan mining area, P.R. China. Environmental Geochemistry and Health, 27, 313–320.

Luengo, C., Puccia, V., & Avena, M. (2011). Arsenate adsorption and desorption kinetics on a Fe(III)-modified montmorillonite. Journal of Hazardous Materials, 186, 1713–1719.

Mahmood, T., Din, S. U., Naeem, A., Mustafa, S., Waseem, M., & Hamayun, M. (2012). Adsorption of arsenate from aqueous solution on binary mixed oxide of iron and silicon. Chemical Engineering Journal, 192, 90–98.

Mohan, D., Pittman, C. U., Jr., Bricka, M., Smith, F., Yancey, B., Mohammad, J., et al. (2007). Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during bio-oil production. Journal of Colloid and Interface Science, 310, 57–73.

Oh, T. K., Choi, B., Shinogi, Y., & Chikushi, J. (2012). Effect of pH conditions on actual and apparent fluoride adsorption by biochar in aqueous phase. Water, Air, and Soil Pollution, 223, 3729–3738.

Park, J. Y., & Kim, J. H. (2011). Characterization of adsorbed arsenate on amorphous and nano crystalline MgFe-layered double hydroxides. Journal of Nanoparticle Research, 13, 887–894.

Peng, X., Ye, L. L., Wang, C. H., Zhou, H., & Sun, B. (2011). Temperature- and duration-dependent rice straw-derived biochar: characteristics and its effects on soil properties of an Ultisol in southern China. Soil and Tillage Research, 112, 159–166.

Pontoni, L., & Fabbricino, M. (2012). Use of chitosan and chitosan-derivatives to remove arsenic from aqueous solutions—a mini review. Carbohydrate Research, 356, 86–92.

Rajapaksha, A. U., Meththika, V., Jayarathna, L., & Kumara, C. K. (2011). Natural red earth as a low cost material for arsenic removal: kinetics and the effect of competing ions. Applied Geochemistry, 26, 648–654.

Sadiq, M. (1997). Arsenic chemistry in soils: an overview of thermodynamic predictions and field observations. Water, Air, and Soil Pollution, 93, 117–136.

Smith, E., Naidu, R., & Alston, A. M. (1998). Arsenic in the soil environment: a review. Advances in Agronomy, 64, 149–195.

Tong, X. J., Li, J. Y., & Xu, R. K. (2011). Adsorption of Cu(II) by biochars generated from three crop straws. Chemical Engineering Journal, 172, 828–834.

Violante, A., & Pigna, M. (2002). Competitive sorption of arsenate and phosphate on different clay minerals and soils. Soil Science Society of America Journal, 66, 1788–1796.

Wang, Z. X., Chai, L. Y., Wang, Y. Y., Yan, Z. H., Wang, H. Y., & Wu, X. (2011). Potential health risk of arsenic and cadmium in groundwater near Xiangjiang river, China: a case study for risk assessment and management of toxic substances. Environmental Monitoring and Assessment, 150, 123–131.

World Health Organization. (2011). Guidelines for drinking-water quality (4th edition) (pp. 176–189). Geneva: WHO.

Yuan, J. H., Xu, R. K., & Zhang, H. (2011). The forms of alkalis in the biochar produced from crop residues at different temperatures. Bioresource Technology, 102, 3488–3497.

Yuan, J. H., & Xu, R. K. (2012). Effects of biochars generated from crop residues on chemical properties of acid soils from tropical and subtropical China. Soil Research, 50, 570–578.

Zhang, G. P., Liu, C. Q., Liu, H., Hu, J., Han, G. L., & Li, L. (2009). Mobilization and transport of arsenic and antimony in the adjacent environment of Yata gold mine, Guizhou province, China. Journal of Environmental Monitoring, 11, 1570–1578.

Zhou, S., Feng, C. H., Huang, X. N., Li, B. H., Niu, J. F., & Shen, Z. Y. (2012). Role of uniform pore structure and high positive charges in the arsenate adsorption performance of Al13-modified montmorillonite. Journal of Hazardous Materials, 203–204, 317–325.

Acknowledgements

This study was supported by the National Natural Science Foundation of China (41230855). We thank two anonymous reviewers for their comments and suggestions to improve our manuscript for this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, W., Zhao, Az. & Xu, Rk. Sorption of As(V) by Aluminum-Modified Crop Straw-Derived Biochars. Water Air Soil Pollut 224, 1610 (2013). https://doi.org/10.1007/s11270-013-1610-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-013-1610-5